[1] National Bureau of Statistics. Statistical bulletin of the people’s Republic of China on national economic and social development in 2021[N]. China Information News, 2022-03-01(1).

国家统计局. 中华人民共和国2021年国民经济和社会发展统计公报[N]. 中国信息报, 2022-03-01(1). 10.1177/000944550103700211

[2] 池峰, 朱煜, 张志平, 等. 双频激光干涉测量中的环境补偿技术[J]. 中国激光, 2014, 41(4): 0408004.

Chi F, Zhu Y, Zhang Z P, et al. Environment compensation technologies in dual-frequency laser interferometer measurement system[J]. Chinese Journal of Lasers, 2014, 41(4): 0408004.

[3] Lee J Y, Jiang G G. Displacement measurement using a wavelength-phase-shifting grating interferometer[J]. Optics Express, 2013, 21(21): 25553-25564.

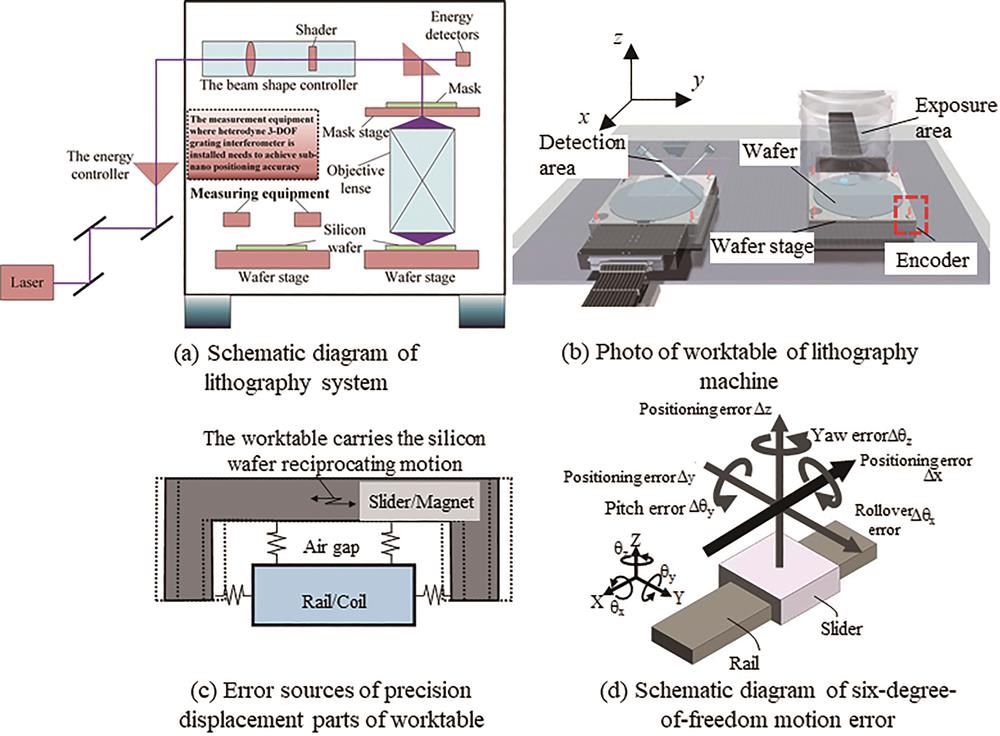

[4] Ye W N, Zhang M, Zhu Y, et al. Real-time displacement calculation and offline geometric calibration of the grating interferometer system for ultra-precision wafer stage measurement[J]. Precision Engineering, 2019, 60: 413-420.

[5] Bryan J B. The Abbé principle revisited: an updated interpretation[J]. Precision Engineering, 1979, 1(3): 129-132.

[6] Zheng F J, Feng Q B, Zhang B, et al. A method for simultaneously measuring 6DOF geometric motion errors of linear and rotary axes using lasers[J]. Sensors, 2019, 19(8): 1764.

