难熔高熵合金激光增材制造的发展:材料性能与制造工艺调控技术(特邀)内封面文章创刊五十周年特邀

Refractory high entropy alloy (RHEA) has superior properties such as high strength, high hardness, high temperature resistance and high corrosion resistance, which is expected to become a new material of high-temperature structure. RHEA has huge application prospects in aerospace, nuclear engineering, weapons and other fields. At present, the RHEA prepared by vacuum arc melting technology has some problems, such as large size limitation, difficult formation of complex structure, serious component segregation and long development cycle. RHEA formed by laser additive manufacturing has obvious advantages such as uniform composition, excellent microstructure and properties, integral forming of complex shape, etc. It has application potential in raw material development and high-performance parts preparation, so it has received hot attention in the research field.

The primary task of RHEA formed by laser additive manufacturing is defect control. The microstructure defects of RHEA produced by laser additive manufacturing can be divided into cracks and pores. The crack defects can be divided into hot crack and cold crack. The addition of a small number of nanoparticles, process optimization and post-treatment can eliminate the crack defects. Pore defects can be divided into four types: unfused pore, metallurgical pore, micro pore and shrinkage pore. The main control method of pore defects is process optimization. By controlling the defects, the forming of RHEA and its properties are improved greatly. Additive manufacturing of RHEAs is an effective method to develop new alloys quickly. The process parameters of laser additive technology are numerous, strongly coupled and nonlinear. Single-factor experiment, numerical overlap optimization of molten pool and numerical simulation are the rapid optimization strategies for laser additive manufacturing of RHEA. Laser additive manufacturing enables rapid development iterations of RHEA. By mechanical mixing powder or preforming alloy powder, laser additive manufacturing technology can realize the formation of various metal powders by varying component ratios, and realize the rapid screening and performance evaluation of alloy composition. NbMoTaW alloys have very high strength but poor ductility, which can be strengthened and toughened by appropriately adding low melting point ductility elements and reducing brittle elements in the matrix. HfNbTaZr alloy has good plasticity, but the yield strength is generally low, which can be strengthened by adding strengthening elements. Due to the difficulty of controlling the forming crack defects, there are few studies on the tensile properties of RHEA formed by laser additive manufacturing. And more research work is needed, especially major breakthroughs in material mechanism and forming process. Finally, the complex structural parts formed by laser additive manufacturing for RHEA is still in the initial attempt stage.

In this paper, the research on RHEAs formed by laser additive manufacturing is reviewed, and the development approaches, forming process and defect control, and the main research and challenges on mechanical properties of refractory high entropy alloys at multiple temperature stages are summarized. The research progress of complex parts of refractory high entropy alloy is introduced. Finally, the future application and development trend of RHEA formed by additive manufacturing are discussed. The integrated manufacturing of materials and shape is essential for RHEA, and laser additive manufacturing is the development direction of component manufacturing. The progress of materials and processes is the prerequisite for the integral forming of complex components in RHEA formed by laser additive manufacturing. At present, it has the ability to form simple samples, so more in-depth research is needed to accelerate the industrial application process of integrated manufacturing of shape and properties for RHEA in laser additive manufacturing.

1 引言

2004年,我国学者叶均蔚突破传统材料设计思路,提出了一种“多主元”合金的设计新理念[1],该合金又被称为“高熵合金”(HEA)。一方面,它激发了人们对多主元合金广阔组成空间的不断探索;另一方面,高熵合金是典型的“浓固溶体”,其所具有的特殊无序固溶体相结构使其具有大晶格畸变、高构型熵、扩散迟滞效应和“鸡尾酒”效应等四大效应。在这些特殊效应的作用下,高熵合金有望突破传统合金的性能极限,集超高硬度、高强度、大延展性、杰出的热稳定性、良好的耐磨性和耐蚀性、良好的抗氧化性等于一体[2-9]。目前研究的高熵合金可以分为过渡元素高熵合金、难熔高熵合金、共晶高熵合金等。近年来,高熵合金成为材料研究领域的一大热点,具有重要的研究价值与应用前景。

难熔高熵合金(RHEA)是由高熔点元素W、Ta、Nb、Mo、Hf、Re等组成的高熵合金,其特点是强度高和密度大[10-11]。相对于常规高熵合金而言,其在高温下仍能保持高强度,而且具有良好的热稳定性。Senkov等[12]于2010年首次设计了WNbMoTa与WNbMoTaV两种难熔高熵合金,WNbMoTaV合金的硬度高达5360 MPa,WNbMoTa在1600 ℃时的压缩强度为405 MPa[12-13]。在纳米尺度下,WNbMoTa难熔高熵合金的屈服强度超过了10 GPa[14],被认为是极具潜力的新型金属材料,引起了新一轮高性能金属研究热潮。

高熵合金含有大密度、高熔点元素,通常采用真空电弧熔炼而成,但真空电弧熔炼易出现成分偏析,而且难以成形大尺寸、复杂结构的零件[12,15-18]。此外,难熔高熵合金大多延展性较低,二次成形和加工比较困难,难以适用由材料向构件发展的长流程制造模式。激光增材制造技术是一种高能激光束点对点的数字化成形工艺,能够成形熔点高、结构复杂的零件,同时,其大通量的试验优势可以实现材料的快速开发和迭代。激光增材制造主要分为激光粉末床熔融(LPBF)和激光定向能量沉积(LDED)。在LPBF技术中,高能激光束按照三维CAD切片模型中规划好的路径,对粉末床上的金属粉层进行逐层扫描,扫描过的金属粉末通过熔化、凝固达到冶金结合的效果,最终获得模型所设计的金属零件。其特点是所制作的构件精密,适合小尺寸精密件的制造。LDED技术将高能量激光束作为热源,在激光四周进行同步送粉形成熔池,同时按照计算机模型所规划的路径进行成形全覆盖,进而实现逐层累加成形。LDED可以实现变金属成分的梯度材料制造,适合大尺寸构件的制造。基于激光增材制造技术,开展难熔高熵合材料的研发以及复杂结构样件一体化成形,将会推进难熔高熵合金的快速研发和工程化应用。

难熔高熵合金激光增材制造以其成形能力和性能优势在航空航天、核工程、**装备等多领域展现出了巨大潜力。例如,在高超声速飞行器制造过程中,激光增材制造可以突破传统多材料组装和成形方法,整体制造大尺寸、复杂结构难熔高熵合金零部件。该工艺的特点在于能够发挥高熵合金耐高温(熔点高于2500 ℃)、比强度高、耐蚀性好、热阻大等物理特性。采用激光增材制造技术替代传统的粉末烧结、焊接、胶接、表面涂层等复杂工艺,可以解决高熔点合金不易成形、加工的难题,同时有望实现成分/性能梯度可变的复合结构,为高超声速飞行器关键部件的一次性快速制造提供了新的技术途径。

