光学 精密工程, 2023, 31 (1): 99, 网络出版: 2023-02-09

单晶硅激光辅助超精密切削工艺优化与表面特性

Optimization of process parameters and surface characteristics in laser-assisted ultra-precision cutting of monocrystalline silicon

激光辅助超精密切削 单晶硅 工艺优化 表面粗糙度 面形精度 残余应力 透过率 laser assisted ultra-precision cutting monocrystalline silicon processing optimization surface roughness surface accuracy residual stress transmittance

摘要

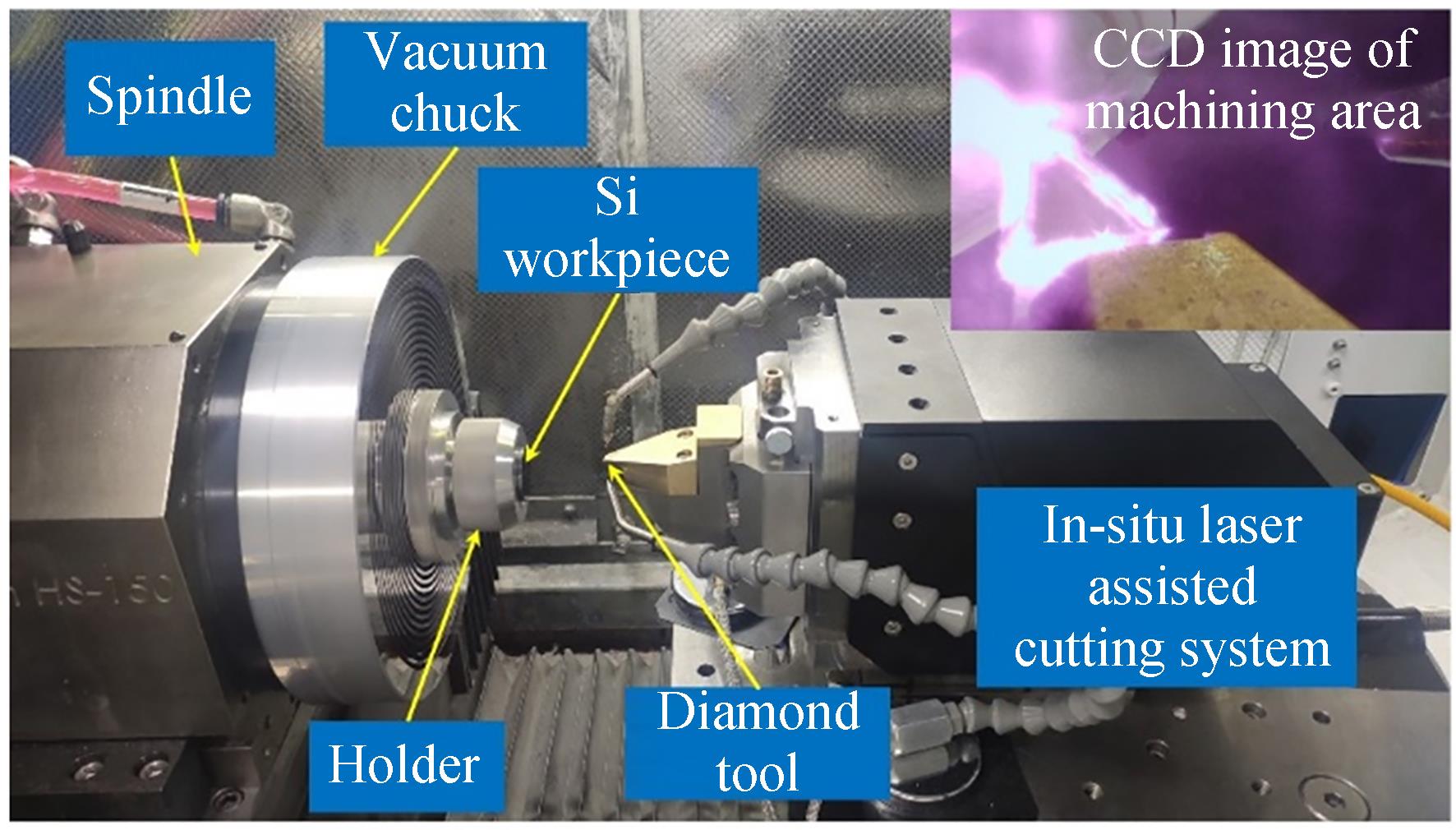

为了获得优化的单晶硅激光辅助超精密切削工艺,探究切削加工后单晶硅元件的表面特性,采用正交实验方法对单晶硅的激光原位辅助单点金刚石切削工艺参数进行优化,并对切削加工单晶硅表面质量、面形精度、残余应力和光学透过率等表面特性进行了测量与分析。通过正交实验数据的表面粗糙度方差分析和信噪比分析,获得的优化工艺参数组合为主轴转速为1 500 r/min、进给速率为5 mm/min、切削深度为3 μm、激光功率为4.5 W。采用上述工艺参数加工的165 mm口径单晶硅非球面光学元件的表面粗糙度和面形精度PV分别为2.74 nm和0.52 μm。激光辅助切削加工后的单晶硅表面存在(-1 760.8±362.1) MPa的残余压应力。激光辅助超精密切削加工的单晶硅光学元件在3~5 μm中红外波段镀膜前后的透过率分别为55%和98%,折射率为3.43。实验结果表明,激光辅助超精密切削技术可作为单晶硅光学元件的半精加工或最终精加工工序,以提升复杂面形单晶硅元件的制造效率。

Abstract

To achieve an optimized laser-assisted ultra-precision cutting process for monocrystalline silicon and to explore the surface characteristics of monocrystalline silicon components after cutting, the in-situ laser-assisted single-point diamond cutting process parameters of monocrystalline silicon are optimized by the orthogonal experimental method. Various parameters of monocrystalline silicon are measured and analyzed, such as surface quality and accuracy, residual stress, and optical transmittance. Through the variance analysis of the surface roughness and signal-to-noise ratio analysis of the orthogonal experimental data, the optimized process parameters are obtained as follows: spindle speed=1 500 r/min, feed rate=5 mm/min, cutting depth=3 μm, and laser power=4.5 W. The surface roughness and accuracy PV are 2.74 nm and 0.52 μm, respectively, for the 165 mm monocrystalline silicon aspheric optical lens processed with the above process parameters. After the laser-assisted cutting, there is residual stress of (-1 760.8±362.1) MPa on the monocrystalline silicon. The machined monocrystalline silicon's refractive index is 3.43, and the transmittance before and after the coating is 55% and 98%, respectively, in the common 3–5 μm mid-infrared band. The above research results show that laser-assisted ultra-precision machining technology can be used as the semi or final finishing process to improve the manufacturing efficiency of complex surface monocrystalline silicon lenses.

陈肖, 柯金洋, 佘中迪, 张建国, 许剑锋. 单晶硅激光辅助超精密切削工艺优化与表面特性[J]. 光学 精密工程, 2023, 31(1): 99. Xiao CHEN, Jinyang KE, Zhongdi SHE, Jianguo ZHANG, Jianfeng XU. Optimization of process parameters and surface characteristics in laser-assisted ultra-precision cutting of monocrystalline silicon[J]. Optics and Precision Engineering, 2023, 31(1): 99.