基于原子层沉积技术的石英管表面减反射膜的制备  下载: 1028次

下载: 1028次

1 引言

大曲率的光学元件如球透镜、非球面镜、石英管等被广泛应用于激光器系统、光学显微镜系统以及投影系统等光学系统中。为了满足不同光学系统对透射率、反射率及偏振的要求,通常需要在大曲率光学元件表面沉积薄膜,而薄膜的均匀性对于光学系统的性能(成像质量、测试精度等)有着重要的影响[1-3]。减反射膜作为目前应用最广、产量最大的一种光学薄膜,可以通过气相法和液相法制备[4-6],其在大曲率光学元件表面的均匀性依然是目前研究的热点之一。

物理气相沉积(PVD)技术广泛应用于光学薄膜的制备,由于PVD沉积过程中沉积粒子分布和运动轨迹具有定向性,空间分布对于薄膜厚度较为敏感,因而对大曲率光学元件和不规则的表面制备薄膜的均匀性有很大限制。通过改变气流分布、元件轨迹、靶材位置等,可以改善规则大曲率光学元件表面薄膜的均匀性[7-8]。Lanzafame等[9]提出一种将倒圆柱磁控管(ICM)溅射阴极与衬底载体配置结合在一起的新型光学镀膜系统,可以在曲率半径为50 mm、直径为50 mm的上凸面和下凹面基板上分别沉积非均匀性为±0.3%、±0.5%的单层膜。但目前PVD技术仍无法保证在整个球表面沉积均匀性较优的薄膜,且无法在具有内外表面的大曲率元件上同时沉积均匀的薄膜。

浸渍法属于液相法的一种,通过直接将基板浸渍在涂布液中,以一定的速度提拉后,可以同时在基板内外形成薄膜,该方法被广泛应用于弯曲表面薄膜的沉积。薄膜厚度和均匀性主要取决于涂布液的黏度及提拉速度[10-13]。但该方法实际成膜会存在一定长度范围的非均匀区域,且经常会发生如液滴、线状条纹等缺陷,较难将薄膜的均匀性控制在较优水平[14-15]。因此,对于制备精度要求较高的光学薄膜,浸渍法具有很大局限性。

化学气相沉积(CVD)技术利用气态反应物在固态基板表面形成薄膜,具有优良的绕镀特性,可以克服上述PVD技术和浸渍法的缺点。原子层沉积(ALD)技术作为一种改进的CVD技术,凭借其优异的表面均匀性和复形性,能够在大曲率光学元件表面内外同时沉积均匀的薄膜[16-19]。通过将前驱体和吹扫气体交替通入至饱和的方法,ALD技术使得腔内仅在基底表面发生化学气相反应,即发生饱和自限制反应[20]。通过控制沉积周期,ALD技术可在深宽比较大的狭缝、天线等微纳结构以及大曲率表面精确沉积厚度均匀的薄膜[21-24]。本文研究ALD技术在大曲率石英管内外表面沉积单点减反射膜的均匀性分布,实验结果表明,石英管表面最低反射率为0.17%,忽略夹具的影响,内外壁均匀性和薄膜厚度的变化趋势一致,且不随石英管的尺寸变化而改变。

2 实验方法

本实验采用芬兰Beneq公司生产的TFS200型ALD设备的三维反应腔。制备550 nm单波长减反射膜的高折射率材料分别是氧化铝(Al2O3)和氧化钛(TiO2)。两种材料均在基板温度120 ℃下制备,腔内吹扫气体为N2。利用前驱体TiCl4和去离子水(H2O)制备TiO2,而Al2O3的前驱体分别是三甲基铝(TMA)和去离子水(H2O),单个周期的ALD沉积过程包括4个步骤和2个半反应。每个半反应开始时,先通入一种反应前驱体,后通入清洗气体对过量反应物和副产物进行吹扫,具体工艺参数见

