Application of nano-patterned InGaN fabricated by self-assembled Ni nano-masks in green InGaN/GaN multiple quantum wells

1 Introduction

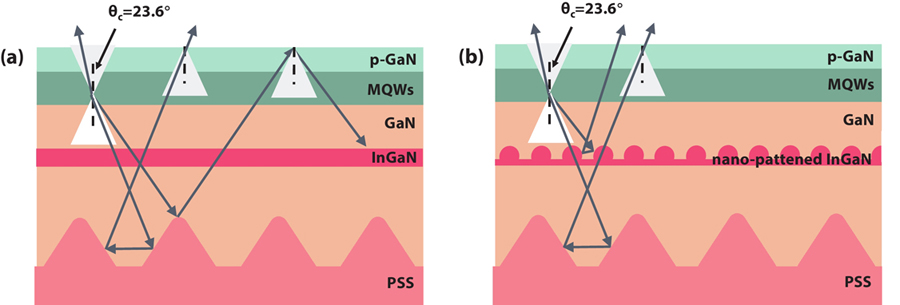

Since the first GaN-based blue light emitting diode (LED) was made by Shuji Nakamura in 1993[1], the LEDs based on Group III-nitride materials developed rapidly and were widely used. However, there has been no solution to the “green gap”, which describes the low efficiency of green LEDs, yet blue and red LEDs achieve relatively high efficiency luminescence[2,3]. One of reasons account for the above problem is the increase of indium component of InxGa1–xN/GaN multiple quantum wells (MQWs), while the increase is necessary to enable InGaN-based LEDs to be luminous with longer wavelengths. Green LEDs with high indium content InGaN QW suffer from deterioration of crystal quality caused by the lattice constants and thermal expansion coefficient mismatch between InGaN and GaN[4,5] as well as the low miscibility of InN in GaN[6]. Meanwhile, there generate numerous dislocations which act as nonradiative recombination centers[7], that is detrimental to luminescence. On the other hand, it is difficult for the light generated in active region to escape from high refractive index semiconductor (nGaN = 2.5) into air (nair = 1). The critical angle (θc) or escape cone for internal light is only ~ 23.6° [θc = sin−1(nair/nGaN)], photon emitted beyond this angle undergoes total internal reflection thus only a small fraction of light can escape to the surrounding air[8]. Green is one of the three primary colors, improving the luminous efficiency of green LEDs is the key to achieving high efficiency and high brightness RGB (red, green, blue) LEDs.

Many efforts have been put into the improvement of green LEDs. To improve the crystal quality of MQWs, some researchers chose to grow a buffer layer prior to the high indium content MQWs to alleviate the mismatch between InGaN and GaN. The InGaN layer with low indium component is reported that it can relieve strain in MQWs structure[9,10], decrease potential fluctuation and nonradiative recombination centers in InGaN QWs[11], and increase carrier localization degree in MQWs[12]. In addition, some efforts focus on the enhancement of light output. Useful techniques contain the use of patterned sapphire substrate (PSS)[13], designing chip shape[14], introducing air voids[15], and roughening the p-GaN surface[16,17]. The point is to offer opportunity for the photons generated within MQWs to find the escape cone by multiple scattering. Therefore, here we introduce a nano-patterned InGaN film into green MQWs structure to take advantage of alleviation role of the InGaN layer, simultaneously to utilize the rough nanometer surface to enhance light output.

In this paper, the self-assembled mask process was used, which utilized the heat shrinkage characteristics of metal to form a mask by annealing and eliminated the need for photolithography[18]. Green InGaN/GaN MQWs structures were grown on different nano-patterned InGaN films etched by self-assembled Ni nano-masks, as well as on unetched InGaN film for comparison. The effects of nano-patterned InGaN layer on crystalline quality and luminescence of green MQWs were investigated.

