激光融合制造及在柔性微纳传感器的应用(特邀)  下载: 734次特邀综述封面文章

下载: 734次特邀综述封面文章

With the increasing demands of internet-of-things and big data, flexible electronics have become a key technology. Among them, flexible micro-nano sensors, as an important part of flexible electronics, have revolutionized the physical form of conventional rigid devices. It has significantly facilitated the interconnections among human beings, machines, and environment, serving as a vital role for the advancement of intelligent electronics. For instance, embedding flexible micro-nano sensors in smart skins renders sensitive detection of external pressure and deformation, making them applicable in robotics and bionic hands. In biosensing applications, these sensors facilitate real-time monitoring of the internal micro-environment, drug release, and cellular activities. When applied in hand motion tracking and tactile feedback, they contribute to enhancing virtual reality interactions. It is envisioned that the emerging development of flexible micro-nano sensors will enable a new era of transformation within the industry.

Currently, a variety of commercial micro-nano manufacturing methods have been widely applied in micro-nano devices, including physical/chemical vapor deposition, photolithography, and nano-imprinting. However, the fabrication of multifunctional flexible micro-nano sensors often involves the combination of multiple manufacturing methods to achieve various tasks like sensitive material deposition, patterning, as well as generation of micro-nano structures. With the evolution of flexible micro-nano sensors towards miniaturization, integration, intelligence, and customization, the higher technical requirements are posed for the efficient multifunctional preparation of sensitive materials and the controllable fabrication of micro-nano structures.

Among various technologies available, hybrid laser fabrication based on laser additive, formative, and subtractive manufacturing, along with their combined processing modes, meets the heterogeneous requirements of multifunctional flexible micro-nano sensors in terms of multiple scales, dimensions, and materials. Leveraging its rich reaction mechanisms, flexible and controllable regulation, high-precision processing, and multi-material compatibility, it breaks through the limitations of traditional manufacturing technologies in multitasking, multithreading, and multifunctional combined processing. Based on laser and matter interactions, hybrid laser fabrication realizes cross-scale shape control and property control, which opens up a new path towards the integrated structure-material-function manufacturing of various flexible micro-nano sensors.

