基于双光子聚合3D打印的光纤法珀微波导腔制备及传感特性研究

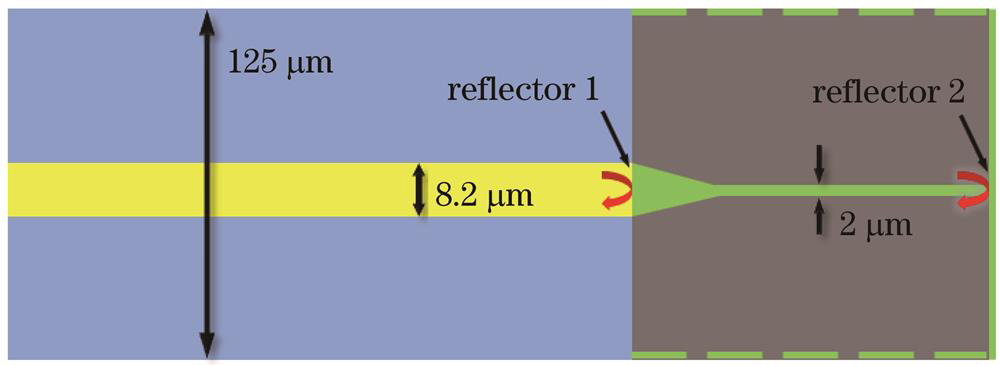

Optical fiber Fabry-Perot microcavity sensor has the advantages of small size and good stability, and it is widely used in the measurement of temperature, magnetic field, refractive index, and other physical quantities. However, the traditional processing method has many drawbacks and limitations. For example, the fusion method of single-mode fibers and special fibers may cause the fusion area to collapse and form a conical structure, resulting in poor performance of the prepared sensor; the operation of the hollow-core fiber filling method is difficult, and the preparation repeatability is poor; the chemical reagents of chemical corrosion method are easy to cause harm to the human body. The femtosecond laser two-photon polymerization 3D printing technology adopted in this paper has the advantages of high processing precision, strong flexibility, and high repeatability and can cope with more complex conditions to achieve structure preparation. In addition, the optical fiber Fabry-Perot microcavity sensor is widely used in refractive index sensing, but due to the introduction of a section of air optical path, its light conduction ability is relatively insufficient, and the insertion loss is large. In this paper, the optical micro-waveguide is introduced to form the integrated sensing and guiding optical fiber Fabry-Perot micro-waveguide cavity. The Fabry-Pert microcavity can limit the light field to the micron range and support and protect the micro-waveguide structure. Meanwhile, micro-waveguides not only ensure good optical conductivity of the structure but also further enhance the refractive index sensitivity of the overall structure based on their strong evanescent field characteristics.

The micro-waveguide Fabry-Perot cavity structure is designed by COMSOL and simulated by finite difference time domain method and finite element method. The simulation results show that the refractive index sensitivity of the proposed structure can reach 555.14 nm/RIU in the range of 1.333-1.337 (Fig. 3). The structure is prepared by femtosecond laser two-photon polymerization 3D printing after setting the printing parameters. First, the fiber coating layer is removed; the flat single-mode fiber core end face with a cutter is cut out, and it is cleaned with a welding machine. Second, the optical fiber is fixed to the printer position, and the lens is focused on the optical fiber end face. Third, the optical fiber end face is adjusted to the center position of the printing equipment for printing. Fourth, the structure is cured using propylene glycol methyl ether acetate solution and isopropyl alcohol solution (Fig. 4).

The reflection spectrum of the printed structure in water is observed by the optical spectrum analyzer. It can be seen that the free spectrum range (FSR) of the structure formed in deionized water is 16.1 nm. The spectral Fourier transform results show that the structure forms a single peak with a good interference effect in the low-frequency band (Fig. 5). It is also confirmed that the micro-waveguide structure can play a good anti-interference role in the optical fiber structure and shield the external disturbance to a certain extent. The structures are placed in 12 sodium chloride solutions with different concentrations in the refractive index range of 1.3346-1.3764 for experiments, and the linear fitting results of the reflection spectra show that the sensing structure has good linearity and sensitivity of 525.81 nm/RIU in the refractive index range of 1.3346-1.3764 (Fig. 6 and Fig. 7). To verify the improvement effect of micro-waveguides on the sensing performance of Fabry-Perot microcavities, a waveguide free optical fiber Fabry-Perot microcavity with the same cavity length is prepared using 3D printing technology, and the structure is placed in different concentrations of sodium chloride solution in the refractive index range of 1.3346-1.3764; the linear fitting results show that the refractive index sensitivity of the microcavity structure without micro-waveguide is 115.31 nm/RIU. It is not difficult to see that with the support of a micro-waveguide, the refractive index sensitivity of the optical fiber Fabry-Perot microcavity has increased by nearly 4 times, and the peak interference spectrum has increased by 8.2 dB (Fig. 9).

Based on femtosecond laser two-photon polymerization 3D printing technology, a novel optical fiber Fabry-Perot micro-waveguides cavity integrated sensing structure is prepared in this paper. By combining the stability spectrum of fiber Fabry-Perot micro-cavity and the strong evanescent field characteristics of the optical micro-waveguide, the refractive index parameter detection with high sensitivity is realized. In the refractive index range of 1.3346-1.3764, the sensitivity is 525.81 nm/RIU, which is 3.56 times higher than that of the waveguide-free Fabry-Perot microcavity, and the peak value of the generated interference spectrum is increased by 8.2 dB. Such a fiber optic sensor with a small sample size, high sensitivity, and good repeatability will undoubtedly become a powerful booster for the rapidly developing fiber optic sensing technology and biomedical research and has a wide range of academic research value and application prospects in biodetection-related fields.

陈茂庆, 刘思源, 蔡露, 刘强, 赵勇. 基于双光子聚合3D打印的光纤法珀微波导腔制备及传感特性研究[J]. 光学学报, 2024, 44(2): 0206002. Maoqing Chen, Siyuan Liu, Lu Cai, Qiang Liu, Yong Zhao. Fabrication and Sensing Characteristics of Optical Fiber Fabry-Perot Micro-Waveguide Cavity Based on Two-Photon Polymerization 3D Printing[J]. Acta Optica Sinica, 2024, 44(2): 0206002.