非球面光学表面缺陷检测技术现状和发展趋势(特邀)  下载: 616次

下载: 616次

0 引 言

非球面光学元件指从元件的中心到边缘,曲率连续发生变化的元件[1-3],按照面形的不同,分为旋转对称和非旋转对称非球面[2],它可以满足一些理论上相互制约的设计需求,从而达到更高的成像质量,提高系统的整体实用性[4-10]。非球面光学元件因具有良好的光学性能而日渐成为一种十分重要的光学元件。

非球面光学元件作为光学元件中一个重要分支,广泛应用在航空航天、微电子装备、光学精密测量、激光光学等领域。光学元件在制造、清洗和运输等环节中,除了本身气泡暴露以及加工过程中不当操作,或者外在因素损伤,均可能形成表面缺陷。缺陷的存在会降低光束质量、破坏膜层、造成元件损伤[11-15],例如,美国国家点火装置(NIF)、法国兆焦耳激光装置以及我国研制的高性能高功率的神光系列装置等大型激光系统中涉及到的光学元件,如果出现一个微小的缺陷都可能导致灾难性的破坏,所以表面缺陷检测对工艺优化改进和系统质量控制至关重要[16-17]。激光光学、X 射线光学、微电子装备等先进光学系统性能不断升,驱动着缺陷检测技术及仪器不断发展,缺陷检测精度要求也随之提高。由于非球面面形复杂程度更高、制造工艺更为复杂,因此未来重点突破大口径、离轴、非球面度大的曲面超精密表面缺陷高精度定量检测,实现高精度、高分辨、多种方法交叉融合检测以及制造研发专用的检测设备仍是一项技术挑战。

文中回顾了非球面光学元件表面缺陷检测技术的发展历程,简述了表面缺陷的类型及标准,重点讨论了已有各类缺陷检测方法,分析对比了各检测技术的优缺点与适用范围、研究进展与应用情况,介绍了高精度表面缺陷检测仪器,从而展望了非球面表面缺陷检测技术的发展趋势。

1 光学元件表面缺陷类别、标准及检测方法

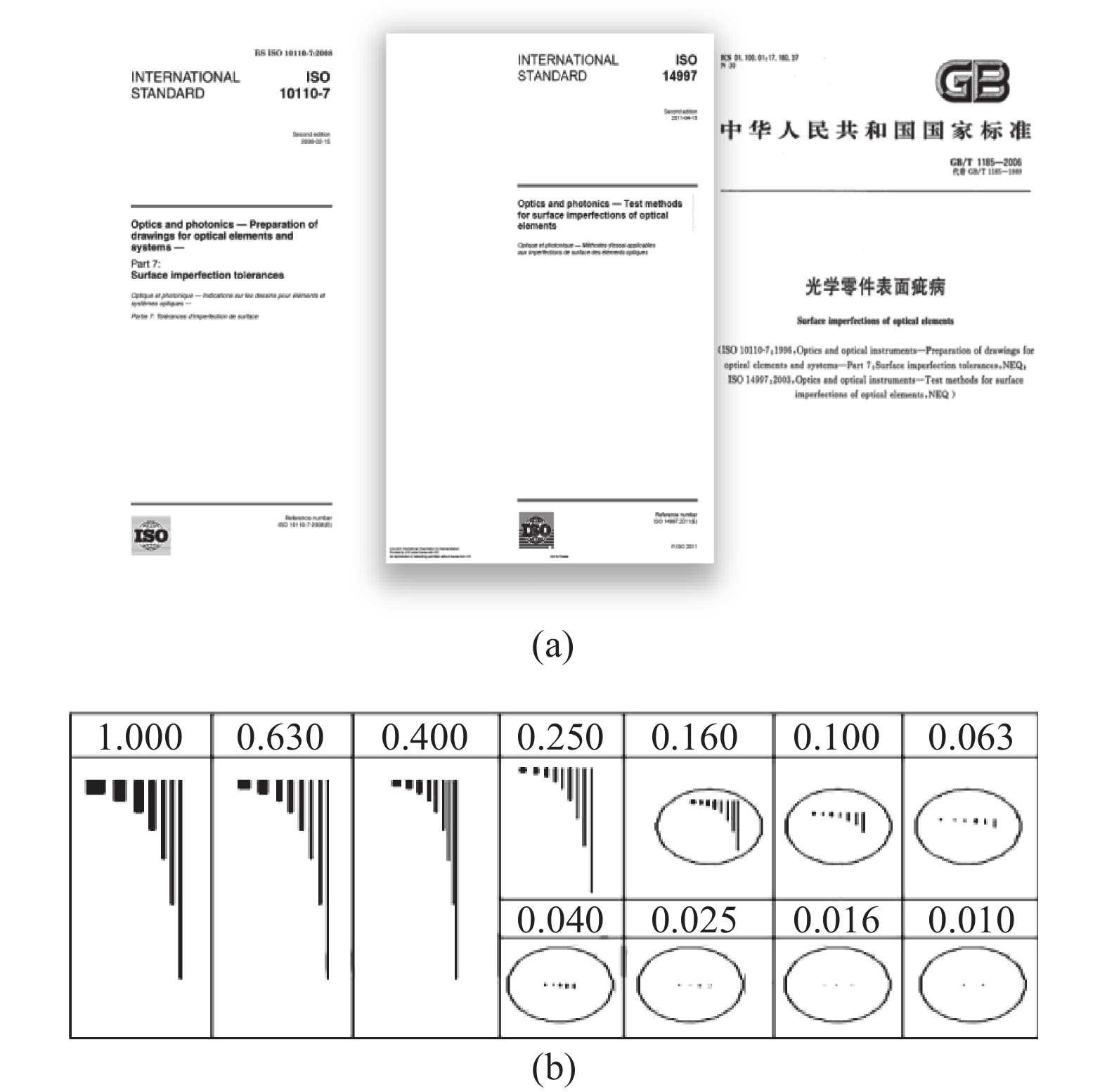

光学元件表面缺陷主要指表面疵病和表面污染物[18],表面疵病指在光学元件生产加工过程中,由于操作不当等原因产生的麻点、划痕、擦痕、破边、气泡等典型缺陷[19-21],见表1。为了对不同类型缺陷进行合理评价,很多国家和国际标准化组织都提出了相应的光学元件表面缺陷评价标准,主要有国际标准ISO 10110-7《光学和光学仪器光学零件和光学系统图样第7部分: 表面疵病公差》[22]、国家标准GB/T 1185—2006《光学零件表面疵病》[23]、美国军用规范MIL-PRF-13830 B《火控仪器光学零件制造、装配和检验通用技术条件》[24-25]。在这些主流的光学元件表面缺陷标准中,划痕和麻点为主要缺陷类别,缺陷标准及标准板图样见图1,最高要求为划痕宽度1 μm,麻点直径4.5 μm。根据这些标准,可以让不同检测人员间有相同检测依据,这在高精度光学元件缺陷检测,以及光学元件的生产、加工、制造中都极具科研意义。

表 1. 典型表面缺陷类型[12,22-29]