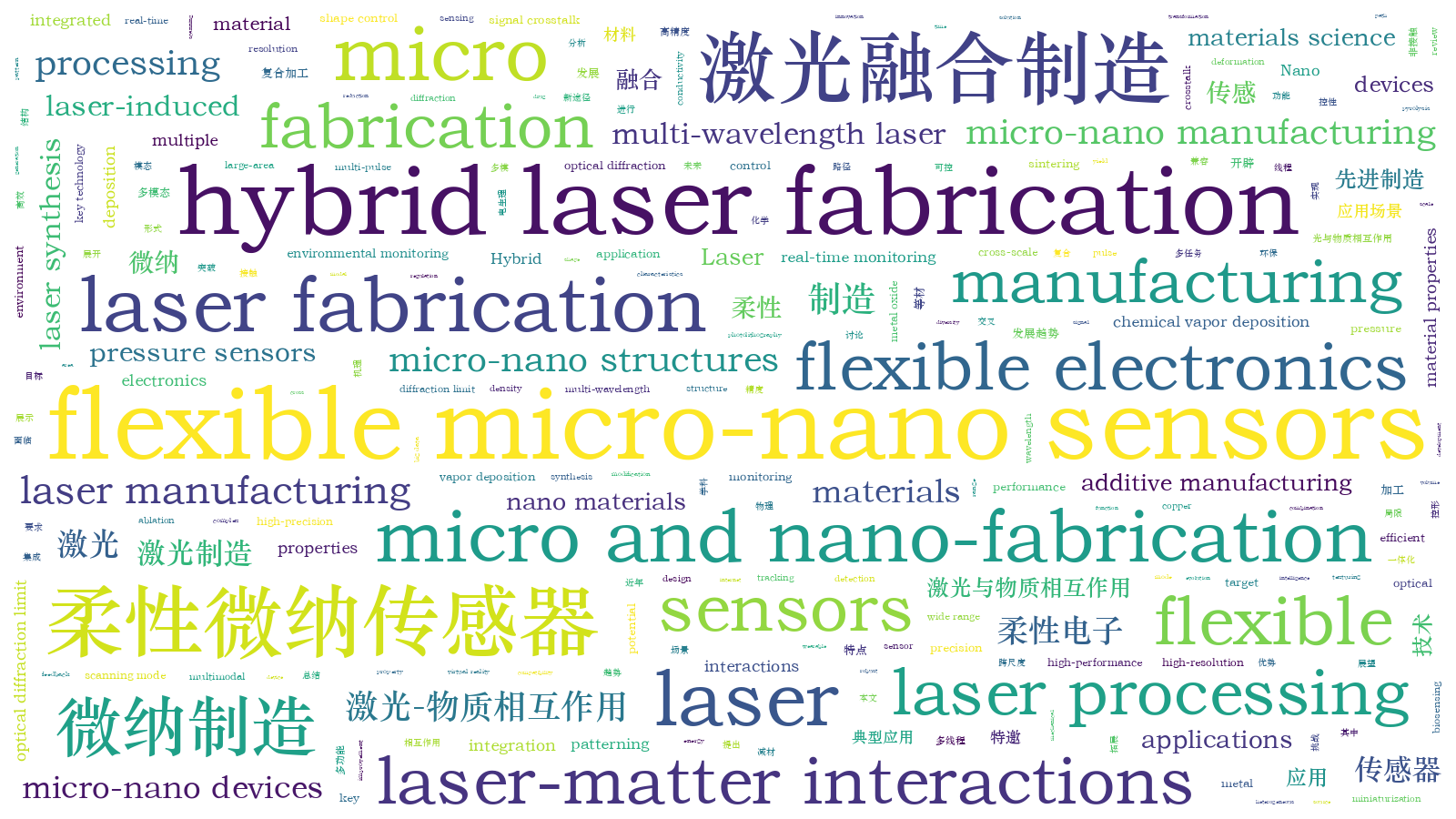

Several published review articles on “laser fabrication of flexible micro-nano sensors” are available, which mainly elaborate on laser synthesis of micro-nano materials and laser processing of micro-nano structures. This paper focuses on hybrid laser fabrication and discusses its application strategies in the realization of flexible micro-nano sensors from a global perspective. It sequentially introduces three laser-based manufacturing methods, including additive, formative, and subtractive fabrication. The processing mechanisms and typical target materials involved are discussed. The paper highlights the technical advantages and applications of hybrid laser fabrication in flexible micro-nano sensors (Fig.1).

In particular, based on different processing strategies of hybrid laser fabrication: (1) Laser additive manufacturing utilizes laser as a localized energy source to heat and melt nano-precursors, which accumulates layer by layer after sintering to form functional structures. Examples include laser reduction sintering of metal or metal oxide nano-inks such as copper, silver, and nickel (Fig.2). (2) Laser formative manufacturing refers to laser-induced interfacial reactions used to change the physical or chemical properties of materials, while almost maintaining their initial volume. This is typically used to regulate the conductivity or functionalize the properties of polymers (Fig.3). (3) Laser subtractive manufacturing mainly achieves pyrolysis, ablation, patterning, and micro-nano texturing of materials. For example, it is applied to enhance the performance of pressure sensors and fabricate high-resolution interconnect circuits (Fig.4). Rationally combining these three laser processing strategies makes it possible to deposit nano-materials, physicochemically modify sensitive media, and pattern and precisely form micro-nano structures in multifunctional devices. This makes it feasible for the multifunctional integration and versatile manufacturing of flexible micro-nano sensors, making it a potential alternative to traditional manufacturing methods.

Subsequently, this paper discusses some typical applications of hybrid laser fabrication in flexible physical, chemical, and electrophysiological sensors in recent years, as well as flexible multi-modal sensor systems. It comprehensively demonstrates a wide range of multifunctional applications in the fields of wearable healthcare, human-machine interactions, and environmental monitoring.

