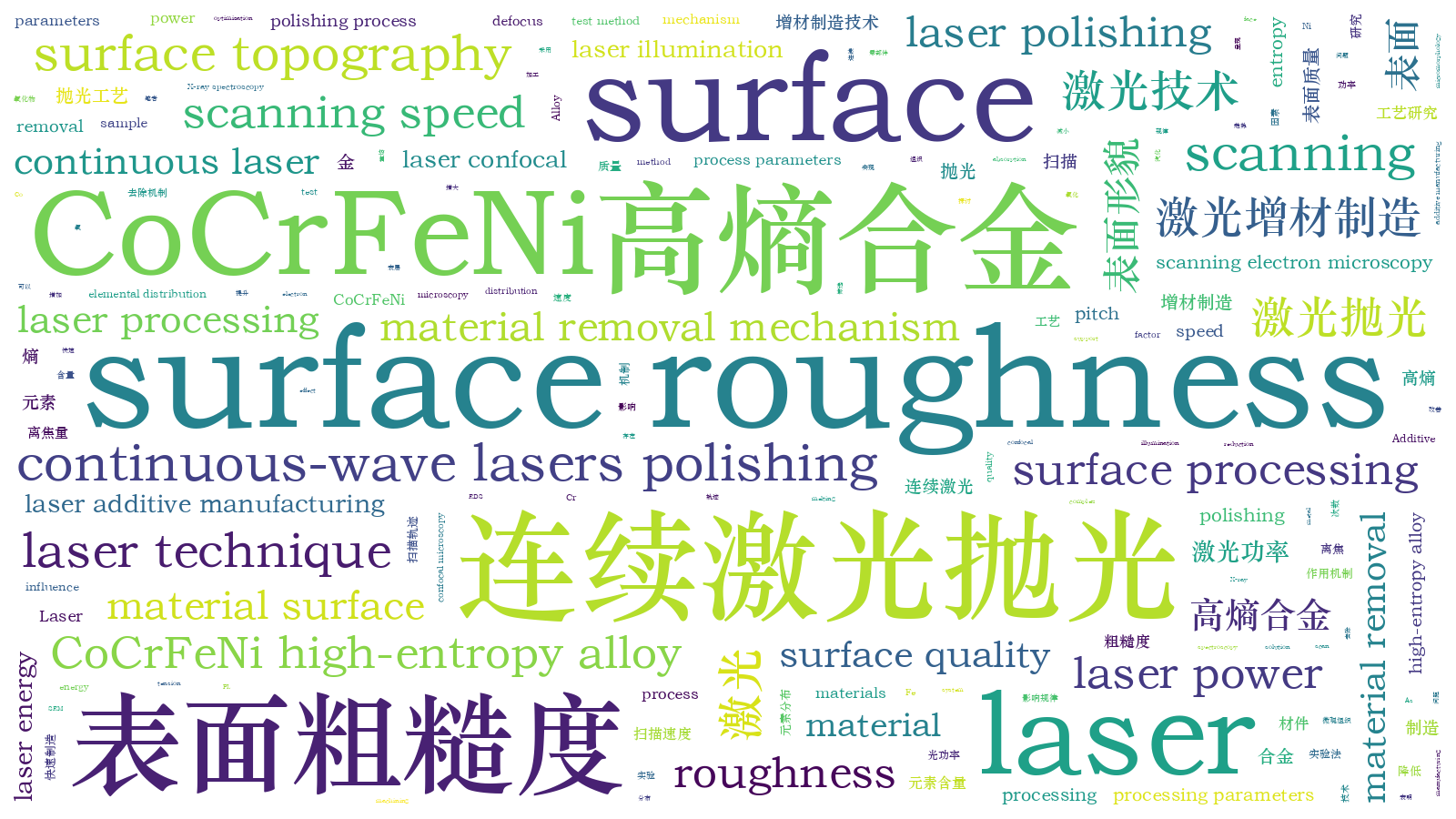

激光增材制造CoCrFeNi高熵合金激光抛光工艺研究【增强内容出版】

High-entropy alloy additive parts face certain difficulties in maintaining surface quality and machining. As a new class of materials, their processing is inevitably different from that of conventional alloys in terms of material removal mechanisms and surface processing methods. To investigate the material removal mechanism of laser-polished high-entropy alloys and to solve the technical problems encountered in their processing and expand the scope of the laser processing system, this study investigated the continuous laser polishing of high-entropy alloy additive parts. The material removal mechanism and the influence of the laser-polishing parameters on the surface quality are analyzed to provide process support for the optimization of the laser-polishing process.

A high-entropy CoCrFeNi alloy was used as the experimental material. First, the high-entropy alloy additive parts were prepared via laser additive manufacturing and then polished using a continuous laser under different processing parameters. Subsequently, their surface roughness was evaluated through laser confocal microscopy. The screening test method was used to determine the contribution of each influencing factor on the surface roughness, followed by the single-factor test method to analyze the influence of the process parameters such as defocus, laser power, scanning pitch, scanning speed, and the number of scanning on the surface roughness of the polished specimen. Finally, scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) were used to analyze the material removal mechanism and the effect of laser polishing on the surface micromorphology and elemental distribution.

The main factors that affect the surface polishing of the high-entropy CoCrFeNi alloy additive parts are defocus, laser power, scanning pitch, scanning speed, and the number of scanning (Fig. 4). The surface roughness of the polished sample tended to decrease at first and then increase with increasing defocus (Fig. 6). At a constant scanning speed (V=300 mm/s) and scanning pitch of 0.005 mm, the surface roughness decreased progressively with increasing laser power. At a scanning pitch of 0.01 mm, the