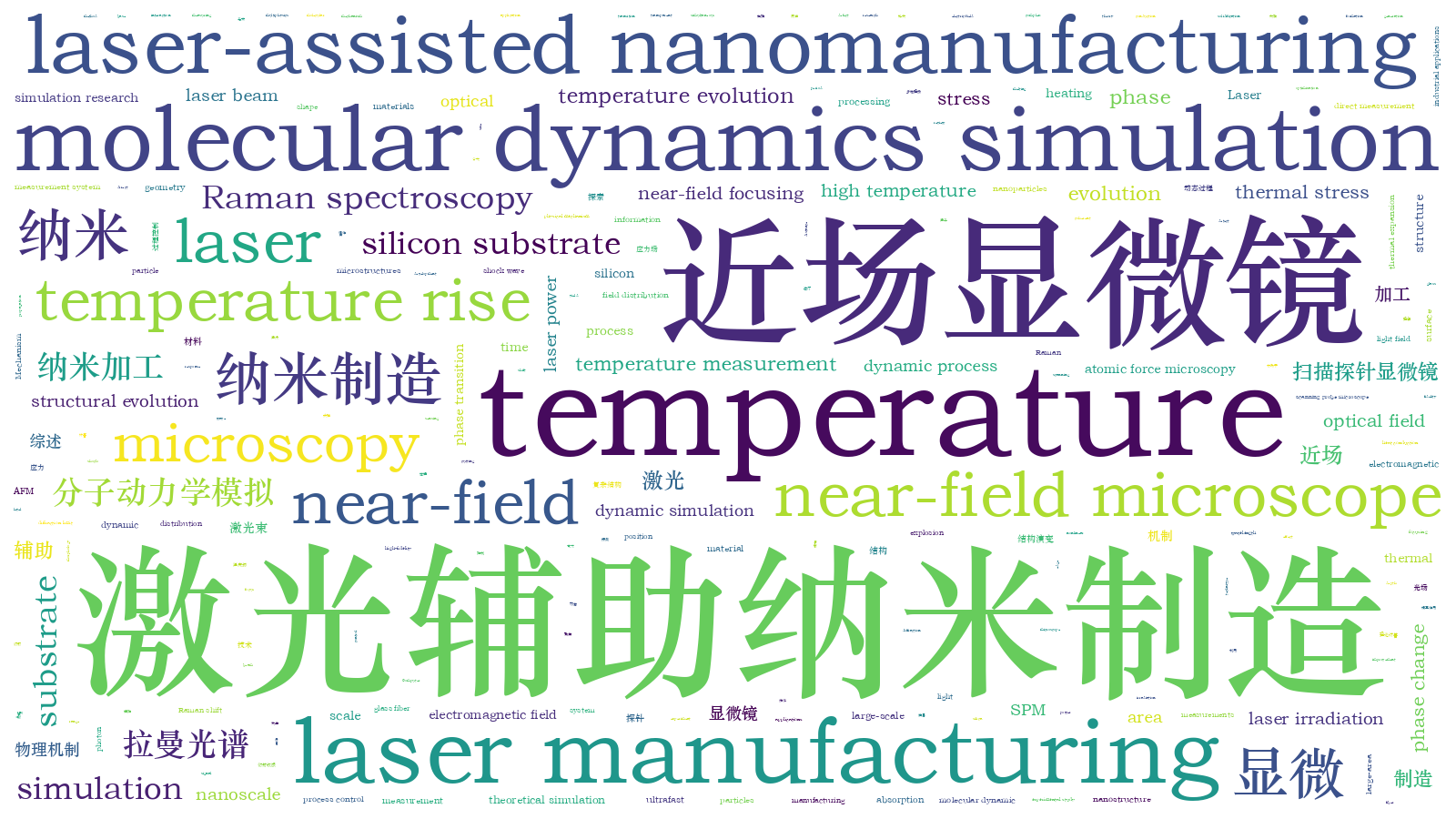

激光辅助近场纳米制造中的物理机制探索  下载: 1184次

下载: 1184次

Significance Laser-assisted near-field nanomanufacturing uses a near-field focused laser beam to break down the diffraction limit and heat materials to induce phase change or phase explosion to fabricate nanoscale materials and complex structures. It has an outstanding feature in both academic and industrial fields due to its highly coherent features, including continuously adjustable incident laser power, highly controllable processing position, and accessible to nanodomains. Among various near-field technologies, the tip-based near-field technique utilizes the tiny but sharp geometry of scanning probe microscope (SPM) tips to focus the incident optical field into an extremely small area in proximity to the tip apex. The highly enhanced electromagnetic field generates huge but localized heat in the surface to be manufactured and modifies its morphology through photon absorption and consequent phase change at the nanoscale.

