光子学报, 2023, 52 (7): 0752302, 网络出版: 2023-09-26

激光诱导薄膜材料二维图案化纳米加工技术(特邀)

Laser-induced Two-dimensional Surface Nanopatterning on Film Materials(Invited)

超快激光 激光诱导周期性表面结构 激光诱导褶皱 薄膜材料 二维纳米结构 飞秒激光 Ultrafast laser Laser-Induced Periodic Surface Structures(LIPSS) Laser-induced wrinkle Thin film materials 2D nanostructures Femtosecond laser

摘要

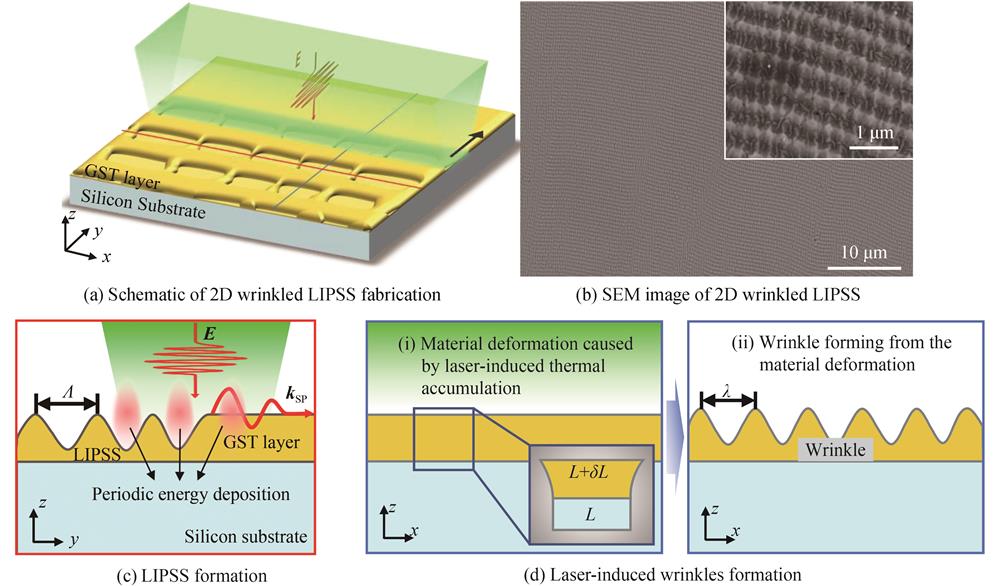

激光诱导周期性表面结构(Laser-Induced Periodic Surface Structures,LIPSS)是一种在激光辐照下自发生成的超衍射极限结构,但其结构类型较为单一。提出了一种新型的二维图案化激光纳米加工方法,通过同时利用激光诱导的热效应及表面等离激元干涉,在正交的两个方向上分别形成褶皱和LIPSS两种周期性结构。这种方法仅通过单步辐照就能在薄膜材料表面生成二维褶皱LIPSS,从而丰富LIPSS的结构类型。同时,通过调整加工材料的膜厚或基底,以及改变入射激光波长或角度,可以分别调制二维纳米结构在两个正交方向上的周期。此外,通过激光偏振也可以调控该结构的取向。该方法能够进一步拓宽基于LIPSS的可加工表面纳米结构的种类及应用。

Abstract

Laser-Induced Periodic Surface Structures (LIPSS) have been extensively studied as grating structures that form beyond the diffraction limit under laser irradiation over a large area. However, most LIPSS are essentially one-dimensional (1D) gratings, and this limited range of structural types in LIPSS hampers their widespread applications. To overcome this challenge, our study proposes a novel maskless two-dimensional (2D) laser nanopatterning method that combines the utilization of laser-induced thermal deformation effects and laser-Surface-Plasmon-Polaritons (SPPs) interference. By harnessing these two effects simultaneously, we can create two distinct periodic structures, namely wrinkles and LIPSS, in orthogonal directions. This innovative approach enables the generation of 2D wrinkled LIPSS on thin-film materials through a single-step laser irradiation process. Moreover, we have made significant advancements in the spatial modulation of the irradiated femtosecond laser, achieving a line shape with a length of 8 mm and a width of 7.78 μm. This spatial modulation facilitates efficient nanopatterning of these 2D LIPSS on a millimeter scale within seconds. These breakthroughs greatly expand the range of achievable structural types with LIPSS, making them more suitable for mass micro/nano fabrication. Our investigation focuses on the formation of wrinkles and LIPSS on Ge2Sb2Te5 (GST) thin-film materials, with an emphasis on laser-induced thermal accumulation, thermal deformation, and laser-SPPs interference. During the laser-induced thermal deformation, wrinkles spontaneously generate with a period of approximately 270 nm on a 50-nm-thick GST film over a silicon substrate. Importantly, these wrinkles maintain their stability in terms of their periods under laser irradiation with varying laser pulse energies. Furthermore, their periods can also be accurately controlled and predicted through a thermal deformation model, which has been validated on GST thin films with different thicknesses and substrate materials. Similarly, another periodic structure, namely LIPSS, can also spontaneously form due to the periodic ablation caused by laser-SPPs interference. The periods of LIPSS, measuring around 410 nm on the same 50-nm-thick GST film, can be modulated by adjusting parameters such as laser wavelength or incident angle. This independent modulation capability allows precise control over the periods of 2D wrinkled LIPSS in both orthogonal directions. Furthermore, we explore the morphological evolution of 2D wrinkled LIPSS and observe a gradual transition from excessive ablation and periodic structure generation to simple crystallization modification as the scanning speed increases or the laser pulse energy decreases. By manipulating the excitation intensity of laser-induced thermal effects and laser-SPPs interference through increasing the laser pulse energy under a fixed scanning speed, we can freely transform the generated periodic structures from wrinkled structures and 2D wrinkled LIPSS to 1D LIPSS. It is worth noting that the height of LIPSS can exceed 65 nm, while the corresponding wrinkle heights typically reach around 34 nm. Additionally, the orientation of 2D wrinkled LIPSS can be controlled by adjusting the polarization angle of the incident laser, adding another parameter to manipulate these structures. Moreover, we have discovered that 2D wrinkled LIPSS formed under different laser polarizations exhibit varying levels of uniformity. Comparatively, LIPSS display superior uniformity when compared to wrinkles, with their orientation being influenced by the polarization angle of the irradiated laser. The laser nanopatterning method proposed in this study demonstrates the immense potential for enhancing the diversity and expanding the applications of LIPSS. It not only overcomes the limitations associated with the monotonous structural type of 1D gratings in LIPSS but also offers a versatile means to engineer and customize the properties of thin-film materials. The increased range of structural possibilities and control over orientations pave the way for a great variety of applications, including surface modification, bionic structural coloration, high-precision detection, photonics, and optoelectronics. The findings presented in this study contribute to advancing laser nanopatterning techniques and provide valuable insights for future research in laser nanofabrication, a rapidly evolving field.

黄佳旭, 李峻, 邱佩, 徐少林. 激光诱导薄膜材料二维图案化纳米加工技术(特邀)[J]. 光子学报, 2023, 52(7): 0752302. Jiaxu HUANG, Jun LI, Pei QIU, Shaolin XU. Laser-induced Two-dimensional Surface Nanopatterning on Film Materials(Invited)[J]. ACTA PHOTONICA SINICA, 2023, 52(7): 0752302.