2 Experimental details

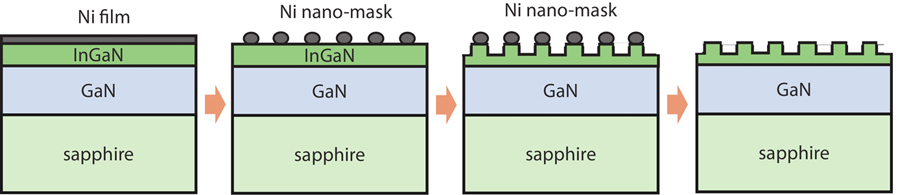

Samples were grown on cone-shaped PSS by metal-organic chemical vapor deposition (MOCVD). The base diameter, interval spacing, and height of the cones were 2.7, 0.3, and 1.7 μm, respectively. Firstly, a 3-μm-thick GaN was grown and a 100-nm-thick InGaN layer with 10% indium was followed. Ni thin layers of different thicknesses (1, 3 and 5 nm) were deposited on InGaN by E-beam evaporation. Then these Ni films were annealed through rapid thermal process at 750 °C for 2 min in N2 ambient, to form self-assembled metal nano-pellets. Using the formed Ni nano-pellets as the etching mask, InGaN layer was etched into nano-patterned film by reactive ion etching (RIE) with 40 sccm Cl2 etchant gas. The etching rate was about 8 nm per minute and the etching process maintained 10 min. After that, Ni nano-mask was removed by dipping the sample into hydrochloric acid. A simple schematic diagram of this whole process is shown in

Fig. 1. (Color online) Schematic representation of the process of preparing a nano-patterned InGaN layer by self-assembled Ni nano-masks.

The green MQWs structures were subsequently grown on the nano-patterned InGaN. First, a heating process was performed in an atmosphere of nitrogen, hydrogen and ammonia for 8 min to 800 °C, and then the GaN growth process begun. In the meantime, the temperature continued to increase until it stopped at 1050 °C. The green InGaN/GaN MQWs structure contained from bottom to top following as: (1) a 500-nm-thick unintentionally doped u-GaN; (2) a 2-μm-thick Si-doped n-GaN layer; (3) a 300-nm-thick lightly doped n–-GaN; (4) 9 pairs of green InGaN/GaN MQWs in which the thicknesses of InGaN well and GaN barrier were 2.5 and 14 nm, respectively; (5) a 35-nm-thick Mg-doped p-GaN grown at low temperature to protect active layer; (6) a 35-nm-thick p-AlGaN electron blocking layer doped with Mg; (7) a 100-nm-thick Mg-doped p-GaN layer and (8) a 5-nm-thick heavily doped p+-GaN contact layer. The MQWs structures grown on Templates I0, I1, I3, and I5 were named Sample M0, Sample M1, Sample M3, and Sample M5, respectively.

The surfaces of Ni nano-masks and nano-patterned InGaN films were displayed by scanning electron microscopy (SEM) (GeminiSEM 500). The surface morphology and crystalline quality of the green InGaN/GaN MQWs structure were identified using atomic force microscopy (AFM) (Agilent 5500) and high resolution X-ray diffraction (HRXRD) (Bruker D8), respectively. Photoluminescence (PL) measurement (LabRam HR800) as well as cathodoluminescence (CL) (Gahan MonoCL) were used to characteristic the luminescence of green MQWs structure.

3 Results and discussion

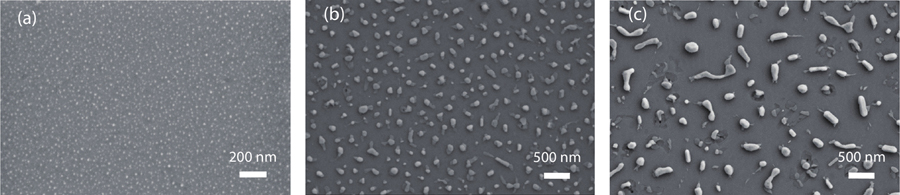

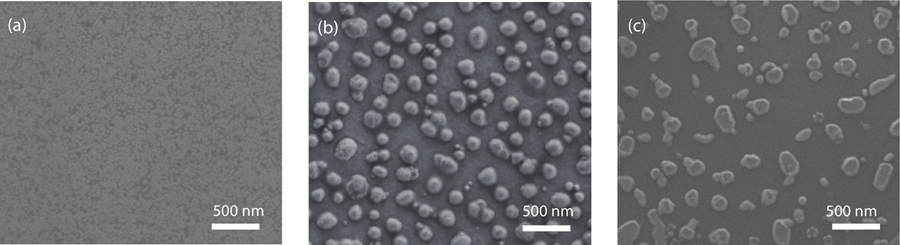

The SEM images of self-assembled Ni nano-masks after annealing process are shown in

Fig. 2. SEM images of the self-assembled Ni nano-masks using (a) 1 nm, (b) 3 nm, and (c) 5 nm deposited Ni film.

