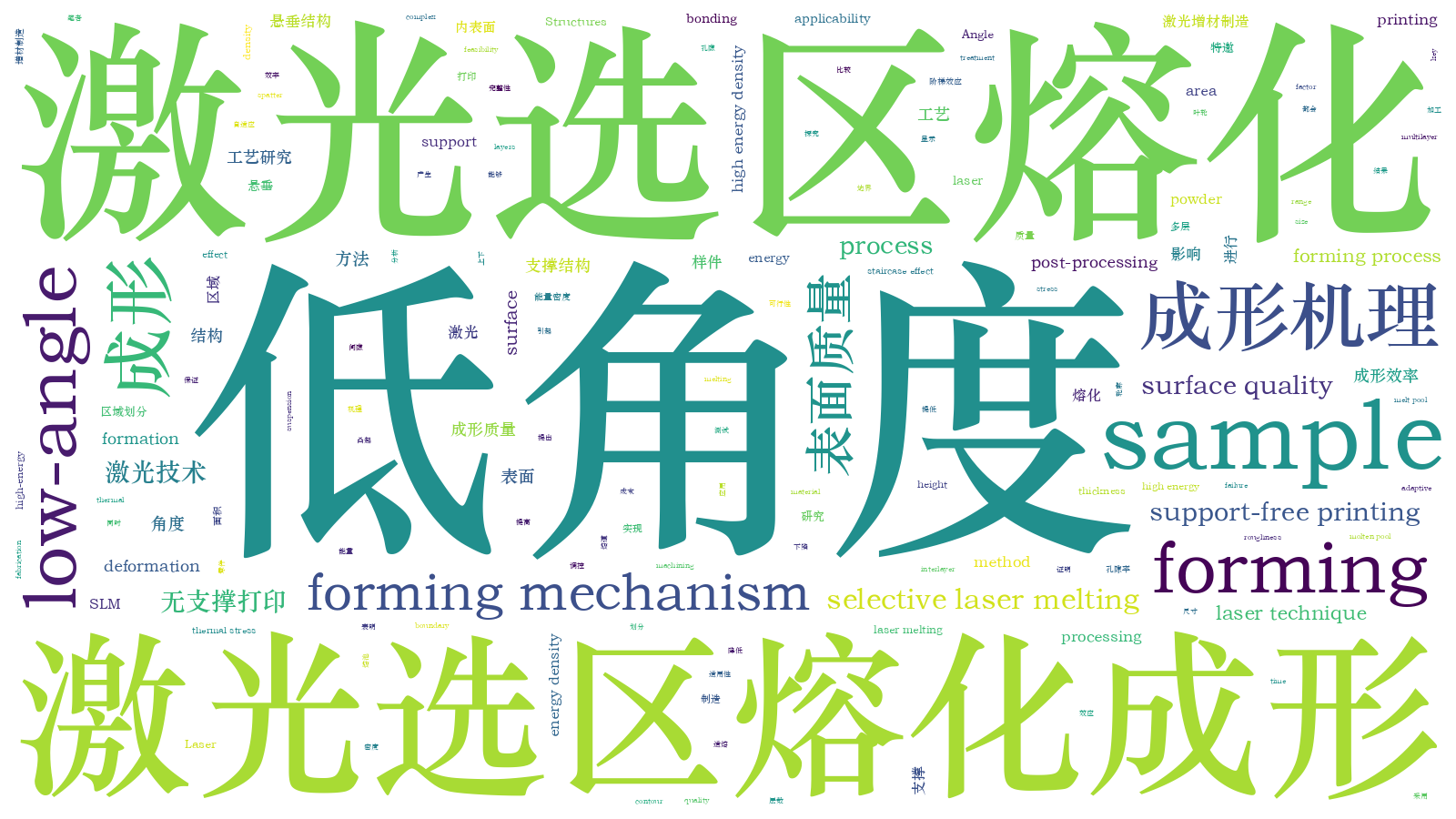

激光选区熔化成形低角度无支撑结构的方法与工艺研究(特邀)特邀研究论文亮点文章

Currently, the recognized optimal forming angle for selective laser melting (SLM) is 45°. When the forming angle of a sample is less than 45°, support structures are required for assisting the formation. Although the addition of support structures can effectively assist in the formation of parts, drawbacks, such as increased printing time, increased material consumption, increased difficulty in post-processing, and increased roughness of the support surfaces, are often observed. In some cases, for parts with internal cavities or complex channels, the inability to remove internal support can render SLM unsuitable for fabrication. Therefore, it is important to explore a forming method for samples with low forming angles in SLM to reduce printing costs and expand the applicability range.

