激光选区熔化Cu‑Al‑Mn合金的组织、相变行为及性能研究  下载: 557次

下载: 557次

Ni-Ti shape memory alloys exhibit excellent superelasticity, shape memory properties, and biocompatibility; however, their poor processing performance, high reaction chemical activity of titanium, and high cost seriously limit their applications. It is necessary to develop low-cost shape memory alloys with sound shape memory effects to replace Ni-Ti for industrial applications. Cu-based shape memory alloys have high strength, high conductivity, excellent superelasticity, shape memory effect, a wide range of phase-transition temperatures (-180-400 °C), and low production cost (about 1/10 of Ni-Ti). Although its shape memory effect and stability are lower than those of Ni-Ti, it has apparent advantages under certain conditions (such as hot water temperature control valves, water heaters, decorations, and toys) where the requirements for its shape memory performance and stability are not too harsh. Cu-Al-Ni and Cu-Zn-Al have strong industrial applications due to their low price; however, their poor thermal stability, high-order degree of the parent phase, and high elastic anisotropy in polycrystalline alloys lead to brittleness during deformation. In recent years, Cu-Al-Mn shape-memory alloys (SMA) have attracted considerable attention because of their low price, shape-memory effect, and excellent mechanical properties. An alloy prepared by selective laser melting (SLM) has the characteristics of a fast cooling rate, small grain size, and no component segregation. It has natural advantages in the preparation of complex-shaped parts and has brought unlimited prospects for the preparation and application of Cu-Al-Mn alloys. However, shape memory alloys prepared by SLM still have problems, such as unstable mechanical properties and degradation of functional properties.

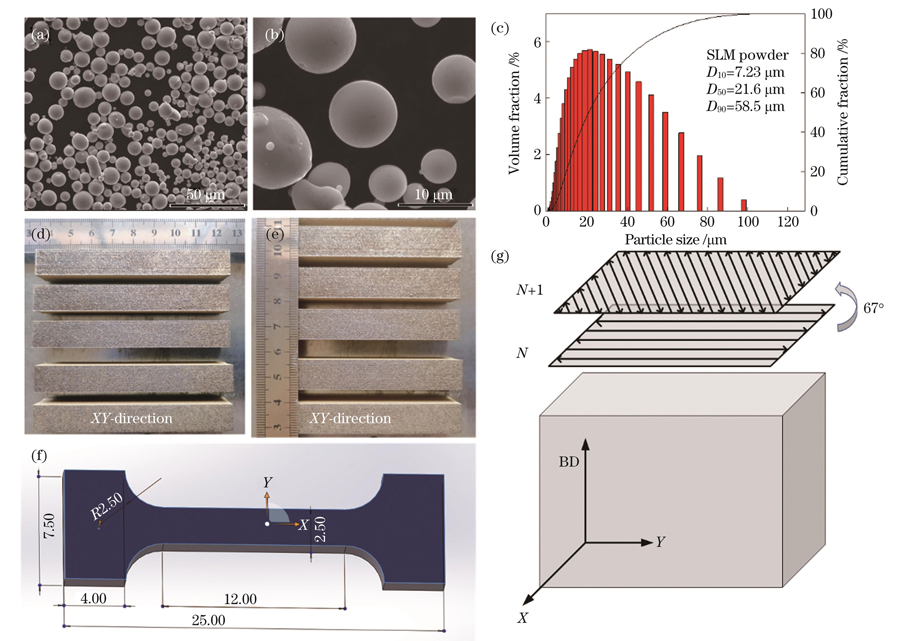

Pre-alloyed powders with high sphericity, fluidity, and uniformity prepared by vacuum atomization were used as raw materials in this study. Cu-Al-Mn alloy samples with different laser powers were formed on a stainless-steel substrate without preheating. The microstructure and martensite type of the alloy were determined by optical microscopy (OM), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). X-ray diffraction (XRD) and differential scanning calorimetry (DSC) determined the alloy’s phase composition and transformation behavior. The functional properties of the alloys were determined using bending and tensile loading recovery experiments. The microhardness and mechanical properties were measured at room temperature. The local deformation behavior during the tensile process at room temperature was analyzed using a full-field strain analysis. The changes in density, phase composition, phase-transition temperature, mechanical properties, and functional properties caused by changes in laser power were studied.

The alloy mainly comprises 18R martensite and γ1 phase at room temperature ( Figs. 4 and 8 ). With the increase of laser power, the molten pool temperature of the alloy increases, the cooling rate decreases, and the solidification path in the alloy changes, which corresponds to the rise in the γ1 phase in the alloy (Fig. 4). However, the precipitation of γ1 phase and the volatilization of Al (Table 2) inhibit its precipitation; therefore, the γ1 phase decreases when the laser power increases from 325 to 375 W. All the alloy samples exhibit the phase-transformation behavior of P (austenite parent phase) ? M (martensite phase) during the heating/cooling process. With the increase in laser power, the intensity of the endothermic/exothermic peak of the DSC curve first increased and then decreased. The number of martensites involved in the phase transformation increased and then decreased (Fig. 6). The sample with 325 W exhibited the best one-way shape memory effect. The shape memory recovery rate exceeded 95% (Fig. 12). The increase of γ1 phase and the solid solution of Mn make the microhardness of the alloy increase when the laser power increases from 175 W to 325 W (Fig. 9). The sample with a laser power of 175 W had a stress platform for stress-induced martensite reorientation almost parallel to the abscissa. With an increase in the laser power, the work-hardening rate increased. The yield strength of the sample decreased and then increased (Fig. 10). This was accompanied by a change in the deformation behavior from uneven to uniform (Fig. 11), corresponding to the residual strain of the former with an increase in pre-deformation, its growth rate gradually slowed. In contrast, the residual stress of the latter was nearly linear with the pre-deformation (Fig. 13).

The results show that the change in type and number of martensite is the main reason for the change in phase transformation behavior and properties of the alloy. With the increase of laser power from 175 W to 325 W, the order degree of the alloy increases, the volatilization of Al element increases, the content of γ

罗梦杰, 李瑞迪, 卢静, 杨小平, 郑聃, 刘鑫炎, 赖端, 吴慧婷, 康景涛, 邓声华. 激光选区熔化Cu‑Al‑Mn合金的组织、相变行为及性能研究[J]. 中国激光, 2023, 50(16): 1602303. Mengjie Luo, Ruidi Li, Jing Lu, Xiaoping Yang, Dan Zheng, Xinyan Liu, Duan Lai, Huiting Wu, Jingtao Kang, Shenghua Deng. Microstructure, Phase‐Transformation Behavior, and Properties of Cu‑Al‑Mn Alloy Fabricated by Selective Laser Melting[J]. Chinese Journal of Lasers, 2023, 50(16): 1602303.