[7] Straube G, Fischer Calderón J S, Ortlepp I, et al. A heterodyne interferometer with separated beam paths for high-precision displacement and angular measurements[J]. Nanomanufacturing and Metrology, 2021, 4(3): 200-207.

[8] LeachR. Abbe Error/offset[M]. CIRP encyclopedia of production engineering. Heidelberg: Springer, 2014. 10.1007/978-3-642-35950-7_16793-1

[9] Schmidt R H M. Ultra-precision engineering in lithographic exposure equipment for the semiconductor industry[J]. Philosophical Transactions. Series A, Mathematical, Physical, and Engineering Sciences, 2012, 370(1973): 3950-3972.

[10] Castenmiller T, van de Mast F, de Kort T, et al. Towards ultimate optical lithography with NXT: 1950i dual stage immersion platform[J]. Proceedings of SPIE, 2010, 7640: 623-634.

[11] YaoS X, DongX G, YuanW, et al. The study of overlay mark in self aligned double patterning and solution[C]∥2015 China Semiconductor Technology International Conference, March 15-16, 2015, Shanghai, China. New York: IEEE Press, 2015. 10.1109/cstic.2015.7153355

[12] IEEE. International Roadmap for Devices and Systems (IRDS) [EB/OL]. (2021-10-10)[2022-04-07]. https://irds.ieee.org/editions. 10.1007/978-3-030-18338-7_2

[13] van Herpen R, Oomen T, Kikken E, et al. Exploiting additional actuators and sensors for nano-positioning robust motion control[J]. Mechatronics, 2014, 24(6): 619-631.

[14] Voorhoeve R, de Rozario R, Aangenent W, et al. Identifying position-dependent mechanical systems: a modal approach applied to a flexible wafer stage[J]. IEEE Transactions on Control Systems Technology, 2021, 29(1): 194-206.

[15] Yang R D, Bi Y F, Zhou Q, et al. A background reduction method based on empirical mode decomposition for tunable diode laser absorption spectroscopy system[J]. Optik, 2018, 158: 416-423.

[16] Chen B Y, Zhang E Z, Yan L P, et al. A laser interferometer for measuring straightness and its position based on heterodyne interferometry[J]. The Review of Scientific Instruments, 2009, 80(11): 115113.

[17] 陈本永, 穆瑞珍, 周砚江, 等. 激光合成波长纳米测量干涉仪的非线性误差分析[J]. 中国激光, 2008, 35(2): 240-244.

Chen B Y, Mu R Z, Zhou Y J, et al. Nonlinear error analysis of laser synthetic-wavelength nanomeasurement interferometer[J]. Chinese Journal of Lasers, 2008, 35(2): 240-244.

[18] Gao W, Kim S W, Bosse H, et al. Measurement technologies for precision positioning[J]. CIRP Annals, 2015, 64(2): 773-796.

[19] Shimizu Y, Chen L C, Kim D W, et al. An insight on optical metrology in manufacturing[J]. Measurement Science and Technology, 2020, 32(4): 042003.

[20] Yu H Y, Chen X L, Liu C J, et al. A survey on the grating based optical position encoder[J]. Optics & Laser Technology, 2021, 143: 107352.

[21] Hu P C, Chang D, Tan J B, et al. Displacement measuring grating interferometer: a review[J]. Frontiers of Information Technology & Electronic Engineering, 2019, 20(5): 631-654.

[22] Gao W, Kimura A. A three-axis displacement sensor with nanometric resolution[J]. CIRP Annals, 2007, 56(1): 529-532.

[23] Kimura A, Gao W, Kim W, et al. A sub-nanometric three-axis surface encoder with short-period planar gratings for stage motion measurement[J]. Precision Engineering, 2012, 36(4): 576-585.

[24] Feng C, Zeng L J, Wang S W. Heterodyne planar grating encoder with high alignment tolerance, especially insensitivity to grating tilts[J]. Proceedings of SPIE, 2013, 8759: 87593L.

