光子学报, 2023, 52 (12): 1214001, 网络出版: 2024-02-19

飞秒激光加工CVD单晶金刚石的烧蚀特征和机理研究

Ablation Characteristics and Material Removal Mechanism of CVD Single Crystal Diamond Under Femtosecond Laser Irradiation

飞秒激光烧蚀 CVD单晶金刚石 纳米条纹 烧蚀速率 石墨化 残余应力 温度场 Femtosecond laser ablation CVD single crystal diamond Nano-ripples Ablation rate Graphitization Residual stress Temperature field

摘要

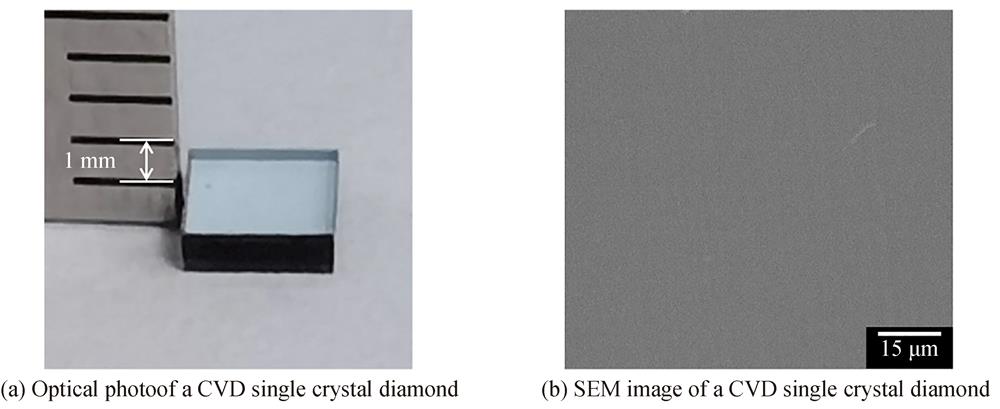

为探究飞秒激光烧蚀金刚石的烧蚀特征及机理,进行了飞秒激光加工CVD单晶金刚石实验及温度场仿真模拟研究。研究了飞秒激光能量密度、扫描速度、扫描次数对金刚石烧蚀区内纳米结构的影响。研究表明,金刚石被加工区域出现了沿着

Abstract

Diamond has a wide range of applications in the field of precision and ultra-precision machining of hard materials, high frequency and high voltage electronic devices, chip thermal management, and precision optics due to its extremely high hardness, excellent thermal conductivity, extremely high electron mobility, and wide-band optical transparency. Furthermore, it has been demonstrated that the preparation of microstructures on diamonds can significantly enhance the performance of diamond-based devices. However, it is difficult to efficiently prepare microstructures on diamond surfaces using conventional mechanical or chemical methods. Laser processing has become an advanced method to fabricate diamond microstructures due to its low cost, simple process, non-contact machining, high flexibility and high efficiency. Currently, most studies are focused on the optimization of processing parameters and the preparation of diamond microstructures. However, little attention has been paid to the effect of laser parameters on the micro/nano-structures in the laser-ablated area, and the material removal mechanism of the femtosecond laser processing diamond is not clear. Here, in this work, the effects of laser processing parameters such as laser fluence, scanning speed, and number of scans on the microscopic morphology of diamond microgrooves were investigated. The ablation threshold, ablation rate, and material removal rate of diamond processed by femtosecond laser were further obtained. Then the phase transformation of the diamond under femtosecond laser irradiation was analyzed through Raman detection. The effect of laser fluence on the Raman spectra which was detected at the central region of the diamond microgroove was further investigated. The residual stresses in the center of the diamond microgrooves under different laser fluences were calculated based on the wave number shift of the diamond peak. Finally, the temperature field of femtosecond laser-irradiated diamond was simulated using ANSYS finite element software, and the removal mechanism of diamond material was analyzed. It was found that femtosecond laser ablation of diamond microgrooves resulted in a clean surface and debris-free edges, but micro-cracks along the

汪晖, 温秋玲, 黄辉, 黄国钦, 姜峰, 陆静, 吴贤. 飞秒激光加工CVD单晶金刚石的烧蚀特征和机理研究[J]. 光子学报, 2023, 52(12): 1214001. Hui WANG, Qiuling WEN, Hui HUANG, Guoqin HUANG, Feng JIANG, Jing LU, Xian WU. Ablation Characteristics and Material Removal Mechanism of CVD Single Crystal Diamond Under Femtosecond Laser Irradiation[J]. ACTA PHOTONICA SINICA, 2023, 52(12): 1214001.