高功率激光光学元件超精密制造技术  下载: 1183次特邀综述

下载: 1183次特邀综述

许乔, 陈贤华, 汪圣飞, 钟波, 谢瑞清, 王健. 高功率激光光学元件超精密制造技术[J]. 光学学报, 2022, 42(17): 1712004.

Qiao Xu, Xianhua Chen, Shengfei Wang, Bo Zhong, Ruiqing Xie, Jian Wang. Ultra-Precision Manufacturing Technology of High Power Laser Optics[J]. Acta Optica Sinica, 2022, 42(17): 1712004.

[1] AikensD M, RichL, BajukD, et al. Developing enabling optics finishing technologies for the National Ignition Facility[M]. California: Lawrence Livermore National Laboratory, 1998.

[2] Campbell J H, Hawley-Fedder R A, Stolz C J, et al. NIF optical materials and fabrication technologies: an overview[J]. Proceedings of SPIE, 2004, 5341: 84-101.

[3] Xu Q, Li W, Wang J, et al. Progress of advanced optical manufacturing technology integrated line[J]. Proceedings of SPIE, 2006, 6149: 614904.

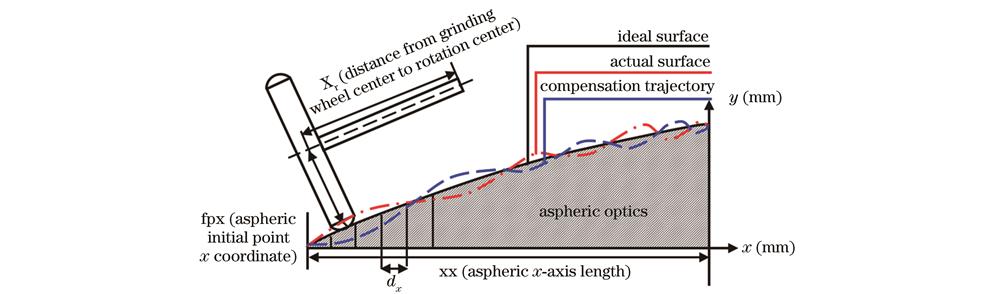

[4] 郭隐彪, 黄元庆, 田波, 等. 非轴对称非球面平行磨削误差补偿技术研究[J]. 机械工程学报, 2002, 38(5): 118-121.

Guo Y B, Huang Y Q, Tian B, et al. Study on compensation of parallel grinding non-axisymmetric aspheric surfaces[J]. Chinese Journal of Mechanical Engineering, 2002, 38(5): 118-121.

[5] Zhou L, Wei Q C, Chen X H, et al. Key technologies in high efficiency and ultra precision grinding of large aperture and complex aspheric lens[J]. Proceedings of SPIE, 2019, 11342: 1134209.

[6] Wei Q C, Zhou L, Chen X H, et al. The effect of grinding processing parameters on aspheric small-scale waviness[J]. Proceedings of SPIE, 2019, 11342: 113420C.

[7] Wei Q C, Zhou L, Chen X H, et al. Influence of grinding force on aspherical small-scale waviness uniformity based on parallel grinding[J]. Proceedings of SPIE, 2019, 11068: 106817.

[8] 樊非, 徐曦, 许乔, 等. 大口径强激光光学元件超精密制造技术研究进展[J]. 光电工程, 2020, 47(8): 200135.

[9] 施晨淳, 王振忠, 彭云峰, 等. PM流量控制器参数对液体静压导轨运动精度影响的研究[J]. 机械工程学报, 2020, 56(1): 157-165.

Shi C C, Wang Z Z, Peng Y F, et al. Influence of PM controller parameters on motion accuracy of hydrostatic guideways[J]. Journal of Mechanical Engineering, 2020, 56(1): 157-165.

[10] Shi C C, Wang Z Z, Peng Y F, et al. Quasi-static kinematics model for motion errors of closed hydrostatic guideways in ultra-precision machining[J]. Precision Engineering, 2021, 71: 90-102.

[11] 许乔, 王健, 马平, 等. 先进光学制造技术进展[J]. 强激光与粒子束, 2013, 25(12): 3098-3105.

[12] Zhou L, Wei Q C, Zheng N, et al. Dressing technology of arc diamond wheel by roll abrading in aspheric parallel grinding[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(5): 2699-2706.

