激光诱导薄膜材料二维图案化纳米加工技术(特邀)

0 引言

亚波长尺度周期性表面结构的制备技术对于光学、化学、材料和能源等领域的研究具有重要意义。近年来,激光诱导周期性表面结构(Laser-Induced Periodic Surface Structures,LIPSS)被广泛报导,其是一种在激光辐照下自发诱导形成的超衍射极限结构[1-3]。相比于传统的制备方法,基于LIPSS的表面结构加工技术具备制备效率高、材料选择性低、环境宽容度高、加工路径自由可控和可突破衍射极限等优势。尽管该技术已经被验证可以在极短时间内实现晶圆级面积内亚波长结构的高效均匀制备[4-7],但由于其表面周期性能量沉积(通常是入射光与激光激发表面等离激元波(Surface Plasmon Polaritons,SPPs)的干涉)引起结构生成的机制[8],LIPSS通常是一维的光栅结构。通过对激光进行时空调制[9-12]、多次扫描[4,13-14]、诱导表面等离激元干涉[15]或引入另一效应(如Marangoni效应[16]、入射光干涉[17]等)等方式能有效实现二维亚波长结构的制备。

在薄膜材料领域,LIPSS加工技术展示了广泛的应用前景。这种技术可以在众多薄膜材料上实现不同类型亚波长尺度的周期性结构制备,从而改善薄膜材料的性能,尤其在光学应用方面表现突出[18-21]。然而,在薄膜系统中,LIPSS技术在加工适用性、稳定性以及能量沉积和热影响等方面的深入研究仍然较少。因此,进一步探讨LIPSS技术在薄膜材料表面结构加工方面的应用将为功能性表面结构器件的发展开辟新的可能性。

本文提出了一种针对薄膜材料的二维周期性结构的高效制备方法。该方法通过调控激光沉积表面的热累积过程引起材料热膨胀诱导褶皱形成,并结合表面等离激元的激发,在薄膜材料表面实现二维周期性结构的制备,具有制备成本低、制备过程简单、制备效率高等优点。

1 实验与设备

本研究中使用的样品主要为沉积在硅基底上的锗锑碲(Ge2Sb2Te5,GST)薄膜,其制备方法为:分别用酒精和异丙醇对硅基底(N型掺杂,<100>晶向)进行超声清洗10 min;然后,通过磁控溅射(KYKY500CK-500ZF)在基底上蒸镀相应的膜层,包括在硅基底上分别蒸镀了20 nm、40 nm和50 nm厚度的GST薄膜,以及在熔融石英基底上蒸镀了50 nm厚度的GST薄膜。在随后的激光纳米图案化加工过程中,通过飞秒激光系统(Spectra-Physics)提供了脉冲宽度为300 fs,中心波长为520 nm,脉冲重复频率为100 kHz的激光脉冲,随后通过半波片和格兰棱镜结合调整激光能量,并通过半波片调制激光偏振角度,而后激光束依次通过一个柱面透镜(焦距f = 25 mm)和一个物镜透镜(0.1 NA,4倍)聚焦,最终获得长度为8 mm,宽度为7.78 μm的线形聚焦光斑。结合高精度位移平台(Newport XMS100-S)控制样品的运动,且在激光加工过程中始终保持样品的运动方向垂直于线形光斑长轴的方向。同时,本研究还通过添加一个辅助气源对样品持续吹气及时排除激光烧蚀碎屑。在激光加工完成后,再分别使用酒精和异丙醇对加工样品进行超声清洗10 min。最后通过扫描电子显微镜(SEM,Zeiss,Merlin)和原子力显微镜(AFM,Bruker,Dimension Edge)对激光加工的表面形貌进行表征测量。

