ER9车轮材料激光熔覆层微观组织及性能研究  下载: 566次

下载: 566次

Wheels and rails of high-speed trains are prone to severe damage, fatigue, and fracture damage on the wheel surface owing to wear, corrosion, strength reduction, fatigue cracking, and other reasons, thus affecting the stability and safety of train operation. The commonly used repair process to eliminate wheel surface defects causes material wastage and economic losses. To improve the service life of a wheel, laser cladding technology is used to prepare a cladding layer on the surface of a wheel and rail to enhance their damage resistance. Therefore, in this study, Fe-, Ni-, and Co-based alloy coatings, widely used in the field of laser cladding, are prepared on the surface of the ER9 wheel material using laser cladding technology. The mechanical properties, damage mechanism, and corrosion behavior of the substrates and coatings are investigated.

The base material of the laser cladding experiment was taken from the ER9 wheel steel tread, and three types of self-fluxing alloy powders—Fe-, Ni-, and Co-based—were used as cladding materials. Laser cladding technology was used to prepare the powder coating with thickness of 15 mm on sample surface by coaxial powder feeding. All samples was cut using the wire-cutting method. First, after the prepared metallographic samples were corroded, a SU8010 scanning electron microscope (SEM) and X-ray diffractometer (XRD) were used to study the microstructure and phase of the cladding layer. The microhardness of the samples was measured with a Vickers hardness tester (Qness-Q60). The prepared tensile and impact specimens were then tested for mechanical properties using an MTS universal testing machine and a Charpy pendulum impact testing machine, respectively. Furthermore, the fracture morphologies of the tensile and impact specimens were observed by SEM. Next, the prepared friction and wear samples were characterized by an MFT-EC4000 tester, and the wear surface, wear debris morphology, and element content of the samples were characterized and analyzed using SEM and its accompanying EDS. An electronic balance scale with an accuracy of 0.1 mg was used to measure the average wear. Finally, potentiodynamic polarization curves (Tafel) and electrochemical impedance spectroscopy (EIS) of the samples were obtained using an electrochemical workstation in a 3.5% NaCl solution at room temperature.

As shown in Fig. 2, the coating surface is uniform and dense, without noticeable cracks, pores, and other defects. Furthermore, the microstructure is mainly composed of dendrites and eutectic structures. XRD spectrum analysis (Fig. 3) shows that the Fe-based coating is mainly composed of α-Fe, (Fe, Ni), Cr7C3, and other solid solutions. The Ni-based coating is mainly composed of solid solution γ-Ni, intermetallic compound FeNi3 and hard Cr23C6 phase. The crystal phases of the Co-based coating are mainly the FeNi3, γ-Co, and Cr23C6 phases. The investigation of mechanical properties indicates that the surface hardness after laser cladding treatment improves significantly (Fig. 4), and the Fe- and Ni-based alloy coatings have the highest microhardness (approximately 716.5 HV). The average hardness of the Ni-based alloy coating and Co-based alloy coating is approximately 384.2 HV and 456.1 HV, which are an increment 45.6% and 72.8%, respectively. The hardness of the coating structure is enhanced to achieve a strengthening effect. Figures 5 and 6 show that the elongation of the Fe-based tensile specimen is the lowest (1.34%), and the tensile fracture has cleavage steps. The tensile strength of the Co-based alloy coating is the highest (approximately 976.41 MPa), and the tensile fracture exhibits a river pattern feature. The tensile strength of the Ni-based alloy coating tensile specimen (approximately 813.95 MPa) decreases compared with the substrate, but the elongation reaches 34.5%, and the tensile fracture exhibits a dimple-like morphology. Figure 7 shows that the impact fractures of Fe- and Co-based coatings are brittle, while the Ni-based coating exhibits good ductility and an impact toughness considerably higher than that of the former two. In terms of friction and wear research (Figs. 9 and 11), the wear amount and wear rate of the coatings are significantly reduced, while those of the Co-based alloy coating are the lowest [4 mg and 0.4×10-4 g/(N·m), respectively], which is 78.9% lower than that of the base material. Only furrows appeared on the wear surface. The wear mechanism is mainly abrasive wear. The wear rate of the Fe-based alloy coating was reduced by approximately 52.6% compared with the substrate, and the wear surface is slightly damaged. The wear mechanism is characterized by abrasive and adhesive wear. The Ni-based alloy coating has a rough grinding surface and a large amount of wear debris accumulation because of the coupling effect of abrasive and adhesive wear. In the electrochemical corrosion study, the Nyquist curves of the substrate and cladding layer in a 3.5% NaCl solution showed capacitive arc characteristics (Fig. 12). The maximum impedance of the cladding layer is two orders of magnitude higher than that of the substrate. According to the test parameters of the polarization curve (Table 4), the self-corrosion potentials of the Fe-, Ni-, and Co-based coatings are -0.475, -0.415, and -0.408 V, respectively, and the self-corrosion densities are 2.980, 0.249, and 0.172 μA/cm2, respectively.

