晶圆金属表面纳米颗粒暗场检测系统设计

Defect detection is an essential process for realizing superdiffraction fabrication based on metal film layer excitation surface plasmons. However, the light source of most existing advanced defect detection equipment operates in the deep ultraviolet band (DUV), which is within the light-sensitive range of DUV photoresists such as KrF. The overlap of working wavelengths between the defect detection equipment and the DUV photoresist can result in a loss of photoresist efficacy. Furthermore, to avoid the influence of the detection equipment's working wavelength on the photoresist when DUV equipment is used to detect particles on the surface of the film, it is necessary to tune the equipment's incident intensity several times. Moreover, the equipment parameters after tuning are only effective for a single film structure. It is necessary to retune equipment parameters when changing the thickness, material, and the number of film layers, which is time consuming and labor intensive. Therefore, a defect-detection device with a wide range of applications that avoids photoresist-sensitive bands must be developed to address this challenge.

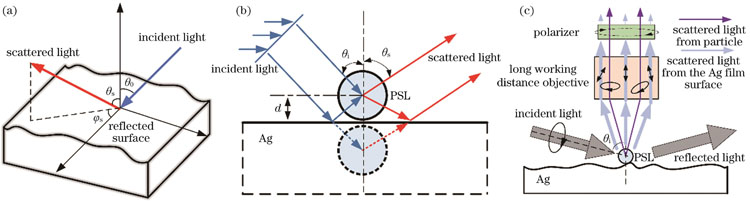

In this study, visible laser polarization defect detection equipment consisting of three parts: polarization modulation, dark-field detection, and motion control (Fig. 8), is theoretically and experimentally demonstrated. A more sensitive scientific CMOS (sCMOS) is used to detect particle scattering signals. The equipment utilizes the polarization conversion principle of a silver film on the top layer of the wafer surface. By modulating the polarization state and incident angle of the incident light, the scattered light polarization states on the slightly rough silver film surface and the particles on the film surface are different. On the receiving side, the light scattered from the surface of the silver film is partially filtered using a polarization detection device, which improves the signal-to-noise ratio of the particle signal to achieve defect detection.

Based on the aforementioned principles, experimental equipment was developed to verify particle detectability [Fig.8(a)]. Standard polystyrene latex (PSL) spheres with diameters of 100 and 50 nm were used as detection targets. Etching marks on the surface of the silicon wafer were used as the detection area, and subsequent processes such as photoresist spin-coating, magnetron sputtering coating, reactive ion beam etching (AFM surface roughness detection), and particle solution atomization were performed on the wafer [Fig.8(b)]. In this experiment, silver films with different surface roughness were processed by controlling the power and etching time of reactive ion beam etching. After dilution and ultrasonic vibration, the particle solution was sprayed onto the surface of the silver film using an atomizer such that standard PSL particles with diameter 100 and 50 nm were uniformly distributed in the surface labeled area. In addition, the samples were maintained under a vacuum insofar as possible during the experiment to decelerate oxidation of the silver film.

The effect of surface roughness on particle detection was subsequently analyzed. Samples with different surface roughness values were observed using identical camera exposure parameters (Fig.10). Experimental results show that as the silver film surface roughness increases, the background noise obtained from the experiment also increases, which can cover up the signal of small-particle defects and cause misclassification. To reduce the effect of surface roughness on particle detection, a polarization device was introduced into the detection equipment and the effect of the incident light polarization state on the signal-to-noise ratio of particles was analyzed. Based on the results, it can be observed that the signal-to-noise ratio of particles differs with different polarization states of the incident light [Fig. 12(a)?(d)]. In the detection experiment involving 100 nm particles, the single exposure time of this equipment was only 150 μs, which is 4‰ of the DSX1000 dark-field microscope based on white light, and the detection efficiency was significantly improved. Finally, it was confirmed using a scanning electron microscope that the proposed experimental system could detect 61 nm PSL particles [Fig.12(l)].

This study conducted targeted research based on defect detection during the plasmon super-diffraction fabrication of metal film layer surfaces. Background noise was suppressed by the polarization modulation technique, and the PSL particles with diameter of 61 nm on the silver film surface were detected with a 473 nm light source for inspection. The equipment operates in the visible wavelength band, which differs from the sensitive wavelength band of the DUV photoresist, thus, effectively avoiding photoresist failure. The proposed method can be theoretically extended to other wavelengths, which can be flexibly selected according to photoresist sensing characteristics, and can improve particle detectability without loss of photoresist efficacy. The proposed solution has a straightforward structure, high practicality, low cost, and good prospects for application in the field of micro-nano fabrication.

邓泉, 赵泽宇, 林鹤, 刘玲, 李夏楚秦, 杨根森, 罗先刚. 晶圆金属表面纳米颗粒暗场检测系统设计[J]. 中国激光, 2023, 50(22): 2204003. Quan Deng, Zeyu Zhao, He Lin, Ling Liu, Xiachuqin Li, Gensen Yang, Xiangang Luo. System Design for Dark‑Field Detection of Nanoparticles on Wafer Metal Surface[J]. Chinese Journal of Lasers, 2023, 50(22): 2204003.