光学仪器, 2021, 43 (2): 55, 网络出版: 2021-07-12

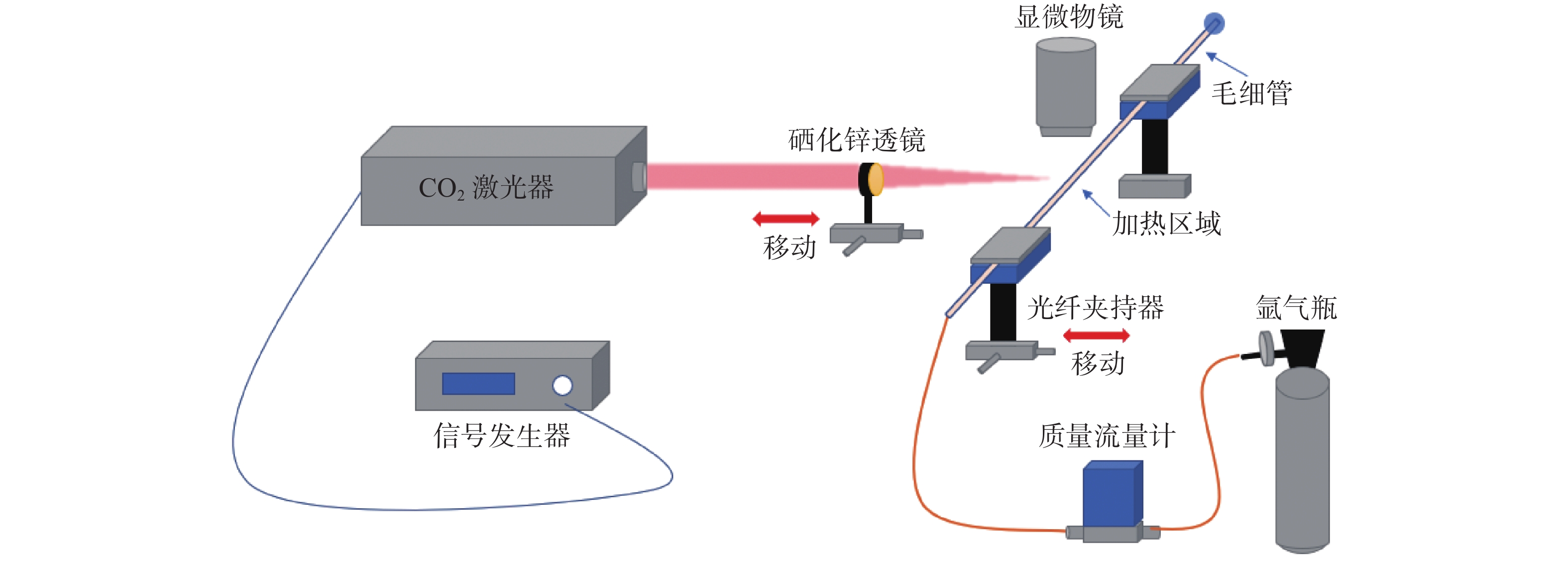

基于CO2激光单点加热的微泡腔制备及其性能研究

Research on fabrication and properties of microbubbles based on CO2 laser single-spot heating

摘要

为了简化微泡腔的制备工艺,在传统 $ \text{C}{\text{O}}_{\text{2}} $ ![]()

![]()

$ \text{C}{\text{O}}_{\text{2}} $ ![]()

![]()

$ \text{C}{\text{O}}_{\text{2}} $ ![]()

![]()

Abstract

In order to simplify the fabrication of microbubble, $ \text{C}{\text{O}}_{\text{2}} $ ![]()

![]()

$ \text{C}{\text{O}}_{\text{2}} $ ![]()

![]()

郭涛, 麻艳娜, 顾兆麒, 谷付星. 基于CO2激光单点加热的微泡腔制备及其性能研究[J]. 光学仪器, 2021, 43(2): 55. Tao GUO, Yanna MA, Zhaoqi GU, Fuxing GU. Research on fabrication and properties of microbubbles based on CO2 laser single-spot heating[J]. Optical Instruments, 2021, 43(2): 55.