The microstructure of the laser cladding coating on the surface of the wheel material is mainly composed of dendritic and eutectic structures. The hardness of the coating is significantly improved. The Ni-based alloy coating has good tensile strength and impact toughness, and the fracture is characterized by toughness, whereas the Co- and Fe-based alloy coatings have a brittle fracture; however, the difference is marginal. Compared with the matrix, the cladding coatings have a lower friction factor, wear rate, and better corrosion resistance, and the Co-based alloy coating has higher hardness (the microhardness was increased by 72.8%). The wear resistance of the Co-based alloy coating is the best (the friction factor is 0.31, the wear amount is approximately 4 mg, and the wear scar depth is 10.70 μm). The corrosion resistance of the Co-based alloy coating is the best (the impedance value is two orders of magnitude higher than that of the substrate). A comparative analysis of the three coatings shows that the Ni-based coating has a rough surface, high wear rate, poor wear reduction effect, and weak hardness and strength. The wear and corrosion resistance of the Co-based coating is higher than that of the Fe-based coating, but the latter has lower engineering costs and also provides overall wheel protection.

1 引言

随着我国列车速度的提高以及轴重、运量的增大,轮轨间运行环境变得更加复杂,车轮表面常常会因磨损、腐蚀、强度下降以及疲劳开裂等出现严重损伤、疲劳和断裂破坏等,极大地影响了行车的安全性和旅客的舒适度[1]。为了消除车轮表面缺陷,目前常用镟修工艺进行修型,这将造成材料浪费与经济损失。据统计,我国每年投入多达80亿元用于轮轨的维护与更新[2]。为了提高车轮的服役寿命,亟须开展提高车轮表面强度和耐蚀性、耐磨性的研究。

目前,主要的金属表面处理技术有超声冲击[3]、激光冲击[4]、激光淬火[5]、层流等离子淬火[6]、激光熔覆[7]等。与其他表面强化技术相比,激光熔覆技术制备的涂层可与基材形成良好的冶金结合,而且涂层厚度和稀释率可控,涂层组织均匀细小。选择不同的材料进行激光熔覆可以实现高强度以及耐磨、耐蚀等性能优良的涂层。目前,已有很多学者通过在轮轨表面制备激光熔覆层来提高其抗损伤能力,并在此方面进行了大量研究[8-9]。慕鑫鹏等[10-11]在车轮钢基材上激光熔覆了铁基和钴基合金涂层,对滚试验后发现两种涂层均呈现出了良好的耐磨效果,磨损率相较于基材降低了80%以上。丁阳喜等[12-13]在轮轨表面熔覆了铁基涂层和铁、钴复合基涂层,这两种涂层表现出了比车轮钢基体材料更加优异的摩擦磨损性能和滚动接触疲劳性能。Guo等[14]在CL60车轮钢表面熔覆了钴基合金涂层并通过滚动试验机来测试其耐磨性,结果发现强化后的表面磨损率相比车轮钢基体下降了42.2%~69.4%。这一结果表明激光熔覆技术可用于车轮损伤修复,有效提高了车轮材料的耐磨性。Ding等[15]通过滚动摩擦磨损试验考察了铁基合金涂层的性能,结果显示,该涂层对降低熔覆层的摩擦因数具有积极作用。Wang等[16]在轮轨材料表面熔覆了铁基合金涂层,该涂层提高了轮轨材料的耐磨性及耐滚动接触疲劳性能。Ringsberg等[17]采用数值分析方法和相关试验研究了Co-Cr合金熔覆层的耐磨性,结果显示,涂层表面不易产生棘轮效应而且能够避免出现滚动接触疲劳损伤。Lewis等[18]采用激光熔覆技术在钢轨材料表面制备了高性能马氏体不锈钢涂层(MSS),测试后发现激光熔覆处理的钢轨试样的疲劳性能显著提高,同时车轮材料的磨损也得以减轻。Zhu等[19]通过滚动接触试验研究了受损车轮表面不锈钢涂层的疲劳性能和耐磨性,结果显示,不锈钢涂层表现出了比车轮基体材料更优异的疲劳强度和耐磨性。这一结果说明激光熔覆技术可用于损伤车轮的强化。分析后可以发现,以上研究主要集中于车轮表面激光熔覆层的滚动接触疲劳性能,而针对熔覆后车轮钢力学性能、耐磨性及耐蚀性能的研究较为欠缺。

