激光瞬态光栅激励下结构的超声响应特性研究

0 引言

超声无损检测支持现场使用且分辨能力强,是结构健康监检测领域重点发展的手段。近年来,相继形成了基于压电传感器的贴片检测、介质耦合检测、空气耦合检测等接触式技术路线,广泛应用于多个行业[1-5]。随着无接触、大范围等应用需求的涌现,以及高品质脉冲激光器技术与激光-物质作用机理研究[6-7]的融合,脉冲激光激发超声的检测技术逐步从实验室研究走向工程应用[8-11],并发展了压电测量等半接触激光超声方案、激光测量等非接触激光超声方案。

激光超声检测的基本原理是激光与物质的相互作用:脉冲激光向结构传递能量,按能量传递后温度上升的程度,进一步分为热蚀效应和热弹效应;热蚀效应下,物质发生熔化甚至气化,表现为质量损失、局部结构缺损,而热弹效应下温度升高、能量积累的程度不足以产生融化或气化。脉冲激光激发的不足在于:激光的单色相干制约了束斑调制能力、导致了超声时频模式受限,结构损伤阈值则限制了脉冲激光的能量、导致超声信号强度的不足。苏琨、宋潮等相继结合实验比较了线光源与点光源所产生超声信号的差异[12-13],证实了线源激发的优势。NISHINO H采用10组分光-光纤模块得到了窄带且相移的阵列脉冲[14],ANTONELLI G A提出了基于透射衍射光栅的空间分布调制技术[15],裴翠祥发展了基于同一激光源的光纤束阵列传输时空调制方法[16]并研究了结构的超声响应规律。

本文基于双光束干涉形成的栅形空间调制,从数值分析及实验研究两方面研究了激光瞬态光栅作用于铝合金平板的结构响应特性,分析了相比于点源、线源等激发模式的优势。

1 激光瞬态光栅激励铝板的数值分析

1.1 热弹效应及其控制方程

对于金属等不透光材料,激光照射时存在反射及吸收等现象。激光瞬态光栅激励下,结构产生超声的热弹机制描述为:脉冲激光辐照材料表面后,激光一部分能量被材料表面反射、其余能量被表面吸收,使表面温度快速上升形成大的温度梯度产生热膨胀现象。

据热弹耦合理论,激光瞬态光栅的时域热弹波动方程表示为[17]