发挥难熔高熵合金增材制造技术的优势,缩短制造流程和提高设计制造柔性,是未来制造技术发展的方向,材料设计和机械结构成形的一体化制造将成为先进制造技术未来的一个重要发展方向。基于难熔高熵合金的梯度材料开发和制备是当前的研究热点。与普通的均匀材料相比,梯度高熵合金材料可以实现材料的连续过渡,将各种优异性能集中在同一个零件上,使零件具有适应不同环境的不同功能。因此,本文围绕难熔高熵合金激光增材制造缺陷控制、工艺窗口优化、材料性能强化以及复杂构件一体化制造的研究进展,总结了难熔高熵合金激光增材形性一体化制造的发展现状和主要挑战。

2 难熔高熵合金激光增材制造缺陷的调控机制

激光增材制造金属部件的显微组织缺陷主要可分为裂纹和孔隙两类。对于单相固溶体的脆性难熔高熵合金而言,其稳定的体心立方(BCC)结构相是其在高温下不易软化的关键。但是,这一特性在激光增材成形的高温梯度下极易诱发裂纹、孔隙等缺陷[19-23]。由于熔池形貌的不稳定性,激光增材制造过渡元素高熵合金同样面临着微孔隙等缺陷难以消除的问题[24-29]。此外,不仅仅是高熵合金,其他金属的增材制造的缺陷控制也是增材制造领域的重要研究方向,也是制约金属增材制造进一步发展的重要因素[30]。因此,对常用金属增材制造中的组织缺陷及控制方法进行研究,对于提升增材制造难熔高熵合金金属部件的力学性能及表面质量具有重要意义。

2.1 裂纹及其调控研究的进展与难点

高熵合金激光增材制造过程中所产生的裂纹主要分为热裂纹和冷裂纹[31]。热裂纹的发生需要同时满足金属熔融液膜缺失和残余热应力存在这两个条件[32]。激光增材制造过程中存在两种主要的热裂行为,即凝固开裂和液化开裂。凝固开裂主要受金属增材制造过程中复杂热循环的影响,一般出现于熔池凝固终止阶段。此时,熔池内部的枝晶正在生长成为完整的晶粒,阻碍了残余液体的流动,从而导致枝晶生长空间被压缩。同时,液膜附近的凝固收缩和热收缩共同产生拉应力/应变,当拉应力超过材料的抗开裂能力时,即发生凝固开裂[33-34]。液化开裂发生在热影响区的加热循环过程中,当热影响区被加热到较高温度时,低熔点相的重熔导致晶界或晶内形成液膜。液膜可能成为裂纹萌生的地方,而热循环过程中产生的较大的热应力会加速裂纹沿晶界扩展。典型的凝固裂纹特征如

![典型的热裂纹[35-37]。(a)(b)具有不规则树枝状形貌的凝固裂纹;(c)(d)无树枝状特征的液化裂纹;(e)(f)凝固裂纹;(g)(h)液化裂纹区域的形貌及位错图;(i)~(k)LPBF制造的AA7075合金的单道显示出不同的熔池形状和热裂纹敏感性](/richHtml/zgjg/2024/51/1/0102001/img_01.jpg)

图 1. 典型的热裂纹[35-37]。(a)(b)具有不规则树枝状形貌的凝固裂纹;(c)(d)无树枝状特征的液化裂纹;(e)(f)凝固裂纹;(g)(h)液化裂纹区域的形貌及位错图;(i)~(k)LPBF制造的AA7075合金的单道显示出不同的熔池形状和热裂纹敏感性

Fig. 1. Typical thermal cracks[35-37]. (a)(b) Solidification cracks with irregular dendritic morphology; (c)(d) liquefaction cracks without dendritic characteristics; (e)(f) solidification cracks; (g)(h) morphology and dislocation maps of the liquefaction crack region; (i)‒(k) single pass of LPBFed AA7075 alloy shows different pool shapes and thermal crack sensitivities

在原始金属粉末中加入少量微纳米颗粒是解决某些高熵合金成形困难和裂纹敏感问题的通用且有效的成分设计方法[38]。例如,Si、TiB2、Al2O3、TiN、TiH2和TiC等颗粒会被用来解决高脆性合金的热裂问题[39-45]。这类抑制开裂的颗粒满足与金属基体相无热膨胀差异的特性,并且与基体相具有良好的化学相容性和黏附性[46]。因此,开发出同时满足以上条件的微纳米颗粒(以抑制缺陷的形成),是难熔高熵合金研发的重要方向。Wang课题组[47]通过在Al6Mg0.2Sc0.1Zr高熵合金中加入质量分数为1.3%的Si元素,有效抑制了LPBF过程中热裂纹的产生,同时细化了组织。此后,他们通过将合金成分进一步细化,开发出了一种新型高熵合金——Al8.0Mg1.3Si0.5Mn0.5Sc0.3Zr[47]。该合金具有极细小的微观结构、高密度层错结构以及独特的9R相。在固溶强化、晶界强化、纳米粒子强化、高密度层错强化的共同作用下,该合金的抗拉强度和断后延伸率分别可达497 MPa和11%;时效热处理后,其抗拉强度提升至550 MPa,断后延伸率根据时效条件的不同在8%~17%之间。

此外,在不改变粉末原料的情况下进行工艺优化和后处理同样可以避免激光增材制造过程中的开裂情况。Xu等[48]发现通过改变扫描策略可将合金组织从较大的柱状晶粒转变成较小的等轴晶粒,从而成功地抑制热裂纹。Stopyra等[37]提出可将0.4<d/w<0.5作为避免LPBF制造热裂纹的最佳窗口,其中d/w表示熔池的深宽比。但是,最佳工艺参数不能完全消除热裂纹。粉末床预热有助于降低凝固速度,使凝固更均匀,从而抑制热裂纹[49-52]。Kempen等[50]在M2高速钢的LPBF期间,对基板进行了500 ℃的预热处理。由于热应力降低,裂纹和分层缺陷被消除。Uddin等[49]在铝合金AA6061的LPBF过程中,对粉末床进行了500 ℃预热。采用优化后的工艺参数,他们制备出了无裂纹的AA6061零件。另外,热等静压(HIP)等后处理被广泛用于闭合内部裂纹[53-56]。虽然HIP可以成功消除微裂纹,提高合金的延展性,但是在HIP过程中晶粒会长大,从而导致合金强度降低[41]。此外,Stopyra等[37]认为HIP处理不能有效闭合合金中的长裂纹缺陷。

2.2 孔隙及其调控研究的进展与难点

激光增材制造金属部件中的孔隙缺陷可以分为4种类型:1)未熔合孔隙;2)冶金孔隙;3)微孔隙(锁孔);4)收缩孔隙。它们的典型结构如

![典型孔隙[32,57-58]。(a)未熔合孔隙和冶金孔隙;(b)锁孔;(c)收缩孔隙;(d)LDED工艺中孔隙的形成机理示意图](/richHtml/zgjg/2024/51/1/0102001/img_02.jpg)