自熔性合金粉末具有良好的自脱氧造渣功能[20]以及制备简单、成形性能优异等特征,鉴于此,本团队采用激光熔覆技术在ER9车轮材料表面分别制备出激光熔覆领域应用广泛的铁基合金熔覆层、镍基合金熔覆层和钴基合金熔覆层,并对熔覆层的显微组织、力学性能、耐磨性以及耐蚀性等展开研究,以揭示基体和熔覆层的力学性能、损伤机制和腐蚀行为。本研究成果可为激光熔覆技术在轨道车轮表面强化领域的应用提供重要的理论支持。

2 试验

2.1 材料

激光熔覆试验的基体材料取自列车车轮(ER9车轮钢)踏面,其化学成分如

表 1. ER9的化学成分

Table 1. Chemical composition of ER9

|

表 2. 粉末材料的化学成分

Table 2. Chemical composition of powder materials

| |||||||||||||||||||||||||||||||||||||||||||||||||

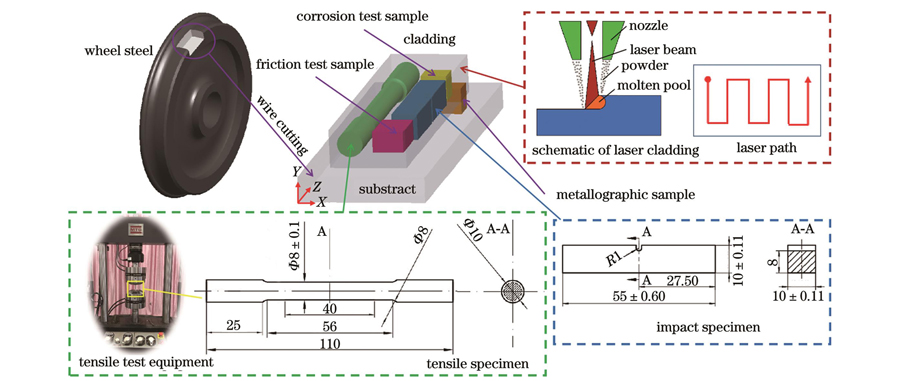

2.2 熔覆工艺及制样

采用LaserlineLDF6000-100激光柔性增材制造系统在试样表面以同轴送粉方式制备厚度约为15 mm的熔覆层。设计并优化的激光工艺参数如下:激光功率1.6 kW,扫描速度7.5 mm/s,光斑直径4 mm,搭接率50%。整个熔覆过程在氩气(纯度大于99.9%)保护下按纵向“弓”形路径进行。最后,利用线切割方法取样,熔覆过程示意图、取样方式及试样尺寸如

图 1. 试样熔覆过程、取样方式及试样尺寸示意图

Fig. 1. Schematic of sample cladding process, sampling and sample size

2.3 测试与分析

沿垂直于扫描速度方向的熔覆层横截面切割出尺寸为10 mm×8 mm×10 mm的样品,制备金相试样,对金相试样进行打磨、抛光后用王水(HCl与HNO3按体积比为3∶1混合配制而成)进行腐蚀,采用SU8010扫描电子显微镜(SEM)对试样的微观组织进行观察。采用X射线衍射(XRD)技术对熔覆层进行物相分析。利用维氏硬度仪(Qness-Q60)测量试样的显微硬度。

采用MTS万能试验机,根据GB/T 228.1—2010《金属材料 拉伸试验 第1部分:室温试验方法》的要求进行拉伸测试;冲击试验参考GB/T 229—2007《金属材料 夏比摆锤冲击试验方法》制备标准U形缺口夏比摆锤冲击试样,拉伸与冲击试验的取样部位以及试样规格如