[13] 周炼, 安晨辉, 侯晶, 等. 圆弧金刚石砂轮三维几何形貌的在位检测和误差评价[J]. 光学 精密工程, 2017, 25(12): 3079-3088.

[14] Wei Q C, Zhou L, Chen X H, et al. Research on full-aperture surface shape in situ measurement technology for grinding large diameter optics[J]. Proceedings of SPIE, 2019, 11189: 111890P.

[15] Suratwala T I, Feit M D, Steele W A. Toward deterministic material removal and surface figure during fused silica pad polishing[J]. Journal of the American Ceramic Society, 2010, 93(5): 1326-1340.

[16] Pal R K, Garg H, Karar V. Material removal characteristics of full aperture optical polishing process[J]. Machining Science and Technology, 2017, 21(4): 493-525.

[17] Suratwala T, Steele R, Feit M, et al. Convergent polishing: a simple, rapid, full aperture polishing process of high quality optical Flats & spheres[J]. Journal of Visualized Experiments, 2014(94): 51965.

[18] SuratwalaT I. Materials science and technology of optical fabrication[M]. Hoboken: John Wiley & Sons, 2018.

[19] Xie R Q, Zhao S J, Liao D F, et al. Recent advances in rapid polishing process of large aperture optical flats[J]. Proceedings of SPIE, 2019, 10841: 108410V.

[20] Ban X X, Zhao H Y, Zhu X L, et al. Improvement and application of pad conditioning accuracy in chemical mechanical polishing[J]. Optical Engineering, 2018, 57(9): 095102.

[21] Deng H, Endo K, Yamamura K. Damage-free finishing of CVD-SiC by a combination of dry plasma etching and plasma-assisted polishing[J]. International Journal of Machine Tools and Manufacture, 2017, 115: 38-46.

[22] Yu G Y, Walker D, Li H Y. Implementing a grolishing process in Zeeko IRP machines[J]. Applied Optics, 2012, 51(27): 6637-6640.

[23] Wang C J, Wang Z Z, Wang Q J, et al. Improved semirigid bonnet tool for high-efficiency polishing on large aspheric optics[J]. The International Journal of Advanced Manufacturing Technology, 2017, 88(5): 1607-1617.

[24] Wang C J, Yang W, Wang Z Z, et al. Highly efficient deterministic polishing using a semirigid bonnet[J]. Optical Engineering, 2014, 53(9): 095102.

[25] Zhong B, Huang H Z, Chen X H, et al. Impact of pad conditioning on the bonnet polishing process[J]. The International Journal of Advanced Manufacturing Technology, 2018, 98(1): 539-549.

[26] Pan R, Zhong B, Chen D J, et al. Modification of tool influence function of bonnet polishing based on interfacial friction coefficient[J]. International Journal of Machine Tools and Manufacture, 2018, 124: 43-52.

[27] Zhong B, Chen X H, Pan R, et al. The effect of tool wear on the removal characteristics in high-efficiency bonnet polishing[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(9): 3653-3662.

[28] Zhong B, Wang C J, Chen X H, et al. Time-varying tool influence function model of bonnet polishing for aspheric surfaces[J]. Applied Optics, 2019, 58(4): 1101-1109.

[29] Zhong B, Chen X H, Deng W H, et al. Improving material removal determinacy based on the compensation of tool influence function[J]. Proceedings of SPIE, 2018, 10710: 107102P.

[30] Zhong B, Huang H Z, Chen X H, et al. Modelling and simulation of mid-spatial-frequency error generation in CCOS[J]. Journal of the European Optical Society-Rapid Publications, 2018, 14(1): 4.

[31] Zhong B, Deng W H, Chen X H, et al. Frequency division combined machining method to improve polishing efficiency of continuous phase plate by bonnet polishing[J]. Optics Express, 2021, 29(2): 1597-1612.

[32] 钟波, 陈贤华, 王健, 等. 高精度离轴非球面透镜的制造与检测[J]. 红外与激光工程, 2018, 47(7): 0718003.

[33] Chen X H, Yu H D, Zhong B, et al. Development of key technologies in the fabrication of large aperture off-axis wedge focusing lens[J]. Proceedings of SPIE, 2017, 10255: 102551C.