图 2. 典型孔隙[32,57-58]。(a)未熔合孔隙和冶金孔隙;(b)锁孔;(c)收缩孔隙;(d)LDED工艺中孔隙的形成机理示意图

Fig. 2. Typical pores[32,57-58]. (a) Unfused and metallurgical pores; (b) keyhole pore; (c) shrinkage pores; (d) schematic diagrams of pore formation mechanism in LDED process

控制孔隙最有效、最常见的方法是对工艺窗口和工艺参数进行优化。相当多的研究人员使用体能量密度E这一综合指标来确定获得全致密金属零件的工艺窗口[63-66]。Saedi等[67]采用LPBF工艺,以55.5~79.4 J/mm3的体能量密度制备了低孔隙率的NiTi合金。Dadbakhsh等[68]建议NiTi合金采用体能量密度为111~126 J/mm3的工艺窗口进行制备。可见,在不同的文献中,由体能量密度定义的工艺窗口差异较大。因此,体能量密度的可靠性和有效性仍然需要进一步深入研究。需要指出的是,即使是采用相同的能量密度也无法保证成形零件孔隙率的稳定性。这是因为忽略了其他的重要因素,如激光光斑尺寸和材料性质等[67,69-70]。因此,为了获得一个最优的工艺窗口,需要开发修正的能量密度公式,或者需要识别单个工艺参数及其相互作用对零件孔隙率的影响。

在难熔高熵合金的激光增材制造过程中,消除裂纹的主要途径是进行成分优化从而使合金具有一定的韧性,而消除孔隙缺陷的主要途径是进行工艺优化。NbMoTaW系列难熔高熵合金虽然具有极高的耐高温性能,但压缩应变大都不足2%。高能激光束能产生105 K/s的温度梯度,热应力远大于材料本身的断裂强度,因此裂纹缺陷很容易产生。在这种情况下,工艺窗口的优化只能减少裂纹,并不能彻底消除裂纹[71]。只能通过控制脆性元素含量和添加低熔点元素来提高合金的韧性,进而抑制裂纹缺陷。在本研究领域,消除裂纹缺陷是研究热点,亦是研究最难点。孔隙缺陷可以通过熔池搭接的优化和最优能量密度的选择进行部分消除[72],到目前为止还未有人通过HIP的方式完全消除孔隙缺陷。裂纹缺陷对于合金的室温力学性能和高温力学性能都是致命的,通过抑制裂纹缺陷才能展现合金的真正性能。同时,孔隙缺陷也制约着合金的疲劳性能。因此,大多数难熔高熵合金激光增材制造的研究都聚焦在裂纹缺陷的控制上。

目前,难熔高熵合金增材制造过程中激光强烈的热作用所导致的裂纹和孔隙缺陷是工艺研究的重点和难点。为了消除裂纹和孔隙缺陷,可从两个方面加以解决:一是通过合金设计进行材料优化,增强材料韧性,从而抑制裂纹产生,减少孔隙形成;二是进行工艺仿真和工艺优化。

3 激光增材制造难熔高熵合金材料的快速研制

相对于真空电弧熔炼等传统的材料成形手段,激光增材制造在快速开发难熔高熵合金上具有明显优势。将几种粉末进行机械混匀或者预制合金粉,然后将激光高能束流作用于粉末,通过形成瞬态的温度在3000 ℃以上的金属熔池,同时借助激光冲击力的作用,能够完全实现金属元素的充分混熔。因此,将W、Nb、Mo、Ta、Zr、Hf、V等元素自由混合并使之充分互溶,能够得到高性能的难熔高熵合金。因此,国内外研究人员已经将激光增材制造作为难熔高熵合金的快速开发手段,从而为难熔高熵合金的高通量实验开发奠定了基础[73-76]。

采用2个或2个以上送粉器的LDED技术可以快速实现难熔高熵合金材料组分及其配比的筛选。Moorehead等[74]结合LDED成形技术研发出了一种高效的材料开发方法。如

![高通量成形的高熵合金相[74]。(a)X射线衍射谱;(b)测量成分与预测成分的对比;(c)SEM图和元素分布图](/richHtml/zgjg/2024/51/1/0102001/img_04.jpg)

图 4. 高通量成形的高熵合金相[74]。(a)X射线衍射谱;(b)测量成分与预测成分的对比;(c)SEM图和元素分布图

Fig. 4. High entropy alloy phase with high flux forming[74]. (a) XRD patterns; (b) measured composition versus predicted composition; (c) SEM image and elemental mapping