2 实验结果与分析

2.1 二维褶皱LIPSS的形成机制

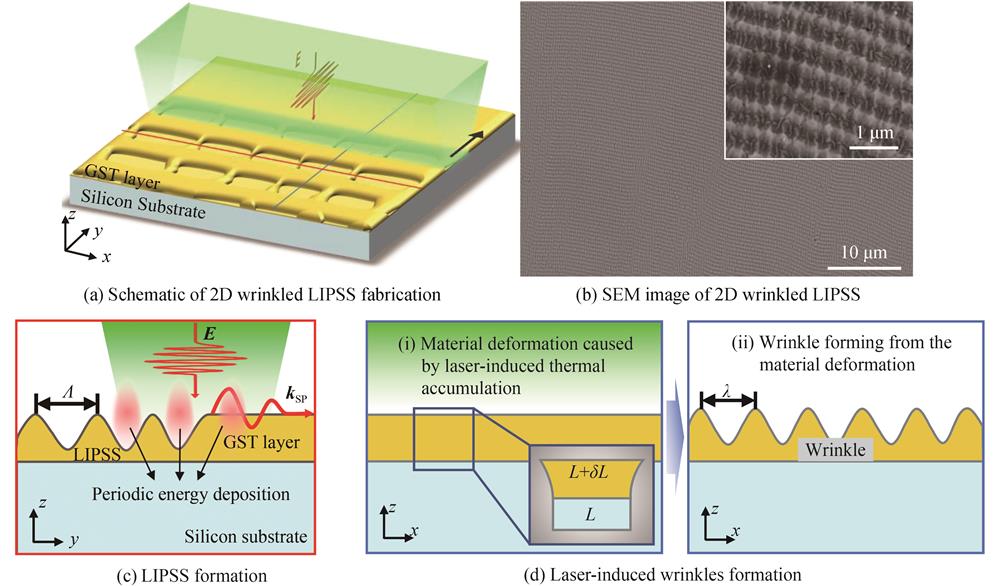

如

图 1. 激光加工二维褶皱LIPSS原理图及加工结果

Fig. 1. Schematics and results of the fabrication of 2D wrinkled LIPSS

研究中激光垂直辐照至材料表面所生成的LIPSS周期Λ在数值上等于激光激发的表面等离激元波长λSPPs(~410 nm),与前期工作研究一致[15,22]。同时,LIPSS周期Λ还可通过调控入射光波长和角度实现进一步调控[3]。如

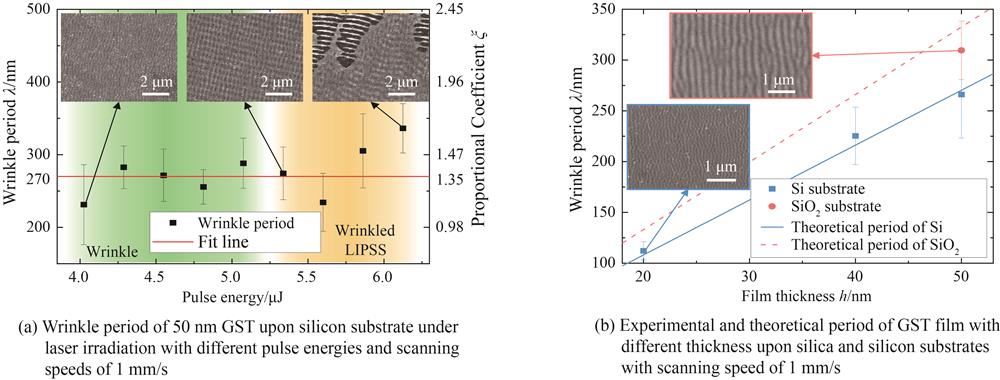

式中,ξ为修正系数(通常取1),h为薄膜厚度,v和E分别是材料的泊松比和杨氏模量,下标s和f表示基底材料和薄膜材料对应的力学参数,研究所使用材料力学参数如

表 1. GST、硅和石英的材料力学参数

Table 1. Mechanic parameters of GST,silicon and quartz

|

如

图 2. 激光诱导褶皱周期与加工能量、膜厚的关系

Fig. 2. Relationship between laser-induced wrinkle period and pulse energies,as well as film thicknesses

