激光与光电子学进展, 2022, 59 (11): 1114007, 网络出版: 2022-06-10

激光直接沉积钛合金热力耦合模型的建立与验证

Establishment and Verification of Thermo-Mechanical Coupled Model for Laser Direct Deposition of Titanium Alloy

激光光学 激光直接沉积 原位测量 热力耦合模型 残余应力与变形 有限元方法 laser optics laser direct deposition in situ measurement thermo-mechanical coupled model residual stress and distortion finite element method

摘要

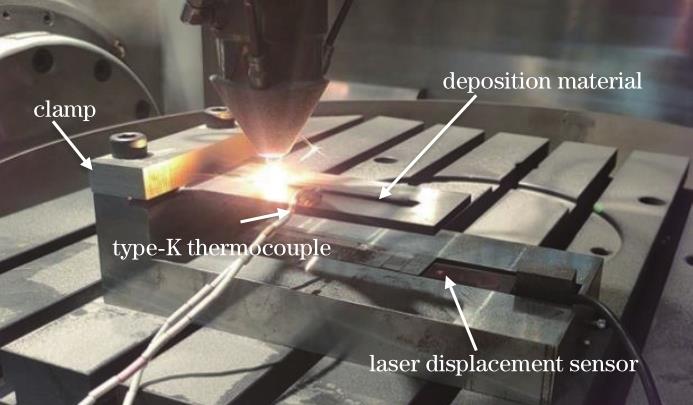

采用MSC Marc软件建立了热力耦合有限元模型,分析了激光直接沉积过程中的温度与应力变形的演变过程。考虑高温下钛合金的应力松弛行为,通过多次迭代修正了材料本构方程。同时,基于热电偶与激光位移传感器开发了成形过程中的瞬态实时测量装置,对钛合金薄壁件实际成形过程中的温度和变形进行了原位测量。对修正后的模型的模拟计算值和实测值进行比较与分析,结果表明:原位测量结果与模拟结果的温度误差仅为7.9%,变形误差为19.6%,基板变形的规律一致;沉积层总体呈拉应力状态,主应力方向与沉积方向一致。

Abstract

The MSC Marc software is used to establish the thermal-mechanical coupled finite element model to analyze the evolution of temperature and stress deformation during laser direct deposition. Considering the stress relaxation behavior of titanium alloy at high temperature, the material constitutive equation is modified through several iterations. At the same time, based on the thermocouple and laser displacement sensor, a transient real-time measurement device is developed to measure the temperature and deformation of titanium alloy thin-wall parts during the actual forming process. By comparing and analyzing the simulated and measured values of the modified model, the results show that the temperature error between the in-situ measurement results and the simulated results is only 7.9%, the deformation error is 19.6%, and the laws of the substrate deformation are consistent. The stress in the deposition layer is generally tensile, and the main stress direction is consistent with the deposition direction.

李柏泓, 郭绍庆, 周标, 秦仁耀, 王天元, 赵梓钧. 激光直接沉积钛合金热力耦合模型的建立与验证[J]. 激光与光电子学进展, 2022, 59(11): 1114007. Bohong Li, Shaoqing Guo, Biao Zhou, Renyao Qin, Tianyuan Wang, Zijun Zhao. Establishment and Verification of Thermo-Mechanical Coupled Model for Laser Direct Deposition of Titanium Alloy[J]. Laser & Optoelectronics Progress, 2022, 59(11): 1114007.