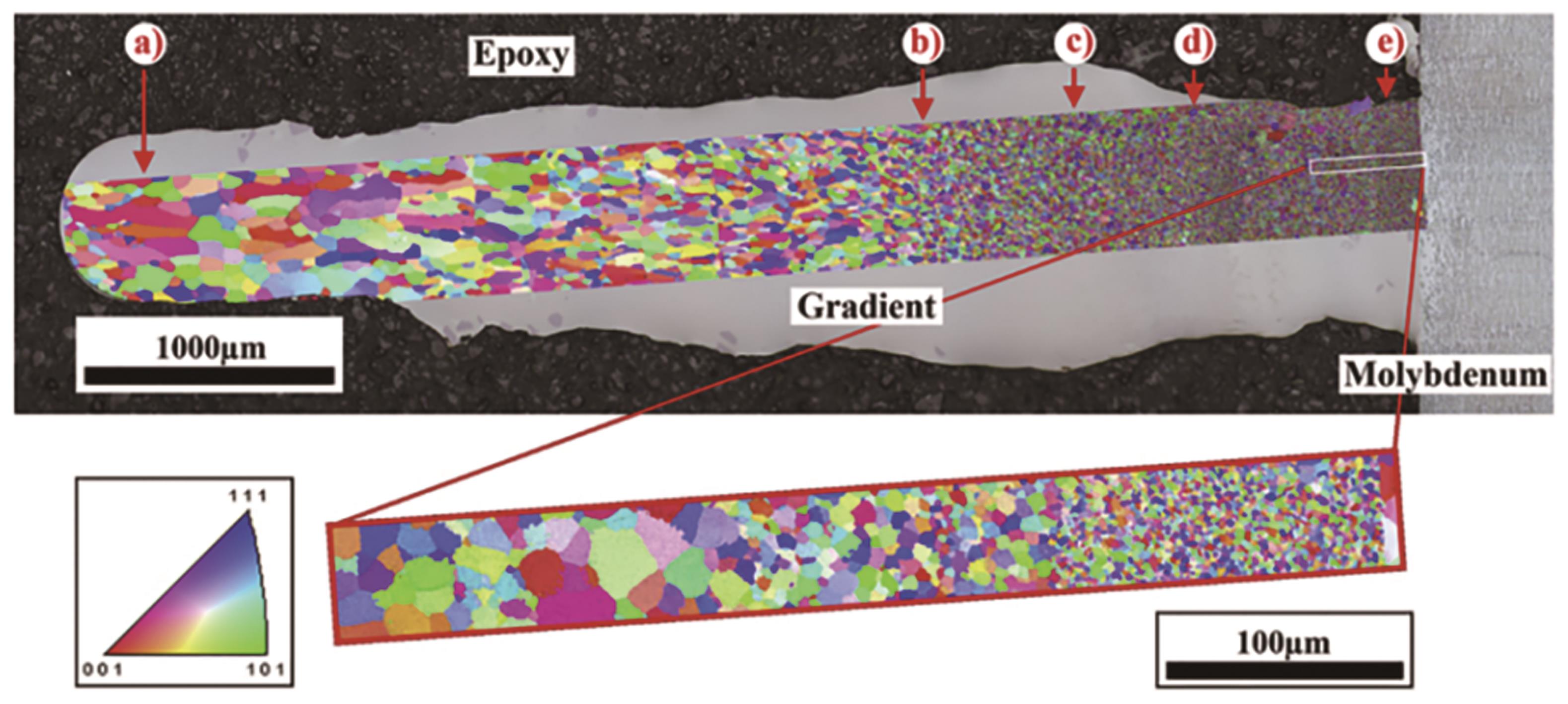

Dobbelstein等[75]首次采用元素粉末原位合金化方法制备了难熔的TiZrNbTa高熵合金。他们采用5种预混合粉末进行Nb到Zr粉的增量代替,通过每层4次重熔的方式在钼基体上成功地构建了无裂纹的单壁结构。该结构具有从Ti25Zr50Ta25到Ti25Nb50Ta25的明确成分梯度,结构的中间部分有近乎等原子的TiZrNbTa。此外,他们对

图 5. 样件截面的背散射图像以及由背向散射电子衍射(EBSD)获得的焊接结构截面上的晶粒方向

Fig. 5. Backscatter image of sample section and grain direction of welded structure section obtained by electron backscatter diffraction (EBSD)

综上所述,采用机械混粉能够有效动态调控合金组分,从而能够实现多型高熵合金材料设计条件下的大通量快速制造和实验验证,而采用预制合金粉则在较大程度上改善了难熔元素和低熔点元素充分混溶的技术难题,易获得无宏微观偏析的高性能高熵合金材料。目前,W、Mo、Ta、Hf等难熔元素的原材料纯度和粉末球化工艺仍然是行业面临的挑战,高质量球形粉价格昂贵是限制难熔高熵合金工业化应用的一个重要因素。

4 激光增材制造难熔高熵合金的力学性能

4.1 激光增材制造难熔高熵合金的室温力学性能

目前,针对传统真空电弧熔炼等方式制备的难熔高熵合金进行性能研究的报道比较多[10,77-78],相对而言,增材制造成形的难熔高熵合金的力学性能数据也在不断更新和发展。

表 1. 增材制造难熔高熵合金的压缩性能

Table 1. Compression properties of AMed RHEAs

|

Ye等[84]系统研究了CNTs/CoCrMoNbTi0.4难熔高熵合金的LDED工艺优化、微观组织演变和力学性能。CNTs/CoCrMoNbTi0.4难熔高熵合金具有多晶结构(BCC、HCP和FCC)。由于形成了高密度和超细组织,合金的显微硬度达到1015 HV0.5,抗压强度达到2110.5 MPa,压缩应变达到2.39%。Chesetti等[85]采用LPBF技术成形了Al10Nb15Ta5Ti30Zr40合金,其压缩屈服强度约为1400 MPa,抗压强度约为1700 MPa,压缩应变大于45%。这些性能可能归因于其独特的微观结构——由包含高密度亚晶界的精细晶粒组成,是包含有序B2和无序BCC固溶体相的纳米级两相混合物。北京航空航天大学的Su等[86]采用LDED技术制备了AlMo0.5NbTa0.5TiZr合金,其显微硬度为(646.4±15.7)HV,室温压缩屈服强度为2000 MPa,抗压强度为2368 MPa。

Zhang等[71]采用LPBF成形了NbMoTaX系难熔高熵合金。研究后发现,Ti或Ni元素的添加均会对NbMoTa合金成形过程中的裂纹产生影响:添加Ti元素后,裂纹尺寸减小;添加Ni元素虽然消除了微裂纹,但由于主体相的塑性降低,出现了贯穿型大裂纹。此外,将Ti和Ni元素以等摩尔比加入所形成的NbMoTaTi0.5Ni0.5合金缺陷明显减少,并且具有一定的室温强度和高温强度。NbMoTaTi0.5Ni0.5合金的室温抗压强度可达到2277.79 MPa,相比于同样工艺成形的NbMoTa合金提高了77.5%。进一步,他们采用LPBF成形了无裂纹缺陷的难熔NbMoTa系高熵合金RHEA01,其室温屈服强度和抗压强度分别为1277.35 MPa和1597.62 MPa,硬度为511.76 HV[87]。该团队采用LPBF成形了超高强度、极细晶粒的NbMoTaTiNi高熵合金,其室温压缩屈服强度可达1728 MPa,抗压强度高达2753 MPa,抗拉强度为1205 MPa。经1200 ℃退火后,合金的压缩应变为33.55%,比退火前提高了54.3%[88]。他们通过调整Mo元素含量设计了Nb3Ta3(Ti2Ni)4、Nb3Ta3Mo(Ti2Ni)3和Nb3Ta3Mo2(Ti2Ni)2三种难熔高熵合金,并采用LPBF技术实现了三种合金的成形。高强Nb3Ta3Mo2(Ti2Ni)2合金的压缩屈服强度高达(1285±56)MPa,抗压强度为2447 MPa,压缩应变为(27.1±2.6)%。高韧Nb3Ta3(Ti2Ni)4合金展现出了抗压超塑性[89]。

由于难熔高熵合金本身的高脆性以及增材制造高温度梯度下的高热应力使得其成形过程中存在缺陷,因此关于其拉伸性能的研究相对较少(如

表 2. 增材制造难熔高熵合金的拉伸性能

Table 2. Tensile properties of AMed RHEAs

|

4.2 激光增材制造难熔高熵合金的高温力学性能

难熔高熵合金的研究重点还是在其高温强度上。高熵合金由于组成元素本身具有较高的熔点,而且具有较好的热稳定性,因而被认为是新一代高温高强结构的替代材料。在难熔高熵合金激光增材制造过程中,制约其高温性能的是缺陷的控制以及低熔点元素含量的调控。Li等[80]采用LDED制备了NbMoTa合金,其在1000 ℃时的压缩屈服强度和压缩应变(εtc)分别为530 MPa和8.5%,如