表 1. 基于ALD技术制备Al2O3和TiO2的工艺参数

Table 1. Process parameters for preparation of Al2O3 and TiO2 based on ALD technology

|

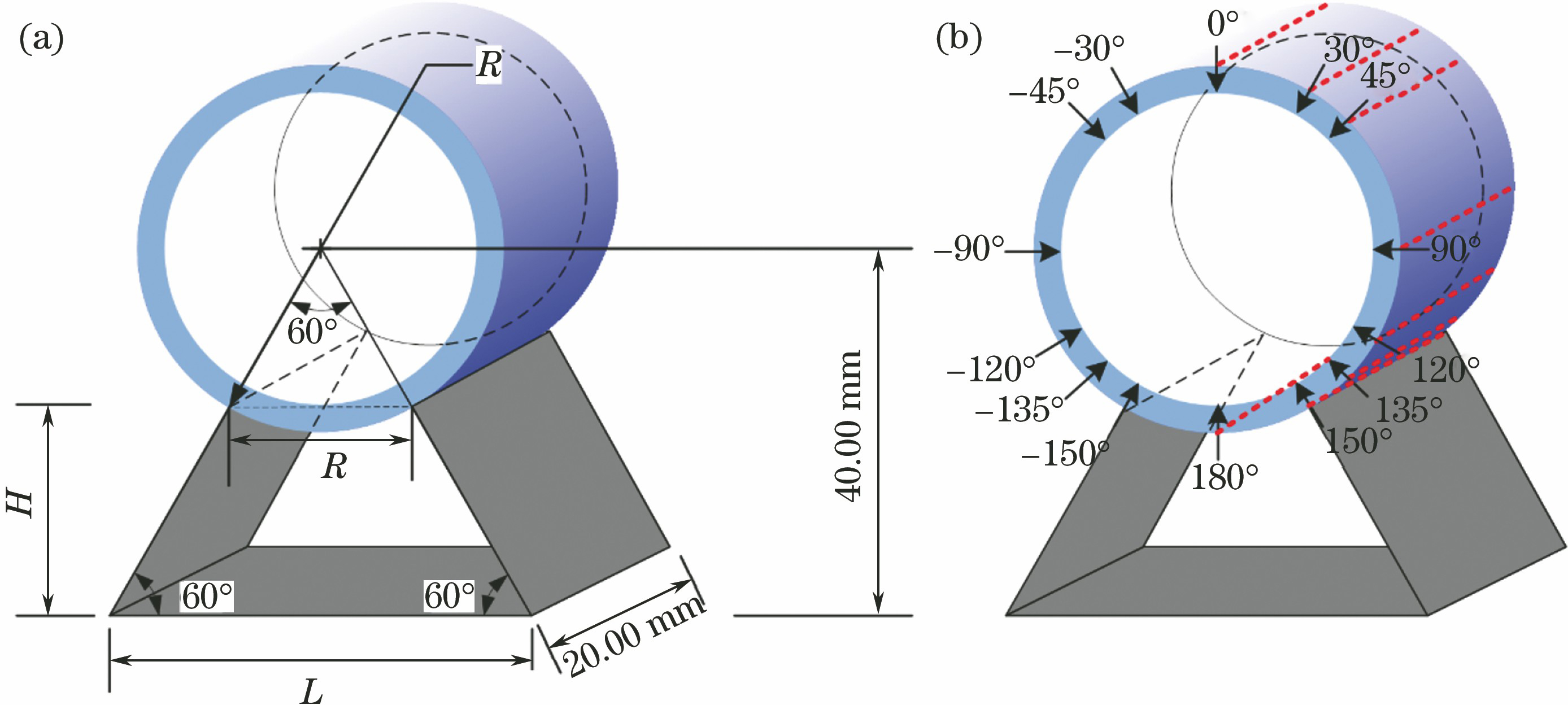

为了在石英管内外壁表面沉积均匀的薄膜,尤其是石英管外壁的底部,实验中采用如

下梁宽度

夹具的长度为20 mm,厚度为0.5 mm。

单个石英管上内外壁的均匀性测试如

式中:

图 1. 石英管夹具和石英管上测试点示意图。 (a)石英管夹具;(b)测试点

Fig. 1. Schematic of quartz tube holder and various testing points on quartz tube. (a) Quartz tube holder; (b) testing points

为了研究内径、外径和长度等参数对石英管内外表面膜厚均匀性的影响,以

表 2. 石英管尺寸

Table 2. Quartz tube size

|

3 结果及分析

3.1 单波长550 nm减反射膜

通过在石英管表面沉积Al2O3薄膜,并采用光度法进行拟合,得到石英管壁表面ALD Al2O3薄膜的稳定生长速率为0.110 nm/cycle。利用内外壁上单点中心波长与平均中心波长的偏差衡量均匀性,整个外壁的厚度分布见

图 2. 单层膜的厚度均匀性分布。(a) Al2O3薄膜;(b) TiO2薄膜

Fig. 2. Thickness uniformity distribution of single layer. (a) Al2O3 film; (b) TiO2 film

图 3. 材料折射率和消光系数。(a) Al2O3折射率;(b) TiO2折射率和消光系数

Fig. 3. Refractive index and extinction coefficient of materials. (a) Refractive index of Al2O3; (b) refractive index and extinction coefficient of TiO2

根据Al2O3和TiO2薄膜的光学常数,设计得到单波长为550 nm的减反射膜系结构Glass/TiO2 (20 nm)/ Al2O3 (113.8 nm),在550 nm处反射率小于0.01%。实际制备的石英管上减反射膜的反射率测试曲线如

图 4. 单波长550 nm减反射膜的反射率曲线

Fig. 4. Experimental and simulated reflectivities of single wavelength 550 nm AR coating

3.2 石英管内外壁的均匀性研究

相比PVD技术只能保证较小角度范围曲面上的薄膜均匀性,ALD技术凭借其特有的自限制反应,能够在整个管柱状光学元件的表面上沉积均匀的薄膜。为了探究ALD技术在石英管外壁制备减反射膜的均匀性以及外壁直径对薄膜厚度和均匀性的影响,选取内壁直径为20 mm,长度为20 mm,外壁直径分别为23、26、30 mm的石英管进行实验。对3种石英管外壁的圆周方向(半长度的横截面上)、长度方向(0°方位)、以及整个外壁表面的非均匀性及单点中心波长与平均中心波长的偏差进行分析。如

表 3. 不同外径石英管的外壁非均匀性

Table 3. Non-uniformity on outer surfaces of quartz tubes with different outer diameters

|

图 5. 不同外径石英管外壁的中心波长偏差。(a)外壁圆周方向;(b)外壁轴向

Fig. 5. Central wavelength deviations on outer surfaces of quartz tubes with different outer diameters. (a) Circumferential direction of outer surface; (b) axial direction of outer surface

不同于PVD技术只能在基板一侧沉积薄膜,ALD技术可以在石英管的内、外壁同时成膜。在外壁直径为40 mm、长度为20 mm、内壁直径分别为37、34、30 mm的石英管上沉积550 nm单点减反射膜。不同内径石英管的内壁非均匀性见

表 4. 不同内径石英管的内壁非均匀性

Table 4. Non-uniformity on inner surfaces of quartz tubes with different inner diameters

|

图 6. 不同内径石英管内壁的中心波长偏差。(a)内壁圆周方向;(b)内壁轴向

Fig. 6. Central wavelength deviations on inner surfaces of quartz tubes with different inner diameters. (a) Circumferential direction of inner surface; (b) axial direction of inner surface

前述实验结果显示,控制石英管长度为20 mm时,内外壁的轴向非均匀性均小于±1%。为了研究长度变化对石英管内外壁薄膜厚度和均匀性的影响,利用内、外壁直径分别为40 mm和34 mm,长度分别为30、40、50 mm的石英管进行实验。实验结果如