Fig. 3. SEM images of the nano-patterned InGaN of (a) Template I1, (b) Template I3, and (c) Template I5.

Table 1. The XRD FWHM of GaN at (002) and (102) plane and the dislocation density of samples.

|

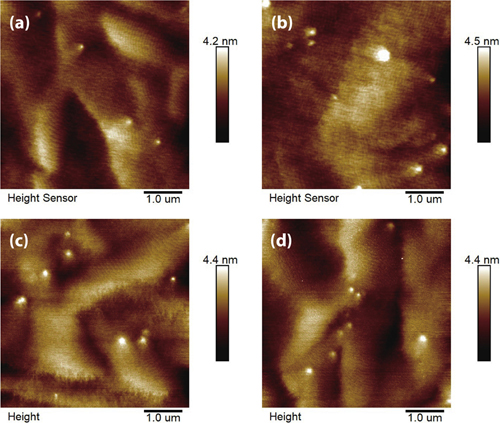

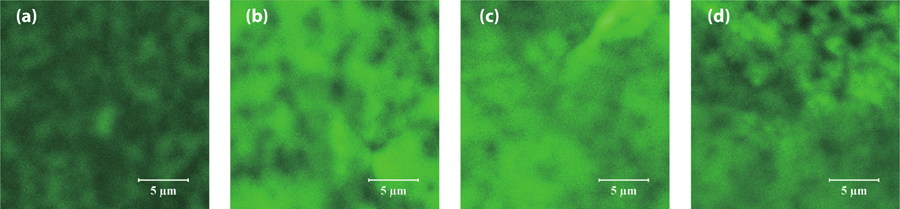

After the growth of green InGaN/GaN MQWs structures on Templates I0–I5, the surface morphologies are exhibited by AFM, as shown in

Fig. 4. (Color online) The 5 × 5 µm2 AFM images of green InGaN/GaN MQWs structures of (a) Sample M0, (b) Sample M1, (c) Sample M3, and (d) Sample M5.

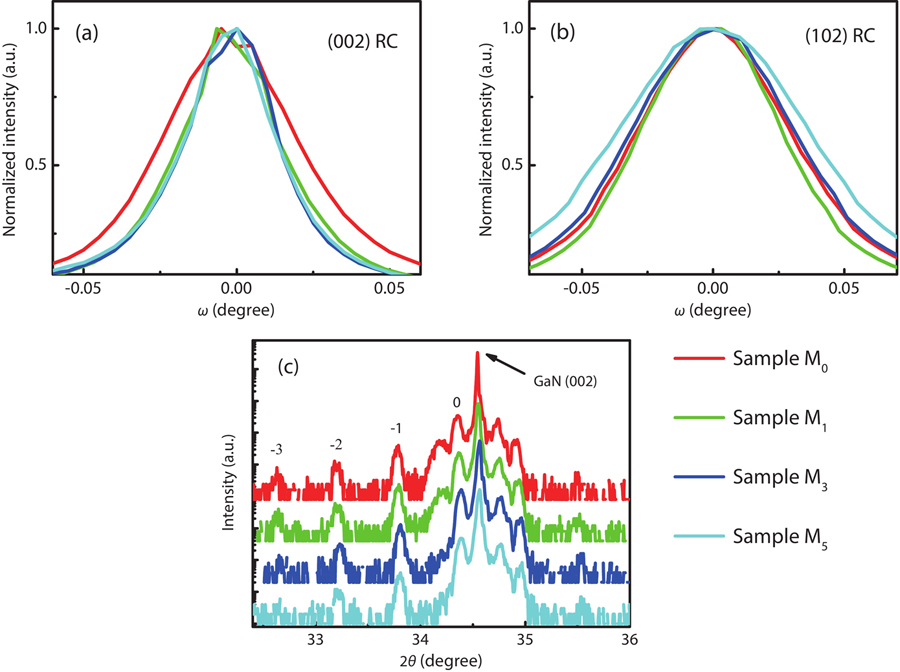

HRXRD is used to identify the crystalline quality. As we known, the full width at half maximum (FWHM) value of XRD rocking curve (RC) can characterize the dislocation density of crystal[21]. The GaN RCs of symmetric (002) and asymmetric (102) reflection for Samples M0–M5 are respectively shown in

