光学学报, 2019, 39 (1): 0122001, 网络出版: 2019-05-10

16 nm极紫外光刻物镜热变形对成像性能影响的研究  下载: 1347次

下载: 1347次

Effect of Thermal Deformation on Imaging Performance for 16 nm Extreme Ultraviolet Lithography Objective

光学设计 热变形 极紫外光刻 有限元分析 反射系统 成像性能 optical design thermal deformation extreme ultraviolet lithography finite element analysis catoptric system imaging performance

摘要

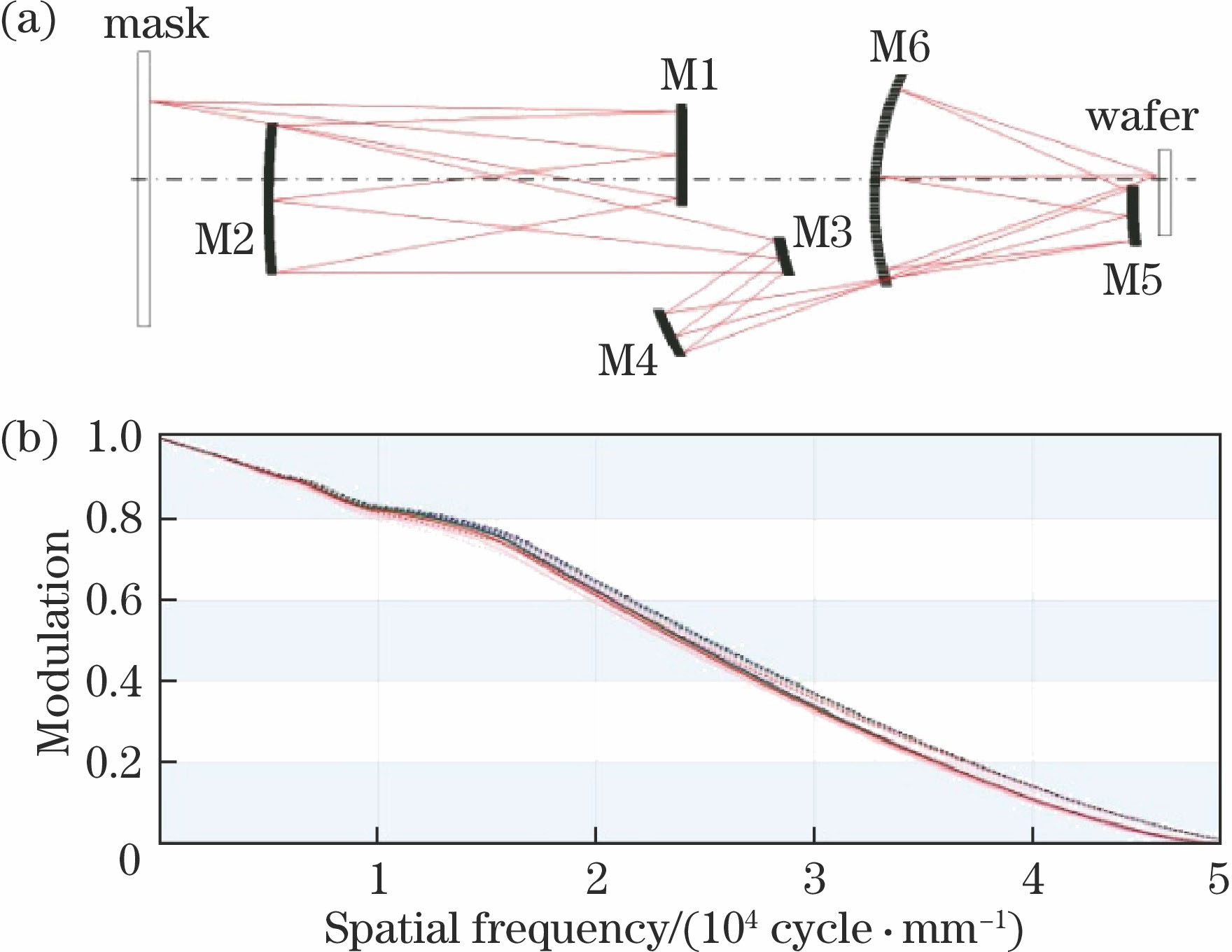

16 nm极紫外光刻(EUVL)物镜热变形是影响其高分辨成像的主要因素之一。为了给EUVL系统热管理提供可靠的技术依据,对数值孔径为0.33且满足16 nm技术节点的典型EUVL物镜进行热变形仿真研究。采用有限元软件ANSYS仿真曝光过程中反射镜的瞬态温度和变形分布。以Zernike多项式为接口拟合变形面,分析热变形对成像性能的影响。结果表明:物镜的最高温升和最大变形分别为3.9 ℃和10.2 nm,高温态物镜的热变形引起的最大波像差均方根和畸变分别为0.1λ 和56 nm,超出了合理范围。M3和M4反射镜热变形累加引起的波像差和畸变的占比分别为88%和99%,对成像性能的影响起主导作用,需要对其进行严格控温。

Abstract

Thermal deformation of 16 nm extreme ultraviolet lithography (EUVL) objective is one of the main factors influencing its high resolution imaging. In order to provide a reliable technical basis for the thermal management of EUVL system, we simulate the thermal deformation of a typical 16 nm EUVL objective with 0.33 numerical aperture. The finite element software ANSYS is used to simulate the transient temperature and thermal deformation of each mirror during exposure. The deformed mirror surface is fitted with Zernike polynomial as an interface tool to evaluate the effect of the thermal deformation on imaging performance. The results show that the maximum temperature rise and the maximum thermal deformation of the objective are 3.9 ℃ and 10.2 nm, respectively. The thermal deformation of the objective in the high temperature state causes maximum wavefront error root mean square (RMS) of 0.1λ and the distortion of 56 nm, which are beyond the reasonable range. The wavefront error RMS and the distortion caused by the thermal deformation of M3 and M4 mirrors together account for 88% and 99%, which play leading roles in the imaging performance. The temperatures of these two mirrors should be controlled strictly.

李艳秋, 刘岩, 刘丽辉. 16 nm极紫外光刻物镜热变形对成像性能影响的研究[J]. 光学学报, 2019, 39(1): 0122001. Yanqiu Li, Yan Liu, Lihui Liu. Effect of Thermal Deformation on Imaging Performance for 16 nm Extreme Ultraviolet Lithography Objective[J]. Acta Optica Sinica, 2019, 39(1): 0122001.