抛光过程中光学元件表面划痕的形成和控制  下载: 1442次

下载: 1442次

汤文龙, 梁尚娟, 焦翔, 樊全堂, 尹进, 朱健强. 抛光过程中光学元件表面划痕的形成和控制[J]. 中国激光, 2019, 46(12): 1202009.

Wenlong Tang, Shangjuan Liang, Xiang Jiao, Quantang Fan, Jin Yin, Jianqiang Zhu. Formation and Control of Scratches on Surfaces of Optical Components During Polishing[J]. Chinese Journal of Lasers, 2019, 46(12): 1202009.

[2] McLeod J H, Sherwood W T. A proposed method of specifying appearance defects of optical parts[J]. Journal of the Optical Society of America, 1945, 35(2): 136-138.

[3] Aikens DM. The truth about scratch and dig[C]//International Optical Design Conference and Optical Fabrication and Testing, June 13-17, 2010, Jackson Hole, Wyoming, United States. Washington, D.C.: OSA, 2010: OTuA2.

[4] 郭亚晶, 唐顺兴, 姜秀青, 等. 基于振镜扫描方式的光学元件表面损伤检测[J]. 光学学报, 2017, 37(6): 0612003.

[5] 韩敬华. 控制光学元件超光滑表面粗糙度的研究[D]. 四川: 四川大学, 2006.

Han JH. Study on controlling the super smooth surface roughness of optical components[D]. Sichuan: Sichuan University, 2006.

[6] 梁尚娟, 汤文龙, 焦翔, 等. 改性抛光剂对光学玻璃抛光质量的影响[J]. 中国激光, 2017, 44(12): 1203001.

[8] Ring T A, Feeney P, Boldridge D, et al. Brittle and ductile fracture mechanics analysis of surface damage caused during CMP[J]. Journal of the Electrochemical Society, 2007, 154(3): H239-H248.

[15] 张义同. 热粘弹性理论[M]. 天津: 天津大学出版社, 2002.

Zhang YT. Theory of thermo-viscoelasticity[M]. Tianjin: Tianjin University Press, 2002.

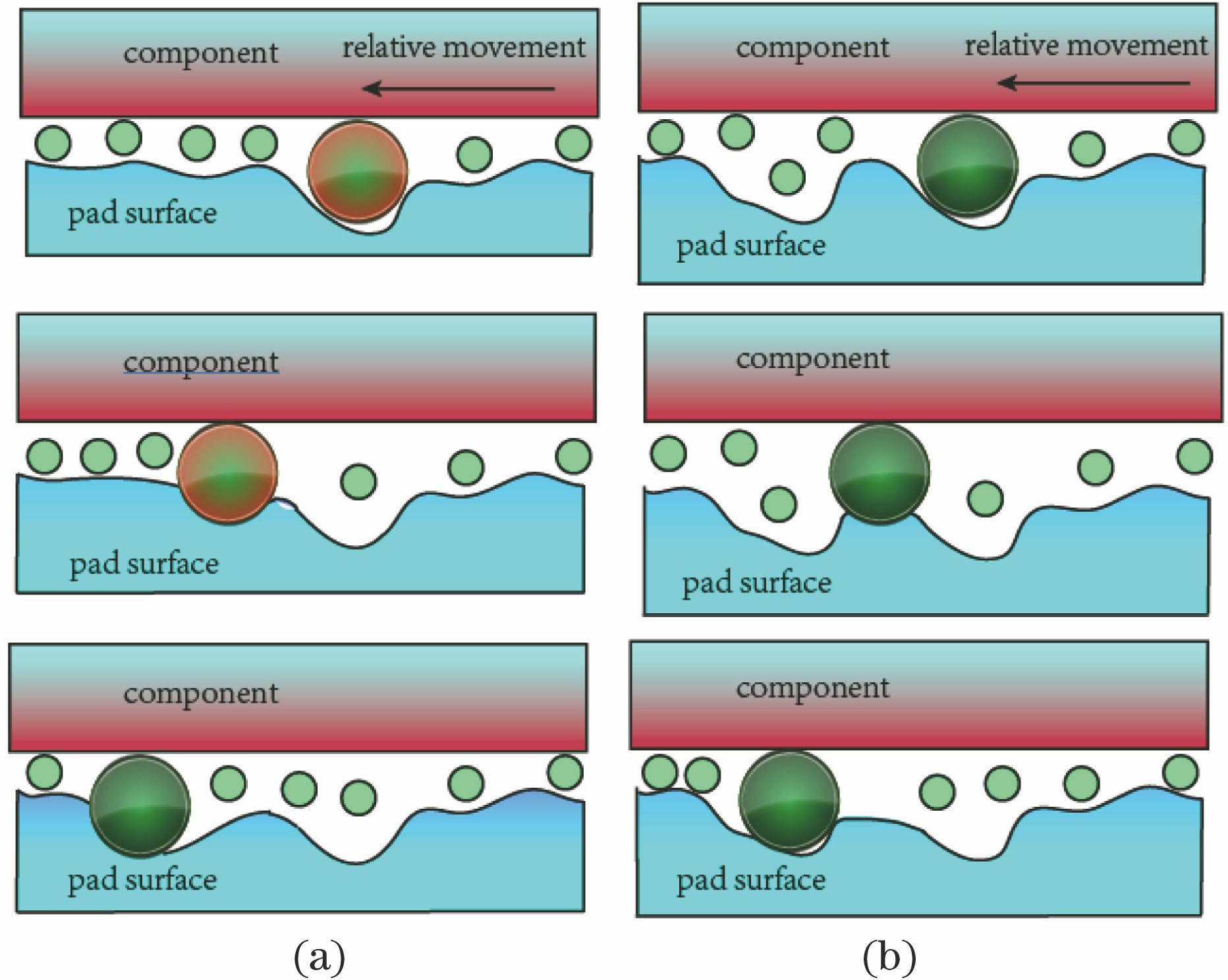

[17] Choi J G, Prasad Y N, Kim I K, et al. The synergetic role of pores and grooves of the pad on the scratch formation during STI CMP[J]. Journal of the Electrochemical Society, 2010, 157(8): H806-H809.

汤文龙, 梁尚娟, 焦翔, 樊全堂, 尹进, 朱健强. 抛光过程中光学元件表面划痕的形成和控制[J]. 中国激光, 2019, 46(12): 1202009. Wenlong Tang, Shangjuan Liang, Xiang Jiao, Quantang Fan, Jin Yin, Jianqiang Zhu. Formation and Control of Scratches on Surfaces of Optical Components During Polishing[J]. Chinese Journal of Lasers, 2019, 46(12): 1202009.