Table 1. Typical surface defect type[12,22-29]

| ||||||||||||||||||||||||||||

图 1. (a) 缺陷ISO、GB标准;(b) 缺陷标准板图样(划痕和麻点)

Fig. 1. (a) ISO, GB standards; (b) Defect standard plate drawings(scratches and digs)

光学元件表面缺陷检测是决定光学系统成像质量好坏的关键因素之一[30],目前,国内外研究机构对缺陷检测技术开展了大量研究,国外有针对性地在部分领域内搭建了专用设施系统,但关于惯性约束聚变、光刻等复杂系统的商业化应用还有待进一步研究。国内的部分高校及科研院所对缺陷检测方法进行了基础理论研究和应用验证,比如浙江大学实现了大口径光学元件表面疵病的自动评价,所研制的缺陷检测设备在神光系统中有所应用[31-34];中国科学院自动化研究所基于机器视觉、深度学习等手段进一步推动了视觉缺陷检测的进步与应用[35-38];中国科学院光电技术研究所针对中小口径平面元件研制的表面缺陷检测仪器精度达亚微米量级,曲面元件检测精度达微米量级[39-42];中国科学院上海光学精密机械研究所针对光学元件表面缺陷定量检测技术和仪器研制取得重要进展,检测口径可达米级[43-45];中国科学院长春光学精密机械与物理研究所对平面及曲面元件进行了表面缺陷检测实验研究,并搭建了相应的检测装置[46-49];成都精密光学工程研究中心[50-51]也进行了大量的测试研究和应用验证;部分公司对缺陷检测仪器进行了研制,比如合肥知常光电科技公司[52]基于显微成像和散射原理,研制了针对不同口径和面形的光学元件缺陷自动化检测装置,杭州晶耐科公司研制了小型超光滑、超光滑大口径、超光滑表面疵病数字化检测仪[53-55]。表面缺陷检测方法主要分为接触式和非接触式[56],如表2所示。接触式检测方法通常可以得到缺陷的三维信息,非接触式检测方法一般获得缺陷的二维信息,但也有部分方法可以得到缺陷三维信息。检测人员通常会采用增加显微镜放大倍率、提高照明光源亮度或改变照明条件等方式,实现对尺寸极其微小的缺陷的检测[57-58]。

表 2. 表面缺陷检测方法[59-174]

Table 2. Surface defect detection methods[59-174]

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 非球面表面缺陷检测方法分类

在现有表面缺陷检测方法中,由于使用条件的限制,并不是所有的方法都适用于非球面光学元件,在对非球面表面缺陷进行检测时,主要采用以下方法(见表3)。

表 3. 非球面表面缺陷检测方法[59-174]

Table 3. Aspheric surface defect detection methods[59-174]

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2.1 接触式非球面表面缺陷检测方法

接触式非球面表面缺陷检测方法需借助扫描探针式表面轮廓仪、原子力显微镜等进行检测[60]。扫描探针式表面轮廓仪通过探针在表面滑动扫描,表面形貌产生相应调制,得到元件表面缺陷的三维信息,具有测量精度高的优点,但触针易磨损、环境要求严苛、多用于长曲率半径的曲面光学元件[61-63]。原子力显微镜通过检测待测元件表面和探针针尖间极微弱的原子间相互作用力,得到悬臂产生的位移形变来对元件表面结构进行测量,该仪器检测精度高,不需对样品进行特殊处理,但成像范围小,速度慢,检测高陡度的曲面元件难度大[64-67]。接触式检测法可以达到纳米量级的纵向分辨率,但接触式与待测元件表面距离过短,容易造成二次损伤[68],部分研究人员对此进行了改进,天津大学提出光学针描法的测量技术,采用光触针代替机械触针[62];中国民航大学设计了光纤探针式轮廓仪,采用光纤探针检测待测元件表面[63];中国科学院北京电子显微镜实验室研制了检测镜面高频粗糙度的激光原子力显微镜[65-66];江西省科学院探测到纳米级表面微观缺陷[67]。虽然改进后造成的二次损伤减少,但仍存在检测成本高、效率较低的缺点,大尺寸、高陡度的曲面光学元件检测难度大。

2.2 非接触式非球面表面缺陷检测方法

从20世纪80年代开始,光学元件表面缺陷的非接触检测受到国内外学者的重视,经过多年研究,已经提出多种不同的检测技术和方法,主要采用光学法[69],具体可分为干涉法、衍射法和散射法[56],一些检测技术仅适用于理论研究或实验室研究,并不能在实际中得到应用,但也有部分机构单位研制出了光学元件表面缺陷的检测仪器和设备。

2.2.1 干涉法

干涉法是一种高精度的缺陷检测方法,它基于光波的干涉原理,见图2,通过干涉条纹的移动变化得到缺陷折射率的微小变量,从而对缺陷进行检测[70-73]。比如激光干涉轮廓仪、白光干涉仪等,通过选择不同的光源实现缺陷的三维检测。国内外的一些院校单位如美国WYKO公司[68]、北京理工大学[74]、浙江大学[75-76]及其他单位[77-83]采用干涉法对光学表面缺陷进行了检测,达到纳米量级的纵向分辨率和微米量级的横向分辨率,实现了快速、准确和可重复的表面缺陷三维检测。干涉法的优点在于可以检测出微损伤的深度信息,但干涉条纹会在微损伤处发生断裂,解调方法复杂,横向分辨率有限,大口径曲面元件检测难度大。

2.2.2 衍射法

衍射法[56]是指通过一束正入射的光照在待测元件表面,在透射表面得到衍射图样,根据衍射图样对缺陷信息做进一步分析。其中,最具代表性的是衍射图样法[84],见表4。美国的Klingsporn P E[85]、清华大学的武勇军等人[86]均实现了采用衍射图样法对缺陷进行检测。衍射图样法通常采用激光或相干性较好的平行光,能够同时检测出缺陷的种类和大小,但这种方法依靠衍射图样来确定缺陷的形貌,多适用于形貌规则的非球面表面缺陷,应用范围并不广泛。

表 4. 衍射图样法检测不同形貌缺陷[86]

Table 4. Detection of defects with different morphologies by diffraction pattern method[86]

|

2.2.3 散射法

缺陷会使元件表面产生折射率突变,表5中分别描述了同轴和离轴时的散射情况。当一束平行光入射到待测元件表面时,若表面存在缺陷,缺陷会使光线发生偏折变为散射光,从而相机可以看到呈现出的缺陷图案[87]。多数的缺陷检测方法都是基于缺陷的散射机理,德国弗劳恩霍夫协会Hauptvogel等人[88]证明即使是微弱缺陷也能采用光散射法精确检测,该方法在非接触、高效、灵敏地检测表面缺陷具有很高的潜力。在缺陷检测方面,浙江大学现代光学仪器国家重点实验室利用显微暗场散射成像技术配合子孔径扫描拼接,实现了1 000 mm×600 mm大口径平面光学元件表面疵病的自动评价;针对大口径非球面光学元件表面缺陷检测的对心、多位控制、数据处理等关键技术,实现了高精度、自优化、自动化检测;此外,该团队在表面缺陷基础上,将被检缺陷范围扩大到了亚表面缺陷以及体缺陷,对缺陷检测的成像、检测系统及仪器、图像处理算法、照明方式、双通道图像采集系统等方面取得了一系列的突破[84,89-95]。为了提高缺陷检测的效率、扩大缺陷检测的视场范围、减小检测仪器对待测元件的二次伤害,研究人员们不断寻找着非接触式的散射缺陷检测方法,主要分为成像法和非成像法[96]。