摩擦磨损试样的尺寸为20 mm×15 mm×10 mm。对激光熔覆样品表面进行磨削、抛光,使熔覆层表面平整,表面粗糙度为0.05~0.1 μm。摩擦磨损试验采用MFT-EC4000试验仪进行,对磨件为Φ6 mm的Si3N4陶瓷球(硬度为1700 HV,表面粗糙度Ra≤0.2 μm),固定载荷为20 N,往复频率为2 Hz,摩擦距离为5 mm,摩擦时间为60 min。试验后,用乙醇对所有样品进行15 min的超声波清洗。借助SEM及其附带的能谱仪(EDS)对试样进行表征分析。使用精度为0.1 mg的电子天平对磨损前后的试样进行称重,取6次称重的平均值计算磨损量。

在室温3.5%NaCl溶液中,利用电化学工作站测试样品的动电位极化曲线(Tafel)与电化学阻抗谱(EIS)。采用标准的三电极体系,其中熔覆层和基体试样为工作电极,饱和甘汞(内充饱和KCl溶液)为参比电极,Pt作为辅助电极,暴露面积为1 cm2。电化学阻抗谱测试频率范围为0.01~105 Hz,振幅为10 mV,随后以1 mV/s的扫描速率完成动电位极化测试。特别地,在阻抗谱和动电位极化测试前,需测试20 min的开路电位(OCP),直至腐蚀电位稳定。

3 结果与讨论

3.1 微观组织

图 2. 激光熔覆层的微观组织与能谱分析

Fig. 2. Microstructures and energy spectra analysis results of laser cladding coating

从熔覆层表面的元素分析及元素定量能谱分析结果可以看出:铁基熔覆层中主要存在Fe、Cr、Ni、C元素,其中Cr、C元素在枝晶间富集,该现象是凝固时晶型转变控制的结果[26];镍基熔覆层主要以Ni和Cr元素为主,并且溶解了Fe和C等元素,涂层内元素分布均匀,未发现明显的富集现象;钴基熔覆层中的主要元素为Co、Cr、Fe和C等,枝晶上和枝晶内的元素分布不一,枝晶上有Cr、C元素富集,Fe元素主要分布在枝晶内。

3.2 熔覆层的力学性能

熔覆层试样的拉伸性能是评价熔覆层成形质量的一个重要指标,

图 5. 熔覆层试样的拉伸性能。(a)应力-应变曲线图;(b)抗拉强度与伸长率

Fig. 5. Tensile properties of laser cladding coating samples. (a) Stress-strain curve graph; (b) tensile strength and elongation

为了明晰各熔覆层试样在室温下的断裂机制,用乙醇对断口进行超声清洗,然后进行SEM观察,各试样的断口形貌如

图 6. 试样的拉伸断口形貌。(a)铁基熔覆层试样;(b)镍基熔覆层试样;(c)钴基熔覆层试样

Fig. 6. Tensile fracture morphologies of samples. (a) Fe-based laser cladding coating sample; (b) Ni-based laser cladding coating sample; (c) Co-based laser cladding coating sample

图 8. 试样的冲击断口形貌。(a)铁基熔覆层试样;(b)镍基熔覆层试样;(c)钴基熔覆层试样

Fig. 8. Impact fracture morphologies of samples. (a) Fe-based laser cladding coating sample; (b) Ni-based laser cladding coating sample; (c) Co-based laser cladding coating sample

3.3 熔覆层的耐磨性

式中:Wr为磨损率,单位为g/(N·m);

图 9. 基体和熔覆层的摩擦磨损测试。(a)摩擦因数;(b)磨损量及磨损率

Fig. 9. Friction and wear experiments of substrate and laser cladding coatings. (a) Friction coefficient; (b) mass loss and wear rate

图 10. 试样的三维磨损轨迹与最大磨损深度。(a)铁基熔覆层;(b)镍基熔覆层;(c)钴基熔覆层;(d)基体

Fig. 10. Three-dimensional wear trajectory and maximum wear depth of samples. (a) Fe-based laser cladding coating; (b) Ni-based laser cladding coating; (c) Co-based laser cladding coating; (d) substrate

图 11. 试样磨损区域的表面形貌。(a)铁基熔覆层;(b)镍基熔覆层;(c)钴基熔覆层;(d)基材

Fig. 11. Surface images of worn area of each sample. (a) Fe-based laser cladding coating; (b) Ni-based laser cladding coating; (c) Co-based laser cladding coating; (d) substrate