表 3. 增材制造难熔高熵合金的高温压缩性能

Table 3. Compression properties of AMed RHEAs at high temperature

|

激光增材制造难熔高熵合金的力学性能直接决定了该材料的工程化应用,材料能否适应短期加速、结构承载、长期疲劳等应用场景,与其室温拉伸性能和塑性是否符合要求紧密相关,而难熔高熵合金的室温拉伸性能较差,直接限制了其在上述场景中的应用。因此,如何提高激光增材制造难熔高熵合金的室温拉伸强度和塑性是一个重要的研究课题。另外,在高温应用场景下,高温结构承载、热防护、动能打击等多种服役条件对材料的高温压缩强度和拉伸强度都有较高要求。目前,高熵合金的高温压缩强度可以达到500 MPa(1600 ℃);在高温拉伸性能方面,由于材料组分和成形工艺的限制,部分牌号高熵合金的高温抗拉强度仅达到高温合金水平,“高熵”效应对高温抗拉强度的提升还需要进一步深入研究。

5 难熔高熵合金的激光增材制造工艺开发

单因素实验、熔池数值化搭接优化、数值模拟辅助等是难熔高熵合金激光增材制造工艺快速优化的常用策略。难熔高熵合金的激光增材制造成形工艺参数较多。LPBF成形工艺参数有激光功率、扫描速度、道间距以及层厚等,LDED成形工艺参数有激光功率、扫描速度、抬升量以及送粉速度等。宁波大学的Ye等[84]采用LDED技术制备了CNTs/CoCrMoNbTi0.4合金,研究了不同工艺参数下成形零件的表面形貌、显微组织和力学性能。如

![不同工艺参数下薄壁件的截面形貌[84]。(a)2.8 J/mm;(b)3.2 J/mm;(c)3.6 J/mm;(d)4.0 J/mm;(e)4.4 J/mm](/richHtml/zgjg/2024/51/1/0102001/img_07.jpg)

图 7. 不同工艺参数下薄壁件的截面形貌[84]。(a)2.8 J/mm;(b)3.2 J/mm;(c)3.6 J/mm;(d)4.0 J/mm;(e)4.4 J/mm

Fig. 7. Cross-section morphology of thin-walled parts under different process parameters[84]. (a) 2.8 J/mm; (b) 3.2 J/mm; (c) 3.6 J/mm; (d) 4.0 J/mm; (e) 4.4 J/mm

![试样在不同加工参数下的性能测试结果[84]。(a)合金截面的平均显微硬度;(b)合金在室温压缩下的工程应力-应变曲线](/richHtml/zgjg/2024/51/1/0102001/img_08.jpg)

图 8. 试样在不同加工参数下的性能测试结果[84]。(a)合金截面的平均显微硬度;(b)合金在室温压缩下的工程应力-应变曲线

Fig. 8. Performance test results of the samples under different processing parameters[84]. (a) Average microhardness of alloy cross-section; (b) engineering stress-strain curves of the alloy under compression at room temperature

西安交通大学的Li教授团队[72]采用LPBF成形了Nb30Mo10Ta30Ti20Ni10合金,并发现通过熔池搭接可以显著改进成形质量,

![LPBF成形过程以及参数之间的几何关系[72]。(a)简化的LPBF成形过程。不同情形下,层厚c与通道间距d之间的几何关系:(b) ml¯ <c,(c) ml¯ >c,(d) ml¯ =c](/richHtml/zgjg/2024/51/1/0102001/img_09.jpg)

图 9. LPBF成形过程以及参数之间的几何关系[72]。(a)简化的LPBF成形过程。不同情形下,层厚c与通道间距d之间的几何关系:(b)

Fig. 9. LPBF forming process and geometric relationship between parameters[72]. (a) Simplified LPBF forming process. Geometric relationship between the layer thickness c and the channel spacing d for the following cases: (b)

如

![LPBF工艺200 s激光光斑周围微区(4 mm×2 mm×1 mm)的温度分布[92]](/richHtml/zgjg/2024/51/1/0102001/img_10.jpg)

图 10. LPBF工艺200 s激光光斑周围微区(4 mm×2 mm×1 mm)的温度分布[92]

Fig. 10. Temperature distribution in the micro-region (4 mm×2 mm×1 mm) around the 200 s laser spot of LPBF process[92]

6 难熔高熵合金复杂构件的形性一体化制造

尽管激光增材制造具有成形复杂结构的技术优势,但因工艺技术问题,成形难熔高熵合金复杂结构件的报道较少。研究人员实现了难熔高熵合金简单试样的激光增材制造,如

![未改进LPBF工艺成形的高熵合金出现翘曲变形[92]](/richHtml/zgjg/2024/51/1/0102001/img_14.jpg)

图 14. 未改进LPBF工艺成形的高熵合金出现翘曲变形[92]

Fig. 14. Warping deformation of HEA formed by LPBF without improvement[92]

西安交通大学的耿佳乐[93]采用LPBF工艺分别以Z字形扫描策略和条带扫描策略(如

![LPBF成形的Nb3Ta3Mo(Ti2Ni)3高熵合金叶轮实体[93]](/richHtml/zgjg/2024/51/1/0102001/img_17.jpg)

图 17. LPBF成形的Nb3Ta3Mo(Ti2Ni)3高熵合金叶轮实体[93]

Fig. 17. Nb3Ta3Mo(Ti2Ni)3 high entropy alloy impeller entity formed by LPBF[93]

总体而言,难熔高熵合金复杂构件一体化控形控性制造的研究报道较少,而工程应用级零件的制备不仅需要难熔高熵合金材料和激光增材制造工艺的迭代进步,还需要更多理论探索和研究投入,以解决材料的原理性脆性,突破拉压不平衡的困境,改善成形过程中的缺陷,最终实现难熔高熵合金复杂构件的整体成形,切实推动难熔高熵合金这种新材料在航空航天、核工程、**装备等多领域广泛应用。

7 结论

采用真空电弧熔炼技术制备难熔高熵合金面临尺寸受限、复杂结构难以成形、成分偏析严重、研发周期长等问题。发展难熔高熵合金的激光增材制造技术,有利于推进难熔高熵合金的快速研发迭代。采用激光直接熔炼可以避免成分偏析以及对高温熔炼设备的需求。发展材料制备与成形一体化技术,可为大承载、耐高温、耐腐蚀的航空航天、核工程、**装备部件的制造提供新途径。

1)难熔高熵合金激光增材成形的首要任务是缺陷控制。激光增材制造难熔高熵合金的显微组织缺陷主要包括裂纹和孔隙:裂纹缺陷主要分为热裂纹和冷裂纹,少量纳米颗粒的加入、工艺优化以及后处理可以消除裂纹缺陷;孔隙缺陷可以分为未熔合孔隙、冶金孔隙、微孔隙、收缩孔隙4种类型,孔隙缺陷的主要控制方法为工艺优化。通过对缺陷进行控制,可以初步实现难熔高熵合金的成形及其性能的大幅提升。

2)难熔高熵合金增材制造是快速开发新合金的有效方法。激光增材制造可以实现难熔高熵合金的快速开发迭代。通过机械混粉或预制合金粉,激光增材制造技术可以实现多种金属粉末的变组分比例成形,进而实现合金组成的快速筛选以及合金性能评测。

