Whispering gallery mode (WGM) microresonators have been explored in wide applications including nonlinear and quantum optics, frequency comb generation, security information, optical delay systems, wavelength division multiplexing (WDM), opto-mechanical systems, and sensing[1–6" target="_self" style="display: inline;">–6]. To date, various WGM microresonators have been developed for lasing generation[7,8], yet owing to the absence of mode selection strategies, lasing generation through WGM microresonators is usually multimode with large spectral mode densities. In sensing applications, the presence of side peaks may bring the difficulty of mode recognizing and tracking and may also limit the spectral shift range of signal peaks. Therefore, realizing single-mode lasing is significantly necessary for sensing applications to improve the detection accuracy and the spectral dynamic range.

Generally, single-WGM lasing can be attained by lessening the sizes of microresonators[9]. Coupled cavities in which one cavity serves as a spectral filter to the other one by using the Vernier effect also enable the single-mode lasing[1012" target="_self" style="display: inline;">–12]. Other new strategies such as using the parity-time symmetry effect[13,14] and piezoelectric effect[15] have also been reported to generate single-WGM lasing. Recently, microbottle resonators have attracted great attentions[16,17], owing to the highly non-degenerated modes with different spatial intensity distribution along the axial direction[18–21" target="_self" style="display: inline;">–21]. This property makes it viable to selectively activate the desired modes. Based on gain engineering via spatial interference excitation[22] and loss engineering via fiber-taper coupling[23], single-WGM lasing in polymer microbottles has been demonstrated and is then used in a stretchable device for strain sensing[24]. In addition, by precisely controlling the axial and radial coupling position using a tapered nanofiber, single-WGM lasing from different-order WGMs is also selectively obtained in polymer microbottles[25]. These aforementioned approaches are very effective, yet they face some problems such as precise manipulation and requiring extra devices.

Alternatively, controlling of mode selection by engineering the surfaces and shapes of the WGM microresonators is of great interest for the researchers. Adding microdroplets[26] and scar carving through focused ion beam milling[27,28] are effective approaches for mode suppression, which can scatter the light out of the microresonators and attenuate the resonant bottle modes. By further using a fiber-taper coupling technique, single-mode lasers are generated in these surface-engineered microbottles[29]. In this work, we use a tungsten probe to destroy the neck of the external surface of polymer microbottle resonators. Such surface destruction induces large optical losses for higher-order bottle modes with large axial orders and ensures direct generation of single fundamental bottle mode lasers just pumped by ordinary free-space light excitation.

Here, the self-assembly fabrication technique[22,23] is used to fabricate laser-dye-doped polymer microbottle resonators. Rhodamine 6G (R6G) was used as a gain material, and epoxy resin was used as a polymer host material. Dye-doped resin has a refractive index of ∼1.53. Vertically suspended silica microfibers over a glass channel were made by stretching standard optical fibers (SMF-28, Corning) on a heated ethanol flame[30]. A drop of solution was transferred with an appropriate volume to the suspended silica microfibers, and it shrank to a bottle shape due to the surface tension of the resin. Subsequently, a curing step was taken to get solid resonators at a temperature of 60°C for 8 h. The sizes of microbottle resonators were varied by tuning the sizes and movement of the droplets. Neck-to-neck distance (), fiber diameter (), and bottle outer diameter () are three parameters that evaluate the profile of each bottle microresonator. In our work, microbottle resonators with ranging from 3 to 10 μm were investigated. The used ordinary free-space pump source was from a 532 nm pulsed laser with a pulse width of 10 ns and a repetition rate of 5 Hz. The photoluminescence (PL) emissions from the microbottle resonators were collected by using a microscope objective (, ). For the analysis of spectral properties and image capturing, these emitted PL signals were transferred to a spectrometer (iHR 550, JY Horiba Ltd.) and a CCD camera (DS-Ri1, Nikon), respectively.

