1 山东大学机械工程学院先进射流工程技术研究中心,山东 济南 250061

2 高效洁净机械制造教育部重点实验室,山东 济南 250061

3 中国重汽集团济南动力有限公司发动机制造公司,山东 济南 250220

采用线激光轮廓仪测量工件表面三维形貌时,轮廓仪与工件通常需要作相对直线运动,这对线性运动平台的精度有较高要求,且系统占用空间大,不易实现在位精密测量。针对上述问题,提出了一种线激光轮廓仪旋转扫描的测量方法。通过图像识别方法拟合线结构光的运动轨迹,进而计算轮廓仪和转台旋转中心的偏心误差,采用Matlab和Java编程软件对测量数据进行三维合成和极坐标化处理,并对转台的跳动和偏心及线激光轮廓仪的倾斜误差进行补偿。球径、特征宽度和平面高度差等的测量结果验证了所提方法的有效性,测量误差<3 μm,已接近仪器测量精度的极限值。在被测工件或运动机构体积和重量较大、相对运动精度不高的情况下,所提方法能实现三维形貌的在位精密测量。

测量 三维形貌 线结构光 旋转测量 图像识别 误差补偿 中国激光

2022, 49(21): 2104004

1 山东大学机械工程学院先进射流工程技术研究中心,山东 济南 250061

2 高效洁净机械制造教育部重点实验室,山东 济南 250061

3 山东大学口腔医学院修复科,山东省口腔组织再生重点实验室,山东 济南 250012

4 山东大学第二医院口腔颌面外科,山东 济南 250033

5 燕山大学机械工程学院,河北 秦皇岛 066004

钛以其优异的力学性能和良好的生物相容性而被广泛用于制造医疗植入体。为提高钛在人体内的稳定性、抗菌性等,需对其表面进行修饰改性。本研究采用飞秒和皮秒激光在钛表面加工出微凹槽和微凸起结构,对比了两种激光技术在钛表面加工的微凸起和微凹槽结构在表面形貌、亲疏水性和生物相容性等方面的差异。表面形貌、轮廓、元素的表征结果表明两种激光加工结构的尺寸主要受能量密度的影响,而形状受光斑重叠率的影响较大,皮秒激光加工表面的氧含量较高。由于飞秒和皮秒激光改性钛表面微织构形貌的差异,水接触角(以下简称“接触角”)从初始的40.25°分别降为9.88°和0°。通过对比样品在空气、真空、生理盐水中保存3 d后的表面接触角发现,皮秒激光加工样品表面能保持稳定的超亲水性;经硅烷处理后,飞秒激光改性表面的接触角可达152.80°,而皮秒激光改性表面的接触角为146.38°。细胞黏附和增殖的实验结果表明飞秒激光加工的微凸起或微凹槽线阵有利于细胞的黏附和排列,而皮秒激光加工的微凸起或微凹槽线阵有利于促进细胞的铺展和迁移。

激光技术 钛 微凸起 微凹槽 润湿性 生物相容性 中国激光

2022, 49(10): 1002605

Author Affiliations

Abstract

State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

In order to improve the morphology of microchannels fabricated by femtosecond laser ablation, the thermal process was introduced into the post-treatment processing. It was found that the thermal process cannot only decrease the roughness but also the width and depth of the microchannel. The change rates of width, depth, and roughness of the microchannel increase with processing temperature. When we prolong the time of constant temperature, the change rate of the width decreases at the beginning, and then it tends to be stable. However, the change rates of depth and roughness increase, and then they tend to be stable. In this Letter, we discuss the reasons of the above phenomena.

140.3390 Laser materials processing 230.7380 Waveguides, channeled Chinese Optics Letters

2018, 16(10): 101402

Author Affiliations

Abstract

1 Hunan Key Laboratory of Super Microstructure and Ultrafast Process, School of Physics and Electronics, Central South University, Changsha 410083, China