[34] YellowhairJ E. Advanced technologies for fabrication and testing of large flat mirrors[D]. Tucson: The University of Arizona, 2007.

[35] Ren L L, Zhang F H, Liao D F, et al. Theoretical model and experimental analysis of non-uniform material removal during full-aperture polishing[J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1): 137-146.

[36] Chen G K, Yi K, Yang M H, et al. Factor effect on material removal rate during phosphate laser glass polishing[J]. Materials and Manufacturing Processes, 2014, 29(6): 721-725.

[37] Liao D F, Xie R Q, Zhao S J, et al. Surface shape development of the pitch lap under the loading of the conditioner in continuous polishing process[J]. Journal of the American Ceramic Society, 2019, 102(6): 3129-3140.

[38] Zhao D W, He Y Y, Wang T Q, et al. Effect of kinematic parameters and their coupling relationships on global uniformity of chemical-mechanical polishing[J]. IEEE Transactions on Semiconductor Manufacturing, 2012, 25(3): 502-510.

[39] Liao D F, Ren L L, Zhang F H, et al. Kinematic model for material removal distribution and surface figure in full-aperture polishing[J]. Applied Optics, 2018, 57(4): 588-593.

[40] Liao D F, Zhang F H, Xie R Q, et al. Effect of interfacial friction force on material removal in full aperture continuous polishing process[J]. Precision Engineering, 2020, 63: 214-219.

[41] Liao D F, Zhang F H, Xie R Q, et al. Deterministic control of material removal distribution to converge surface figure in full-aperture polishing[J]. Journal of Manufacturing Processes, 2020, 53: 144-152.

[42] Zhang F H, Wang Y R. Method to improve the surface shape of BK7 glass in full-aperture polishing[J]. Applied Optics, 2021, 60(23): 6910-6917.

[43] HoonD M. Configuring of lapping and polishing machines: US8123593B2[P]. 2012-02-28.

[44] 尹进. 环形抛光中抛光盘表面面形的在线检测和控制技术研究[D]. 北京: 中国科学院大学, 2018.

YinJ. Research on on-line detection and control technology of surface shape of polishing disc in ring polishing[D]. Beijing: University of Chinese Academy of Sciences, 2018.

[45] 安磊, 王伟, 廖德锋. 超精密全口径抛光机气浮转台的静态特性[J]. 光学 精密工程, 2021, 29(7): 1640-1652.

[46] 尹进, 朱健强, 焦翔, 等. 基于环形抛光的稳态确定性抛光方法[J]. 中国激光, 2017, 44(11): 1102001.

[47] 孙荣康, 王金栋, 成聪, 等. 小工具修正下抛光盘材料的去除特性[J]. 中国激光, 2020, 47(4): 0403001.

[48] 侯晶, 王洪祥, 陈贤华, 等. 大口径平面光学元件的磁流变加工[J]. 光学 精密工程, 2016, 24(12): 3054-3060.

[49] 黄文, 张云飞, 郑永成, 等. 基于双磨头的磁流变抛光机床与工艺研究[J]. 应用光学, 2014, 35(3): 494-499.

[50] Hou J, Wang H X, Chen X H, et al. Effect of magnetorheological processing parameters on polishing spots[J]. Proceedings of SPIE, 2018, 10847: 108470P.

[51] Liu S W, Wang H X, Zhang Q H, et al. Regionalized modeling approach of tool influence function in magnetorheological finishing process for aspherical optics[J]. Optik, 2020, 206: 164368.

[52] Wang Y B, Dai Y F, Hu H, et al. Study on rapid convergence strategy of nano-precision optical surface by ion beam figuring[J]. Optics Communications, 2022, 507: 127614.

[53] Wang T Y, Huang L, Choi H, et al. RISE: robust iterative surface extension for sub-nanometer X-ray mirror fabrication[J]. Optics Express, 2021, 29(10): 15114-15132.

[54] Deng W H, Chen X H, Jin H L, et al. Optimization of IBF parameters based on adaptive tool-path algorithm[J]. Proceedings of SPIE, 2018, 10710: 107102W.

[55] Wang C J, Wang Z Z, Xu Q. Unicursal random maze tool path for computer-controlled optical surfacing[J]. Applied Optics, 2015, 54(34): 10128-10136.