式中,k为热传导率,c为比热容,T(x,y,t)为温度,Q(x,y,t)为脉冲热源。脉冲激光热源可以表示为

式中,f(t)、g(x)、h(y)分别表示脉冲激光时间分布函数和脉冲激光空间分布函数,I0是入射到材料表面的激光功率密度。I0表示为

式中,E是泵浦光束的激光入射能量。

脉冲激光激励的超声包含纵波、横波及表面波,其传播速度和材料的密度和弹性常数有关。根据固体力学理论,可知

式中,CL为纵波波速,CS为横波波速,CR为表面波波速,E为弹性模量,μ为泊松比,ρ为材料的密度。

1.2 仿真模型及参数

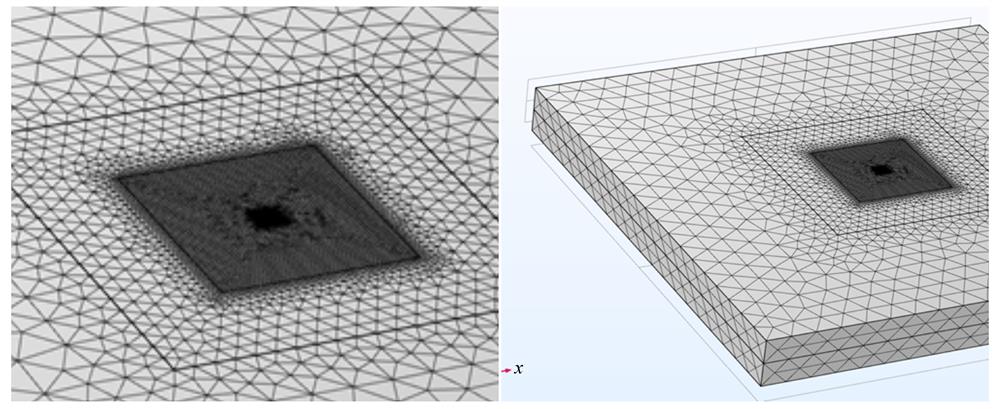

结构尺寸为50 mm×50 mm×5 mm,网格离散情况见

参数取值见

表 1. 参数取值

Table 1. Parameter value

|

1.3 结构粗糙表面对激光吸收率的分析

在激光处理与激光加工领域,针对粗造表面对激光的吸收过程,发展了反射-吸收综合模型和集总测试法等测定激光吸收率的方法。

本文按反射-吸收综合模型处理。对于一定的表面形貌,对其做倒三角下折处理,如

图 2. 粗糙表面的倒三角下折处理

Fig. 2. Treatment of rough surface with inverted triangle and downward folding

定义宏观尺度的取样长度L、轮廓算术平均偏差Ra(粗糙度)、波谷数N,则有等效粗糙度倾角θ满足

求解θ后,根据其数值大小落到的范围,可判定激光全反射的次数及占比,进而按理论公式获得吸收率A。

1)若0<θ≤(π/6),为1次反射,A同垂直理想表面的吸收率。

2)若(π/6)<θ≤(π/4),为全部1次反射、部分2次发射,A与入射角、垂直理想表面吸收率等相关。

本文采用表面粗糙度仪对所用铝合金上表面靠近中间位置进行了测试,结果为:粗糙度Ra=0.584 μm、波谷数N=94、取样长度L=287.3 μm。

求得吸收率为A=11.29%。

1.4 仿真结果分析

以脉冲宽度1 ns、单脉冲6 mJ为输入激光束斑,对应的瞬态激光光栅的直径为1 mm、条纹数量为11。结果提取时,均按

1)瞬态光栅激励的结果

图 5. 沿X方向距离中心点不同距离处的纵向位移对比情况

Fig. 5. Comparison of longitudinal displacements at different distances from the center point along the X direction

图 6. 沿Y方向距离中心点不同距离处的纵向位移对比情况

Fig. 6. Comparison of longitudinal displacements at different distances from the center point along the Y direction

为比对不同方向位移响应的特征,以

表 2. 沿X轴、Y轴不同距离处峰值位移数据

Table 2. Peak displacement data at different distances along X axis and Y axis

|

2)相同能量输入时传统点源/线源激发模式的结果

维持结构形式、材料性能以及激光脉宽不变,对点源、线源等传统激发模式进行仿真分析,并开展比对分析。其中:1)点源直径按0.1 mm,线源宽度按0.1 mm、长度按1 mm;2)点源、线源对应的功率,由线阵列6 mJ按面积均匀折算。

考虑脉冲光栅特性对响应模式的影响,结合

图 8. 3类激发模式下距离中心1 mm处的纵向位移对比

Fig. 8. Comparison of longitudinal displacements at 1 mm from the center under three excitation modes

图 9. 3类激发模式下距离中心2 mm处的纵向位移对比

Fig. 9. Comparison of longitudinal displacements at 2 mm from the center under three excitation modes

图 10. 3类激发模式下距离中心4 mm处的纵向位移对比

Fig. 10. Comparison of longitudinal displacements at 4 mm from the center under three excitation modes

表 3. 不同激发模式下特征数据比对

Table 3. Comparison of feature data in different excitation modes

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

2 激光瞬态光栅激励铝板的实验研究

2.1 实验原理及实验装置

图 11. 激光瞬态光栅激励铝板的实验原理

Fig. 11. Experimental principle of laser transient grating excitation aluminum plate

实验装置含脉冲激光器、瞬态光栅模块、激光干涉仪、示波器及铝合金板。

图 12. 实验装置布局情况以及激发-检测光路示意

Fig. 12. Experimental device layout and excitation - detection light circuit diagram