[25] Lee J Y, Chen H Y, Hsu C C, et al. Optical heterodyne grating interferometry for displacement measurement with subnanometric resolution[J]. Sensors and Actuators A: Physical, 2007, 137(1): 185-191.

[26] Wu C C, Hsu C C, Lee J Y, et al. Optical heterodyne laser encoder with sub-nanometer resolution[J]. Measurement Science and Technology, 2008, 19(4): 045305.

[27] Wu C C, Hsu C C, Lee J Y, et al. Heterodyne common-path grating interferometer with Littrow configuration[J]. Optics Express, 2013, 21(11): 13322-13332.

[28] de Vine G, Rabeling D S, Slagmolen B J J, et al. Picometer level displacement metrology with digitally enhanced heterodyne interferometry[J]. Optics Express, 2009, 17(2): 828-837.

[29] Yang H X, Yin Z Q, Yang R T, et al. Design for a highly stable laser source based on the error model of high-speed high-resolution heterodyne interferometers[J]. Sensors, 2020, 20(4): 1083.

[30] Yokoyama S, Yokoyama T, Araki T. High-speed subnanometre interferometry using an improved three-mode heterodyne interferometer[J]. Measurement Science and Technology, 2005, 16(9): 1841-1847.

[31] Fu H J, Ji R D, Hu P C, et al. Measurement method for nonlinearity in heterodyne laser interferometers based on double-channel quadrature demodulation[J]. Sensors, 2018, 18(9): 2768.

[32] Yokoyama S, Hori Y, Yokoyama T, et al. A heterodyne interferometer constructed in an integrated optics and its metrological evaluation of a picometre-order periodic error[J]. Precision Engineering, 2018, 54: 206-211.

[33] Teimel A. Technology and applications of grating interferometers in high-precision measurement[J]. Precision Engineering, 1992, 14(3): 147-154.

[34] Magnescale laser scale[EB/OL]. (2022-04-01)[2022-04-07]. https://www.magnescale.com/en/laserscale/. 10.54513/bsj.2022

[35] 王磊杰, 张鸣, 朱煜, 等. 超精密外差利特罗式光栅干涉仪位移测量系统[J]. 光学 精密工程, 2017, 25(12): 2975-2985.

Wang L J, Zhang M, Zhu Y, et al. A displacement measurement system for ultra-precision heterodyne Littrow grating interferometer[J]. Optics and Precision Engineering, 2017, 25(12): 2975-2985.

[36] 夏豪杰. 高精度二维平面光栅测量系统及关键技术研究[D]. 合肥: 合肥工业大学, 2006: 51-76.

XiaH J. Research on precise 2-D plane grating measurement system and key technology[D]. Hefei: Hefei University of Technology, 2006: 51-76.

[37] HEIDENHAINKGM282 grid encoder[EB/OL]. (2022-04-01)[2022-04-07]. https://www.heidenhain.com/products/testing-and-inspection-devices/testing-of-machine-tools. 10.1055/s-0029-1204845

[38] Li X H, Wang H H, Ni K, et al. Two-probe optical encoder for absolute positioning of precision stages by using an improved scale grating[J]. Optics Express, 2016, 24(19): 21378-21391.

[39] Shi Y P, Ni K, Li X H, et al. Highly accurate, absolute optical encoder using a hybrid-positioning method[J]. Optics Letters, 2019, 44(21): 5258-5261.

[40] Shi Y P, Zhou Q, Li X H, et al. Design and testing of a linear encoder capable of measuring absolute distance[J]. Sensors and Actuators A: Physical, 2020, 308: 111935.

[41] Lin C B, Yan S H, Du Z G, et al. High-efficiency gold-coated cross-grating for heterodyne grating interferometer with improved signal contrast and optical subdivision[J]. Optics Communications, 2015, 339: 86-93.

[42] Zhu Z B, Wu G H. Dual-comb ranging[J]. Engineering, 2018, 4(6): 772-778.