2.2 二维褶皱LIPSS的演化规律

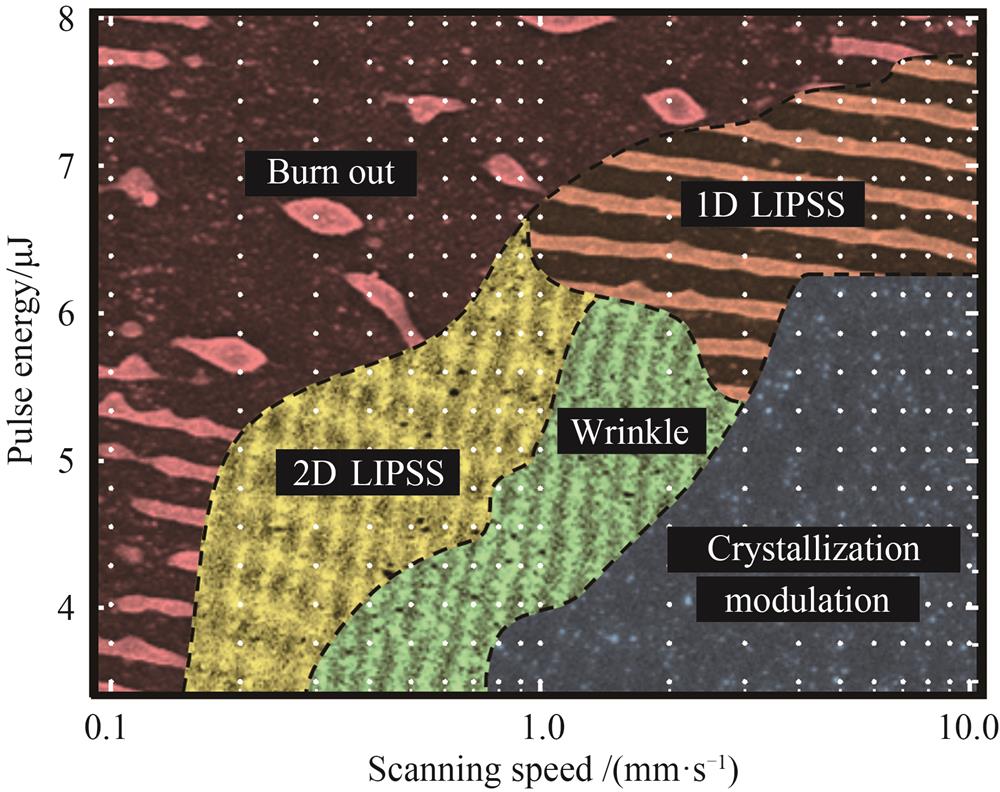

如2.1节所述,二维褶皱LIPSS可在特定激光沉积能量和脉冲数量下产生,而进一步调控激光加工的沉积能量和脉冲数量可以使得加工结果从过度烧蚀、周期性结构生成到晶化改性的逐步演化(

图 3. 脉冲重复频率为100 kHz,不同脉冲能量和扫描速度的飞秒激光加工中50 nm GST薄膜(硅基底)形成表面结构的演化坐标

Fig. 3. Morphology evolution of wrinkled LIPSS on 50 nm GST thin film upon silicon through laser processing with its repetition rate of 100 kHz,different pulse energies and scanning speeds

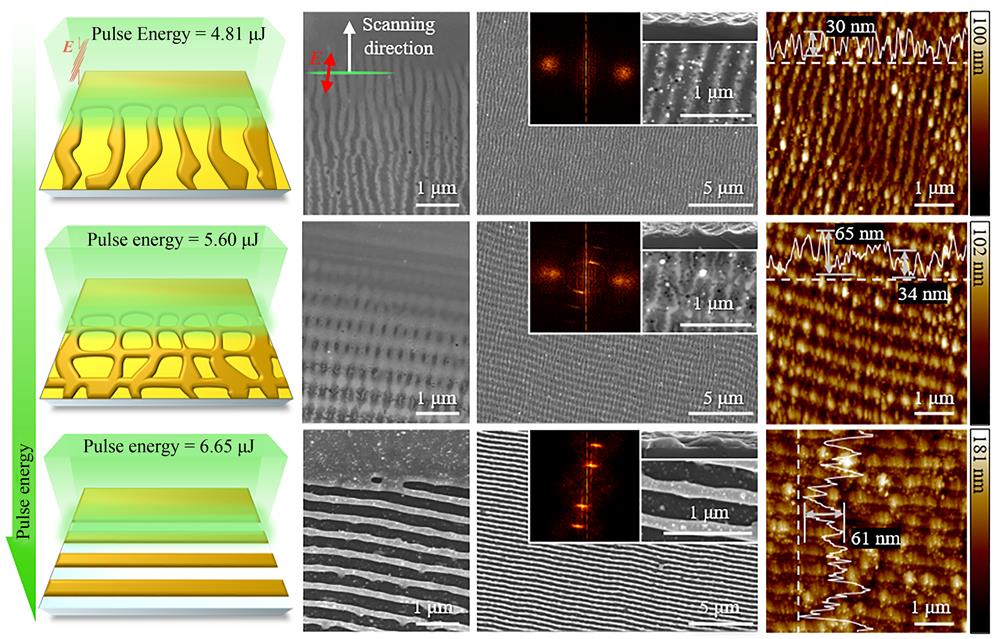

如

上述的演化过程主要取决于激光激发表面等离激元和热累积效应的强度。如

图 4. 在扫描速度为0.1 mm/s,不同激光能量下50 nm GST薄膜(硅基底)形成的周期性结构的示意图和SEM图,以及形成结构和其截面轮廓的SEM、二维傅里叶变换和AFM图像

Fig. 4. Schematics,SEM,cross-section profile,2D Fourier transformation,and AFM images of wrinkled LIPSS on 50 nm GST thin film upon silicon under scanning speed of 0.1 mm/s and different pulse energies