表 5. 不同长度石英管的内壁和外壁均匀性

Table 5. Uniformity of inner and outer surfaces of quartz tubes with different lengths

|

图 7. 不同长度石英管内外壁的轴向中心波长偏差。(a)内壁轴向;(b)外壁轴向

Fig. 7. Axial central wavelength deviations on inner and outer surfaces of quartz tubes with different lengths. (a) Axial direction of inner surface; (b) axial direction of outer surface

以外径为40 mm、内径为34 mm和长度为50 mm的石英管为例,对同一管子内外壁的厚度均匀性进行分析,该石英管的中心波长分布如

图 8. 外径为40 mm,内径为34 mm,长度为50 mm石英管的中心波长分布。(a)外壁;(b)内壁

Fig. 8. Central wavelength distributions of quartz tube with outer diameter of 40 mm, inner diameter of 37 mm, and length of 50 mm. (a) Outer surface; (b) inner surface

4 结论

通过ALD Al2O3和TiO2材料在石英管上制备550 nm单波长减反射膜,研究ALD技术在大曲率石英管表面沉积薄膜的厚度和均匀性分布,以及石英管内径、外径及长度尺寸的影响。实验测试结果显示,最低点反射率为0.17%。在不考虑夹具影响的条件下,单个石英管内壁和外壁的横截面和轴向非均匀性均小于±1%,圆周方向特别是底部均可以获得较好的均匀性,轴向均匀性优于浸渍法。同一个石英管内壁和外壁的整体非均匀性基本一致,为±1.5%左右。与其他气相、PVD技术及液相薄膜制备技术相比,ALD技术可以同时在大曲率光学元件内外侧两个表面同时涂覆均匀性相似且厚度一致的薄膜而不受石英管尺寸的影响。近年来,前驱体材料的丰富,等离子体增强ALD技术(PEALD)和快速ALD技术(RALD)的出现,原有的反应速率慢,沉积周期长,使用温度高的缺点都在逐渐被优化, 结合ALD技术独有的在大曲率元件表面沉积薄膜的优势,其在大批量生产应用中的适用性将会不断被提高。

[2] 张宝仁, 吴礼明, 刘贵萍. 高功率CO2激光器的增透膜[J]. 中国激光, 1980, 7(11): 48-51.

张宝仁, 吴礼明, 刘贵萍. 高功率CO2激光器的增透膜[J]. 中国激光, 1980, 7(11): 48-51.

张宝仁, 吴礼明, 刘贵萍. 高功率CO2激光器的增透膜[J]. 中国激光, 1980, 7(11): 48-51.

张宝仁, 吴礼明, 刘贵萍. 高功率CO2激光器的增透膜[J]. 中国激光, 1980, 7(11): 48-51.

张宝仁, 吴礼明, 刘贵萍. 高功率CO2激光器的增透膜[J]. 中国激光, 1980, 7(11): 48-51.

[3] 来邻, 李旸晖, 周辉, 等. 基于原子层沉积的大曲率基底表面薄膜均匀性研究[J]. 激光与光电子学进展, 2018, 55(3): 033101.

来邻, 李旸晖, 周辉, 等. 基于原子层沉积的大曲率基底表面薄膜均匀性研究[J]. 激光与光电子学进展, 2018, 55(3): 033101.

来邻, 李旸晖, 周辉, 等. 基于原子层沉积的大曲率基底表面薄膜均匀性研究[J]. 激光与光电子学进展, 2018, 55(3): 033101.

来邻, 李旸晖, 周辉, 等. 基于原子层沉积的大曲率基底表面薄膜均匀性研究[J]. 激光与光电子学进展, 2018, 55(3): 033101.

来邻, 李旸晖, 周辉, 等. 基于原子层沉积的大曲率基底表面薄膜均匀性研究[J]. 激光与光电子学进展, 2018, 55(3): 033101.