[56] Dunn C R, Walker D D. Pseudo-random tool paths for CNC sub-aperture polishing and other applications[J]. Optics Express, 2008, 16(23): 18942-18949.

[57] Wan S L, Wei Y C, Hu C, et al. Magnetorheological finishing ultra-precision polishing mid-spatial-frequency error tool influence function[J]. International Journal of Machine Tools and Manufacture, 2021, 161(2): 103673.

[58] Wan K P, Wan S L, Jiang C, et al. Sparse bi-step raster path for suppressing the mid-spatial-frequency error by fluid jet polishing[J]. Optics Express, 2022, 30(5): 6603-6616.

[59] Shu Y, Nie X, Shi F, et al. Smoothing evolution model for computer controlled optical surfacing[J]. Journal of Optical Technology, 2014, 81(3): 164-167.

[60] Kim D W, Park W H, An H K, et al. Parametric smoothing model for visco-elastic polishing tools[J]. Optics Express, 2010, 18(21): 22515-22526.

[61] 雷鹏立, 侯晶, 王健, 等. 小工具数控抛光对元件表面中频误差的匀滑研究[J]. 强激光与粒子束, 2019, 31(11): 11-17.

Lei P L, Hou J, Wang J, et al. Smoothing of mid-spatial frequency errors by computer controlled surface processing[J]. High Power Laser and Particle Beams, 2019, 31(11): 11-17.

[62] 王强国. KDP晶体精密切割与磨削工艺的研究[D]. 大连: 大连理工大学, 2010.

WangQ G. Study on precision slicing and grinding processes of KDP crystal[D]. Dalian: Dalian University of Technology, 2010.

[63] Yang X, An C H, Wang Z Z, et al. Research on surface topography in ultra-precision flycutting based on the dynamic performance of machine tool spindle[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87(5): 1957-1965.

[64] An C H, Deng C Y, Miao J G, et al. Investigation on the generation of the waviness errors along feed-direction on flycutting surfaces[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1): 1457-1465.

[65] Wei R C, An C H, Wang Z Z, et al. Dynamic performance analysis and quantitative evaluation for ultraprecision aerostatic spindle[J]. Journal of Engineering Manufacture, 2019, 234(1/2): 218-228.

[66] Deng C Y, An C H, Wei B, et al. Investigation on the influence of aerostatic pressure upon surface generation in flycutting[J]. Journal of Engineering Manufacture, 2018, 233(4): 1136-1143.

[67] Wang S F, An C H, Zhang F H, et al. Simulation research on the anisotropic cutting mechanism of KDP crystal using a new constitutive model[J]. Machining Science and Technology, 2017, 21(2): 202-222.

[68] 汪圣飞, 安晨辉, 张飞虎, 等. 基于纳米划痕实验和有限元仿真的KDP晶体断裂性能研究[J]. 人工晶体学报, 2015, 44(9): 2325-2329, 2337.

Wang S F, An C H, Zhang F H, et al. Study on the fracture properties of KDP crystal by nanoscratch experiment and finite element simulation[J]. Journal of Synthetic Crystals, 2015, 44(9): 2325-2329, 2337.

[69] Wang S F, An C H, Zhang F H, et al. An experimental and theoretical investigation on the brittle ductile transition and cutting force anisotropy in cutting KDP crystal[J]. International Journal of Machine Tools and Manufacture, 2016, 106: 98-108.

[70] Zhang F H, Wang S F, An C H, et al. Full-band error control and crack-free surface fabrication techniques for ultra-precision fly cutting of large-aperture KDP crystals[J]. Frontiers of Mechanical Engineering, 2017, 12(2): 193-202.

[71] MenapaceJ A, PetersonJ, PenetranteB, et al. Combined advanced finishing and UV laser conditioning process for producing damage resistant optics: US6920765[P]. 2005-07-26.

[72] Suratwala T I, Miller P E, Bude J D, et al. HF-based etching processes for improving laser damage resistance of fused silica optical surfaces[J]. Journal of the American Ceramic Society, 2011, 94(2): 416-428.

[73] Bude J, Miller P, Baxamusa S, et al. High fluence laser damage precursors and their mitigation in fused silica[J]. Optics Express, 2014, 22(5): 5839-5851.