3)激光增材制造难熔高熵合金的合金化对其力学性能影响显著。NbMoTaW系合金具有极高的强度,但塑性较差,通过适当添加低熔点塑性元素和减少基体脆性元素可以实现此类合金的强韧化。HfNbTaZr系合金的塑性较好,但屈服强度普遍较低,可以通过添加强化元素进行强化。由于成形裂纹缺陷难以控制,激光增材制造难熔高熵合金的抗拉性能研究较少,还需要开展更多研究工作,尤其是材料机理和成形工艺方面的研究。

4)难熔高熵合金必须走材料结构一体化的道路,激光增材制造是向构件制造发展的重要途径。材料和工艺的进步是难熔高熵合金激光增材制造复杂构件整体成形的前提,目前已具备成形简单试样的能力,但仍需要进行深入研究来加快激光增材制造难熔高熵合金形性一体化制造工业化应用的进程。

[1] Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[2] Huo W Y, Liu X D, Tan S Y, et al. Ultrahigh hardness and high electrical resistivity in nano-twinned, nanocrystalline high-entropy alloy films[J]. Applied Surface Science, 2018, 439: 222-225.

[3] Xin S W, Zhang M, Yang T T, et al. Ultrahard bulk nanocrystalline VNbMoTaW high-entropy alloy[J]. Journal of Alloys and Compounds, 2018, 769: 597-604.

[4] Li Z M, Pradeep K G, Deng Y, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off[J]. Nature, 2016, 534(7606): 227-230.

[5] Sun S J, Tian Y Z, Lin H R, et al. Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure[J]. Materials & Design, 2017, 133: 122-127.

[6] Yang X G, Sun D F, Zhou Y, et al. A novel, non-equiatomic NiCrWFeTi high-entropy alloy with exceptional phase stability[J]. Materials Letters, 2020, 263: 127202.

[7] Nair R B, Arora H S, Mukherjee S, et al. Exceptionally high cavitation erosion and corrosion resistance of a high entropy alloy[J]. Ultrasonics Sonochemistry, 2018, 41: 252-260.

[8] Shuang S, Ding Z Y, Chung D, et al. Corrosion resistant nanostructured eutectic high entropy alloy[J]. Corrosion Science, 2020, 164: 108315.

[9] Gorr B, Azim M, Christ H J, et al. Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys[J]. Journal of Alloys and Compounds, 2015, 624: 270-278.

[10] Roh A, Kim D, Nam S, et al. NbMoTaW refractory high entropy alloy composites strengthened by in situ metal-non-metal compounds[J]. Journal of Alloys and Compounds, 2020, 822: 153423.

[11] Kunce I, Polanski M, Bystrzycki J. Microstructure and hydrogen storage properties of a TiZrNbMoV high entropy alloy synthesized using laser engineered net shaping (LENS)[J]. International Journal of Hydrogen Energy, 2014, 39(18): 9904-9910.

[12] Senkov O N, Wilks G B, Miracle D B, et al. Refractory high-entropy alloys[J]. Intermetallics, 2010, 18(9): 1758-1765.

[13] Senkov O N, Wilks G B, Scott J M, et al. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys[J]. Intermetallics, 2011, 19(5): 698-706.

[14] Zou Y, Ma H, Spolenak R. Ultrastrong ductile and stable high-entropy alloys at small scales[J]. Nature Communications, 2015, 6: 7748.

[15] Han Z D, Chen N, Zhao S F, et al. Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys[J]. Intermetallics, 2017, 84: 153-157.

[16] Senkov O N, Senkova S V, Woodward C. Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys[J]. Acta Materialia, 2014, 68: 214-228.

[17] Juan C C, Tsai M H, Tsai C W, et al. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys[J]. Intermetallics, 2015, 62: 76-83.

[18] Dobbelstein H, Thiele M, Gurevich E L, et al. Direct metal deposition of refractory high entropy alloy MoNbTaW[J]. Physics Procedia, 2016, 83: 624-633.

[19] Grasso M, Demir A G, Previtali B, et al. In situ monitoring of selective laser melting of zinc powder via infrared imaging of the process plume[J]. Robotics and Computer-Integrated Manufacturing, 2018, 49: 229-239.

[20] AlMangour B, Grzesiak D, Borkar T, et al. Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting[J]. Materials & Design, 2018, 138: 119-128.

[21] Olakanmi E O, Cochrane R F, Dalgarno K W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: processing, microstructure, and properties[J]. Progress in Materials Science, 2015, 74: 401-477.

[22] Zhou L B, Yuan T C, Li R D, et al. Selective laser melting of pure tantalum: densification, microstructure and mechanical behaviors[J]. Materials Science and Engineering: A, 2017, 707: 443-451.

[23] Zhang M N, Zhou X L, Wang D F, et al. AlCoCuFeNi high-entropy alloy with tailored microstructure and outstanding compressive properties fabricated via selective laser melting with heat treatment[J]. Materials Science and Engineering: A, 2019, 743: 773-784.

[24] Seede R, Shoukr D, Zhang B, et al. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: densification, microstructure, and mechanical properties[J]. Acta Materialia, 2020, 186: 199-214.

[25] Liu Y J, Zhang Y S, Zhang L C. Transformation-induced plasticity and high strength in beta titanium alloy manufactured by selective laser melting[J]. Materialia, 2019, 6: 100299.

[26] Yao H L, Tan Z, He D Y, et al. High strength and ductility AlCrFeNiV high entropy alloy with hierarchically heterogeneous microstructure prepared by selective laser melting[J]. Journal of Alloys and Compounds, 2020, 813: 152196.

[27] Fujieda T, Chen M C, Shiratori H, et al. Mechanical and corrosion properties of CoCrFeNiTi-based high-entropy alloy additive manufactured using selective laser melting[J]. Additive Manufacturing, 2019, 25: 412-420.

[28] Zhu Z G, An X H, Lu W J, et al. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy[J]. Materials Research Letters, 2019, 7(11): 453-459.

[29] Ladani L, Sadeghilaridjani M. Review of powder bed fusion additive manufacturing for metals[J]. Metals, 2021, 11(9): 1391.

[30] Fu J, Li H, Song X, et al. Multi-scale defects in powder-based additively manufactured metals and alloys[J]. Journal of Materials Science & Technology, 2022, 122: 165-199.

[31] Oliveira J P, Santos T G, Miranda R M. Revisiting fundamental welding concepts to improve additive manufacturing: from theory to practice[J]. Progress in Materials Science, 2020, 107: 100590.

[32] Chauvet E, Kontis P, Jägle E A, et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron beam melting[J]. Acta Materialia, 2018, 142: 82-94.

[33] Kou S. Solidification and liquation cracking issues in welding[J]. JOM, 2003, 55(6): 37-42.