[4] 郑臻荣, 顾培夫, 陈海星, 等. 超宽带减反射膜的设计和制备[J]. 光学学报, 2009, 29(7): 2026-2029.

郑臻荣, 顾培夫, 陈海星, 等. 超宽带减反射膜的设计和制备[J]. 光学学报, 2009, 29(7): 2026-2029.

郑臻荣, 顾培夫, 陈海星, 等. 超宽带减反射膜的设计和制备[J]. 光学学报, 2009, 29(7): 2026-2029.

郑臻荣, 顾培夫, 陈海星, 等. 超宽带减反射膜的设计和制备[J]. 光学学报, 2009, 29(7): 2026-2029.

郑臻荣, 顾培夫, 陈海星, 等. 超宽带减反射膜的设计和制备[J]. 光学学报, 2009, 29(7): 2026-2029.

[7] TomofujiT, OkadaN, HirakiS, et al. A new coating technique for lenses which have steep curved surface[C]. Optical Interference Coatings, 2001: MD2.

TomofujiT, OkadaN, HirakiS, et al. A new coating technique for lenses which have steep curved surface[C]. Optical Interference Coatings, 2001: MD2.

TomofujiT, OkadaN, HirakiS, et al. A new coating technique for lenses which have steep curved surface[C]. Optical Interference Coatings, 2001: MD2.

TomofujiT, OkadaN, HirakiS, et al. A new coating technique for lenses which have steep curved surface[C]. Optical Interference Coatings, 2001: MD2.

TomofujiT, OkadaN, HirakiS, et al. A new coating technique for lenses which have steep curved surface[C]. Optical Interference Coatings, 2001: MD2.

[8] 袁文佳, 沈伟东, 郑晓雯, 等. 离子束溅射制备Nb2O5、Ta2O5和SiO2薄膜的光学、力学特性和微结构[J]. 光学学报, 2017, 37(12): 1231001.

袁文佳, 沈伟东, 郑晓雯, 等. 离子束溅射制备Nb2O5、Ta2O5和SiO2薄膜的光学、力学特性和微结构[J]. 光学学报, 2017, 37(12): 1231001.

袁文佳, 沈伟东, 郑晓雯, 等. 离子束溅射制备Nb2O5、Ta2O5和SiO2薄膜的光学、力学特性和微结构[J]. 光学学报, 2017, 37(12): 1231001.

袁文佳, 沈伟东, 郑晓雯, 等. 离子束溅射制备Nb2O5、Ta2O5和SiO2薄膜的光学、力学特性和微结构[J]. 光学学报, 2017, 37(12): 1231001.

袁文佳, 沈伟东, 郑晓雯, 等. 离子束溅射制备Nb2O5、Ta2O5和SiO2薄膜的光学、力学特性和微结构[J]. 光学学报, 2017, 37(12): 1231001.

[9] Lanzafame JF, Glocker D. System forsputtering optical coatings on curved surfaces[C]. Optical Interference Coatings, 2016: WE. 5.

Lanzafame JF, Glocker D. System forsputtering optical coatings on curved surfaces[C]. Optical Interference Coatings, 2016: WE. 5.

Lanzafame JF, Glocker D. System forsputtering optical coatings on curved surfaces[C]. Optical Interference Coatings, 2016: WE. 5.

Lanzafame JF, Glocker D. System forsputtering optical coatings on curved surfaces[C]. Optical Interference Coatings, 2016: WE. 5.

Lanzafame JF, Glocker D. System forsputtering optical coatings on curved surfaces[C]. Optical Interference Coatings, 2016: WE. 5.

[11] 敖登格日乐. 浸渍法在制备薄膜中的应用[J]. 内蒙古石油化工, 2013( 21): 20- 21.

敖登格日乐. 浸渍法在制备薄膜中的应用[J]. 内蒙古石油化工, 2013( 21): 20- 21.

