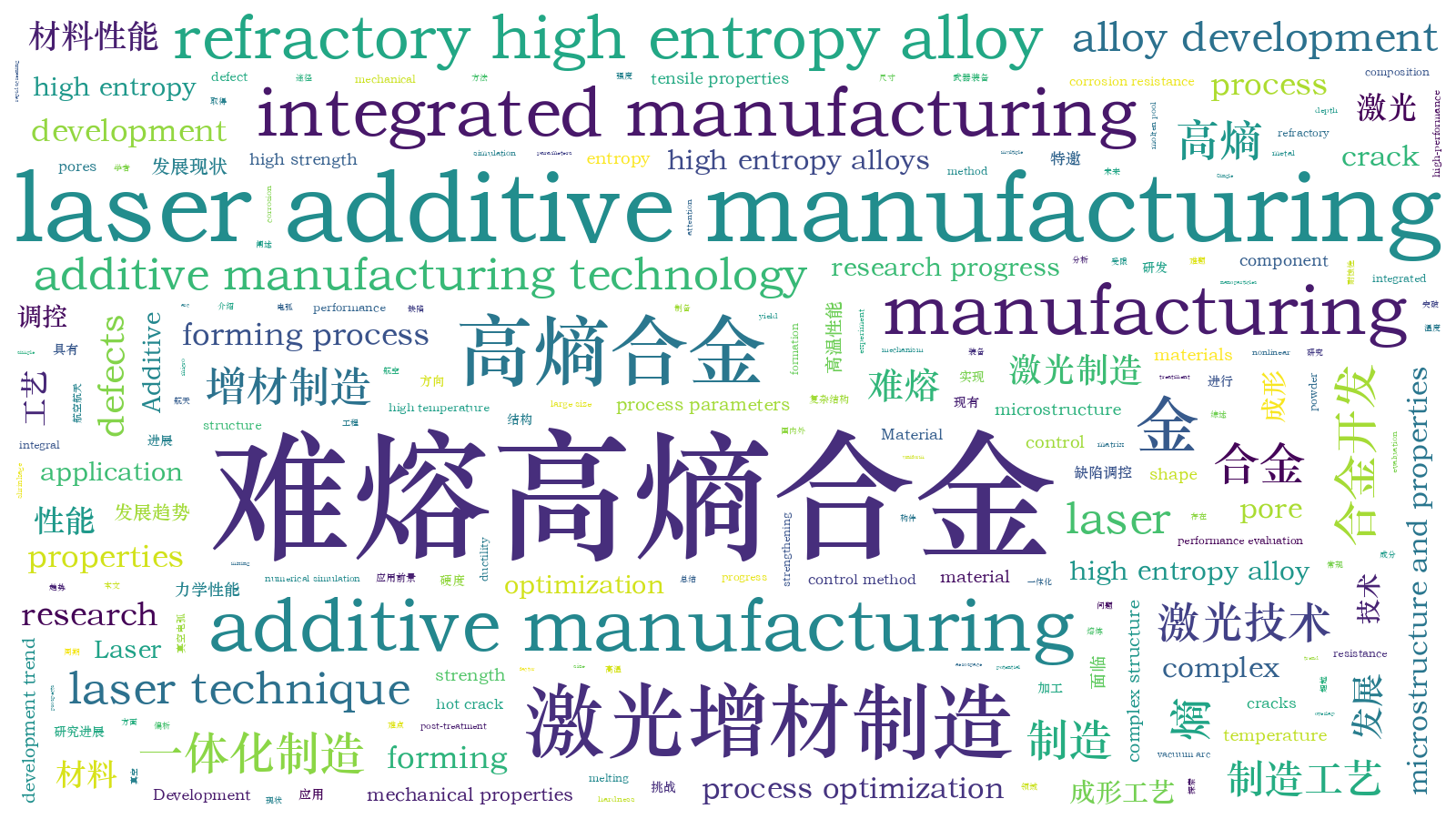

难熔高熵合金激光增材制造的发展:材料性能与制造工艺调控技术(特邀)内封面文章创刊五十周年特邀

Refractory high entropy alloy (RHEA) has superior properties such as high strength, high hardness, high temperature resistance and high corrosion resistance, which is expected to become a new material of high-temperature structure. RHEA has huge application prospects in aerospace, nuclear engineering, weapons and other fields. At present, the RHEA prepared by vacuum arc melting technology has some problems, such as large size limitation, difficult formation of complex structure, serious component segregation and long development cycle. RHEA formed by laser additive manufacturing has obvious advantages such as uniform composition, excellent microstructure and properties, integral forming of complex shape, etc. It has application potential in raw material development and high-performance parts preparation, so it has received hot attention in the research field.

The primary task of RHEA formed by laser additive manufacturing is defect control. The microstructure defects of RHEA produced by laser additive manufacturing can be divided into cracks and pores. The crack defects can be divided into hot crack and cold crack. The addition of a small number of nanoparticles, process optimization and post-treatment can eliminate the crack defects. Pore defects can be divided into four types: unfused pore, metallurgical pore, micro pore and shrinkage pore. The main control method of pore defects is process optimization. By controlling the defects, the forming of RHEA and its properties are improved greatly. Additive manufacturing of RHEAs is an effective method to develop new alloys quickly. The process parameters of laser additive technology are numerous, strongly coupled and nonlinear. Single-factor experiment, numerical overlap optimization of molten pool and numerical simulation are the rapid optimization strategies for laser additive manufacturing of RHEA. Laser additive manufacturing enables rapid development iterations of RHEA. By mechanical mixing powder or preforming alloy powder, laser additive manufacturing technology can realize the formation of various metal powders by varying component ratios, and realize the rapid screening and performance evaluation of alloy composition. NbMoTaW alloys have very high strength but poor ductility, which can be strengthened and toughened by appropriately adding low melting point ductility elements and reducing brittle elements in the matrix. HfNbTaZr alloy has good plasticity, but the yield strength is generally low, which can be strengthened by adding strengthening elements. Due to the difficulty of controlling the forming crack defects, there are few studies on the tensile properties of RHEA formed by laser additive manufacturing. And more research work is needed, especially major breakthroughs in material mechanism and forming process. Finally, the complex structural parts formed by laser additive manufacturing for RHEA is still in the initial attempt stage.

In this paper, the research on RHEAs formed by laser additive manufacturing is reviewed, and the development approaches, forming process and defect control, and the main research and challenges on mechanical properties of refractory high entropy alloys at multiple temperature stages are summarized. The research progress of complex parts of refractory high entropy alloy is introduced. Finally, the future application and development trend of RHEA formed by additive manufacturing are discussed. The integrated manufacturing of materials and shape is essential for RHEA, and laser additive manufacturing is the development direction of component manufacturing. The progress of materials and processes is the prerequisite for the integral forming of complex components in RHEA formed by laser additive manufacturing. At present, it has the ability to form simple samples, so more in-depth research is needed to accelerate the industrial application process of integrated manufacturing of shape and properties for RHEA in laser additive manufacturing.

李涤尘, 张航, 蔡江龙. 难熔高熵合金激光增材制造的发展:材料性能与制造工艺调控技术(特邀)[J]. 中国激光, 2024, 51(1): 0102001. Dichen Li, Hang Zhang, Jianglong Cai. Development of Refractory High Entropy Alloys by Laser Additive Manufacturing: Regulating Material Properties and Manufacturing Processes (Invited)[J]. Chinese Journal of Lasers, 2024, 51(1): 0102001.