表 5. 不同方式下散射法检测表面缺陷原理

Table 5. Principle of surface defect detection by scattering method under different modes

|

2.2.3.1 非成像缺陷检测法

1988年,前苏联科学家格列波聂夫等人[97]根据接收到的缺陷散射光能量实现了表面缺陷检测。散射光能量分析法和激光频谱分析法是散射法中的非成像法(见表6),根据探测到表面缺陷所产生的散射光,对散射光能量的强度和分布进行分析,实现对缺陷的定量检测[49]。散射光能量分析法主要包括以标量散射理论为基础的全积分散射法和以矢量散射理论为基础的角分辨散射谱法[98],德国Fraunhofer IOF研究所研制了ALBATROSS-TT能够用于表面的散射测量,具有检测速度快,结构简单的优点,但检测结果并不直观,不能准确确定非球面缺陷的具体位置和形貌。激光频谱分析法在原理上比较严谨,但易受缺陷深层结构的干扰,检测精度较低,难以实现扫描效率和精度的平衡。

表 6. 非成像缺陷检测方法[98-109]

Table 6. Non imaging defect detection methods[98-109]

| ||||||||||||||||||||

2.2.3.2 成像法

国内外关于非球面光学元件表面缺陷定量化检测方法中,发展最为迅速和成熟的是散射成像法,如图3所示。

目视法是最为传统和应用最为广泛的典型成像法,检测人员在一定的照明条件下,通过人眼直接对非球面元件进行观察并判断缺陷,将待检元件表面上观察到的缺陷与缺陷标准板上的缺陷样本进行比对,从而实现缺陷的检测和分级。它因装置简单、成本低,目前在光学车间广泛使用,但这种方法的检测结果受限于人眼分辨能力和检测人员的主观判断,检测结果可靠性较低,数据传递和质量追溯较难,并不能够给出准确的非球面表面缺陷检测结果[49]。

为了提高目视法的观测灵敏度,在其基础上加入一个放大镜,形成了虚像叠加比较法[23,110]。将待检元件放置在放大镜的前焦点处,元件成正立的虚像,人眼直接观察所成的像,并将结果与标准板的样本作比较,从而对非球面缺陷进行评价,虽然精度相较于目视法有了一定程度的提高,但检测过程依旧利用人眼进行检测,仍会受主观判断的影响,存在着较大误差。

在直接散射的基础上,发展出了明场/暗场散射成像法[118]。平行光入射到待测元件表面后,缺陷会对入射光产生调制作用并得到散射像,变焦显微镜只采集在缺陷处产生的散射光,CCD采集散射像,进一步获得缺陷的信息[119]。为了进一步提高明场/暗场散射成像法的检测精度,国内外做了一些相关研究[120-125],如表7所示。明场/暗场散射法具有灵敏度高、精度高、分辨率高、对比度高的优点,能够有效地检测到非球面表面划痕、麻点等缺陷,区分深度达数nm量级的缺陷,实现了对光学元件表面缺陷的综合性检测。

表 7. 明场/暗场散射成像相关研究[44,49,120-125]

Table 7. Research on bright field /dark field scattering imaging[44,49,120-125]

|

随着光学传感器件的日益成熟和计算机图像技术的不断发展,以显微成像为代表的数字化检测法以其非接触、高分辨率、量化评估等优点成为了缺陷定量检测领域的重要手段。激光散射共聚焦显微法使用扫描器对非球面表面进行逐点扫描,将探测收集到的光束信号传输至计算机进行处理[56],相关研究(表8)[126-128]表明该方法可得到非球面表面缺陷位置和尺寸,成像精度高,分辨率高,是一种能够精确检测表面缺陷并适应超精密光学制造流程的有效手段,对曲面微米级甚至亚微米级尺度、几纳米到几十纳米深度微弱缺陷的检测是该技术的关键难点。

表 8. 激光散射共聚焦显微法相关研究[126-128]

Table 8. Research on laser scattering confocal microscopy[126-128]

|

2.2.3.3 条纹反射法检测非球面表面缺陷

条纹反射法作为一种高效检测非球面元件的成像法,在元件的三维形貌测量基础上,实现了对表面缺陷的三维检测。检测系统仅需显示屏、相机及计算机,如图4所示,LCD显示屏显示编码好的水平和垂直方向的标准条纹图,将条纹图投射到待测元件表面,若表面存在缺陷,反射条纹图会发生变形并被相机接收,通过相位解算及梯度积分重建,实现对表面缺陷的三维检测。

![条纹反射法。(a) 测量原理示意图[134] ;(b) 实验装置图[168]; (c) 检测流程图[135]](/richHtml/irla/2022/51/9/20220457/img_4.jpg)

图 4. 条纹反射法。(a) 测量原理示意图[134] ;(b) 实验装置图[168]; (c) 检测流程图[135]

Fig. 4. Fringe reflection method. (a) Schematic diagram of measurement principle[134]; (b) Diagram of experimental device[168]; (c) Flow chart of detection[135]

表面缺陷所引起的相位变化为[135]:

缺陷的深度信息S与变化角度

式中:p为条纹周期;

条纹反射法发展历程见图5,目前,采用条纹反射法检测非球面成为研究热点,许多高校和科研院所进行了大量研究,比如四川大学、南京理工大学、中国科学院光电所等。四川大学苏显渝、张启灿等人[144-153]对条纹反射法进行了大量研究,包括相位展开和三维形貌重建两个核心算法,所研究的方法和结果为缺陷三维检测提供了重要参考价值。光电所[135,154-155]、电子科技大学[156-160]、天津大学[161-166]等其他院校[134,167-171]进行了光学表面缺陷检测的研究,目前能够检测到亚微米级的缺陷深度。可见,条纹反射法分辨率较高,装置及操作简便,是表面缺陷三维检测中十分有潜力的手段,一次检测能够获得相位、梯度、缺陷尺寸等信息,实现了多通道检测(表9)。将条纹反射法应用到非球面元件表面缺陷三维检测中,为评价光学元件提供了更加可靠的参考依据。将机器视觉、神经网络等技术与条纹反射法相结合将会进一步优化检测过程,有效提高检测精度和效率,这具有重要的研究意义和价值。

表 9. 条纹反射法表面缺陷多通道检测[135]

Table 9. Multi channel detection of surface defects by fringe reflection method[135]

|

2.3 高精度表面缺陷检测仪器现状

为了实现缺陷的快速、自动化和数字化检测,国内外先后研制出了性能优异的光学元件表面缺陷检测仪器[38,52,175-177],见图6,这些仪器主要采用显微成像法或激光散射法。与平面光学元件相比,曲面元件(特别是非球面)缺陷检测技术和仪器仍处于发展阶段。国外所研制的曲面缺陷检测仪器比如美国Savvy Inspector TM SIL-4和德国DIOPTIC的ARGOS2主要用于检测平面和小相对口径曲面元件表面缺陷[175-177],德国弗朗霍夫研究所IOF研制的horos传感器可直接集成到光学制造过程中进行质量控制;近年来,国内也研制出多种规格的曲面缺陷检测仪器,其分辨率可达到微米级[52-55,177],目前主要处于优化改进和应用验证阶段。未来针对大口径大相对口径非球面光学元件表面缺陷的高分辨、高效率和高精度检测仍是重要发展方向。