surface roughness tended to increase and then decrease with increasing laser power, whereas it tended to decrease and then increase with increasing scanning speed (Fig. 8). At a scanning pitch of 0.05 mm, the surface roughness of the sample increased by approximately 166% with increasing scanning speed. Further, at V=300 mm/s, the surface roughness tended to increase and then decrease with increasing scanning pitch. At V>300 mm/s, the surface roughness exhibited a progressively larger increase with increasing scanning pitch. Furthermore, the surface roughness of the laser-polished specimen tended to increase, then decrease, and then increase again as the number of scanning increased (Fig. 11). The O and Cr contents of the polished material decreased significantly, whereas the Co, Fe, and Ni contents increased (Fig. 15), and no new solid-solution structures were generated (Fig. 13). The surface roughness of the sample was reduced by 90% at the optimized polishing parameters (PL=400 W, V=300 mm/s, d=0.05 mm, z=+2 mm, and n=6).

In this study, laser polishing of a high-entropy alloy was performed using a continuous laser to investigate the influence of the process parameters on its roughness. And the study analyzes the mechanism of laser removal of high-entropy alloy surface materials. The surface material removal under continuous laser illumination mainly occurs through instantaneous melting or the evaporation of the surface material after the absorption of the laser energy, resulting in "peak and valley reduction." Some metal solutes form new protrusions on the surface under surface tension and gravity. The surface roughness of the sample decreases as the laser power increases, and it tends to decrease and then increase with increasing scanning speed, defocus, and scan cycles. During the laser-polishing process, the material surface undergoes complex physical and chemical reactions, and the surface elemental distribution changes.

周宇航, 张咪娜, 陈晓晓, 张群莉, 张文武. 激光增材制造CoCrFeNi高熵合金激光抛光工艺研究[J]. 中国激光, 2023, 50(20): 2002304. Yuhang Zhou, Mina Zhang, Xiaoxiao Chen, Qunli Zhang, Wenwu Zhang. Surface Laser Polishing of High-Entropy CoCrFeNi Alloy Prepared by Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2023, 50(20): 2002304.