2.2 实验结果

提取示波器信号、将信号电压值转化为位移值后,经标定相对时延,得到位移数据见

图 13. 瞬态光栅激发的位移数据原始值

Fig. 13. The original displacement data of transient grating excitation

图 14. 观测点位移的实测与仿真数据比对情况

Fig. 14. Comparison between measured and simulated data of observation point displacement

同时,提取了距离光栅中心位置10 mm处的响应。其峰值的信号时延为3.35 μs;按10 mm布设距离,3.35 μs的峰值信号时延对应的声表面波速度2 974.3 m/s。由弹性波理论求得的速度为2 789.5 m/s,两者偏差为6.62%。

3 结论

仿真分析及实验验证表明,栅形激发技术通过分散降低单位面积的能级,并沿栅形方向形成了超声增强。对于距离中心相同距离的观测点,垂直于瞬态光栅方向与沿瞬态光栅方向的响应规律、峰值大小一致;相同距离下,垂直于瞬态光栅方向的响应存在峰值附近的小幅震荡,沿瞬态光栅方向的位移曲线更为光滑。为避免近场检测时因局部震荡的干扰,应将观察采样位置沿瞬态光栅方向部署。点源激发、线源激发以及瞬态光栅激发的位移响应均呈现“正峰值-负峰值-正峰值”的规律;小于等于4 mm的观测距离范围内,位移响应的峰值大小依次为瞬态光栅激发、点源激发和线源激发,瞬态光栅激发下峰值为点源激发的2~5倍,为提升信噪比、减小近场盲区奠定了良好基础。鉴于3类激发模式下总的输入能量一致,瞬态光栅激发对应的结构表面能量密度约为点源模式的1%、线源模式的12.7%,可降低激光热烧蚀风险、具有更好的结构安全性。

[1] 郭洪涛, 曹付齐. 固体火箭发动机装药界面胶接质量超声波检测[J]. 航空兵器, 2006(6): 49-52.

GUO Hongtao, CAO Fuqi. Ultrasonic testing of the interface bonding quality of solid rocket motor charge[J]. Aero Weaponry, 2006(6): 49-52.

[2] SIMONETTI F. Localization of pointlike scatterers in solids with subwavelength resolution[J]. Applied Physics Letters, 2006, 89(9): 513-36619.

[3] 刘继忠, 周晓军, 蒋志峰. 碳纤维复合材料孔隙率超声衰减测试研究[J]. 材料科学与工艺, 2007(2): 260-263.

LIU Jizhong, ZHOU Xiaojun, JIANG Zhifeng. Porosity test in carbon composites based on a new ultrasonic attenuation method[J]. Materials Science & Technology, 2007(2): 260-263.

[4] 刘松平, 刘菲菲, 史俊伟, 等. 复合材料冲击损伤高分辨率超声成像检测与损伤行为分析[J]. 机械工程学报, 2013, 49(22): 16-23.

LIU Songping, LIU Feifei, SHI Junwei, et al. High-resolution ultrasonic imaging evaluation and behavior analysis of impact damages in composites[J]. Journal of Mechanical Engineering, 2013, 49(22): 16-23.

[5] 马保全, 周正干. 航空航天复合材料结构非接触无损检测技术的进展及发展趋势[J]. 航空学报, 2014, 35(7): 1787-1803.

MA Baoquan, ZHOU Zhenggan. Progress and development trends of composite structure evaluation using noncontact nondestructive testing techniques in aviation and aerospace industries[J]. Aero Weaponry, 2014, 35(7): 1787-1803.

[6] 周锐, 李峰平, 洪明辉. 激光与物质相互作用及其精密工程应用[J]. 中国科学: 物理学、力学、天文学, 2017, 47(2): 25-34.

ZHOU Rui, LI Fengping, HONG Minghui. Laser interaction with materials and its applications in precision engineering[J]. Scientia Sinica: Physica, Mechanica & Astronomica, 2017, 47(2): 25-34.

[7] 王颖泽, 昝晨. 基于DPL模型对超短脉冲激光辐照金属薄板传热行为的渐进分析[J]. 江苏大学学报(自然科学版), 2020, 41(2): 243-248.