Hybrid laser fabrication involves multiple disciplines such as optical engineering, materials science, and mechanical manufacturing. Utilizing multi-pulse and multi-wavelength laser manufacturing systems, it judiciously integrates the characteristics of additive, formative, and subtractive processing, allowing efficient deposition of sensitive materials, modification of material properties, and precise preparation of micro-nano structures. This integration provides a robust solution for realizing high-performance flexible micro-nano sensors, overcoming the technical challenges of traditional methods. Nevertheless, there are still a couple of challenges to address for practical applications. First, the further improvement of precision is restricted by the optical diffraction limit, which hinders the manufacturing of high-density and highly integrated devices. Second, traditional laser processing mainly works through the point scanning mode, and the preparation of complex structures usually takes several hours or even longer, which greatly reduces the yield and cannot meet the needs of large-area or mass-processing. In addition, the diversity of target materials has posed a challenge for hybrid laser fabrication in relation to multimodal processing. Finally, in terms of device applications, overcoming signal crosstalk among different sensing units is a key issue in the design and fabrication of devices, given the potential of hybrid laser fabrication for the integrated processing of multifunctional sensors. In conclusion, hybrid laser fabrication is envisioned to accelerate the innovation of flexible micro-nano sensors and expand the application scenarios of laser processing.

1 引言

随着可穿戴设备、健康医疗、人机交互等领域的蓬勃兴起,柔性电子技术已成为驱动发展的关键技术之一。其中,柔性微纳传感器作为柔性电子技术的重要体现形式,颠覆了常规刚性器件的物理形态,极大促进了人-机-环境三元互联,是助力智能电子发展的重要力量。在智能皮肤中嵌入柔性微纳传感器,可以灵敏地感知外部压力和形变,常用于机器人、假肢等;在体内植入柔性微纳传感器,可以实现对体内微环境以及药物释放、细胞活动等的实时监测;将柔性微纳传感器应用于手部动作追踪、触觉反馈等方面,可以提升虚拟现实交互的真实感。当前,柔性微纳传感器是欧美日韩等发达国家竞相发展的技术。相比较而言,我国传感器产业发展较慢,高端产品主要依赖进口。因此,中国工程院发布的《全球工程前沿2020》将“柔性电子制造技术”和“可穿戴多功能集成传感器开发”列为TOP10工程研究前沿。中华人民共和国工业和信息化部印发的《基础电子元器件产业发展行动计划(2021—2023年)》聚焦产品高端提升,其中包括智能传感器、穿戴式设备、电子元器件柔性化和轻型化应用等。由此可见,柔性微纳传感器的新兴发展将赋能新一轮科技产业变革,同时驱动微纳制造技术日益精进。

目前,多种成熟的微纳制造工艺已被广泛应用于各类微纳器件的制造。物理/化学气相沉积法可以制备高性能器件,但通常需要特定环境和昂贵设备,在工业大规模生产方面存在一定挑战;纳米压印技术虽然能实现高分辨制造,但存在流程复杂与成本高昂等问题;印刷法在大面积制造方面具有工艺简单、成本低廉等优势,但通常需要掩模版,而且制造精度受限。另外,多功能柔性微纳传感器的构建通常涉及多种微纳制造工艺的复合联用,以便实现敏感材料沉积、图案化以及微纳结构制造等。当下,柔性微纳传感器正向小型化、集成化、智能化和定制化方向发展,这将对敏感材料的高效多功能制备和微纳结构的灵活可控制造提出更高技术要求。