2.3 二维褶皱LIPSS的偏振依赖性

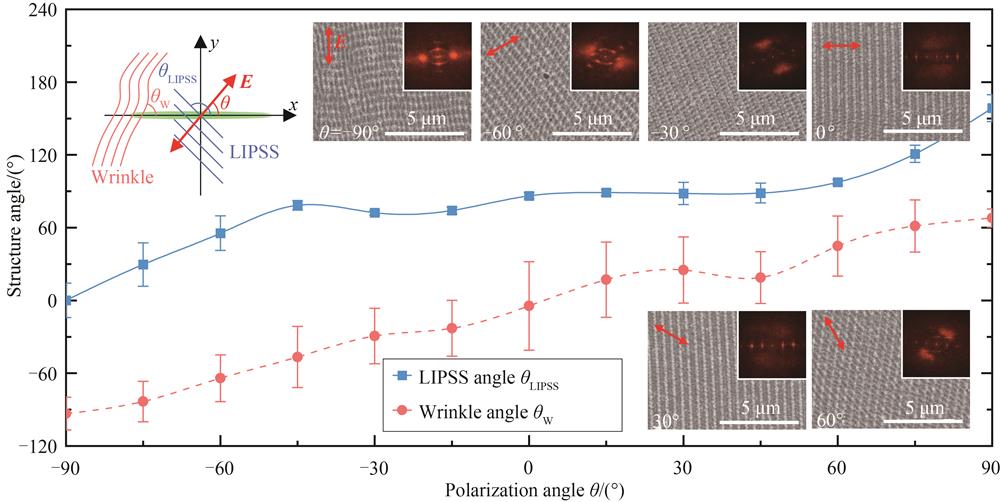

二维褶皱LIPSS的取向还可以通过调控入射光偏振角度实现进一步的调控。如

图 5. 不同偏振角度θ下50 nm GST薄膜(硅基底)上制备二维褶皱LIPSS的褶皱角度θW和LIPSS角度θLIPSS的变化趋势

Fig. 5. Change curves of the angles of wrinkle angles θW and LIPSS θLIPSS versus polarization angle θ on 50 nm GST thin film upon silicon

3 结论

本研究提出了一种基于激光诱导周期性表面结构(LIPSS)的新型二维纳米图案化的高效激光加工方法,该方法能够在单步激光加工中实现方向、周期可控的均匀二维纳米结构的大面积制备。通过利用激光诱导的热效应和表面等离激元波的干涉,可以在激光照射过程中同时生成方向正交的褶皱和LIPSS两种周期性图案。此外,这两种结构的周期可以通过调整加工材料的膜厚(或基底材料)以及激光的波长(或入射角度)来分别实现进一步调控,而它们的方向可以通过激光偏振角度进行调节。该激光图案化方法无需掩膜、低成本,仅需通过简单的激光照射便能实现薄膜材料表面的大面积二维图案化,可为激光诱导表面结构的研究提供一种新思路。

[1] BONSE J, HOHM S, KIRNER S V, et al. Laser-induced periodic surface structures—a scientific evergreen[J]. IEEE Journal of Selected Topics in Quantum Electronics, 2017, 23(3): 1-59.

[2] VOROBYEV A Y, GUO C. Direct femtosecond laser surface nano/microstructuring and its applications[J]. Laser & Photonics Reviews, 2013, 7(3): 385-407.

[3] BONSE J, GRÄF S. Maxwell meets Marangoni—a review of theories on laser-induced periodic surface structures[J]. Laser & Photonics Reviews, 2020, 14(10): 2000215.

[4] WANG L, CHEN Q D, CAO X W, et al. Plasmonic nano-printing: Large-area nanoscale energy deposition for efficient surface texturing[J]. Light: Science & Applications, 2017, 6(12): e17112.

[5] ZOU T, ZHAO B, XIN W, et al. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse[J]. Light: Science & Applications, 2020, 9(1): 69.

[6] GENG J, YAN W, SHI L, et al. Surface plasmons interference nanogratings: wafer-scale laser direct structuring in seconds[J]. Light: Science & Applications, 2022, 11(1): 189.

[7] XU K, HUANG L, XU S. Line-shaped laser lithography for efficient fabrication of large-area subwavelength nanogratings[J]. Optica, 2023, 10(1): 97.

[8] HUANG M, ZHAO F, CHENG Y, et al. Origin of laser-induced near-subwavelength ripples: interference between surface plasmons and incident laser[J]. ACS Nano, 2009, 3(12): 4062-4070.

