基于蓝宝石材料的微结构增透性能研究

Diode-pumped alkali lasers are a new type of gas lasers that utilize the high energy levels of alkali metal atoms to achieve particle number inversion. However, conventional fused-silica laser windows are easily subjected to corrosion in the alkali metal vapor environment. Therefore, in this study, we select sapphire as a window material, considering its high hardness and thermal conductivity, low expansion coefficient, and high temperature and erosion resistance. Owing to its large refractive index, the sapphire surface presents relevant anti-reflection properties, including high air and interface reflectivity. Anti-reflection surfaces are usually obtained by preparing optical films or microstructures. Anti-reflection films often require coating materials with specific refractive indices that are difficult to source. Moreover, they are susceptible to gaseous corrosion. However, their fabrication technology is relatively mature. Conversely, the production of anti-reflection microstructures requires complex processing. However, using the same substrate material to build the microstructure results in high chemical stability, mechanical properties, and resistance to laser damage. In this study, we implement a diode-pumped alkali metal laser with a 795 nm center wavelength and a working environment temperature of 200 ℃ by combining two different anti-reflection technologies to obtain a double-sided anti-reflection sapphire window. This is characterized by a microstructure on the side of the vapor chamber and a coating film on the side exposed to air, which enhances the temperature and corrosion resistance of the resulting laser window.

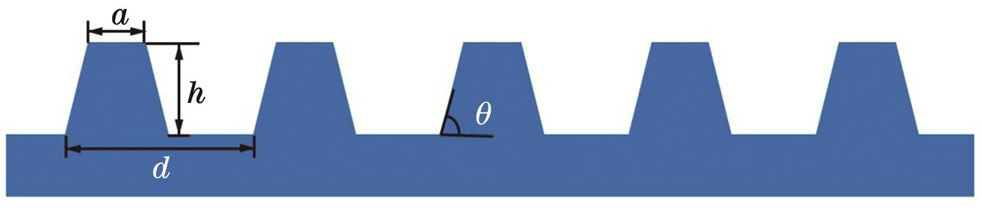

Based on vector diffraction theory, the effects of depth, bottom angle, period, and duty cycle on the transmittance of a one-dimensional trapezoidal structure are analyzed using COMSOL software to obtain the process tolerance of the microstructure. We use laser interference exposure to prepare a photoresist mask on a sapphire surface, and then we transfer it using reactive ion beam etching to form microstructures. The ion-beam sputtering is used to prepare an anti-reflection film on the sapphire surface. To ensure that the microstructure satisfies the requirements of the application environment, we test the temperature increase in the sample under the action of a high-power laser. Moreover, we test the changes in the beam quality of the probe light passing through the sample at different temperatures.

Our simulation results show that the transmittance can reach above 99.90% with a period of 400 nm, bottom angle of 78°±2°, depth of (190±5)nm, duty cycle of 0.25±0.05, and large margin of error (Figs. 2?6). Morphology test results show that the duty cycle of the experimentally prepared microstructure is in the range of 0.22?0.31, consistently with the designed parameters, whereas the height is in the range of 155?175 nm, thus failing to reach the designed value (Table 1). Transmittance test results show that the transmittances of the single-sided anti-reflection microstructure and film reach 99.23% and 99.91%, respectively. The transmittances of the double-sided anti-reflection sapphire window are 98.01% and 98.90% for the one-sided microstructure and anti-reflection film, respectively. The transmittances of these two samples increase by 12.13% and 13.02% compared to that of a bare sapphire substrate (Fig. 10). The temperature rise test results show that when the laser power is increased from 35 W to 99.6 W, the temperatures of substrates 1 and 2 increase by 4.3 ℃ and 5.9 ℃, respectively, whereas the temperature of the double-sided anti-reflection sample increases only by 3.8 ℃. Near the target wavelength, the temperature increase in the anti-reflection window is smaller than that in the bare substrate, and the temperature increase in the double-sided anti-reflection sample can be appropriately reduced (Fig. 12). The beam quality test results show that the temperature has a greater effect on the beam quality factor in the longitudinal direction of the sapphire samples compared to that in the transverse direction. Moreover, the sapphire batch significantly influences the associated beam quality factor (Fig. 14). When the temperature of the window is kept at 200 ℃ under the action of a high-power laser, the beam quality factor of the samples with the double-sided anti-reflection microstructure varies less than 0.05 and 0.06 in the transverse and longitudinal directions, respectively. Therefore, the anti-reflection window has a limited effect on the beam quality of the incident light (Table 2).

Based on our theoretical simulation, in this study, we develop anti-reflection microstructures on the surface of a sapphire substrate by interference exposure and reactive ion beam etching, which can reach a single-sided transmittance of 99.23% at a 795 nm light wavelength. Using this technique, we prepare two sapphire windows: one characterized by a double-sided microstructure, and one presenting a microstructure on one side and a coating film on the opposite side. At a wavelength of 795 nm, the transmittance of these samples improves by 12.13% and 13.02%, respectively, compared with that of the bare sapphire substrate. The temperature rise test under high-power laser irradiation shows that when the laser power increases from 35.0 W to 99.6 W, the temperature of the bare substrate rises by 5.9 ℃, whereas that of both samples obtained using the double-sided antireflective treatment increases only by 3.8 ℃. These results indicate that our treatment can effectively reduce thermal effects by exploiting the higher transmittance rates of the double-sided samples. Moreover, beam quality test results indicate that when the microstructure window temperature is kept below 200 ℃ under high-power laser irradiation, the variation of the beam quality factor for double-sided anti-reflection samples remains below 0.05 and 0.06 along the transverse and longitudinal directions, respectively, indicating that the anti-reflection window has a negligible effect on the beam quality of the incident light. In this study, we successfully fabricate antireflective windows on a sapphire substrate characterized by either a double-sided antireflective microstructure or an antireflective microstructure and antireflective film on the opposite sides, achieving in both cases high temperature and corrosion resistance as well as high transmission performance. Our antireflective fabrication process solves the traditional performance issues of fused-quartz laser windows, which are prone to corrosion in alkali metal vapor environments, and provides a reference framework for fabricating antireflective windows that can be used effectively under harsh conditions.

张文妮, 曹红超, 孔钒宇, 张益彬, 汪瑞, 晋云霞, 邵建达. 基于蓝宝石材料的微结构增透性能研究[J]. 中国激光, 2023, 50(22): 2203101. Wenni Zhang, Hongchao Cao, Fanyu Kong, Yibing Zhang, Rui Wang, Yunxia Jin, Jianda Shao. Study on Microstructure Anti-reflection Performance Based on Sapphire Material[J]. Chinese Journal of Lasers, 2023, 50(22): 2203101.