激光与光电子学进展, 2023, 60 (5): 0514009, 网络出版: 2023-03-06

间隔重熔对TC4选区激光熔化样件的影响研究

Impact of Interval Remelting on TC4 Selective Laser Melting Samples

激光技术 选区激光熔化 Ti-6Al-4V 激光重熔 表面质量 力学性能 成形效率 laser technique selective laser melting Ti-6Al-4V laser remelting surface quality mechanical properties forming efficiency

摘要

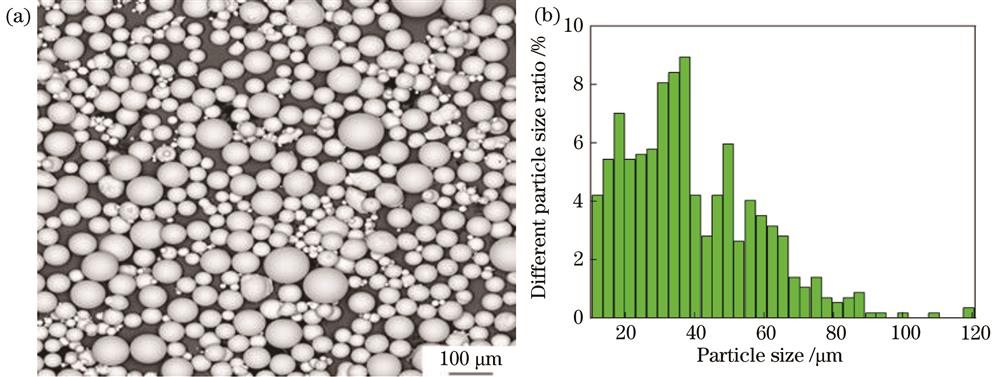

探究间隔重熔工艺对三维打印Ti-6Al-4V(TC4)样件成形质量的影响。在大层厚(150 μm)成形提高样件成形效率的基础上,采取 “表面重熔+内部间隔重熔”的优化工艺方式,以达到改善大层厚成形样件内部缺陷的目的。试验结果表明:与未重熔的样件相比,间隔重熔、逐层重熔样件对于表面质量改善效果显著,且二者差异较小。进行间隔一层重熔的样件,抗拉强度增加97.84 MPa,屈服强度增加了45.96 MPa,延伸率增加0.9 %。从断口形貌看,间隔一层重熔样件除了孔洞数量略多于逐层重熔样件外,断裂特征均为河流状解理断裂及韧窝断裂,二者力学性能改善效果差异较小。研究同时发现:样件的显微组织与激光间隔重熔工艺方式有关,间隔一层重熔样件显微组织均匀致密,显微硬度最佳,达到442.1 HV0.3。

Abstract

This paper investigates the effect of the interval remelting process on the forming quality of three-dimensional printing Ti-6Al-4V (TC4) samples. To improve the internal defects and hence the efficiency of forming samples with thick layers (150 μm), the optimized process mode of "surface remelting + internal interval remelting" was applied. Comparison tests with samples formed without remelting showed that interval remelting and layer-by-layer remelting significantly improved the surface quality of the samples, with little difference between the results of both processes. The tensile strength, yield strength, and elongation of the samples remelted with a one layer interval were 97.84 MPa, 45.96 MPa, and 0.9% higher, respectively, than those of the samples formed without remelting. The fracture morphologies showed river-cleavage and dimple fractures, with slightly more holes in the one-interval remelted sample than in the layer-by-layer remelted sample. The mechanical property improvements of both samples were very similar. Meanwhile, the microstructure of the sample was related to the laser interval remelting process. The one-interval remelted sample gave a uniform and dense surface and the highest microhardness (442.1 HV0.3) among the samples.

刘玉德, 李鹏跃, 石文天, 刘帅, 韩玉凡, 周裕圣. 间隔重熔对TC4选区激光熔化样件的影响研究[J]. 激光与光电子学进展, 2023, 60(5): 0514009. Yude Liu, Pengyue Li, Wentian Shi, Shuai Liu, Yufan Han, Yusheng Zhou. Impact of Interval Remelting on TC4 Selective Laser Melting Samples[J]. Laser & Optoelectronics Progress, 2023, 60(5): 0514009.