Progress In the processing domain, in-situ information about the optical field, temperature rise, stress, and material structure evolution is critical for understanding and refining nanomanufacturing. It is helpful for in-depth understanding of the physical mechanism of multiphysics interaction and further optimization and process control. The enhanced electromagnetic field in and around SPM tips has been fully studied in recent decades; however, a knowledge gap remains relative to temperature rise and thermal stress evolution in the same region. A high-fidelity simulation on atomic force microscopy (AFM) tungsten tip under laser irradiation demonstrated that the electric field was primarily concentrated at the apex outside the tip rather than inside (

Micro/nanoparticles represent an alternative geometry employed to introduce near-field focusing and simultaneous heating at the sub-wavelength scale, especially in the application of laser-assisted nanopatterning and nanolithography on a large-area substrate. Knowledge of the temperature and thermal stress beneath particles is critical; however, acquiring this knowledge remains a significant challenge for immediate sensing. Tang et al. has conducted pioneering experimental work on direct measurement of temperature and thermal stress in a silicon substrate beneath various transparent microstructures, including a single silica particle, a glass fiber, and a layer of particles (

Although various experimental methods have been developed for nanoscale probing, the theoretical simulation, e.g., molecular dynamic simulation, is a predominant method to predict atomic-level phenomena in an ultrafast period in laser-assisted near-field nonmanufacturing processes. In addition, the previous work primarily focused on enhancing the optical field under SPM tips, the light confinement effect, and the temperature evolution of the tip and substrate only under the condition of no phase change. However, the incident laser is extremely focused and enhanced in a nanodomain in the surface to be processed under the tip; thus, the material in this domain undergoes intense heating, phase change, phase explosion, stress generation and propagation, and rapid structural evolution in a very short time. Computer simulation research has focused more on small-scale and short-time heating processes, which would lose important information on material/structure evolution. Wang established a large-scale system with hundreds of millions of atoms and studied the long-term behavior and structural evolution of heating, melting, phase transition, solidification, and defect formation in laser-assisted tip-based near-field nanomanufacturing (Figs. 9--14). In addition, the shock wave during the nanomanufacturing process has been studied extensively (Figs. 16--18). Although simulation results were based on a few assumptions, the models used in the simulations were designed according to real dimensions, and this provided cutting-edge and detailed knowledge and understanding of physical images.

Conclusions and Prospects This review primarily focuses on experimental and theoretical investigations of the optical, temperature, and stress fields, and simulation study of the structural evolution in SPM tip-based laser-assisted near-field nanomanufacturing. However, unsolved problems remain in laser-assisted near-field nanomanufacturing. In the ultrafast and dynamic process of nanostructure manufacturing, the physical phenomena in such a small domain (e.g., nano to subnano domains) are difficult to observe and detect. Although newly developed laser-assisted probe methods are nanoscale accessible, they take much more time to satisfy signal collecting than the entire time range of ultrafast dynamic process of nanomanufacturing. In addition, SPM tips are fragile and can be easily damaged and contaminated, and their geometric shape change significantly affects the near-field electromagnetic field distribution. The unexpected change in tips shape will then widen the near-field light field distribution around the needle apex and make the manufactured structure deviate from expectation. The high temperature rise in laser-assisted near-field nanomanufacturing will introduce large thermal expansion in both the tip and the processed surface, and yield unstable measurements because the distance between the tip and substrate is only several nanometers. In terms of rapid response measurement, large-scale manufacturing, and improving and expanding industrial applications, this technology still has room for significant development and improvement.

徐屾, 朱红阳, 张莉君, 岳亚楠, 王信伟. 激光辅助近场纳米制造中的物理机制探索[J]. 中国激光, 2021, 48(6): 0600001. Shen Xu, Hongyang Zhu, Lijun Zhang, Yanan Yue, Xinwei Wang. Exploration of Physical Mechanism in Laser Assisted Near-field Nanomanufacturing[J]. Chinese Journal of Lasers, 2021, 48(6): 0600001.