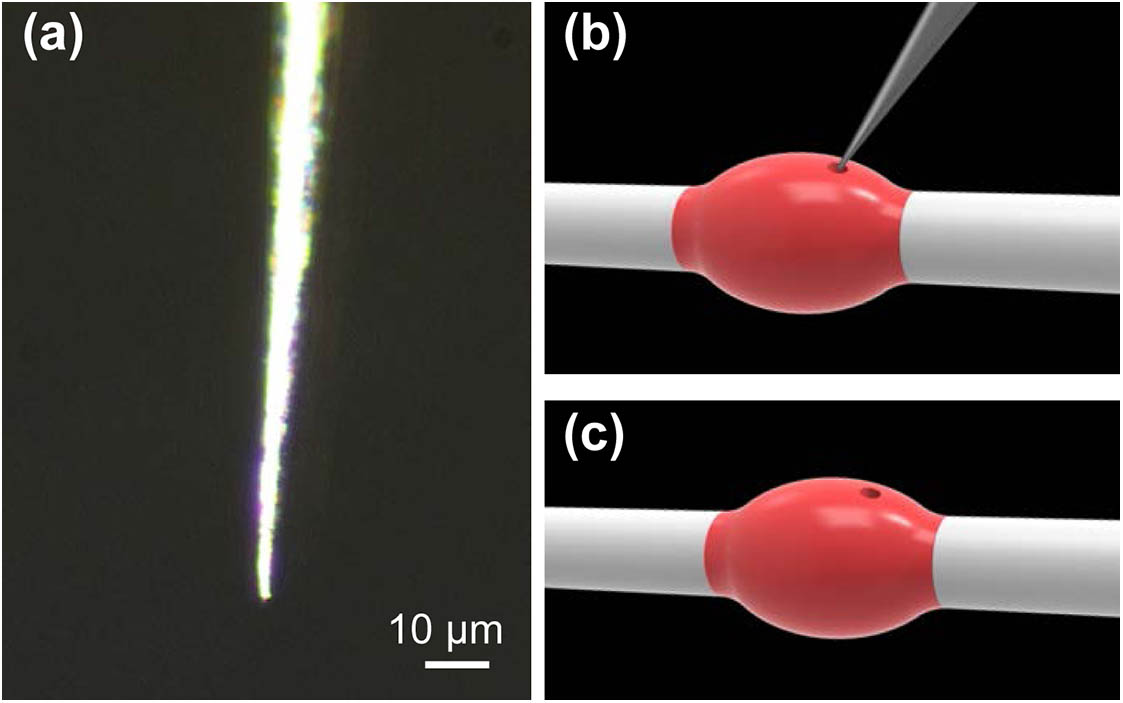

The spectral resolution of our spectrometer is 0.02 nm, which is high enough for distinguishing the spectra in used microbottle resonators being single or multimode lasing. To minimize the numbers of lasing modes, the external surface of the microbottle resonators is destroyed by a tungsten probe, which was made through the electrochemical etching process[31,32], as shown in Fig. 1(a). The size of the tungsten probe tip is about 1 to 3 μm. As illustrated in Figs. 1(b) and 1(c), under an optical microscope equipped with a long working distance objective (), the tungsten probe is mounted on a triple-axis micromanipulator (M-462, Newport) with a sensitivity of 1 μm and is precisely struck to the neck of a microbottle resonator, and, in this way, a small part of the resonator’s surface is destroyed.

Fig. 1. (a) Microscope image of a tungsten probe. (b), (c) Schematic illustration of surface destruction of a polymer microbottle resonator by using a tungsten probe.

下载图片 查看所有图片

A microbottle resonator having dimensions of , , and is first used and excited by the ordinary pump source under excitation power of , with a bright field microscope image shown in Fig. 2(a1). The dark field microscope image in Fig. 2(b1) shows that two long, bright red emission patterns are generated at the upper and lower boundaries of the neck surface, which is contributed from the overlap of different higher-order bottle modes with large axial orders and mode volume. A series of sharp spectral peaks is observed in the spectrum shown in Fig. 2(c), the black line, further suggesting the multimode behavior. By using a three-dimensional finite-difference time-domain (FDTD) method, Figs. 2(d) and 2(e) show the electric field intensity distributions of the fundamental bottle mode and a typical higher-order bottle mode on the cross plane of the microresonator along its axis direction. The spacing between the maximum intensity position of the higher-order bottle mode and the bottle centerline is about 1.4 μm. Thus, it is very possible that by carefully manipulating the tungsten probe under the microscope and destroying the surface near the bottle neck, the higher-order WGMs with spatial intensity profiles that meet up with the destroyed neck surface will suffer large scattering loss and be suppressed, and only the fundamental bottle mode distributed at the center can survive.