[43] Lin J, Guan J, Wen F, et al. High-resolution and wide range displacement measurement based on planar grating[J]. Optics Communications, 2017, 404: 132-138.

[44] 林杰, 关健, 金鹏, 等. 一种使用双频激光的三维光栅位移测量系统: CN103644848A[P]. 2014-03-19.

LinJ, GuanJ, JinP, et al. Three-dimensional grating displacement measuring system with dual-frequency laser: CN103644848A[P]. 2014-03-19.

[45] Hsieh H L, Pan S W. Three-degree-of-freedom displacement measurement using grating-based heterodyne interferometry[J]. Applied Optics, 2013, 52(27): 6840-6848.

[46] Gao W, Saito Y, Muto H, et al. A three-axis autocollimator for detection of angular error motions of a precision stage[J]. CIRP Annals, 2011, 60(1): 515-518.

[47] Li X H, Gao W, Muto H, et al. A six-degree-of-freedom surface encoder for precision positioning of a planar motion stage[J]. Precision Engineering, 2013, 37(3): 771-781.

[48] Li X H, Shimizu Y, Ito T, et al. Measurement of six-degree-of-freedom planar motions by using a multiprobe surface encoder[J]. Optical Engineering, 2014, 53(12): 122405.

[49] Lee C, Kim G H, Lee S K. Design and construction of a single unit multi-function optical encoder for a six-degree-of-freedom motion error measurement in an ultraprecision linear stage[J]. Measurement Science and Technology, 2011, 22(10): 105901.

[50] Hsieh H L, Pan S W. Development of a grating-based interferometer for six-degree-of-freedom displacement and angle measurements[J]. Optics Express, 2015, 23(3): 2451-2465.

[51] Yu K N, Zhu J H, Yuan W H, et al. Two-channel six degrees of freedom grating-encoder for precision-positioning of sub-components in synthetic-aperture optics[J]. Optics Express, 2021, 29(14): 21113.

[52] Lin C B, Yan S H, Wei C H, et al. Optimized design and error analysis of optical system for heterodyne grating interferometry[J]. Proceedings of SPIE, 2013, 9046: 90460C.

[53] Shimizu Y. Laser interference lithography for fabrication of planar scale gratings for optical metrology[J]. Nanomanufacturing and Metrology, 2021, 4(1): 3-27.

[54] WeiG. Precision nanometrology[M]. London: Springer, 2010. 10.1007/978-1-84996-254-4

[55] Jain K, Zemel M, Klosner M. Large-area high-resolution lithography and photoablation systems for microelectronics and optoelectronics fabrication[J]. Proceedings of the IEEE, 2002, 90(10): 1681-1688.

[56] Lu C, Lipson R H. Interference lithography: a powerful tool for fabricating periodic structures[J]. Laser & Photonics Reviews, 2010, 4(4): 568-580.

[57] Ma D H, Zeng L J. Fabrication of low-stray-light gratings by broad-beam scanning exposure in the direction perpendicular to the grating grooves[J]. Optics Letters, 2015, 40(7): 1346-1349.

[58] Ma D, Zhao Y, Zeng L. Achieving unlimited recording length in interference lithography via broad-beam scanning exposure with self-referencing alignment[J]. Scientific Reports, 2017, 7: 926.

[59] Shi L, Zeng L J, Li L F. Fabrication of optical mosaic gratings with phase and attitude adjustments employing latent fringes and a red-wavelength dual-beam interferometer[J]. Optics Express, 2009, 17(24): 21530-21543.

[60] Shi L, Zeng L J. Fabrication of optical mosaic gratings: a self-referencing alignment method[J]. Optics Express, 2011, 19(10): 8985-8993.

[61] Zhou H Y, Zeng L J. Optical mosaic method for orthogonally crossed gratings by utilizing information about both main periodic directions simultaneously[J]. Optics Communications, 2017, 385: 181-187.