![表面缺陷检测仪器[38,52,175-177]。 (a) 美国Savvy Inspector TM SIL-4; (b) 德国ARGOS2;(c) 德国horos; (d) 知常光电全自动缺陷检测系统; (e) 浙江大学大口径元件缺陷检测仪器; (f) 中国科学院自动化所大口径光学玻璃检测装置; (g) 中国科学院光电所表面缺陷检测装置](/richHtml/irla/2022/51/9/20220457/img_6.jpg)

图 6. 表面缺陷检测仪器[38,52,175-177]。 (a) 美国Savvy Inspector TM SIL-4; (b) 德国ARGOS2;(c) 德国horos; (d) 知常光电全自动缺陷检测系统; (e) 浙江大学大口径元件缺陷检测仪器; (f) 中国科学院自动化所大口径光学玻璃检测装置; (g) 中国科学院光电所表面缺陷检测装置

Fig. 6. Surface defect detection instruments[38,52,175-177]. (a) Savvy Inspector TM SIL-4; (b) ARGOS2; (c) horos; (d) Zhichang photoelectric automatic defect detection system; (e) Large aperture element defect detector of Zhejiang University; (f) Large aperture optical glass detection device of Institute of Automation, Chinese Academy of Sciences; (g) Surface defect detection device of Institute of Optics and Electronics, Chinese Academy of Sciences

3 非球面表面缺陷检测技术发展趋势

随着非球面光学元件在重大领域中广泛应用,国内外均对非球面缺陷检测技术进行了大量的研究和相关改进工作,包括基础理论研究、理论仿真分析、实验研究、原理样机研制和缺陷检测仪器研制,不断提高着检测的精度和效率。通过对非球面光学元件表面缺陷检测标准和检测方法归纳,可以看出表面缺陷标准和检测方法的发展趋势如下:

(1) 缺陷检测基础理论进一步完善。随着光学元件面形复杂度以及缺陷检测精度要求不断提高,对缺陷检测中的干涉、衍射、散射和显微成像等基础理论需要进一步更新和完善。

(2) 缺陷完整信息获取。对不同类型表面缺陷进行完整、准确检测;在缺陷二维信息基础上,精确获取缺陷的位置、尺寸、深度、微观形貌等三维信息。

(3) 缺陷标准进一步完善。目前常用标准规范仅能展示缺陷长度、宽度、面积等二维信息,并不能给出深度方面的标准,应扩展现有基于二维信息的缺陷检测标准,开发融合三维信息的缺陷数据库,以对缺陷进行完整客观的描述。

(4) 多传感、多方法融合检测。不同检测方法交叉融合,结合光机、传感技术、运动控制,融合先进光学、图像处理、深度学习等前沿学科相关方法,提高检测结果的可靠性、准确性。

(5) 缺陷检测综合性能再提升。在传统平面和小口径曲面缺陷检测基础上不断拓展应用场景,针对高复杂度的离轴、大偏离非球面表面缺陷检测,实现分辨率、重复精度、准确度、检测效率的进一步提升。

(6) 缺陷检测仪器装备集成创新发展。不断拓展缺陷检测应用场景,融合先进技术关键部件,根据不同需求实现在线、在位、离线等场景灵活部署,整个仪器发展实现集成化、系列化、柔性化、智能化。

4 结 论

文中介绍了光学元件表面缺陷的类型、标准、检测方法及高精度检测仪器,重点讨论了非球面元件表面缺陷检测方法,指出了各检测方法的优缺点及适用范围。由于存在非球面元件面形复杂以及检测仪器视场受限等难题,大口径超精密曲面光学元件表面缺陷的快速高精度定量检测仍是许多应用领域亟待突破的关键技术,建立高效、精密、自动化的检测设备仍需进一步研究。

[2] Zhang Xiaobing. Review on manufacture and measurement method of aspheric surface optical part[J]. Ordnance Material Science and Engineering, 2014, 37(2): 106-111.

[3] 王洪臣. 二次旋转曲面法线等距离线加工法及机床研制[D]. 长春理工大学, 2007.

Wang Hongchen. Development machine of tool machining method f rotated conicoid using nmal equidistance method [D]. Changchun: Changchun University of Technology, 2007. (in Chinese)

[5] 舒朝濂. 现代光学制造技术[M]. 北京: 国防工业出版社, 2008.

Shu Chaolian. Modern Optical Manufacturing Technology [M]. Beijing: National Defense Industry Press, 2008. (in Chinese)

[6] Li Chijuan, Sun Changfeng, Xi Zhe, , et al. Application of optical aspheric element[J]. Laser and Infrared, 2013, 43(3): 244-247.

[7] Li Shuping, Zhang Yu. Application of single point diamond turning in infrared optics[C]Proceedings of the 2016 International Symposium on Advances In Electrical, Electronics Computer Engineering, 2016.

[8] Luo Chi, Shi Feng, Tian Ye, et al. A combination process of magheological finishing computer controlled optical surfacing on singlecrystal silicon surface[C]International Symposium on Advanced Optical Manufacturing Testing Technologies (AOMATT), 2019.

[9] Karabyn V, Polák J, Procháska F, et al. Ion beam figuring with using Einzel lens[C]Optics Measurement 2019 International Conference, 2019, 11385: 1138508.

[10] Liao Wenlin, Dai Yifan, Nie Xuqing, , et al. Rapid fabrication technique for nanometer-precision aspherical surfaces[J]. Applied Optics, 2015, 54(7): 1629-1638.

[11] 孙丹丹. 精密表面缺陷特性及光学显微散射成像系统的研究[D]. 浙江大学, 2006.

Sun Dan. Study on the acteristics of precise surface defects optical micro scattering imaging system[D]. Hangzhou: Zhejiang University, 2006. (in Chinese)

[16] Rainer F. Mapping inspection of damage artifacts in largescale optics[C]Proceedings of SPIE, Laser Damage, 1998, 3244: 272281.

[17] 陈竹. 基于数字全息术的光学元件表面疵病三维形貌测量技术研究[D]. 中国工程物理研究院, 2017.

Chen Zhu. Research on threedimensional topography measurement of optical element surface defects based on digital holography [D]. Mianyang: Academy of Engineering Physics, 2017. (in Chinese)

[18] 楚红雨. 基于机器视觉的高功率激光装置光学元件表面缺陷检测技术研究[D]. 重庆: 重庆大学, 2011.

Chu Hongyu. Research on surface defect detection technology of high power laser device based on machine vision [D]. Chongqing: Chongqing University, 2011. (in Chinese)

[19] 中国机械工业联合会. GB 1185—1989 光学零件表面疵病[S]. 北京: 中国标准出版社, 1989.