敖登格日乐. 浸渍法在制备薄膜中的应用[J]. 内蒙古石油化工, 2013( 21): 20- 21.

敖登格日乐. 浸渍法在制备薄膜中的应用[J]. 内蒙古石油化工, 2013( 21): 20- 21.

敖登格日乐. 浸渍法在制备薄膜中的应用[J]. 内蒙古石油化工, 2013( 21): 20- 21.

Ao D G R L. Application of dip-coating in preparation of thin films[J]. Inner Mongolia Petrochemical Industry, 2013( 21): 20- 21.

Ao D G R L. Application of dip-coating in preparation of thin films[J]. Inner Mongolia Petrochemical Industry, 2013( 21): 20- 21.

Ao D G R L. Application of dip-coating in preparation of thin films[J]. Inner Mongolia Petrochemical Industry, 2013( 21): 20- 21.

Ao D G R L. Application of dip-coating in preparation of thin films[J]. Inner Mongolia Petrochemical Industry, 2013( 21): 20- 21.

Ao D G R L. Application of dip-coating in preparation of thin films[J]. Inner Mongolia Petrochemical Industry, 2013( 21): 20- 21.

[14] 谢俊舰, 李木军, 沈连婠, 等. 提拉法涂胶膜厚均匀性研究[J]. 机械与电子, 2016, 34(7): 6-10.

谢俊舰, 李木军, 沈连婠, 等. 提拉法涂胶膜厚均匀性研究[J]. 机械与电子, 2016, 34(7): 6-10.

谢俊舰, 李木军, 沈连婠, 等. 提拉法涂胶膜厚均匀性研究[J]. 机械与电子, 2016, 34(7): 6-10.

谢俊舰, 李木军, 沈连婠, 等. 提拉法涂胶膜厚均匀性研究[J]. 机械与电子, 2016, 34(7): 6-10.

谢俊舰, 李木军, 沈连婠, 等. 提拉法涂胶膜厚均匀性研究[J]. 机械与电子, 2016, 34(7): 6-10.

[15] 曹鸿, 张传军, 王善力, 等. 聚苯乙烯滤光膜均匀性的研究[J]. 激光技术, 2012, 36(5): 623-626.

曹鸿, 张传军, 王善力, 等. 聚苯乙烯滤光膜均匀性的研究[J]. 激光技术, 2012, 36(5): 623-626.

曹鸿, 张传军, 王善力, 等. 聚苯乙烯滤光膜均匀性的研究[J]. 激光技术, 2012, 36(5): 623-626.

曹鸿, 张传军, 王善力, 等. 聚苯乙烯滤光膜均匀性的研究[J]. 激光技术, 2012, 36(5): 623-626.

曹鸿, 张传军, 王善力, 等. 聚苯乙烯滤光膜均匀性的研究[J]. 激光技术, 2012, 36(5): 623-626.

[16] George S M. Atomic layer deposition: an overview[J]. Chemical Reviews, 2010, 110(1): 111-131.

George S M. Atomic layer deposition: an overview[J]. Chemical Reviews, 2010, 110(1): 111-131.

George S M. Atomic layer deposition: an overview[J]. Chemical Reviews, 2010, 110(1): 111-131.

George S M. Atomic layer deposition: an overview[J]. Chemical Reviews, 2010, 110(1): 111-131.

George S M. Atomic layer deposition: an overview[J]. Chemical Reviews, 2010, 110(1): 111-131.

[18] Dasgupta N P. Lee H B R, Bent S F, et al. Recent advances in atomic layer deposition[J]. Chemistry of Materials, 2016, 28(7): 1943-1947.

Dasgupta N P. Lee H B R, Bent S F, et al. Recent advances in atomic layer deposition[J]. Chemistry of Materials, 2016, 28(7): 1943-1947.

Dasgupta N P. Lee H B R, Bent S F, et al. Recent advances in atomic layer deposition[J]. Chemistry of Materials, 2016, 28(7): 1943-1947.