[74] Bude J, Carr C W, Miller P E, et al. Particle damage sources for fused silica optics and their mitigation on high energy laser systems[J]. Optics Express, 2017, 25(10): 11414-11435.

[75] 周炼, 谢瑞清, 陈贤华, 等. 熔石英磨削砂轮截面轮廓分析与优化[J]. 金刚石与磨料磨具工程, 2018, 38(1): 59-64.

Zhou L, Xie R Q, Chen X H, et al. Analysis and optimization on cross section profile of fused silica grinding wheel[J]. Diamond & Abrasives Engineering, 2018, 38(1): 59-64.

[76] Zhou L, Zheng N, Chen X H, et al. Crack depth uniformity control techniques for large scale fused silica optics in grinding process[J]. Proceedings of SPIE, 2019, 11068: 1106815.

[77] Zhou L, Wei Q C, Chen X H, et al. In-situ detection and evaluation of wear state of micro-powder diamond wheel in optics grinding[J]. Proceedings of SPIE, 2019, 11189: 1118904.

[78] Zhou L, Wei Q C, Li J, et al. The effect of diamond wheel wear on surface and sub-surface quality in fused silica optics grinding[J]. IOP Conference Series: Materials Science and Engineering, 2019, 677(2): 022091.

[79] ZhouL, ZhengN, WangJ, et al. Research on the signal de-noising method of acoustic emission in fused silica grinding[C]//Proceedings of the 2018 International Conference on Signal Processing and Machine Learning-SPML'18, November 28-30, 2018, Shanghai, China. New York: ACM Press, 2018: 26-32.

[80] Suratwala T I, Steele W A, Wong L L, et al. Chemistry and formation of the Beilby layer during polishing of fused silica glass[J]. Journal of the American Ceramic Society, 2015, 98(8): 2395-2402.

[81] Liao D F, Wang J, Zhao S J, et al. Analysis of the optic/impurity-particle/pad interaction for reduction of scratches formed on optics during pad polishing[J]. Journal of Non-Crystalline Solids, 2014, 391: 96-100.

[82] Li Y G, Yuan Z G, Wang J, et al. Laser-induced damage characteristics in fused silica surface due to mechanical and chemical defects during manufacturing processes[J]. Optics & Laser Technology, 2017, 91: 149-158.

[83] Ye H, Li Y G, Yuan Z G, et al. Laser induced damage characteristics of fused silica optics treated by wet chemical processes[J]. Applied Surface Science, 2015, 357: 498-505.

[84] Ye H, Li Y G, Yuan Z G, et al. Ultrasonic-assisted wet chemical etching of fused silica for high-power laser systems[J]. International Journal of Applied Glass Science, 2018, 9(2): 288-295.

[85] Manes K R, Spaeth M L, Adams J J, et al. Damage mechanisms avoided or managed for NIF large optics[J]. Fusion Science and Technology, 2016, 69(1): 146-249.

[86] Wang S F, Wang J, Lei X Y, et al. Simulation of the nanosecond-pulse laser damage of KDP surface by the smoothed particle hydrodynamics method[J]. Optics Letters, 2019, 44(21): 5338-5341.

[87] Wang S F, Wang J, Lei X Y, et al. Investigation of the laser-induced surface damage of KDP crystal by explosion simulation[J]. Optics Express, 2019, 27(11): 15142-15158.

[88] Wang S F, Wang J, Xu Q, et al. Influences of surface defects on the laser-induced damage performances of KDP crystal[J]. Applied Optics, 2018, 57(10): 2638-2646.

[89] 汪圣飞, 许乔, 王健, 等. KDP晶体飞切加工表面缺陷的抑制方法[J]. 光学学报, 2018, 38(11): 1116001.

许乔, 陈贤华, 汪圣飞, 钟波, 谢瑞清, 王健. 高功率激光光学元件超精密制造技术[J]. 光学学报, 2022, 42(17): 1712004. Qiao Xu, Xianhua Chen, Shengfei Wang, Bo Zhong, Ruiqing Xie, Jian Wang. Ultra-Precision Manufacturing Technology of High Power Laser Optics[J]. Acta Optica Sinica, 2022, 42(17): 1712004.