[20] MIL013830 AB 光学零件表面疵病标准[S]. 美国国防部标准化局, 1994.

[21] Dimitrios Kosmopoulos, Theodora Varvarigou. Automated inspection of gaps on the automobile production line through stereo vision and specular reflection[J]. Computers in Industry, 2001, 46(1): 49-63.

[22] International Stard ganization. ISO 101107: 2008(E), Optics photonics preparation of drawings f optical elements systems Part 7: Surface imperfection tolerances [S]. Geneva: International Stard ganization, 2008.

[23] 中国国家标准化管理委员会. GBT 1185—2006, 光学零件表面疵病[S]. 北京: 中国标准出版社, 2007.

[24] U. S. Army. MILPRF13830 B Optical components f fire control instruments; General specification governing the manufacture, assembly, inspection of [S]. U. S. Army, 1997.

[25] 王丽荣. 美国军用规范 MIL-PRF-13830 B 表面疵病要求详解[J]. 硅谷, 2012(4): 181-182,193.

[26] Aikens D M, Bissinger H D. Overview of small optics f the National Ignition Facility [C]Proceedings of SPIE, 1999, 3782: 476487.

[27] 肖冰. 大口径光学元件表面疵病自动化检测系统关键问题讨论与研究[D]. 浙江大学, 2010.

Xiao Bing. Discussion research on key problems of automatic inspection system f surface defects of large aperture optical elements [D]. Hangzhou: Zhejiang University, 2010. (in Chinese)

[28] 米曾真. 基于数字图像处理技术的光学元件表面缺陷检测与分析[D]. 重庆大学, 2009.

Mi Zengzhen. Surface defect detection analysis of optical elements based on digital image processing technology [D]. Chongqing: Chongqing University, 2011. (in Chinese)

[29] Preston F W. The structure of abraded glass surfaces[J]. Transactions of the Optical Society, 1922, 23(3): 141-164.

[30] Wang Yuanqing. Measurement of surface flaw by grazing incidence[J]. Applied Laser, 1998, 18(2): 55-58.

[32] 李东明. 神光Ⅲ远场诊断系统光学设计及关键技术研究[D]. 浙江大学, 2004.

Li Dongming. Optical design key technology research of Shenguang Ⅲ far field diagnosis system [D]. Hangzhou: Zhejiang University, 2004. (in Chinese)

[33] 何志平. 激光多程放大系统杂散光分析[D]. 浙江大学, 2003

He Zhiping. Stray light analysis of laser multipass amplification system[D]. Hangzhou: Zhejiang University, 2003. (in Chinese)

[34] 曹频. 球面光学元件表面疵病评价系统中关键技术研究[D]. 浙江大学, 2015.

Cao Pin. Research on key technologies in surface defect evaluation system of spherical optical elements [D]. Hangzhou: Zhejiang University, 2015. (in Chinese)

[35] Tao Xian, Hou Wei, Xu De. A survey of surface defect detection methods based on deep learning[J]. Acta Automatica Sinica, 2021, 47(5): 1017-1034.

[36] Wang Dong, Li Wanyi, Sun Jia, , et al. Research of small parts’ surface defects inspection based on machine vision[J]. Applied Science And Technology, 2018, 45(4): 131-136.

[37] 陶显, 张正涛, 张峰, 等. 基于机器视觉的大口径光学元件表面损伤检测技术研究进展[C]第三十三届中国控制会议论文集(B卷), 2014: 12441249.

[42] 张文学. 光学元件缺陷在线检测技术研究[D]. 中国科学院大学(中国科学院光电技术研究所), 2020.

Zhang Wenxue. Research on online detection technology of optical element defects [D]. Chengdu: University of Chinese Academy of Sciences (Institute of Optics Electronics, Chinese Academy of Sciences), 2020. (in Chinese)

[43] Zhao Yuan’an, Shao Jianda, Liu Xiaofeng, , et al. Tracking and understanding laser damage events in optics[J]. High Power Laser and Particle Beams, 2022, 34(1): 61-72.

[44] 邵建达, 刘世杰, 董敬涛, 等. 高速激光线扫描的表面缺陷检测装置: 中国, 201610943020.1[P]. 20170222.

[46] 马天娇. 基于机器视觉的缺陷检测与识别方法研究[D]. 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2018.

Ma Tianjiao. Research on defect detection recognition methods based on machine vision [D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics Physics, Chinese Academy of Sciences), 2018. (in Chinese)

[47] 杨荟琦. 大口径球面非球面疵病检测仪结构设计及实验研究[D]. 中国科学院长春光学精密机械与物理研究所, 2017.

Yang Huiqi. Structural design experimental research of large aperture sphericalaspheric defect detect [D]. Changchun: Changchun Institute of Optics, Precision Mechanics Physics, Chinese Academy of Sciences, 2017. (in Chinese)

[48] Yang Huiqi, Li Xianling. Accuracy modeling and prediction of optical element surface defect detector[J]. Machinery Design and Manufacture, 2018(6): 98-101.

[49] 陈雪. 大口径高精度光学元件疵病检测关键技术研究[D]. 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2020.

Chen Xue. Research on key technologies f defect detection of large caliber high precision optical components [D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics Physics, Chinese Academy of Sciences), 2020. (in Chinese)

[50] He Xiang, Xie Lei, Zhao Heng, , et al. Characterization of polishing induced subsurface damages in fused silica optics[J]. High Power Laser and Particle Beams, 2016, 28(10): 151108.

[52] 合肥知常光电科技有限公司. 自动光学表面检测系统[EBOL]. [20200420]. http:www.zchightech.comprodetail14.

[53] 杭州晶耐科光电技术有限公司. 小型表面疵病数字化检测仪[EBOL]. [20200420]. https:www.china.cnqtzhuanyongyiqiyib3373780407.html.

[54] 杭州晶耐科光电技术有限公司. 大口径表面疵病检测仪[EBOL]. [20200420]. https:zernikeoptics.cn.china.cnsupply3373791501.html.

[55] 杭州晶耐科光电技术有限公司. 中型表面疵病数字化检测仪[EBOL]. [20200420]. https:Zernike optics.cn.china.cnsupply3373787172.html.

[57] Langer G, Langer A, Buchegger B, et al. Frequency domain optical resolution photoacoustic fluescence microscopy using a modulated laser diode[C]Proceedings of SPIE, BiOS, 2017, 10064: 1006426.

[59] 尹朝阳. 非球面光学元件表面微缺陷的自动化检测及修复系统研究[D]. 哈尔滨工业大学, 2020.

Yin Chaoyang. Research on automatic detection repair system of surface micro defects of aspheric optical elements [D]. Harbin: Harbin Institute of Technology, 2020. (in Chinese)

[60] Tian Xianghui, Song Dazhao, He Xueqiu, , et al. Surface microtopography and micromechanics of various rank coals[J]. International Journal of Minerals, Metallurgy and Materials, 2019, 26(11): 1351-1363.

[61] Han Zhiguo, Li Suoyin, Feng Yanan, , et al. Development of contact profilometer probe status inspection graphic sample block[J]. Micronanoelectronic Technology, 2019, 56(9): 761-765.