图 12. 表面氧化物的EDS结果。(a)点1;(b)点2;(c)点3;(d)点4

Fig. 12. EDS results of surface oxides. (a) Spot 1; (b) spot 2; (c) spot 3; (d) spot 4

3.4 熔覆层的耐蚀性

图 13. 试样在3.5%NaCl溶液中的电化学阻抗谱。(a)Nyquist图;(b)Bode图

Fig. 13. Electrochemical impedance spectra of samples in 3.5% NaCl solution. (a) Nyquist diagram; (b) Bode diagram

图 14. 等效电路。(a)基体;(b)熔覆层

Fig. 14. Equivalent circuit. (a) Substrate; (b) laser cladding coatings

表 3. 熔覆层与基体的电化学阻抗拟合结果

Table 3. Electrochemical impedance fitting results of cladding layers and substrate

|

为了进一步研究试样的耐蚀性,进行了动电位极化试验,试验结果如

表 4. 熔覆层与基体的极化参数

Table 4. Polarization parameters of cladding layers and substrate

|

4 结论

在ER9车轮材料表面制备了铁基、镍基和钴基合金熔覆层,研究了熔覆层的微观组织及性能,得到如下结论:

1)车轮材料表面激光熔覆层的微观组织主要由枝晶组织和共晶组织构成;铁基熔覆层主要由α-Fe、(Fe,Ni)、Cr7C3等固溶体组成,镍基熔覆层主要由固溶体γ-Ni、金属间化合物FeNi3和硬质相Cr23C6组成,钴基涂层的结晶相主要是FeNi3相、γ-Co相和Cr23C6相。

2)激光熔覆处理后,铁基熔覆层的显微硬度显著提升至716.5 HV左右,镍基和钴基合金熔覆层的硬度相比基体分别提高了45.6%和72.8%。铁基熔覆层的伸长率和冲击韧度最低,塑性较差;钴基涂层的抗拉强度最大,约为976.41 MPa;镍基涂层的伸长率约为34.5%,冲击韧度高达163.56 J/cm2,说明镍基涂层获得了良好的延展性。

3)激光熔覆钴基合金涂层的摩擦因数(约0.31)和磨损率[约0.4×10-4 g/(N·m)]均最低,损伤最轻,磨损机制主要为磨粒磨损;铁基熔覆层的磨损率相比基体降低了52.6%,其磨损机制以磨粒磨损为主,并伴有少量的黏着磨损特征;镍基熔覆层的磨损表面较为粗糙且存在磨屑堆积,其磨损机制为磨粒磨损与黏着磨损。

4)铁基、镍基和钴基合金熔覆层在3.5%NaCl溶液中的电荷转移电阻分别为135.55、288.14、535.89 kΩ·cm2,均显著高于基体的电荷转移电阻,且钴基熔覆层具有最优的耐蚀性。

5)对3种熔覆层进行比较及综合评价后可知,镍基熔覆层具有良好的塑韧性,但其耐磨性效果不佳,钴基熔覆层相对于铁基熔覆层具有更优异的耐磨和耐蚀性。在实际工程应用中,考虑到成本效益,铁基合金粉末仍为优选。

本文可为激光熔覆技术在车轮表面强化方面的工程应用提供一定的技术指导。

[1] 王金能, 郭鑫, 敬霖, 等. 高速列车车轮踏面剥离引起的轮轨冲击力学响应有限元模拟[J]. 爆炸与冲击, 2022, 42(4): 151-165.

Wang J N, Guo X, Jing L, et al. Finite element simulations of wheel-rail impact response induced by wheel tread spalling of high-speed trains[J]. Explosion and Shock Waves, 2022, 42(4): 151-165.

[2] 朱爱华. 地铁车轮磨耗及其对动力学性能影响的研究[D]. 北京: 北京交通大学, 2020.

ZhuA H. Study on the subway wheel wear and influence on dynamic performance[D]. Beijing: Beijing Jiaotong University, 2020.

[3] 何柏林, 史建平, 颜亮, 等. 超声冲击对钢轨钢组织与性能的影响[J]. 中国铁道科学, 2009, 30(4): 58-62.

He B L, Shi J P, Yan L, et al. The influence of the ultrasonic impact on the microstructure and properties of rail steel[J]. China Railway Science, 2009, 30(4): 58-62.