2 The State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

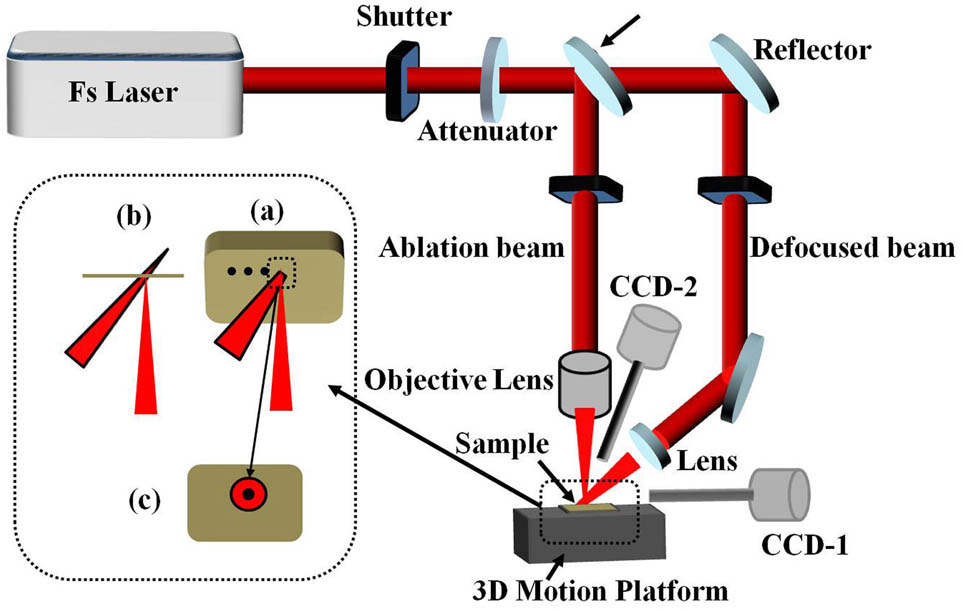

We evaluate the effects of the holes geometry drilled by a femtosecond laser on a stainless alloy with various defocused irradiation time, which ranges from 0 min to 1 h. The laser ablation efficiency is increased by a factor of 3 when the irradiation time is elevated from 0 to 30 min. Also, the morphology of the hole is observed by a scanning electron microscope, where the result indicates that the defocused irradiation time has a significant influence on the morphology changes. The reason for such changes is discussed based on the pretreatment effect and the confined plasma plume. As an application example, the microchannel is fabricated by a femtosecond laser combined with the defocused irradiation to demonstrate the advantage of the proposed method in fabricating functional structures.

140.0140 Lasers and laser optics Chinese Optics Letters

2018, 16(1): 011401

Author Affiliations

Abstract

The State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

A fused silica glass micro-channel can be formed by chemical etching after femtosecond laser irradiation, and the successful etching probability is only 48%. In order to improve the micro-channel fabrication success probability, the method of processing a high-temperature lattice by a femtosecond laser pulse train is provided. With the same pulse energy and scanning speed, the success probability can be increased to 98% by optimizing pulse delay. The enhancement is mainly caused by the nanostructure, which changes from a periodic slabs structure to some intensive and loose pore structures. In this Letter, the optimum pulse energy distribution ratio to the etching is also investigated.

140.0140 Lasers and laser optics 230.7380 Waveguides, channeled Chinese Optics Letters

2017, 15(7): 071403

Author Affiliations

Abstract

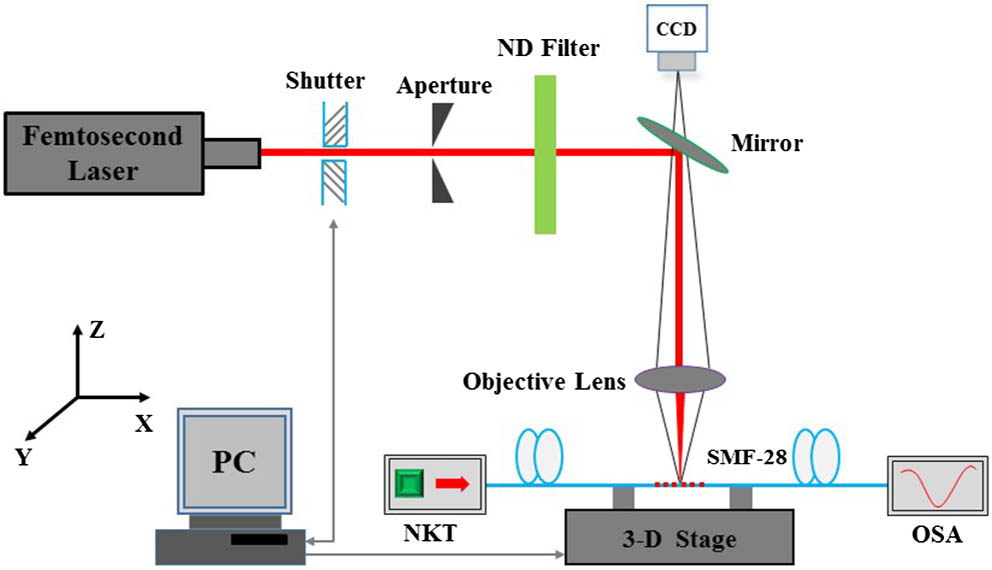

State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

We propose a high temperature-sensitive long period fiber grating (LPFG) sensor fabricated by using the femtosecond laser transversal-scanning method. The femtosecond pulses scan over the whole fiber core and some part of the cladding region; the modified regions are more extended. It is found that the LPFG-I fabricated by the transversal-scanning method shows higher temperature sensitivity and better temperature uniformity than that of LPFG-II written by the femtosecond laser point-by-point method. The LPFG-I with a temperature sensitivity of 75.96 pm/°C in the range of 25°C–400°C is measured. Moreover, in the range from 400°C to 800°C, a higher temperature sensitivity of 148.64 pm/°C and good linearity of 0.99 are achieved, while the temperature sensitivity of LPFG-II is only 95.55 pm/°C. LPFG-I exhibits better temperature characteristics, which, to the best of our knowledge, has the highest sensitivity in silica fiber temperature sensors.

