光学 精密工程, 2024, 32 (1): 53, 网络出版: 2024-01-23

ZC1蜗杆齿廓测量测头对准误差修正

Correction of probe alignment error for ZC1 worm gear profile measurement

精密测量 ZC蜗杆 测头对准 误差修正 齿轮测量中心 precision measurement ZC worm probe alignment error correction gear measurement center

摘要

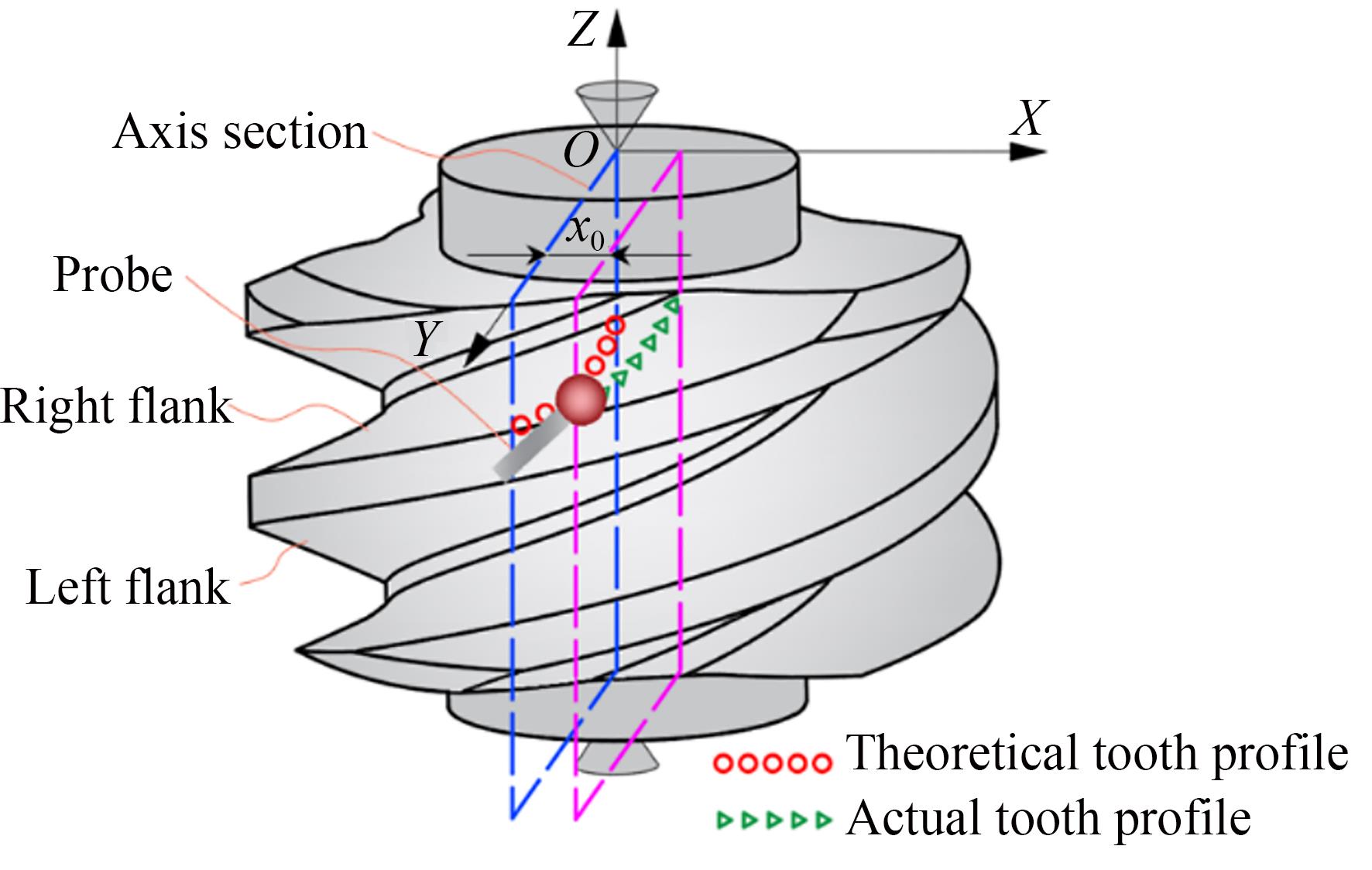

测头对准误差对齿轮测量中心ZC蜗杆齿廓偏差测量结果的影响较大,需要建立测头对准误差修正方法。基于ZC1蜗杆齿面方程,建立了蜗杆轴向齿廓测量误差模型,修正得到轴截面上齿廓测量点的轴向坐标,再依据精度标准评定得到蜗杆齿廓偏差,并分析了蜗杆的不同头数、模数和分度圆直径对蜗杆轴向齿廓测量误差的影响规律。在齿轮测量中心上开展了蜗杆轴截面齿廓测量实验,测头对准误差对齿廓形状偏差的影响较小;测头对准误差修正前后齿廓测量总偏差的最大差异由1.2 μm降为0.2 μm;齿廓形状测量偏差的最大差异由0.5 μm降为0.3 μm;齿廓倾斜测量偏差的最大差异由2.5 μm降为0.4 μm。该方法可有效减小齿轮测量中心测头对准误差对蜗杆轴截面齿廓偏差测量的影响。

Abstract

As the probe alignment error influences measurement results of tooth profile deviations of arc cylindrical worms (ZC worm) on the gear measuring center, a probe alignment error correction method should be established. Based on the equation of toroidal enveloping cylindrical worm (ZC1 worm) tooth flank and the probe alignment error, an axial profile measurement error model for the ZC1 worm is established to correct the axial coordinates of the tooth profile measurement points. Then, the worm axial profile deviations were evaluated according to the accuracy standards. The effects of varying thread number, module, and reference circle diameter on the tooth profile measurement error were analyzed. The experimental results show that the probe alignment error has little effect on the tooth profile form deviation, while the maximum difference between the total profile deviations before and after the probe alignment error correction reduced from 1.2 μm to 0.2 μm; that between the profile form deviation measurements reduced from 0.5 μm to 0.3 μm; and that between the profile slope deviations reduced from 2.5 to 0.4 μm. The proposed probe alignment error correction method can effectively reduce the effect of probe alignment errors on worm profile deviation measurements of gear measurement centers.

万辉, 汤洁, 石照耀. ZC1蜗杆齿廓测量测头对准误差修正[J]. 光学 精密工程, 2024, 32(1): 53. Hui WAN, Jie TANG, Zhaoyao SHI. Correction of probe alignment error for ZC1 worm gear profile measurement[J]. Optics and Precision Engineering, 2024, 32(1): 53.