Fig. 5. (Color online) XRD results of Samples M0–M5. (a) GaN (002) reflection RC. (b) GaN (102) reflection RC. (c) Spectra of (002) ω–2θ scans.

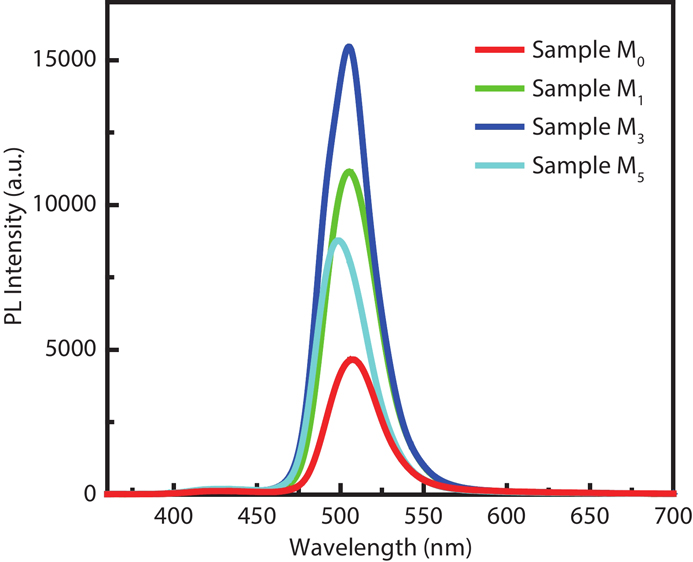

The PL spectra of green InGaN/GaN MQWs are revealed in

To visualize the enhancement of light output by nano-patterned InGaN, a schematic diagram of the light-emission path of green InGaN/GaN MQWs is shown in

Fig. 7. (Color online) Schematic diagram of the light-emission path of the green InGaN/GaN MQWs (a) with untreated InGaN film and (b) with nano-patterned InGaN film.

The CL mapping images of green MQWs are processed in a unified way of color and intensity range to facilitate comparison. The information of luminous intensity and luminous uniformity of samples can be obtained from the color shading and brightness distribution. From

Fig. 8. (Color online) CL images of (a) Sample M0, (b) Sample M1, (c) Sample M3, and (d) Sample M5.

4 Conlusion

In this article, the flat InGaN film and the nano-patterned InGaN film etched by self-assembled Ni nano-mask were introduced in green InGaN/GaN MQWs. Three different Ni nano-masks were formed by annealing thin Ni films of different thickness (1, 3, and 5 nm). Using these self-assembled Ni nano-masks in the etching process, the different nano-patterned InGaN films were obtained. No degradation of the surface morphology was observed in the samples grown on nano-patterned InGaN. When the pattern size was small, the nano-patterned InGaN film improved the crystalline quality of sample. However, when the nano-pattern reached a certain size, the crystal quality decreased instead due to serious etching damage. It was worth mentioning that the nano-pattern benefited light output by helping photons generated within the MQWs to find the escape cones. The MQWs structure using 3 nm thick Ni film as the etching mask was found to have the best luminescence of all samples, because the fact that it balanced effects of nano-patterned InGaN film on the crystal quality and the light output. For this sample the crystal quality did not deteriorate too much, and its nano-pattern was beneficial to the photon emergent.

Ruoshi Peng, Shengrui Xu, Xiaomeng Fan, Hongchang Tao, Huake Su, Yuan Gao, Jincheng Zhang, Yue Hao. Application of nano-patterned InGaN fabricated by self-assembled Ni nano-masks in green InGaN/GaN multiple quantum wells[J]. Journal of Semiconductors, 2023, 44(4): 042801.