[9] ZHENG J, HUANG J, XU S. Multiscale micro-/nanostructures on single crystalline SiC fabricated by hybridly polarized femtosecond laser[J]. Optics and Lasers in Engineering, 2020, 127: 105940.

[10] DURBACH S, KRAUSS F T, HOFFMANN M, et al. Laser-driven one- and two-dimensional subwavelength periodic patterning of thin films made of a metal-organic MoS2 precursor[J]. ACS Nano, 2022, 16(7): 10412-10421.

[11] MASTELLONE M, BELLUCCI A, GIROLAMI M, et al. Deep-subwavelength 2D periodic surface nanostructures on diamond by double-pulse femtosecond laser irradiation[J]. Nano Letters, 2021, 21(10): 4477-4483.

[12] ZHENG X, ZHAO B, YANG J, et al. Noncollinear excitation of surface plasmons for triangular structure formation on Cr surfaces by femtosecond lasers[J]. Applied Surface Science, 2020, 507(November 2019): 144932.

[13] ÖKTEM B, PAVLOV I, ILDAY S, et al. Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses[J]. Nature Photonics, 2013, 7(11): 897-901.

[14] HUANG J X, XU K, XU S L, et al. Self-aligned laser-induced periodic surface structures for large-area controllable nanopatterning[J]. Laser & Photonics Reviews, 2022, 16(5): 2200093.

[15] HUANG J, XU K, HU J, et al. Self-aligned plasmonic lithography for maskless fabrication of large-area long-range ordered 2D nanostructures[J]. Nano Letters, 2022, 22(15): 6223-6228.

[16] DOSTOVALOV A, BRONNIKOV K, KOROLKOV V, et al. Hierarchical anti-reflective laser-induced periodic surface structures (LIPSSs) on amorphous Si films for sensing applications[J]. Nanoscale, 2020, 12(25): 13431-13441.

[17] HUANG J, WANG X, MIZUTANI M, et al. Generation mechanisms of laser-induced periodic nanostructures on surfaces of microgrooves[J]. Optics and Laser Technology, 2023, 160: 109056.

[18] DESTOUCHES N, SHARMA N, VANGHELUWE M, et al. Laser-empowered random metasurfaces for white light printed image multiplexing[J]. Advanced Functional Materials, 2021: 2010430.

[19] MA H, DALLOZ N, HABRARD A, et al. Predicting laser-induced colors of random plasmonic metasurfaces and optimizing image multiplexing using deep learning[J]. ACS Nano, 2022, 16(6): 9410-9419.

[20] DALLOZ N, LE V D, HEBERT M, et al. Anti-counterfeiting white light printed image multiplexing by fast nanosecond laser processing[J]. Advanced Materials, 2022, 34(2): 2104054.

[21] MAKAROV S V, TSYPKIN A N, VOYTOVA T A, et al. Self-adjusted all-dielectric metasurfaces for deep ultraviolet femtosecond pulse generation[J]. Nanoscale, 2016, 8(41): 17809-17814.

[22] YUAN D, HUANG J, LI J, et al. Laser constructing short-range disordered metagratings for visible near-infrared polarization-independent absorption[J]. Advanced Optical Materials, 2023: 2202585.

[23] LIU N, SUN Q, YANG Z, et al. Wrinkled interfaces: taking advantage of anisotropic wrinkling to periodically pattern polymer surfaces[J]. Advanced Science, 2023: 2207210.

[24] GROENEWOLD J. Wrinkling of plates coupled with soft elastic media[J]. Physica A: Statistical Mechanics and its Applications, 2001, 298(1-2): 32-45.

[25] LEE J H, RO H W, HUANG R, et al. Anisotropic, hierarchical surface patterns via surface wrinkling of nanopatterned polymer films[J]. Nano Letters, 2012, 12(11): 5995-5999.

[26] FILLOT F, SABBIONE C. Nanoscale mechanics of thermally crystallized GST thin film by in situ X-ray diffraction[J]. Journal of Applied Physics, 2020, 128(23): 235107.

[27] CALLISTERW D JR, RETHWISCHD G. Fundamentals of materials science and engineering[M]. 5th ed. Wiley, 2018: 858-863.

黄佳旭, 李峻, 邱佩, 徐少林. 激光诱导薄膜材料二维图案化纳米加工技术(特邀)[J]. 光子学报, 2023, 52(7): 0752302. Jiaxu HUANG, Jun LI, Pei QIU, Shaolin XU. Laser-induced Two-dimensional Surface Nanopatterning on Film Materials(Invited)[J]. ACTA PHOTONICA SINICA, 2023, 52(7): 0752302.