[34] Dupont J N, Robino C V, Michael J R, et al. Physical and welding metallurgy of Gd-enriched austenitic alloys for spent nuclear fuel applications - part II: nickel-based alloys - tests proved Gd-enriched Ni-based alloys are excellent candidates for use in storing spent nuclear fuels[J]. Welding Journal, 2004, 83(12): 319-329.

[35] Tang Y T, Panwisawas C, Ghoussoub J N, et al. Alloys-by-design: application to new superalloys for additive manufacturing[J]. Acta Materialia, 2021, 202: 417-436.

[36] Zhou Z P, Huang L, Shang Y J, et al. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing[J]. Materials & Design, 2018, 160: 1238-1249.

[37] Stopyra W, Gruber K, Smolina I, et al. Laser powder bed fusion of AA7075 alloy: influence of process parameters on porosity and hot cracking[J]. Additive Manufacturing, 2020, 35: 101270.

[38] Li N, Huang S, Zhang G D, et al. Progress in additive manufacturing on new materials: a review[J]. Journal of Materials Science & Technology, 2019, 35(2): 242-269.

[39] Han Q Q, Gu Y C, Huang J, et al. Selective laser melting of Hastelloy X nanocomposite: effects of TiC reinforcement on crack elimination and strength improvement[J]. Composites Part B: Engineering, 2020, 202: 108442.

[40] Han Q Q, Gu Y C, Setchi R, et al. Additive manufacturing of high-strength crack-free Ni-based Hastelloy X superalloy[J]. Additive Manufacturing, 2019, 30: 100919.

[41] Han Q Q, Gu Y C, Wang L Q, et al. Effects of TiC content on microstructure and mechanical properties of nickel-based hastelloy X nanocomposites manufactured by selective laser melting[J]. Materials Science and Engineering: A, 2020, 796: 140008.

[42] Zhou S Y, Su Y, Wang H, et al. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: cracking elimination by co-incorporation of Si and TiB2[J]. Additive Manufacturing, 2020, 36: 101458.

[43] Biffi C A, Bassani P, Fiocchi J, et al. Selective laser melting of AlCu-TiB2 alloy using pulsed wave laser emission mode: processability, microstructure and mechanical properties[J]. Materials & Design, 2021, 204: 109628.

[44] Liu X H, Liu Y Z, Zhou Z G, et al. Grain refinement and crack inhibition of selective laser melted AA2024 aluminum alloy via inoculation with TiC-TiH2[J]. Materials Science and Engineering: A, 2021, 813: 141171.

[45] Choi H, Cho W H, Konishi H, et al. Nanoparticle-induced superior hot tearing resistance of A206 alloy[J]. Metallurgical and Materials Transactions A, 2013, 44(4): 1897-1907.

[46] Malaki M, Xu W W, Kasar A, et al. Advanced metal matrix nanocomposites[J]. Metals, 2019, 9(3): 330.

[47] Li R D, Wang M B, Li Z M, et al. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: crack-inhibiting and multiple strengthening mechanisms[J]. Acta Materialia, 2020, 193: 83-98.

[48] Xu J Y, Ding Y T, Gao Y B, et al. Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting[J]. Materials & Design, 2021, 209: 109940.

[49] Uddin S Z, Murr L E, Terrazas C A, et al. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing[J]. Additive Manufacturing, 2018, 22: 405-415.

[50] Kempen K, Vrancken B, Buls S, et al. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating[J]. Journal of Manufacturing Science and Engineering, 2014, 136(6): 061026.

[51] Polozov I, Sufiiarov V, Kantyukov A, et al. Microstructure, densification, and mechanical properties of titanium intermetallic alloy manufactured by laser powder bed fusion additive manufacturing with high-temperature preheating using gas atomized and mechanically alloyed plasma spheroidized powders[J]. Additive Manufacturing, 2020, 34: 101374.

[52] Shang C, Wang C Y, Li C F, et al. Eliminating the crack of laser 3D printed functionally graded material from TA15 to Inconel 718 by base preheating[J]. Optics & Laser Technology, 2020, 126: 106100.

[53] Chen J H, Li K L, Wang Y F, et al. The effect of hot isostatic pressing on thermal conductivity of additively manufactured pure tungsten[J]. International Journal of Refractory Metals and Hard Materials, 2020, 87: 105135.

[54] Wang H, Chen L, Dovgyy B, et al. Micro-cracking, microstructure and mechanical properties of Hastelloy-X alloy printed by laser powder bed fusion: as-built, annealed and hot-isostatic pressed[J]. Additive Manufacturing, 2021, 39: 101853.

[55] Sentyurina Z A, Baskov F A, Loginov P A, et al. The effect of hot isostatic pressing and heat treatment on the microstructure and properties of EP741NP nickel alloy manufactured by laser powder bed fusion[J]. Additive Manufacturing, 2021, 37: 101629.

[56] Li R D, Niu P D, Yuan T C, et al. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: processability, non-equilibrium microstructure and mechanical property[J]. Journal of Alloys and Compounds, 2018, 746: 125-134.

[57] King W E, Barth H D, Castillo V M, et al. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing[J]. Journal of Materials Processing Technology, 2014, 214(12): 2915-2925.

[58] Wolff S J, Wang H, Gould B, et al. In situ X-ray imaging of pore formation mechanisms and dynamics in laser powder-blown directed energy deposition additive manufacturing[J]. International Journal of Machine Tools and Manufacture, 2021, 166: 103743.

[59] Brennan M C, Keist J S, Palmer T A. Defects in metal additive manufacturing processes[J]. Journal of Materials Engineering and Performance, 2021, 30(7): 4808-4818.

[60] Cunningham R, Zhao C, Parab N, et al. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed X-ray imaging[J]. Science, 2019, 363(6429): 849-852.

[61] Zhao C, Parab N D, Li X X, et al. Critical instability at moving keyhole tip generates porosity in laser melting[J]. Science, 2020, 370(6520): 1080-1086.

[62] Kyogoku H, Ikeshoji T T. A review of metal additive manufacturing technologies: mechanism of defects formation and simulation of melting and solidification phenomena in laser powder bed fusion process[J]. Mechanical Engineering Reviews, 2020, 7(1): 19-182.

[63] Shipley H, McDonnell D, Culleton M, et al. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review[J]. International Journal of Machine Tools and Manufacture, 2018, 128: 1-20.

[64] Kasperovich G, Haubrich J, Gussone J, et al. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting[J]. Materials & Design, 2016, 105: 160-170.

[65] Han J, Yang J J, Yu H C, et al. Microstructure and mechanical property of selective laser melted Ti6Al4V dependence on laser energy density[J]. Rapid Prototyping Journal, 2017, 23: 217-226.

[66] Tucho W M, Lysne V H, Austbø H, et al. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L[J]. Journal of Alloys and Compounds, 2018, 740: 910-925.

[67] Saedi S, Moghaddam N S, Amerinatanzi A, et al. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi[J]. Acta Materialia, 2018, 144: 552-560.