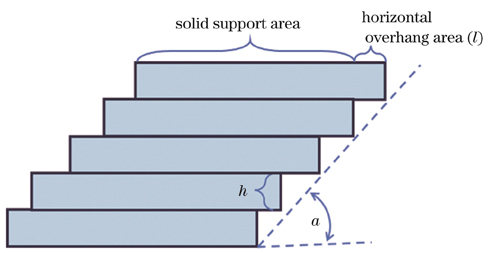

First, the treatment process of a horizontal suspension sample is discussed. Different process combinations are used to form single- and double-layer overhanging structures to obtain a stable overhang process. Accordingly, an adaptive method of lower surface process area division based on the machining layer angle is proposed to adjust the size of the lower surface process area applied to the overhanging sample. The feasibility of the low angle forming method was verified by forming a 30° overhanging sample with different downward comparison layer numbers. Samples with different widths and thicknesses were formed using the same forming process, and the applicability of the forming method was verified.

No obvious overheating was observed on the surface of the single-layer overhang formed by the fusible process, and only a few micropores were present. The formation of a double-layer overhang effectively ensured bonding between the layers. When the layer comparison interval was opened, the sample was forced to interrupt printing at a 6 mm overhang length when T=1, 10, and 20, whereas the sample without layer comparison could be formed up to a 10 mm overhang length. When the layer interval T was further increased to 30, the effective forming length of the sample reached 12 mm. Finally, when T was greater than 40, stable formation of the designed height of the sample was achieved. When printing overhang samples of different sizes, it was found that increasing the thickness exacerbated the deformation of the sample but did not affect the realization of the designed height. This indicates that this method has a certain applicability in low-angle forming.

(1) In the horizontal overhang formation process, a high energy density caused serious spatter accumulation on the surface of the overhanging sample and destroyed the interlayer bonding under the action of the scraper. However, an energy density that is very low will lead to an insufficient weld lap or even failure to form. Using a fusible process, the sample can achieve an effective multilayer lap. (2) Under suitable conditions for the overhang process, the division of the forming region on the inner surface was a key factor affecting the formation of low-angle samples. For 30° forming, the overhanging area of the sample can resist the thermal stress deformation caused by the high-energy inner surface laser only when the layer comparison interval T is greater than or equal to 40, thus achieving low-angle printing. (3) The quality of the lower surface was mainly affected by powder bonding and sinking of the molten pool. In addition to powder sticking, the upper surface was mainly influenced by the staircase effect and the gap between the laser contour and the boundary of the melt pool. Additionally, the difference in the contact area with the powder was the main reason for the difference in powder sticking between the upper and lower surfaces. (4) When forming the low-angle samples, as the thickness of the sample increased, the deformation of the sample gradually intensified, whereas an increase in the width had almost no effect on the deformation of the low-angle samples.

胡伟南, 冯颖, 王迪, 闫星辰, 蒋梦龙, 晋刚, 杨超, 杨永强, 吴杰华, 陈思敏. 激光选区熔化成形低角度无支撑结构的方法与工艺研究(特邀)[J]. 中国激光, 2024, 51(4): 0402303. Weinan Hu, Ying Feng, Di Wang, Xingchen Yan, Menglong Jiang, Gang Jin, Chao Yang, Yongqiang Yang, Jiehua Wu, Simin Chen. Method and Process of Selective Laser Melting Forming Low‐Angle Support‐Free Structures (Invited)[J]. Chinese Journal of Lasers, 2024, 51(4): 0402303.