1 厦门大学航空航天学院,福建 厦门 361005

2 厦门大学深圳研究院,广东 深圳 518057

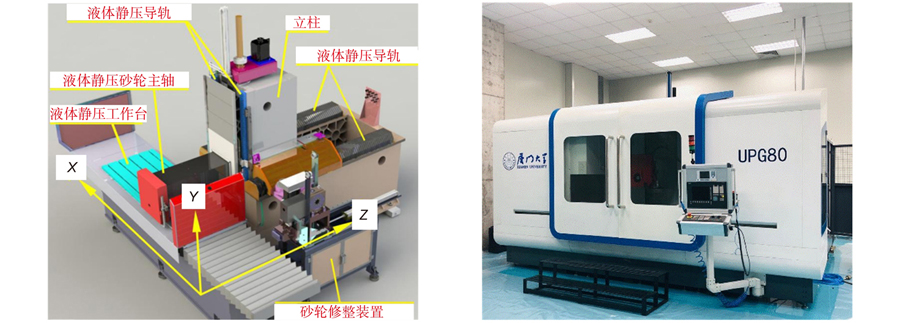

Overview: Driven by the rapid development of national optical projects such as laser nuclear fusion and aerospace telescopes, as well as high-end civilian fields such as advanced instruments and optical lenses, the requirements for full-frequency domain processing errors and surfaces of optical components are becoming more and more stringent. At this stage, the optical components generally need to go through rough grinding, fine grinding, polishing and coating, and other processes, and their surface quality mainly depends on the defect removal ability and error control level of the polishing process. Whether the fine grinding process can obtain better surface shape accuracy and low surface/subsurface damage suppression determines the processing efficiency, and the ultra-precision processing manufacturing equipment is the premise of the realization of ultra-precision machining of the optical components. So far, all countries in the world have invested in the research and development of optical ultra-precision grinding and polishing technology, and have developed more relatively mature high-precision grinding and polishing equipment, which can better meet the processing needs of most of the current optical components. For the core equipment and key technologies required for ultra-precision manufacturing, China has long relied on imports. In order to break through the bottleneck restricting the development of ultra-precision technology in China at this stage, under the traction and drive of the national large-scale engineering project, China has made remarkable progress in optical ultra-precision manufacturing equipment and technology. However, for the optical ultra-precision technology and equipment, there is still a certain gap between China and the international advanced level, and it is necessary to continue to strengthen the research. In addition to the high-end grinding and polishing equipment necessary for the ultra-precision machining of optical components, it is also necessary to strengthen the technical level of a series of key supporting units, such as ultra-precision grinding and polishing processing technology, high-end key functional components, intelligent monitoring technology of processing environment, efficient ultra-precision machining tools, processing and inspection path planning and compensation processing strategies, computer-aided manufacturing and testing software, etc. The research, development, and application of these technologies are related to the development of high-end manufacturing in the civilian fields and national defense fields, and are also the focus of the country. This paper mainly focuses on the ultra-precision machining of large-diameter optical aspherical components. Starting from the grinding and polishing process route, this paper introduces the long-term research progress of the Precision Engineering Laboratory of Xiamen University in the field of large-diameter optical aspherical component processing, and introduces in detail the technical and system achievements such as ultra-precision grinding and polishing equipment, robot-assisted grinding and polishing, equipment intelligent monitoring system, processing technology and control software.

超精密加工 磨抛装备 加工工艺 CAM软件 ultra-precision machining grinding and polishing equipment processing technology CAM software

为了改善铝/钢连接性能, 采用激光技术通过调整工艺参数获得了拉伸强度达到铝母材40%的不等厚铝/钢对焊接头, 并对接头焊缝组织、界面化合物、力学性能展开了分析。结果表明, 焊接速率为1.8 m/min、激光向钢侧偏置0.3 mm、离焦量为0 mm、激光功率为3.0 kW时, 接头抗拉强度达到38 MPa; 保持其它焊接参数不变, 离焦量为-2 mm时, 接头抗拉强度进一步提升至57.7 MPa, 焊缝截面形状由酒杯状变为束腰状, 熔合线更加整齐, 附近裂纹、气孔缺陷明显减少; 焊缝界面区域物相衍射与能谱分析表明, 沿熔合线垂直方向生长的化合物为脆韧程度不尽相同的FeAl、FeAl3、Fe2Al5和Fe2CrAl、Fe3Al; 接头整体拉伸断裂模式为脆性断裂, 断口表面部分位置连接强度较好, 呈凹陷状, 检测发现Fe3Al。此研究结果在提升车身铝/钢连接处性能、车身减重以及节能减排方面具有重要现实意义。

激光技术 不等厚铝/钢 激光焊接 铁-铝化合物 微观组织 力学性能 laser technique unequal thickness aluminum/steel laser welding iron aluminum compound microstructure mechanical property

强激光与粒子束

2021, 33(4): 044005

Author Affiliations

Abstract

1 Division of Nanophotonics, CAS Center for Excellence in Nanoscience, National Center for Nanoscience and Technology, Beijing 100190, China

2 Center of Materials Science and Optoelectronics Engineering, University of Chinese Academy of Sciences, Beijing 100049, China

3 CAS Key Laboratory for Biomedical Effects of Nanomaterials & Nanosafety, National Center for Nanoscience and Technology, Beijing 100190, China

4 Institute of High Energy Physics, Chinese Academy of Sciences, Beijing 100049, China

Monitoring the chemical and structural changes in protein side chains and endpoints by infrared (IR) spectroscopy is important for studying the chemical reaction and physical adsorption process of proteins. However, the detection of side chains and endpoints in nanoscale proteins is still challenging due to its weak IR response. Here, by designing a double layered graphene plasmon sensor on MgF2/Si substrate in the IR fingerprint region, we detect the vibrational modes in side chains and endpoints (1397 cm 1 and 1458 cm 1) of monolayer protein. The sensor could be applied on biochemistry to investigate the physical and chemical reaction of biomolecules.

240.6680 Surface plasmons 300.6340 Spectroscopy, infrared 160.4236 Nanomaterials Chinese Optics Letters

2019, 17(6): 062401

1 郑州轻工业学院 物理与电子工程学院, 河南 郑州 450002

2 郑州轻工业学院 机电工程学院, 河南 郑州 450002

激光准直技术在位移测量及相关应用中具有重要作用, 其核心器件是位置敏感探测器, 环境杂散光、电源波动、光电信号处理电路噪声等是影响测量精度的主要因素。针对以上问题, 提出一种基于激光调制的高精度位移测量方法。将激光器由直流驱动的连续输出模式改为交流驱动的调制模式输出, 优化设计光电探测器微弱光电信号的调理与采集系统, 通过编写Labview软件对信号进行频谱分析、带通滤波、均值处理等, 对激光连续输出和激光调制输出2种情况分别进行了实验测试与分析, 并对比了位移测量的稳定性。实验结果表明: 其测量值波动范围从7 μm减少到了2.6 μm, 验证了基于激光调制方法的有效性, 可以通过滤波更加有效地消除噪声, 测量精度提高至3 μm以内。

位移测量 激光准直技术 激光调制 滤波 displacement measurement laser collimation technology laser modulation filtering