[68] Dadbakhsh S, Speirs M, Kruth J P, et al. Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts[J]. Advanced Engineering Materials, 2014, 16(9): 1140-1146.

[69] Bertoli U S, Wolfer A J, Matthews M J, et al. On the limitations of volumetric energy density as a design parameter for selective laser melting[J]. Materials & Design, 2017, 113: 331-340.

[70] Prashanth K G, Scudino S, Maity T, et al. Is the energy density a reliable parameter for materials synthesis by selective laser melting?[J]. Materials Research Letters, 2017, 5(6): 386-390.

[71] Zhang H, Zhao Y Z, Cai J L, et al. High-strength NbMoTaX refractory high-entropy alloy with low stacking fault energy eutectic phase via laser additive manufacturing[J]. Materials & Design, 2021, 201: 109462.

[72] Zhao Y Z, Zhang H, Cai J L, et al. An efficient pores suppression process design method for high strength BCC high entropy alloys via powder bed fusion[J]. Journal of Manufacturing Processes, 2023, 101: 371-385.

[73] Lei Z F, Liu X J, Wu Y, et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes[J]. Nature, 2018, 563(7732): 546-550.

[74] Moorehead M, Bertsch K, Niezgoda M, et al. High-throughput synthesis of Mo-Nb-Ta-W high-entropy alloys via additive manufacturing[J]. Materials & Design, 2020, 187: 108358.

[75] Dobbelstein H, Gurevich E L, George E P, et al. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends[J]. Additive Manufacturing, 2019, 25: 252-262.

[76] Dobbelstein H, Gurevich E L, George E P, et al. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy[J]. Additive Manufacturing, 2018, 24: 386-390.

[77] Xu Z Q, Ma Z L, Tan Y, et al. Designing TiVNbTaSi refractory high-entropy alloys with ambient tensile ductility[J]. Scripta Materialia, 2022, 206: 114230.

[78] Wang S B, Wu M X, Shu D, et al. Mechanical instability and tensile properties of TiZrHfNbTa high entropy alloy at cryogenic temperatures[J]. Acta Materialia, 2020, 201: 517-527.

[79] Xiao B, Jia W P, Tang H P, et al. Microstructure and mechanical properties of a newly developed WTaRe refractory alloy by selective electron beam melting[J]. Additive Manufacturing, 2022, 54: 102738.

[80] Li Q Y, Zhang H, Li D C, et al. WxNbMoTa refractory high-entropy alloys fabricated by laser cladding deposition[J]. Materials, 2019, 12(3): 533-547.

[81] Xu J T, Duan R, Feng K, et al. Enhanced strength and ductility of laser powder bed fused NbMoTaW refractory high-entropy alloy via carbon microalloying[J]. Additive Manufacturing Letters, 2022, 3: 100079.

[83] Ron T, Leon A, Popov V, et al. Synthesis of refractory high-entropy alloy WTaMoNbV by powder bed fusion process using mixed elemental alloying powder[J]. Materials, 2022, 15(12): 4043.

[84] Ye X Y, Zhang M N, Wang D F, et al. Carbon nanotubes (CNTs) reinforced CoCrMoNbTi0.4 refractory high entropy alloy fabricated via laser additive manufacturing: processing optimization, microstructure transformation and mechanical properties[J]. Crystals, 2022, 12(11): 1678.

[85] Chesetti A, Banerjee S, Dasari S, et al. 3D printable low density B2+BCC refractory element based complex concentrated alloy with high compressive strength and plasticity[J]. Scripta Materialia, 2023, 225: 115160.

[86] Su B, Li J, Yang C, et al. Microstructure and mechanical properties of a refractory AlMo0.5NbTa0.5TiZr high-entropy alloy manufactured by laser-directed energy deposition[J]. Materials Letters, 2023, 335: 133748.

[87] 赵懿臻, 张航, 蔡江龙, 等. 激光增材制造BCC基难熔高熵合金组织与性能研究[J]. 中国激光, 2022, 49(14): 1402105.

[88] Zhang H, Cai J L, Geng J L, et al. Study on annealing treatment of NbMoTaTiNi high-entropy alloy with ultra-high strength disordered-ordered transition structure for additive manufacturing[J]. Journal of Alloys and Compounds, 2023, 941: 168810.

[89] Zhang H, Cai J L, Geng J L, et al. Development of high strength high plasticity refractory high entropy alloy based on Mo element optimization and advanced forming process[J]. International Journal of Refractory Metals and Hard Materials, 2023, 112: 106163.

[90] Jeong H I, Lee C M, Kim D H. Manufacturing of Ti-Nb-Cr-V-Ni high entropy alloy using directed energy deposition and evaluation of materials properties[J]. Journal of Materials Research and Technology, 2023, 23: 5606-5617.

[91] Gou S Y, Gao M Y, Shi Y Z, et al. Additive manufacturing of ductile refractory high-entropy alloys via phase engineering[J]. Acta Materialia, 2023, 248: 118781.

[92] Zhang H, Xu W, Xu Y J, et al. The thermal-mechanical behavior of WTaMoNb high-entropy alloy via selective laser melting (SLM): experiment and simulation[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1/2/3/4): 461-474.

[93] 耿佳乐. 基于Mo成分和退火工艺的粉末床熔融NbMoTaTiNi系高熵合金强塑化研究[D]. 西字: 西安交通大学, 2023.

GengJ L. Study on strong plasticization of NbMoTaTiNi based high entropy alloy melted in powder bed based on Mo composition and annealing process[D]. Xi’an: Xi’an Jiaotong University, 2023.

Article Outline

李涤尘, 张航, 蔡江龙. 难熔高熵合金激光增材制造的发展:材料性能与制造工艺调控技术(特邀)[J]. 中国激光, 2024, 51(1): 0102001. Dichen Li, Hang Zhang, Jianglong Cai. Development of Refractory High Entropy Alloys by Laser Additive Manufacturing: Regulating Material Properties and Manufacturing Processes (Invited)[J]. Chinese Journal of Lasers, 2024, 51(1): 0102001.

![高通量成形原理[74]](/richHtml/zgjg/2024/51/1/0102001/img_03.jpg)

![TiNbCrVNi合金的拉伸性能曲线[90]](/richHtml/zgjg/2024/51/1/0102001/img_06.jpg)

![LPBF成形样件[89]](/richHtml/zgjg/2024/51/1/0102001/img_11.jpg)

![LPBF成形的拉伸样件(抛光后)[89]](/richHtml/zgjg/2024/51/1/0102001/img_12.jpg)

![LDED成形的初始样件[76]](/richHtml/zgjg/2024/51/1/0102001/img_13.jpg)

![改进LPBF工艺成形的样件[92]](/richHtml/zgjg/2024/51/1/0102001/img_15.jpg)

![Z字形(左)和带状扫描策略[93]](/richHtml/zgjg/2024/51/1/0102001/img_16.jpg)