本文提出“激光融合制造”这一概念,即基于激光增材、等材、减材加工及其复合加工模式来满足多功能柔性微纳传感器件在多尺度、多维度、多材料异构方面的制造需求。激光融合制造利用激光在时间、空间与能量等方面的多维特性与物质相互作用,并通过调控脉宽、波长、功率、频率和速度等工艺参数诱导材料发生熔融烧结、等体改性、热解烧蚀与刻写去除等物化现象[1-2],使其在激光辐照与扫描空间内形成具有宏、微、纳观多尺度的特定功能结构与物质,实现跨尺度“控形”与“控性”。激光融合制造凭借作用机理丰富、调控方式灵活、高精密加工、多材料兼容等特点突破了传统制造技术在多任务、多线程、多功能复合加工中的局限。此外,激光融合制造兼具非接触、成本低、效率高、可控性强、绿色环保与个性化定制等优势,为各类柔性微纳传感器的结构-材料-功能一体化制造提供了全新机遇[3-8]。

激光融合制造主要包括增材、等材与减材三种形式。激光增材制造,即利用激光作为局部能量源,将纳米前驱体材料加热熔融(还原),之后经烧结、累加、逐层堆积形成功能结构。铜、银、镍等金属或金属氧化物纳米油墨的烧结(还原)便属于激光增材制造。激光等材制造,即通过激光诱导界面反应,使材料在基本保持初始体量的同时改变其本征组织结构和物化特性。激光等材制造可用于调控聚合物材料的导电性能。激光减材制造,即主要对材料进行热解、烧蚀、图案化刻写与微纳结构制造,可用于增强压力传感器性能、实现高分辨互联电路制造等。通过上述三种激光加工形式的复合联用,能够同时实现纳米材料的堆叠沉积、敏感介质的物化改性、图案化与微纳结构的精细直写,使柔性微纳传感器的多功能集成与一体化制造成为可能[9-18],因而有望成为传统微纳复合制造工艺的替代方案。

通过激光融合制造工艺,目前国内外已实现多类柔性微纳传感器,主要包括柔性物理类传感(压力[19-20]/应变[21-23]、温度[24-25]、湿度[26-27]、流量[28]、姿态[29-31]、振动[32]、角度[33]等)、柔性化学类传感(唾液[34]、汗液[35-37]、呼吸[38-39]等)、柔性电生理传感(心电[40-43]、肌电[42-45]、脑电[42-43]等)以及多功能柔性传感集成系统[33,35,46-47]。在柔性物理传感方面,采用激光减材结合等材诱导改性可以低成本制备湿度传感器[48],通过综合利用激光作用下的高密度能量与强光热吸收,分别实现传感层图案化与敏感材料物态转变,赋予器件理想的湿敏特性。在柔性化学传感方面,利用多激光融合工艺可以实现气体传感器的一体化集成制备[49],过程包括电极制造(激光刻蚀)、纳米材料合成(激光沉积)和后镀(激光原位退火)。在柔性电生理传感方面,根据不同类型激光器的加工热效应差异,可以实现大面积可拉伸穿戴式肌电传感器阵列[50],其过程包含光-化学、光热等多种电子-光子反应机制,最终实现器件图案化刻写、堆叠层烧蚀和弹性体钻孔等。在柔性多模态集成传感方面,激光融合制造综合利用可见光的热效应与短脉冲紫外激光的冷加工依次实现材料沉积、图案化、过孔等功能,赋予器件“绘制”、“擦除”、多层互联等特性,促进了多功能皮肤电子系统的开发[51]。此外,基于激光增材、等材、减材加工的激光融合制造还可以用于实现柔性电路[52]/电极[53-54]、柔性加热器[55]、柔性光电探测器[56-58]、柔性储能设备[59-61]等多类柔性电子器件的一步式加工与系统集成。

目前已有多篇关于激光制造柔性微纳传感器的综述性文章[5,7-8,62],它们主要就激光合成微纳材料与激光加工微纳结构两方面进行阐述。本文聚焦激光融合制造,从全局视角讨论该工艺在柔性微纳传感器制造中的应用形式,依次介绍了激光增材、等材、减材三种制造方法,并重点分析其加工机理与典型目标材料,突出了激光融合制造在柔性微纳传感领域的技术优势与应用价值(

![基于激光增材、等材与减材加工的激光融合制造及其在柔性微纳传感器中的应用[32,35,51]](/richHtml/zgjg/2024/51/4/0402403/img_01.jpg)