[63] Sun Junqing, Qiu Daoyuan. Theory and experiment of optical fiber probe profilemeter[J]. Journal of University of Electronic Science and Technology of China, 2003, 32(1): 35-38.

[64] Zhu Jie, Sun Runguang. Introduction to atomic force microscope and its manipulation[J]. Life Science Instruments, 2005, 3(1): 22-26.

[65] Qian Jianqiang, Gao Song, Yu Jin, , et al. Laser atomic force microscopy and its observation on the surface of optical materials[J]. Journal of Chinese Electron Microscopy Society, 1993(2): 198.

[66] Qian Jianqiang, Yu Jin, Gao Song, , et al. Laser atomic force microscope and its study on optical surface roughness[J]. Journal of Chinese Electron Microscopy Society, 1993(2): 200.

[68] Caber P J. Interferometric profiler for rough surfaces[J]. Applied Optics, 1993, 32(19): 3438-3441.

[69] Li Xiaozhou, Yu Huadong, Yu Zhanjiang, , et al. Optical inspection method for surface defects of micro-components[J]. Acta Armamentarii, 2011, 32(7): 872-877.

[70] Zhang Hongliang, Wang Qin. Interferometer and its application in optical detection[J]. Science and Technology Information, 2007(1): 79, 114.

[71] Liu Chen, Lu Rongsheng, Chen Lei, , et al. Research progress of surface roughness measurement based on optical method[J]. Semiconductor Optoelectronics, 2010, 31(4): 495-500.

[72] Chi Guichun, Zhou Zhaofei, Zhou Weidong. Development of laser interference profilometry[J]. Modern Scientific Instruments, 1996(4): 33-35.

[73] Wang Xuanyang, Chen Guang. Detection and control of surface defects of ultra smooth optical elements[J]. Optics and Optoelectronic Technology, 2018, 16(4): 52-57.

[74] Hao Qun, Ning Yan, Hu Yao. Interferometric testing of aspheric surface[J]. Metrology and Measurement Technology, 2018, 38(1): 1-8.

[75] Yang Yongying, Zhuo Yongmo, Xu Min. The system on real-time scanning and data treating of the double focus laser interference spherical profilometer[J]. Optical Instruments, 1994(z1): 26-33.

[76] Yang Yongying, Zhuo Yongmo, Xu Min. Laser double focus interference spherical micro profilometer[J]. Modern Scientific Instruments, 1995(4): 36-38, 40.

[77] You Zheng, Li Zhu. A non-contact light heterodyne profilometer[J]. Journal of Astronautic Metrology and Measurement, 1992(4): 17-21.

[78] Oh Jeong Seok, Kim Seung-Woo. Femtosecond laser pulses for surface-profile metrology[J]. Optics Letters, 2005, 30(19): 2650-2652.

[79] Deck L, de Groot P. High-speed noncontact profiler based on scanning white-light interferometry[J]. Applied Optics, 1994, 33(31): 7334-7338.

[80] David Grigg, Eric Felkel, John Roth, et al. Static dynamic acterization of MEMS MOEMS devices using optical interference microscopy[C]Proceedings of SPIE, 2004, 5455: 429435.

[81] Dai Rong, Xie Tiebang, Chang Suping. A vertical scanning white-light interfering profilometer[J]. Optical Technique, 2006, 32(4): 545 - 547, 552.

[82] 李萍. 基于白光干涉法的表面形貌评价和误差补偿[D]. 大连理工大学, 2021.

Li Ping. Surface topography evaluation err compensation based on white light interferometry [D]. Dalian: Dalian University of Technology, 2021. (in Chinese)

[83] Feng Hui, Wei Boxin, Liu Lusheng, , et al. Study on the application of white light interferometer in metal material surface testing[J]. Optics and Optoelectronic Technology, 2020, 18(6): 80-85.

[84] 王世通. 精密表面缺陷检测散射成像理论建模及系统分析研究[D]. 浙江大学, 2015.

Wang Shitong. Theetical modeling system analysis of scattering imaging f precision surface defect detection [D]. Hangzhou: Zhejiang University, 2015. (in Chinese)

[85] Klingsporn P E. Determination of the diameter of an isolated surface defect based on Fraunhofer diffraction[J]. Applied Optics, 1980, 19(9): 1435-1438.

[86] Wu Yongjun, Bai Wenxi. Defects inspection of optical, surface by recognizing laser diffraction patterns[J]. Optical Technique, 1996(4): 4-6.

[88] Hauptvogel M, Schröder S, Herffurth T, et al. Light scattering techniques f the acterization of optical components[C]International Conference on Space Optics, 2017, 10563: 1056347.

[89] Yang Yongying, Gao Xin, Xiao Bing, , et al. Optical micro imaging and digital evaluation system for super smooth surface defects[J]. Infrared and Laser Engineering, 2010, 39(2): 325-329.

[91] Yang Yongying, Zhuo Yongmo, Yang Mingjian. Optical profilometer for nondestructive testing of ultra smooth surfaces[J]. Opto-Electronic Engineering, 1999(6): 12-16.

[92] 张健浦. 熔石英光学元件亚表面体缺陷检测关键技术研究[D]. 浙江大学, 2020.

Zhang Jianpu. Research on key technologies of subsurfacebulk defect detection of fused silica optical elements [D]. Hangzhou: Zhejiang University, 2020. (in Chinese)

[93] 卢岸. 大口径光学元件亚表面缺陷双通道图像采集系统研究[D]. 浙江大学, 2021.

Lu An. Research on two channel image acquisition system f subsurface defects of large aperture optical elements [D]. Hangzhou: Zhejiang University, 2021. (in Chinese)

[94] 王悦. 光学元件亚表面缺陷检测自动调平与对焦研究[D]. 浙江大学, 2020.

Wang Yue. Research on automatic leveling focusing f subsurface defect detection of optical elements [D]. Hangzhou: Zhejiang University, 2020. (in Chinese)

[96] 李成瑞. 曲面光学元件表面缺陷检测技术研究[D]. 电子科技大学, 2020.

Li Chengrui. Research on surface defect detection technology of curved optical element [D]. Chengdu: University of Electronic Science Technology, 2020. (in Chinese)

[97] Greponev A, Grebinyuk E N, Wittman A Д, , et al. Automatic inspection of optical part defects[J]. Optical Technique, 1988(5): 20-22.

[98] Wang Lulu, Gao Aihua, Liu Weiguo, , et al. Angular resolution space laser scattering measurement system based on LabVIEW[J]. Optics and Optoelectronic Technology, 2018, 16(3): 40-45.

[100] Pezzaniti J L, Hadaway J B, Chipman R A, et al. Total integrated scatter instrument f inspace moniting of surface degradation[C]Proceedings of SPIE, 1990, 1329: 200210.

[101] Hou Haihong. Light scattering measurement method of optical surface[J]. Journal of Changshu Institute of Technology, 2008(8): 46-50.

[102] Stefan G, Jörg S, Angela D. Light-scattering measurements of optical thin-film components at 157 and 193 nm[J]. Applied Optics, 2002, 41(16): 3224-3235.