Fig. 2. (a1)–(a3) Bright and (b1)–(b3) dark field microscope images of a microbottle resonator (, , and ) and (c) their corresponding emission spectra. Electric field intensity distributions of (d) the fundamental bottle mode and (e) a typical higher-order bottle mode on the cross plane of the microresonator along its axis direction.

下载图片 查看所有图片

To demonstrate this strategy, we slightly destroy a small part around the neck surface [Fig. 2(a2)]. From the dark field microscope image in Fig. 2(b2), the emission patterns around the neck of the microbottle resonator disappear, and a dominant pattern is generated at center boundary of the microresonator. The spectrum provided in Fig. 2(c) (red line) shows a dominant peak with a wavelength of 616.9 nm and several small peaks beside it, suggesting the resonant energy inside the cavity is mainly converted from the higher-order bottle modes to the fundamental bottle mode, i.e., a mode modulation effect or a mode competition effect is achieved. In order to achieve high-purity single-mode lasing, the neck surface of the microbottle resonator is destroyed again [Fig. 2(a3)]. Then, only a single bright spot on the center boundary of the microresonator, as shown in Fig. 2(b3), is observed. The spectrum in Fig. 2(c) (blue line) shows that only one dominant peak with a wavelength of 616.1 nm is left, and no obvious sideband peaks are observed. The measured full width at half-maximum (FWHM) of the 616.1 nm peak is about 0.21 nm, and the calculated quality factor is 2934. The side mode suppression factor (SMSF) can characterize the spectral purity of the single-mode laser, and its calculation can be found elsewhere[22,23]. So, as the surface of the microbottle resonator is destroyed from the state in Fig. 2(a2) to the state in Fig. 2(a3), the calculated SMSF increases from 10.2 dB to 13.7 dB. It is also observed that the lasing wavelength slightly shifts from 616.9 nm to 616.1 nm, which is due to the photo-bleaching phenomenon under long-time excitation. This effect induces the effective refractive index of the microbottle resonators to be decreased, and the fundamental mode peak is blue-shifted[23]. In addition, because the quality factor of our microbottle resonator is low, the mode splitting effect induced by the clockwise and counterclockwise WGMs is not observed here in the spectra[33], and also the axial mode shifting effect[34,35] induced by strong coupling with outer metal media is not observed.

Figure 3 shows the measured threshold of an undestroyed microbottle [see inset (a1)] at a 579.3 nm wavelength is about , which is reduced to about at a 579.5 nm wavelength after surface destruction [see inset (b1)]. Thus, after the surface destruction approach, the usage of pump energy is more efficiently transferred to the fundamental bottle mode, which has stronger light confinement and higher factor than higher-order bottle modes. The measured efficiency of lasing generation through the polymer microresonators has a range of 5%–10% above the threshold. Thus, for the used 532 nm pump with average power on orders of tens of nanowatts, the generated lasing intensity is around 1 nW.

Fig. 3. Comparison of lasing threshold between the undestroyed and destroyed microbottle resonators (, , and ). Inset (a1) shows the lasing microscope image for an undestroyed microbottle and inset (b1) shows the lasing microscope image for a destroyed microbottle.

下载图片 查看所有图片

From the results mentioned above, it can be seen that the mode modulation through surface destruction greatly depends on the sizes of the fabricated microresonators. When this surface destruction method is applied to small microbottle resonators, achievement of single-mode lasing is very easy by just slightly touching the tungsten probe. A scanning electron microscope (SEM) image of a destroyed microbottle resonator with is shown in Fig. 4(a), in which a small hole was induced by slightly striking the tungsten probe [Figs. 4(b1) and 4(b2)]. When this resonator is excited under excitation power of , it is observed that the emission patterns corresponding to higher-order bottle modes around the neck surface [Fig. 4(c1)], are eliminated, and only a single emission spot corresponding to the fundamental bottle mode on the center surface is left [Fig. 4(c2)]. The red line of spectrum in Fig. 4(d) shows that only a spectral peak with a wavelength of 587.7 nm and with an FWHM of about 0.17 nm is observed. So, it offers a good SMSF as high as 17.9 dB. It is also noticed that in Fig. 4(d), the quality factor of this microresonator is 2969 before surface destruction (multimode, black line) and is increased to 3457 after surface destruction (single mode, red line), because the pump energy is more efficiently transferred to the fundamental bottle mode.