[4] Zhang Y, Lian Q L, Wang X. Enhancement of rolling contact fatigue performance of ferrite-pearlite steel with laser shock peening[J]. Advances in Mechanical Engineering, 2019, 11(5): 1-9.

[5] Meng L, Xian C, Zhu B B, et al. Comparison on the microstructure, bending properties and tribological behaviors of rail materials treated by laser dispersed quenching and induction assisted laser dispersed quenching[J]. Surface and Coatings Technology, 2021, 410: 126936.

[6] Zhang Q S, Toda-Caraballo I, Dai G Z, et al. Influence of laminar plasma quenching on rolling contact fatigue behaviour of high-speed railway wheel steel[J]. International Journal of Fatigue, 2020, 137: 105668.

[7] 余敏, 张鸿羽, 曹开, 等. 激光熔覆在高速列车上的应用研究现状[J]. 表面技术, 2020, 49(10): 12-20, 38.

Yu M, Zhang H Y, Cao K, et al. Application status of laser cladding in high-speed trains[J]. Surface Technology, 2020, 49(10): 12-20, 38.

[8] 孟丽. 钢轨表面激光-感应复合熔覆技术基础研究[D]. 武汉: 华中科技大学, 2019. 10.1016/j.msea.2019.01.068

MengL. Fundamental studies of laser-induction hybrid cladding technique on full-scale rail surface[D]. Wuhan: Huazhong University of Science and Technology, 2019.

[9] 丁昊昊, 慕鑫鹏, 祝毅, 等. 车轮材料表面h-BN/CaF2/Fe基激光熔覆涂层组织与磨损性能[J]. 中国表面工程, 2021, 34(4): 139-148.

Ding H H, Mu X P, Zhu Y, et al. Microstructures and wear properties of h-BN/CaF2/Fe based laser claddings on wheel material surface[J]. China Surface Engineering, 2021, 34(4): 139-148.

[10] 慕鑫鹏, 王文健, 祝毅, 等. 两种激光熔覆涂层对轮轨材料磨损与损伤性能的影响[J]. 摩擦学学报, 2020, 40(2): 225-233.

Mu X P, Wang W J, Zhu Y, et al. Effects of two laser cladding coatings on wear and damage properties of wheel/rail materials[J]. Tribology, 2020, 40(2): 225-233.

[11] 慕鑫鹏. 车轮材料激光熔覆涂层微观组织与磨损性能研究[D]. 成都: 西南交通大学, 2020. 10.16078/j.tribology.2019105

MuX P. Study on microstructure and wear properties of laser cladding coating on wheel materials[D]. Chengdu: Southwest Jiaotong University, 2020.

[12] 丁阳喜, 邵晓峰, 袁颖群, 等. 高速车轮钢表面激光熔覆铁基合金涂层的摩擦磨损性能[J]. 材料保护, 2017, 50(4): 6-9, 19.

Ding Y X, Shao X F, Yuan Y Q, et al. Friction and wear performance of laser cladding iron-based alloy coating on high-speed wheel steel[J]. Materials Protection, 2017, 50(4): 6-9, 19.

[13] 丁阳喜, 张远昊, 邵晓峰. 激光熔覆层对轮轨滚动接触疲劳磨损性能的影响[J]. 热加工工艺, 2020, 49(2): 80-83.

Ding Y X, Zhang Y H, Shao X F. Effects of laser cladding layers on wheel/rail rolling contact fatigue wear performance[J]. Hot Working Technology, 2020, 49(2): 80-83.

[14] Guo H M, Wang Q, Wang W J, et al. Investigation on wear and damage performance of laser cladding Co-based alloy on single wheel or rail material[J]. Wear, 2015, 328/329: 329-337.

[15] Ding H H, Mu X P, Zhu Y, et al. Effect of laser claddings of Fe-based alloy powder with different concentrations of WS2 on the mechanical and tribological properties of railway wheel[J]. Wear, 2022, 488//489: 204174.

[16] Wang W J, Fu Z K, Cao X, et al. The role of lanthanum oxide on wear and contact fatigue damage resistance of laser cladding Fe-based alloy coating under oil lubrication condition[J]. Tribology International, 2016, 94: 470-478.

[17] Ringsberg J W, Franklin F J, Josefson B L, et al. Fatigue evaluation of surface coated railway rails using shakedown theory, finite element calculations, and lab and field trials[J]. International Journal of Fatigue, 2005, 27(6): 680-694.