Dasgupta N P. Lee H B R, Bent S F, et al. Recent advances in atomic layer deposition[J]. Chemistry of Materials, 2016, 28(7): 1943-1947.

Dasgupta N P. Lee H B R, Bent S F, et al. Recent advances in atomic layer deposition[J]. Chemistry of Materials, 2016, 28(7): 1943-1947.

[19] Yuan GJ, WangN, Huang SR, et al. A brief overview of atomic layer deposition and etching in the semiconductor processing[C]. International Conference on Electronic Packaging Technology, 2016: 1365- 1368.

Yuan GJ, WangN, Huang SR, et al. A brief overview of atomic layer deposition and etching in the semiconductor processing[C]. International Conference on Electronic Packaging Technology, 2016: 1365- 1368.

Yuan GJ, WangN, Huang SR, et al. A brief overview of atomic layer deposition and etching in the semiconductor processing[C]. International Conference on Electronic Packaging Technology, 2016: 1365- 1368.

Yuan GJ, WangN, Huang SR, et al. A brief overview of atomic layer deposition and etching in the semiconductor processing[C]. International Conference on Electronic Packaging Technology, 2016: 1365- 1368.

Yuan GJ, WangN, Huang SR, et al. A brief overview of atomic layer deposition and etching in the semiconductor processing[C]. International Conference on Electronic Packaging Technology, 2016: 1365- 1368.

[20] Pfeiffer K, Schulz U, Tünnermann A, et al. Antireflection coatings for strongly curved glass lenses by atomic layer deposition[J]. Coatings, 2017, 7(8): 118.

Pfeiffer K, Schulz U, Tünnermann A, et al. Antireflection coatings for strongly curved glass lenses by atomic layer deposition[J]. Coatings, 2017, 7(8): 118.

Pfeiffer K, Schulz U, Tünnermann A, et al. Antireflection coatings for strongly curved glass lenses by atomic layer deposition[J]. Coatings, 2017, 7(8): 118.

Pfeiffer K, Schulz U, Tünnermann A, et al. Antireflection coatings for strongly curved glass lenses by atomic layer deposition[J]. Coatings, 2017, 7(8): 118.

Pfeiffer K, Schulz U, Tünnermann A, et al. Antireflection coatings for strongly curved glass lenses by atomic layer deposition[J]. Coatings, 2017, 7(8): 118.

[24] 卫耀伟, 刘志超, 陈松林. TiO2/Al2O3薄膜的原子层沉积和光学性能分析[J]. 中国光学, 2011, 4(2): 188-195.

卫耀伟, 刘志超, 陈松林. TiO2/Al2O3薄膜的原子层沉积和光学性能分析[J]. 中国光学, 2011, 4(2): 188-195.

卫耀伟, 刘志超, 陈松林. TiO2/Al2O3薄膜的原子层沉积和光学性能分析[J]. 中国光学, 2011, 4(2): 188-195.

卫耀伟, 刘志超, 陈松林. TiO2/Al2O3薄膜的原子层沉积和光学性能分析[J]. 中国光学, 2011, 4(2): 188-195.

卫耀伟, 刘志超, 陈松林. TiO2/Al2O3薄膜的原子层沉积和光学性能分析[J]. 中国光学, 2011, 4(2): 188-195.

Article Outline

沐雯, 沈伟东, 杨陈楹, 郑晓雯, 王震, 袁华新, 袁文佳, 章岳光. 基于原子层沉积技术的石英管表面减反射膜的制备[J]. 光学学报, 2019, 39(3): 0324001. Wen Mu, Weidong Shen, Chenying Yang, Xiaowen Zheng, Zhen Wang, Huaxin Yuan, Wenjia Yuan, Yueguang Zhang. Preparation of Anti-Reflection Coatings on Quartz Tube Surfaces Based on Atomic Layer Deposition[J]. Acta Optica Sinica, 2019, 39(3): 0324001.