图 1. 基于激光增材、等材与减材加工的激光融合制造及其在柔性微纳传感器中的应用[32,35,51]

Fig. 1. Laser hybrid fabrication based on laser additive, formative, and subtractive manufacturing and its applications in flexible micro-nano sensors[32,35,51]

2 激光增材制造

2.1 激光增材制造技术特点

利用激光作为高能量源,通过熔化和层压目标材料实现三维结构的逐层构筑,即为“激光增材制造”。迄今为止,基于激光加工的增材制造技术已与各类纳米材料实现良好兼容[63],如纳米颗粒(NP)[64-66]、纳米线(NW)[67-69]、纳米管(NT)[70-71]、纳米球[72]等。其中,激光烧结纳米前驱体作为一种快速制备连续导电结构的新路径,可直接在柔性可拉伸基材上形成功能层[73],目前已被广泛应用于电气互连[74-76]、感知元件[77-79]与加热器[80-81]等。本部分主要讨论激光烧结金属纳米油墨的机理(

![激光增材制造技术特点及典型目标材料。(a)激光烧结工艺流程简图[83];(b)激光烧结过程中金属纳米油墨变化过程示意图[83];(c)PI薄膜上的Cu电极(插图:显微图)[54];(d)PET基底上的Ni导电图案(插图:放大扫描电镜图)[55];(e)弯曲并共形附着的Ag NP基应变传感器(插图:导电迹线的光学图像)[23];(f)激光烧结Au NP薄膜的光学显微图(插图:放大扫描电镜图)[84];(g)激光数字印刷烧结的Zn NP基瞬态器件阵列和网格图案(插图:Zn迹线的光学图像)[85];(h)由沉积在柔性印刷电路板上的激光烧结LM NP薄膜组成的柔性可拉伸电子器件照片,其中激光烧结图案(浅灰色)用于在Cu走线和集成电路之间创建导线、电阻和电容器(插图:印刷和激光烧结的LM NP薄膜代表性区域的SEM图像)[74]](/richHtml/zgjg/2024/51/4/0402403/img_02.jpg)

图 2. 激光增材制造技术特点及典型目标材料。(a)激光烧结工艺流程简图[83];(b)激光烧结过程中金属纳米油墨变化过程示意图[83];(c)PI薄膜上的Cu电极(插图:显微图)[54];(d)PET基底上的Ni导电图案(插图:放大扫描电镜图)[55];(e)弯曲并共形附着的Ag NP基应变传感器(插图:导电迹线的光学图像)[23];(f)激光烧结Au NP薄膜的光学显微图(插图:放大扫描电镜图)[84];(g)激光数字印刷烧结的Zn NP基瞬态器件阵列和网格图案(插图:Zn迹线的光学图像)[85];(h)由沉积在柔性印刷电路板上的激光烧结LM NP薄膜组成的柔性可拉伸电子器件照片,其中激光烧结图案(浅灰色)用于在Cu走线和集成电路之间创建导线、电阻和电容器(插图:印刷和激光烧结的LM NP薄膜代表性区域的SEM图像)[74]

Fig. 2. Technical characteristics and typical target materials of laser additive manufacturing. (a) Schematic diagram of laser sintering process[83]; (b) schematic diagram of changes in metal nano ink during laser sintering process[83]; (c) Cu electrodes on PI film (inset: microscopic image)[54]; (d) Ni conductive patterns on PET substrate (inset: magnified SEM image)[55]; (e) flexible and conformally adhered Ag NP-based strain sensor (inset: optical image of conductive traces)[23]; (f) optical micrograph of laser-sintered Au NP film (inset: magnified SEM image)[84]; (g) Zn NP-based transient device array and grid pattern by laser digital printing and sintering (inset: optical image of Zn traces)[85]; (h) photograph of a flexible and stretchable electronic device composed of a laser-sintered LM NP film deposited onto a flexible printed circuit board, where the laser-sintered patterns (light gray) are used to create conductive traces, resistors and capacitors between Cu traces and integrated circuits (inset: SEM images of representative areas of the as-printed and laser-sintered LM NP film)[74]