[18] Lewis S R, Lewis R, Goodwin P S, et al. Full-scale testing of laser clad railway track; case study-testing for wear, bend fatigue and insulated block joint lipping integrity[J]. Wear, 2017, 376/377: 1930-1937.

[19] Zhu Y, Yang Y, Mu X, et al. Study on wear and RCF performance of repaired damage railway wheels: assessing laser cladding to repair local defects on wheels[J]. Wear, 2019, 430/431: 126-136.

[20] 姜威. CrN/Ni60(WC)涂镀复合涂层组织和性能研究[D]. 兰州: 兰州理工大学, 2016.

JiangW. Microstructure and property of flame sprayed and welded/PVD Ni60(WC)/CrN multilayer coatings[D]. Lanzhou: Lanzhou University of Technology, 2016.

[21] 时晓宇, 温道胜, 王守仁, 等. 激光熔覆灰铸铁制动盘Fe-Ni-Cr梯度复合涂层微观组织及高温摩擦磨损性能研究[J]. 中国激光, 2022, 49(2): 0202017.

[22] Li Y J, Dong S Y, Yan S X, et al. Phase evolution of ductile iron during laser cladding processing[J]. Surface and Coatings Technology, 2018, 339: 37-47.

[23] 范鹏飞, 孙文磊, 张冠, 等. 激光熔覆铁基合金梯度涂层的组织性能及应用[J]. 材料导报, 2019, 33(22): 3806-3810.

Fan P F, Sun W L, Zhang G, et al. Microstructure, properties and applications of laser cladding Fe-based alloy gradient coatings[J]. Materials Reports, 2019, 33(22): 3806-3810.

[24] Roy T, Lai Q, Abrahams R, et al. Effect of deposition material and heat treatment on wear and rolling contact fatigue of laser cladded rails[J]. Wear, 2018, 412/413: 69-81.

[25] He X M, Liu X B, Wang M D, et al. Elevated temperature dry sliding wear behavior of nickel-based composite coating on austenitic stainless steel deposited by a novel central hollow laser cladding[J]. Applied Surface Science, 2011, 258(1): 535-541.

[26] 黄杰, 贺定勇, 杜开平, 等. FeCrNiMo激光熔覆层组织与电化学腐蚀行为研究[J]. 表面技术, 2020, 49(12): 228-234.

Huang J, He D Y, Du K P, et al. Microstructure and electrochemical corrosion behavior of FeCrNiMo layer fabricated by laser cladding[J]. Surface Technology, 2020, 49(12): 228-234.

[27] Lu J Z, Cao J, Lu H F, et al. Wear properties and microstructural analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding[J]. Surface and Coatings Technology, 2019, 369: 228-237.

[28] Ma Q S, Li Y J, Wang J, et al. Investigation on cored-eutectic structure in Ni60/WC composite coatings fabricated by wide-band laser cladding[J]. Journal of Alloys and Compounds, 2015, 645: 151-157.

[29] 童文辉, 赵子龙, 张新元, 等. 球墨铸铁表面激光熔覆TiC/钴基合金组织和性能研究[J]. 金属学报, 2017, 53(4): 472-478.

Tong W H, Zhao Z L, Zhang X Y, et al. Microstructure and properties of TiC/Co-based alloy by laser cladding on the surface of nodular graphite cast iron[J]. Acta Metallurgica Sinica, 2017, 53(4): 472-478.

[30] Ren B, Zhang M, Chen C J, et al. Effect of heat treatment on microstructure and mechanical properties of stellite 12 fabricated by laser additive manufacturing[J]. Journal of Materials Engineering and Performance, 2017, 26(11): 5404-5413.

[31] Li J J, Ju J, Chang W W, et al. Investigation on the microstructure and wear behavior of laser-cladded high aluminum and chromium Fe-B-C coating[J]. Materials, 2020, 13(11): 2443.

[32] 杨振, 柳宁, 樊湘芳, 等. 2Cr12NiMoWV钢表面激光熔覆铁基合金组织及力学性能研究[J]. 应用激光, 2020, 40(1): 22-28.

[33] 王少杰, 韩靖, 曾伟, 等. 低温对ER8车轮钢力学性能的影响[J]. 材料研究学报, 2018, 32(6): 401-408.

Wang S J, Han J, Zeng W, et al. Effect of low temperature on mechanical properties of ER8 steel for wheel rim[J]. Chinese Journal of Materials Research, 2018, 32(6): 401-408.