[103] Krč J, Zeman M, Kluth O, , et al. Effect of surface roughness of ZnO: Al films on light scattering in hydrogenated amorphous silicon solar cells[J]. Thin Solid Films, 2003, 426(1-2): 296-304.

[104] Guenther K H, Gruber H L, Pulker H K. Morphology and light scattering of dielectric multilayer systems[J]. Thin Solid Films, 1976, 34(2): 363-367.

[105] Bennett Jean M. Comparison of techniques for measuring the roughness of optical surfaces[J]. Optical Engineering, 1985, 24(3): 243380.

[106] Duparré A, Kassam S. Relation between light scattering and the microstructure of optical thin films[J]. Applied Optics, 1993, 32(28): 5475-5480.

[107] Amra C, Grezes-Besset C, Roche P, , et al. Description of a scattering apparatus: application to the problems of characterization of opaque surfaces[J]. Applied Optics, 1989, 28(14): 2723-2730.

[108] Elson J M, Rahn J P, Bennett J M. Light scattering from multilayer optics: comparison of theory and experiment[J]. Applied Optics, 1980, 19(5): 669-679.

[109] Zhang Xiao, Yang Guoguang, Cheng Shangyi, , et al. Laser spectrum analysis method of optical surface defects and its automatic detector[J]. Chinese Journal of Scientific Instrument, 1994(4): 396-399.

[110] Buchtel M E. Virtual image superposing comparat[C]Proceedings of SPIE, 1993, 1821: 130151.

[111] Baker L R. Inspection of surface flaws by comparator microscopy[J]. Applied Optics, 1988, 27(22): 4620-4625.

[112] Baker L R. Onmachine measurement of roughness, waviness, flaws[C]Proceedings of SPIE, 1990, 1333: 248256.

[113] Cormack R, Johnson K M, Zhang Lin, , et al. Optical inspection of manufactured glass using adaptive fourier filtering[J]. Optical Engineering, 1988, 27(5): 275358.

[114] 刘江. 球面及非球面表面疵病检测关键技术研究[D]. 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.

Liu Jiang. Research on key technologies of spherical aspheric surface defect detection [D]. Changchun: Graduate School of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics Physics), 2016. (in Chinese)

[115] Druy M A, Bolduc R A. Fiber optic noncontact reflectance probe f detection of contamination in pharmaceutical mixing vessels[C]Proceedings of SPIE, 1999, 3538: 167171.

[116] 马云. 光学元件位相缺陷的动态检测方法研究[D]. 南京理工大学, 2019.

Ma Yun. Research on dynamic detection method of phase defects of optical elements [D]. Nanjing: Nanjing University of Science Technology, 2019. (in Chinese)

[117] Choi W J, Ryu S Y, Kim J K, , et al. Fast mapping of absorbing defects in optical materials by full-field photothermal reflectance microscopy[J]. Optics Letters, 2013, 38(22): 4907-4910.

[118] 赵丽敏. 基于机器视觉的表面缺陷定量检测技术研究[D]. 浙江大学, 2016.

Zhao Limin. Research on quantitative detection technology of surface defects based on machine vision [D]. Hangzhou: Zhejiang University, 2016. (in Chinese)

[119] 卢国平. 大口径曲面光学元件检测系统及表面疵病图像处理研究[D]. 哈尔滨工业大学, 2018.

Lu Guoping. Research on inspection system of large aperture curved optical element surface defect image processing [D]. Harbin: Harbin Institute of Technology, 2018. (in Chinese)

[120] Truckenbrodt H, Duparre A, Schuhmann U. Roughness defect acterization of optical surfaces by lightscattering measurements [C]Proceedings of SPIE, 1993, 1781: 139151.

[121] Yamane T, Tanaka T, Terasawa T, et al. Phase defect analysis with actinic fullfield EUVL mask blank inspection[C]Proceedings of SPIE, 2011, 8166: 4.

[123] Wang Fanyi, Yang Yongying, Lou Weiming. Fast path planning algorithm for large-aperture aspheric optical elements based on minimum object depth and a self-optimized overlap coefficient[J]. Applied Optics, 2022, 61(11): 3123-3133.

[124] 张璇, 宋德林, 张涛, , 等. 光学表面微缺陷的高对比度暗场成像检测方法[J]. 机电技术, 2019(1): 86-87, 108.

[129] Lu S H, Hua H. Structured illumination assisted microdeflec-tometry with optical depth scanning capability[J]. Optics Letters, 2016, 41(17): 4114-4117.

[130] Sheehan L M, Kozlowski M R, Camp D W. Application of total internal reflection microscopy f laser damage studies on fused silica[C]Proceedings of SPIE, 1998, 3244: 282295.

[131] Temple P A. Total internal reflection microscopy: a surface inspection technique[J]. Applied Optics, 1981, 20(15): 2656-2664.

[132] Fähnle O W, Wons T, Koch E, , et al. iTIRM as a tool for qualifying polishing processes[J]. Applied Optics, 2002, 41(19): 4036-4038.

[133] Conder A, Alger T, Azevedo S, et al. Final optics damage inspection (FODI) f the National Ignition Facility[C]Preceedings of SPIE, 2007, 6720: 672010.

[134] 程洁. 基于条纹反射法的镜面物体表面缺陷无损检测技术研究[D]. 湘潭大学, 2019.

Cheng Jie. Research on nondestructive testing technology of surface defects of mirr objects based on fringe reflection method [D]. Xiangtan: Xiangtan University, 2019. (in Chinese)

[136] 满玉春. 基于数字莫尔条纹的非球面检测技术研究[D]. 中国科学院研究生院(长春光学精密机械与物理研究所), 2011.

Man Yuchun. Research on aspheric surface detection technology based on digital moire fringe [D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics Physics, Chinese Academy of Sciences), 2011. (in Chinese)

[137] Perard D, Beyerer J. Threedimensional measurement of specular freefm surfaces with a structuredlighting reflection technique[C]Proceedings of SPIE, 1997, 3204: 7480.

[138] Lei H, Seng N C, Asundi A K. Dynamic three-dimensional sensing for specular surface with monoscopic fringe reflectometry[J]. Optics Express, 2011, 19(13): 12809-12814.

[139] Petz M, Ritter R. Reflection grating method f 3D measurement of reflecting surfaces[C]Proceedings of SPIE, 2001, 4399: 3541.

[140] Knauer M C, Kaminski J, Hausler G. Phase measuring deflectometry: a new approach to measure specular freefm surfaces[C]Proceedings of SPIE, 2004, 5457: 366376.

[141] Bothe T, Li Wansong, von Kopylow C, et al. Highresolution 3D shape measurement on specular surfaces by fringe reflection[C]Proceedings of SPIE, 2004, 5457: 411422.

[142] Petz M, Tutsch R. Reflection grating photogrammetry: a technique f absolute shape measurement of specular freefm surfaces[C]Proceedings of SPIE, 2005, 5869: 58691D.

[143] Su Peng, Wang Shanshan, Khreishi Manal, et al. SCOTS: a reverse Hartmann test with high dynamic range f Giant Magellan Telescope primary mirr segments [C]Proceedings of SPIE, 2012, 8450: 84500W.