060.0060 Fiber optics and optical communications 060.2370 Fiber optics sensors 140.7090 Ultrafast lasers Chinese Optics Letters

2017, 15(9): 090602

中南大学机电工程学院 高性能复杂制造国家重点实验室, 湖南 长沙 410083

传统的半导体工艺制作微流体系统中微通道, 只能对材料进行表面加工。飞秒激光具有极高的峰值功率和超短的脉冲持续时间, 能够对材料直接进行三维加工, 为高效率、高质量的微通道加工提供了可能。通过研究飞秒激光加工参数, 包括激光脉冲能量、扫描速度和偏振态对玻璃微通道的选择性腐蚀比影响规律, 发现当激光脉冲能量在2~10 μJ变化时, 微通道宽度变大, 2 μJ时微通道长宽选择性腐蚀比L/D高于其它脉冲能量参数, 但随着腐蚀时间的延长, 宽度变化越来越小, 最后趋于稳定; 当激光扫描速度在0.20~0.45 mm/s之间变化时, 随着腐蚀时间的延长微通道长宽选择性腐蚀比L/D逐渐增大, 但当速度增加到0.35 mm/s左右时选择性腐蚀比L/D增到最大, 此后呈现下降趋势, 同样随着腐蚀时间的延长, 腐蚀通道的宽度变化越来越小, 逐渐趋于平稳; 当偏振态从线偏振到圆偏振变化时, 线偏振时的微通道长宽选择性腐蚀比L/D更大。实验结果表明: 获得较大微通道长宽选择性腐蚀比L/D的最优加工参数为激光脉冲能量2 μJ, 激光扫描速度0.35 mm/s, 线偏振。

微流体系统 飞秒激光 微通道 选择性腐蚀比 microfluidic system femtosecond laser microchannel selective etching ratio

1 中南大学 高性能复杂制造国家重点实验室, 湖南 长沙 410083

2 罗彻斯特大学光学研究所, 纽约 14627

与传统传感器相比, 全光纤马赫泽德尔干涉仪(MZI)传感器, 具有结构简单、分辨率高、稳定性好等优点, 在石油化工、健康监测、生物化学等领域有广泛应用。介绍了MZI全光纤传感器的传感机理,对比了其他的加工方法, 如电弧放电、加热拉伸、CO2激光诱导微变形等的优缺点, 详细介绍了飞秒激光加工得到的MZI传感器的结构形式、折射率和温度等传感性能。重点阐述了飞秒激光加工MZI的研究现状和优点, 并对运用飞秒激光方法加工的MZI进行了总结和展望。

飞秒激光 全光纤MZI传感器 传感特性 Femtosecond laser All fiber MZI sensors Sensing performances

中南大学 高性能复杂制造国家重点实验室, 湖南 长沙 410083

随着光信息技术的发展, 长周期光纤光栅(LPFG)凭借其插入损耗小、传感灵敏度高, 体积小等优点, 广泛应用于光纤传感和光纤通信等领域, 成为最具有发展前途的光子无源器件。作为加工光纤传感器等重要功能器件的飞秒激光, 其在透明介质内部的三维结构加工上具有高峰值功率、热效应小等得天独厚的优势。介绍了采用飞秒激光刻写不同扭转周数的扭转型长周期光纤光栅, 并分析了其扭转特性。通过对比扭转2、4、6和8周的长周期光纤光栅的扭转调控实验结果, 发现8周的扭转型长周期光纤光栅在单方向上主谐振峰波长对扭转率的响应灵敏度达到了117.4 pm/(rad/m), 线性度达到了0.999 5, 波长调控范围约12.33 nm, 非常适合波长和带宽调控。实验研究了8周扭转型长周期光纤光栅的曲率特性, 发现这种方式下刻写的扭转型LPFG在大曲率(13)各个方向下, 光谱0°和180°相似, 90°和270°相似, 但是这两对光谱差异很大, 即该光栅依然有各向异性。

飞秒激光 扭转型长周期光纤光栅 扭转率 曲率 femtosecond laser twisted long period fiber grating torsion rate curvature