WANG Yingze, ZAN Chen. Asymptotic analysis of heat transfer behavior of metal sheet irradiated by ultra-short pulse laser based on DPL model[J]. Journal of Jiangsu University(Natural Science Edition), 2020, 41(2): 243-248.

[8] 李一波, 韩毅, 杨光, 等. 激光超声检测激光沉积制造TA15合金弱小缺陷的增强[J]. 中国激光, 2018, 45(11): 69-76.

LI Yibo, HAN Yi, YANG Guang, et al. Weak defect enhancement in ultrasonic testing of laser deposition manufactured TA15 alloys[J]. Chinese Journal of Lasers, 2018, 45(11): 69-76.

[9] DENNETT C A, BULLER D L, HATTAR K, et al. Real-time thermomechanical property monitoring during ion beam irradiation using in situ transient grating spectroscopy[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials & Atoms, 2019, 440: 126-138.

[10] 袁久鑫, 秦训鹏, 张进朋, 等. 基于激光超声的电弧增材制件内部缺陷深度检测[J]. 中国机械工程, 2021, 32(1): 65-73.

YUAN Jiuxin, QIN Xunpeng, ZHANG Jinpeng, et al. Depth detection of internal defects for arc additive products based on laser ultrasound[J]. China Mechanical Engineering, 2021, 32(1): 65-73.

[11] 卢明辉, 丁雷, 颜学俊, 等. 激光超声技术在工业检测中的应用与展望[J]. 振动、测试与诊断, 2021, 41(4): 631-643.

LU Minghui, DING Lei, YAN Xuejun, et al. Application and prospect of laser ultrasonic nondestructive testing technology in advanced manufacturing[J]. Journal of Vibration, Measurement & Diagnosis, 2021, 41(4): 631-643.

[12] 苏琨, 任大海, 李建, 等. 激光制声技术的研究[J]. 光电工程, 2002, 29(5): 68-72.

[13] 宋潮, 郑宾, 郭华玲, 等. 光源对激光超声信号特性的影响分析[J]. 应用光学, 2017, 38(3): 494-498.

[14] NISHINO H, TSUKAHARA Y, NAGATA Y, et al. Optical probe detection of high-frequency SAWS generated by phase velocity scanning of laser interference fringes[J]. Japanese Journal of Applied Physics, 1994, 33: 3260-3264.

[15] ANTONELLI G A, ZANNITTO P, MARIS H J, et al. New method for the generation of surface acoustic waves of high frequency[J]. Physica B Physics of Condensed Matter, 2002, 2(2): 377-379.

[16] 裴翠祥, 弋东驰, 刘天浩, 等. 基于时空调制的增强型激光超声检测方法[C]. 哈尔滨: 2018年全国固体力学学术会议, 2018.

FEICuixiang, YIDongchi, LIUTianhao, et al. Enhanced laser ultrasonic detection method based on space time modulation[C]. Harbin: 2018 National Conference on Solid Mechanics, 2018.

[17] 黄巧建, 刘晓峻, 张淑仪. 利用瞬态热栅技术研究Sr2FeMoO6的热扩散系数及其温度效应[J]. 声学学报, 2011, 36(2): 134-138.

HUANG Qiaojian, LIU Xiaojun, ZHANG Shuyi. Influence of temperature on thermal diffusivity of double perovskite Sr2FeMoO6 studied by laser-induced transient thermal grating[J]. Acta Acustica, 2011, 36(2): 134-138.

[18] 陈君, 张群莉, 姚建华, 等. 材料表面粗糙度对激光吸收率影响的研究[J]. 激光技术, 2008, 32(6): 624-627.

Article Outline

姚东, 高波, 宋英政, 李群, 高贵龙. 激光瞬态光栅激励下结构的超声响应特性研究[J]. 光子学报, 2022, 51(9): 0914001. Dong YAO, Bo GAO, Yingzheng SONG, Qun LI, Guilong GAO. Research on Ultrasonic Response Characteristics of Structures Excited by Laser Transient Grating[J]. ACTA PHOTONICA SINICA, 2022, 51(9): 0914001.