[144] Su Xianyu, Zhang Guanshen, Chen Zexian, , et al. Photoelectric automatic measurement system for three-dimensional surface shape of shoe last[J]. Optical Engineering, 1989(6): 1-5.

[145] Su Xianyu, Zhou Wensen, von Bally G, , et al. Automated phase-measuring profilometry using defocused projection of a Ronchi grating[J]. Optics Communications, 1992, 94(6): 561-573.

[146] Chen Z Y, Zhao W C, Zhang Q C, , et al. Shape measurement of stressed mirror based on stereoscopic phase measuring deflectometry[J]. Opto-Electronic Engineering, 2020, 47(8): 84-92.

[147] Su Xianyu. Three dimensional (digital) imaging based on the concept of equivalent light wave[J]. Journal of Optoelectronics·Laser, 2000, 11(3): 330.

[148] Tang Yan, Su Xianyu, Hu Song. Measurement based on fringe reflection for testing aspheric optical axis precisely and flexibly[J]. Applied Optics, 2011, 50(31): 5944-5948.

[150] Tang Yan, Su Xianyu, Liu Yuankun, , et al. 3D shape measurement of the aspheric mirror by advanced phase measuring deflectometry[J]. Optics Express, 2008, 16(19): 15090-15096.

[151] Tang Yan, Su Xianyu, Wu Fan, , et al. A novel phase measuring deflectometry for aspheric mirror test[J]. Optics Express, 2009, 17(22): 19778-19784.

[154] Zhao Wenchuan, Fan Bin, Wu Fan, , et al. Experimental analysis of reflector test based on phase measuring deflectometry[J]. Acta Optica Sinica, 2013, 33(1): 98-101.

[155] Zhu Cong, Yu Guangting, Li Bolin, , et al. A new method for measuring the surface defect width of precision optical lenses[J]. Computer Applications and Software, 2014, 31(12): 259-261, 286.

[156] 宋一平. 基于条纹反射的手机玻璃盖板三维面形检测方法研究[D]. 电子科技大学, 2019.

Song Yiping. Research on threedimensional surface shape detection method of mobile phone glass cover based on stripe reflection [D]. Chengdu: University of Electronic Science Technology, 2019. (in Chinese)

[157] Huang Yiyang, Wang Jie, Song Yiping, , et al. A novel defect detection method with eliminating dust for specular surfaces based on structured-light modulation analysis technique[J]. Optics and Laser Technology, 2021, 141: 107089.

[159] 周政. 基于相位测量偏折术的石墨烯光学表征方法研究[D]. 电子科技大学, 2019.

Zhou Zheng. Research on optical acterization of graphene based on phase measurement deflection [D]. Chengdu: University of Electronic Science Technology, 2019. (in Chinese)

[160] 吴雨祥. 基于光学三维成像的镜面物体表面质量检测方法研究[D]. 电子科技大学, 2017.

Wu Yuxiang. Research on surface quality detection method of mirr object based on optical threedimensional imaging [D]. Chengdu: University of Electronic Science Technology, 2017. (in Chinese)

[161] Sun Ying, Fu Luhua, Wang Zhong. A fast detection algorithm for ceramic ball surface defects based on fringe reflection[J]. Journal of Measurement Science and Instrumentation, 2020, 11(1): 28-37.

[162] 张恺. 陶瓷球表面缺陷视觉检测关键技术研究[D]. 天津大学, 2017.

Zhang Kai. Research on key technologies of visual inspection of ceramic ball surface defects [D]. Tianjin: Tianjin University, 2017. (in Chinese)

[163] Jiang Meihua, Fu Luhua, Wang Zhong, , et al. A new method for specular curved surface defect inspection based on reflected pattern integrity[J]. Journal of Measurement Science and Instrumentation, 2016, 7(3): 221-228.

[164] Song Yuhang, Wang Zhong, Fu Luhua, , et al. A method for detecting reflection fringes of surface defects on highly reflective surfaces[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(8): 1250-1254.

[165] Chen Mingzhou, Wang Zhong, Kou Xinyu, , et al. Non-contact nondestructive testing method of 3D curved surface based on vision technology[J]. Nondestructive Testing, 2001, 23(9): 372-374, 413.

[166] Jiang Shuo, Yang Linghui, Ren Yongjie, , et al. Defect detection in mirror-like object surface based on phase deflection[J]. Laser and Optoelectronics Progress, 2020, 57(3): 031201.

[167] Zhu Ronggang, Zhu Rihong, Song Qian, et al. Specular surface measurement based on fringe reflection study on 3D shape reconstruction technique[C]Proceedings of SPIE, 2013, 8769: 87692S.

[168] 袁婷. 基于条纹反射法的大口径非球面反射镜面形检测技术研究[D]. 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.

Yuan Ting. Research on the detection technology of large aperture aspheric surface reflection based on fringe reflection [D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics Physics, Chinese Academy of Sciences), 2016. (in Chinese)

[169] Wan Xinjun, Bin Boyi, Xie Shuping, et al. Development of an integrated freefm optics measurement system based on phase measuring deflectometry[C]Proceedings of SPIE, 2018, 10847: 1084710.

[170] Guo C F, Hu A D. Three-dimensional shape measurement of aspheric mirrors with null phase measuring deflectometry[J]. Optical Engineering, 2019, 58(10): 104102.

[171] Tao Tao, Guo Hongwei, He Haitao. Overview of optical three-dimensional measurement technique for specular reflection surfaces[J]. Optical Instruments, 2005, 27(2): 90-95.

[172] Zhao Wenchuan, Zhou Min, Liu Haitao, , et al. The off-axis aspheric mirror testing based on the fringe reflection technique[J]. Opto-Electronic Engineering, 2018, 45(7): 32-39.

[174] Duncan M, Bashkansky M, Reintjes J. Subsurface defect detection in materials using optical coherence tomography[J]. Optics Express, 1998, 13(2): 540-545.

[175] Savvy Inspect. Savvy Inspect Technical Specification[EBOL]. [20200420]. http:www.savvyoptics.comSavvyInspectTM.html.

[176] DIOPTIC. ARGOS–Optical surface inspection[EBOL]. [20200420]. https:www.dioptic.deenargosen.

[177] 杨甬英, 刘东, 谢世斌, 等. 可用于车间现场精密元件表面缺陷自动化检测的装置[C]第十五届全国光学测试学术交流会论文摘要集, 2014: 123.

Article Outline

李明泽, 侯溪, 赵文川, 王洪, 李梦凡, 胡小川, 赵远程, 周杨. 非球面光学表面缺陷检测技术现状和发展趋势(特邀)[J]. 红外与激光工程, 2022, 51(9): 20220457. Mingze Li, Xi Hou, Wenchuan Zhao, Hong Wang, Mengfan Li, Xiaochuan Hu, Yuancheng Zhao, Yang Zhou. Current situation and development trend of aspheric optical surface defect detection technology (invited)[J]. Infrared and Laser Engineering, 2022, 51(9): 20220457.

![成像法[23,30,49,56,134]](/richHtml/irla/2022/51/9/20220457/img_3.jpg)

![条纹反射法发展历程[136-153]](/richHtml/irla/2022/51/9/20220457/img_5.jpg)