[62] Li X H, Ni K, Zhou Q, et al. Fabrication of a concave grating with a large line spacing via a novel dual-beam interference lithography method[J]. Optics Express, 2016, 24(10): 10759-10766.

[63] Li X H, Zhou Q, Zhu X W, et al. Holographic fabrication of an arrayed one-axis scale grating for a two-probe optical linear encoder[J]. Optics Express, 2017, 25(14): 16028-16039.

[64] Li X H, Gao W, Shimizu Y, et al. A two-axis Lloyd's mirror interferometer for fabrication of two-dimensional diffraction gratings[J]. CIRP Annals, 2014, 63(1): 461-464.

[65] Li X H, Lu H O, Zhou Q, et al. An orthogonal type two-axis lloyd's mirror for holographic fabrication of two-dimensional planar scale gratings with large area[J]. Applied Sciences, 2018, 8(11): 2283.

[66] Li X H, Shimizu Y, Ito S, et al. Fabrication of scale gratings for surface encoders by using laser interference lithography with 405 nm laser diodes[J]. International Journal of Precision Engineering and Manufacturing, 2013, 14(11): 1979-1988.

[67] Xue G P, Lu H O, Li X H, et al. Patterning nanoscale crossed grating with high uniformity by using two-axis Lloyd’s mirrors based interference lithography[J]. Optics Express, 2020, 28(2): 2179-2191.

[68] Xue G, Zhai Q, Lu H, et al. Polarized holographic lithography system for high-uniformity microscale patterning with periodic tunability[J]. Microsystems & Nanoengineering, 2021, 7: 31.

[69] de Jong F, van der Pasch B, Castenmiller T, et al. Enabling the lithography roadmap: an immersion tool based on a novel stage positioning system[J]. Proceedings of SPIE, 2009, 7274: 608-617.

[70] Ye W N, Zhang M, Zhu Y, et al. Ultraprecision real-time displacements calculation algorithm for the grating interferometer system[J]. Sensors, 2019, 19(10): 2409.

[71] Kang H J, Chun B J, Jang Y S, et al. Real-time compensation of the refractive index of air in distance measurement[J]. Optics Express, 2015, 23(20): 26377-26385.

[72] Weichert C, Köchert P, Köning R, et al. A heterodyne interferometer with periodic nonlinearities smaller than ±10 pm[J]. Measurement Science and Technology, 2012, 23(9): 094005.

[73] Chen G H, Zhang L, Wang X J, et al. Modeling method of CNC tooling volumetric error under consideration of Abbé error[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(11/12): 7875-7887.

[74] Liu H W, Xiang H, Chen J H, et al. Measurement and compensation of machine tool geometry error based on Abbé principle[J]. The International Journal of Advanced Manufacturing Technology, 2018, 98(9/10/11/12): 2769-2774.

[75] 吴新朴, 韦怀坤, 刘正坤, 等. 用于检测光栅线密度的长程面形仪系统[J]. 光学学报, 2021, 41(6): 0612002.

Wu X P, Wei H K, Liu Z K, et al. Long trace profiler for measuring groove density of diffraction gratings[J]. Acta Optica Sinica, 2021, 41(6): 0612002.

[76] 高静, 焦东东, 刘杰, 等. 基于短光纤循环自外差法的激光线宽测量[J]. 光学学报, 2021, 41(7): 0712002.

Gao J, Jiao D D, Liu J, et al. Laser linewidth measurement based on recirculating self-heterodyne method with short fiber[J]. Acta Optica Sinica, 2021, 41(7): 0712002.

[77] 张博, 严利平, 刁晓飞. 波片阵列对准误差对激光干涉非线性误差的影响[J]. 中国激光, 2022, 49(9): 0904003.

Zhang B, Yan L P, Diao X F. Effect of alignment error of wave plate array on nonlinear error of laser interference[J]. Chinese Journal of Lasers, 2022, 49(9): 0904003.