Fig. 4. (a) SEM image of a small destroyed microbottle resonator (, , and ). (b1), (b2) Bright and (c1), (c2) dark field microscope images and (d) their corresponding emission spectra.

下载图片 查看所有图片

The destruction procedure of mode suppression is then used for the large size resonators. A microbottle resonator with sizes of , , and is excited through the ordinary pump source under excitation power of , as shown in Fig. 5(a1). The emission patterns in Fig. 5(b1) and the spectrum in Fig. 5(c), black line, confirm its multimode lasing behavior. Then, the neck area of this microresonator is struck to the tungsten probe, which destroys the higher-order bottle WGMs, as shown in Fig. 5(b2). From the dark field microscope image shown in Fig. 5(b2), the generated red PL emission patterns are distributed from the neck area to the area near the center of the microresonator. From the spectra shown in Fig. 5(c), red line, the density of lasing peaks is decreased gradually. The surface of microbottle resonator is destroyed again until a single-mode laser with a peak wavelength of 609.4 nm is achieved, as shown in Fig. 5(c), blue line. The measured FWHM of this peak is about 0.19 nm. From the SEM image shown in Fig. 5(d), it is observed that for such a large size, the part of the destroyed surface by the tungsten probe is very large compared with that in smaller ones.

Fig. 5. (a1)–(a3) Bright and (b1)–(b3) dark field microscope images and (c) their corresponding emission spectra in a microbottle resonator (, , and ). (d) SEM image of the destroyed surface.

下载图片 查看所有图片

When further increasing the outer diameter () of microbottle resonators, it is difficult to achieve high-purity single-mode lasing. As shown in Figs. 6(a1) and 6(b1), a microbottle resonator with sizes of , , and is struck again and again by the tungsten probe [Figs. 6(a2) and 6(a3)]. The excitation power for resonator in Fig. 6(a1) is . Though the density of lasing peaks is decreased, there are a few obvious peaks, which appear in spectra of Fig. 6(c). Additionally, from the blue line in Fig. 6(c), it can be seen that surface destruction in large microbottle resonators makes it possible to get three different longitudinal modes with free-space ranges (FSRs) of about 9.5 nm and 9.7 nm, which are consistent with the calculated value of 9.6 nm in the microbottle resonator. Because the PL spectrum of the R6G-doped epoxy resin has a broad FWHM of ∼48 nm[21], there will be two or more longitudinal modes within the resonant range of the whole cavity. Although high-purity single-bottle WGMs are not obtained in large microbottle resonators that usually have outer diameters above 7 μm, this approach provides an effective way to get mode reduction in these resonators.

Fig. 6. (a1)–(a3) Bright and (b1)–(b3) dark field microscope images of a microbottle resonator (, , and ) and (c) their corresponding emission spectra.

下载图片 查看所有图片

It can be concluded that an effective approach of mode suppression by destroying the external neck surface of microbottle resonators has been presented by using a tungsten probe. Large scattering losses for higher-order bottle modes are introduced, and when pumped by ordinary free-space light irradiation, we can directly achieve single-mode lasing from the fundamental bottle modes. The mode suppression depends on the amount of surface destruction by the tungsten probe and the sizes of the microbottle resonators. This method is very flexible, inexpensive, and convenient, and can obtain high SMSF. More generally, this approach can also motivate other techniques such as ultrafast laser inscribing[36] to effectively reduce the mode density and obtain single-mode lasing in microbottle resonators. In the future, using piezo stages with nanoscale positioning resolutions to drive the tungsten probes will improve the precision of our approach. Benefitting from the narrow linewidth, reduced side competing modes, and large spectral dynamic range of single-mode lasers, our work demonstrated here may have promising applications such as in lasing and sensing devices[24,25,28,3739" target="_self" style="display: inline;">–39].

Saima Ubaid, Feng Liao, Tao Guo, Zhaoqi Gu, Shuangyi Linghu, Yanna Ma, Jiaxin Yu, Fuxing Gu. Direct single-mode lasing in polymer microbottle resonators through surface destruction[J]. Chinese Optics Letters, 2019, 17(12): 121401.

Download: 812次

Download: 812次