[34] 韩滨. CeO2对模具表面激光熔覆Fe基复合涂层组织和性能的影响研究[D]. 济南: 济南大学, 2021.

HanB. Effect of CeO2 on microstructure and properties of Fe-based composite coatings on die by laser cladding[D]. Jinan: University of Jinan, 2021.

[35] 衡钊, 舒林森. 激光功率对27SiMn钢激光熔覆力学性能的影响[J]. 中国激光, 2022, 49(8): 0802011.

[36] 董月, 舒林森, 林冉. 激光熔覆Fe-Cr-Mo-Si合金涂层的组织与摩擦磨损性能[J]. 激光与光电子学进展, 2021, 58(19): 1914007.

Dong Y, Shu L S, Lin R. Microstructure and friction and wear properties of laser cladded Fe-Cr-Mo-Si alloy coating[J]. Laser&Optoelectronics Progress, 2021, 58(19): 1914007.

[37] 李聪玮. 27SiMn钢表面激光熔覆铁基合金组织和性能研究[D]. 西安: 西安科技大学, 2021.

LiC W. Microstructure and properties of laser cladding Fe-based coatings on 27SiMn steel[D]. Xi’an: Xi’an University of Science and Technology, 2021.

[38] 欧阳春生, 刘秀波, 罗迎社, 等. 304不锈钢表面激光制备Ti3SiC2-Ni基自润滑复合涂层的高温摩擦学性能[J]. 表面技术, 2020, 49(8): 161-171.

Ouyang C S, Liu X B, Luo Y S, et al. High-temperature tribological properties of Ti3SiC2-Ni based self-lubricating composite coatings prepared on 304 stainless steel by laser cladding[J]. Surface Technology, 2020, 49(8): 161-171.

[39] 刘正林. 摩擦学原理[M]. 北京: 高等教育出版社, 2009.

LiuZ L. Principles of tribology[M]. Beijing: Higher Education Press, 2009.

[40] Chen J L, Zhou Y J, Shi C, et al. Microscopic analysis and electrochemical behavior of Fe-based coating produced by laser cladding[J]. Metals, 2017, 7(10): 435.

[41] 王刚. Q345表面激光熔覆镍基合金组织演化及性能研究[D]. 西安: 西安理工大学, 2021.

WangG. Study on microstructure evolution and properties of laser cladding nickel-based alloy on Q345 surface[D]. Xi’an: Xi’an University of Technology, 2021.

[42] 倪晓杰, 张博文, 赵忠贤, 等. 激光熔覆Mo2NiB2-Cr7C3复合陶瓷熔覆层组织结构与性能研究[J]. 表面技术, 2021, 50(5): 60-69.

Ni X J, Zhang B W, Zhao Z X, et al. Investigation on the microstructure and properties of the laser cladded Mo2NiB2-Cr7C3 composite coatings[J]. Surface Technology, 2021, 50(5): 60-69.

[43] Karuppasamy S S, Jeyaprakash N, Yang C H. Microstructure, nanoindentation and corrosion behavior of colmonoy-5 deposition on SS410 substrate using laser cladding process[J]. Arabian Journal for Science and Engineering, 2022, 47(7): 8751-8767.

[44] DennisJ K. Nickel and chromium plating[M]. Boca Raton: CRC Press, 1993.

[45] Fan L, Chen H Y, Dong Y H, et al. Wear and corrosion resistance of laser-cladded Fe-based composite coatings on AISI 4130 steel[J]. International Journal of Minerals, Metallurgy, and Materials, 2018, 25(6): 716-728.

[46] Hermas A A, Morad M S. A comparative study on the corrosion behaviour of 304 austenitic stainless steel in sulfamic and sulfuric acid solutions[J]. Corrosion Science, 2008, 50(9): 2710-2717.

Article Outline

杨文斌, 李仕宇, 肖乾, 杨春辉, 陈道云, 廖晓咏. ER9车轮材料激光熔覆层微观组织及性能研究[J]. 中国激光, 2023, 50(8): 0802202. Wenbin Yang, Shiyu Li, Qian Xiao, Chunhui Yang, Daoyun Chen, Xiaoyong Liao. Microstructure and Properties of Laser Cladding Coatings for ER9 Wheel Materials[J]. Chinese Journal of Lasers, 2023, 50(8): 0802202.