[78] Gao W, Kimura A. A fast evaluation method for pitch deviation and out-of-flatness of a planar scale grating[J]. CIRP Annals, 2010, 59(1): 505-508.

[79] Xiong X, Shimizu Y, Chen X G, et al. Uncertainty evaluation for measurements of pitch deviation and out-of-flatness of planar scale gratings by a Fizeau interferometer in Littrow configuration[J]. Applied Sciences, 2018, 8(12): 2539.

[80] Quan L, Shimizu Y, Xiong X, et al. A new method for evaluation of the pitch deviation of a linear scale grating by an optical angle sensor[J]. Precision Engineering, 2021, 67: 1-13.

[81] Yang H X, Yang R T, Hu P C, et al. Ultrastable offset-locked frequency-stabilized heterodyne laser source with water cooling[J]. Applied Optics, 2017, 56(33): 9179-9185.

[82] Fu H J, Wang Y, Hu P C, et al. Nonlinear errors resulting from ghost reflection and its coupling with optical mixing in heterodyne laser interferometers[J]. Sensors, 2018, 18(3): 758.

[83] Fu H J, Wang Y, Hu P C, et al. Real-time compensation of nonlinearity in heterodyne interferometers based on quadrature demodulation and extremum operation[J]. Optical Engineering, 2020, 59(4): 044101.

[84] 郝义伟, 孔新新, 才啟胜, 等. 环形器噪声对激光干涉测量系统影响分析[J]. 光学学报, 2021, 41(9): 0912003.

Hao Y W, Kong X X, Cai Q S, et al. Analysis of effect of circulator noise on laser interferometry system[J]. Acta Optica Sinica, 2021, 41(9): 0912003.

[85] Cosijns S J A G, Haitjema H, Schellekens P H J. Modeling and verifying non-linearities in heterodyne displacement interferometry[J]. Precision Engineering, 2002, 26(4): 448-455.

[86] Yang Y, Deng Y, Tan Y D, et al. Nonlinear error analysis and experimental measurement of Birefringence-Zeeman dual-frequency laser interferometer[J]. Optics Communications, 2019, 436: 264-268.

[87] Wu C M, Lawall J, Deslattes R D. Heterodyne interferometer with subatomic periodic nonlinearity[J]. Applied Optics, 1999, 38(19): 4089-4094.

[88] Zhao S J, Wei H Y, Zhu M H, et al. Green laser interferometric metrology system with sub-nanometer periodic nonlinearity[J]. Applied Optics, 2016, 55(11): 3006-3011.

[89] Hu P C, Chen P, Diao X F, et al. Highly stable heterodyne interferometer without periodic nonlinearity[J]. Tm-Technisches Messen, 2014, 81(5): 246-254.

[90] Xing X, Chang D, Hu P C, et al. Spatially separated heterodyne grating interferometer for eliminating periodic nonlinear errors[J]. Optics Express, 2017, 25(25): 31384-31393.

[91] 邢旭, 常笛, 胡鹏程, 等. 空间分离式外差二自由度平面光栅干涉仪[J]. 光学 精密工程, 2019, 27(8): 1727-1736.

Xing X, Chang D, Hu P C, et al. Spatially separated heterodyne grating interferometer for in-plane displacement measurement[J]. Optics and Precision Engineering, 2019, 27(8): 1727-1736.

[92] Chang D, Xing X, Hu P C, et al. Double-diffracted spatially separated heterodyne grating interferometer and analysis on its alignment tolerance[J]. Applied Sciences, 2019, 9(2): 263.

[93] 胡鹏程, 谭久彬, 陈朋. 抗光学混叠的双频激光光栅干涉三维测量方法及系统: CN103604376B[P]. 2017-02-01.

HuP C, TanJ B, ChenP. Double frequency laser grating interference three-dimensional measurement method and system with optical aliasing resistance: CN103604376B[P]. 2017-02-01.

下载: 3401次特邀综述

下载: 3401次特邀综述