此处以金属纳米颗粒为例,简要介绍激光选择性烧结金属纳米前驱体油墨的过程。如

激光烧结技术所产生的高强能量具有局域性特点,而且热效应持续短,可以降低局部热能累积和周围区域温升,不会对底层基材造成长时间、大面积损伤,特别适用于柔性聚合物基材。此外,激光烧结制备的金属导电基质与基材之间通常具有良好界面结合力,这源于基材表面被激光渗透热量部分熔化后冷却凝固,继而与金属薄膜形成互锁嵌合。目前,各种不同波长和脉宽的激光源已经实现了材料烧结[83]。

综上可见,激光烧结金属纳米油墨作为一种高效获得导电功能层的增材制造方法,可有效克服传统制造工艺存在的材料成本高昂、沉积工序繁琐、导电基质机械特性不足、基底兼容性差等问题。同时,随着激光制造系统的不断升级,纳米功能结构的最小特征尺寸日益精进,进一步拓展了该工艺的应用范围。

2.2 激光增材制造典型目标材料

金属纳米油墨是激光烧结制造导电功能结构的关键一环,常用的金属纳米油墨主要包括以下几类:1)单元素金属纳米油墨,如Au[84-85]、Zn[86]、Ag[87-89]、Cu[90-92]纳米油墨等;2)金属氧化物纳米油墨,如CuO[93-94]、NiO[95]、Cu2O[96]、ZnO[97-98]纳米油墨等;3)核壳双金属纳米油墨,如Cu-Ag纳米油墨[99]等;4)合金金属纳米油墨,如Cu-Ni合金纳米油墨[87]、Au-Ag合金纳米油墨[100]、液态金属(LM)合金纳米油墨[74]等。本部分主要介绍常见的适用于激光烧结技术的几种典型金属纳米前驱体油墨。

2.2.1 激光烧结CuO纳米油墨

在非贵金属中,Cu因具有可媲美贵金属的高导电性与优异成本效益而备受关注[101]。基于Cu纳米前驱体,可利用激光烧结技术完成熔融连接与图案化制造。然而,纳米级Cu的氧化势能(约为0.34 V)较低,很容易在常温环境下氧化,导致烧结时所需能量升高,从而降低了本征电导率。为解决这一问题,研究人员采用空气环境下稳定、成本低廉的CuO纳米前驱体,结合有机还原剂、分散助剂等制成纳米油墨,通过激光光热作用诱导化学还原-团聚烧结来高效制备Cu导体。

Kang等[54]报道了一种通过激光还原烧结工艺生成Cu电极的简易制造方法[

2.2.2 激光烧结NiO纳米油墨

尽管Cu作为Au、Ag等贵金属的替代品极具吸引力,但其在高温高湿环境与腐蚀性介质中容易氧化失效。相比较下,Ni具有较高的耐蚀性与耐温性,且色泽与Ag类似,适合用作电子器件导体、电化学器件集流器/催化剂、复合材料以及电镀金属等[73]。然而,目前关于激光烧结沉积Ni电极及其应用的报道尚且不多,人们通常选择NiO纳米材料用于激光增材制造,在光热作用下同时完成还原和烧结。

Lee等[82]基于NiOx NP油墨,利用激光快速图案化分别在玻璃和PI基底上制备出高分辨Ni电极。其中,油墨含有尺寸极小且分散均匀的NiOx NP,致使生成的导电基质层表面形貌光滑。此外,不同于常规油墨体系(以EG/PVP作为还原剂),NiOx纳米薄膜首先受激光辐照升温,引发薄膜中残留甲苯溶剂分解和NP中电子带间激发;随后甲苯分解产生的质子与NP提供的自由电子共同参与还原过程;最终,NiOx NP被还原至Ni NP后熔接成体,完成烧结。与之类似,Nam等[55]先通过化学沉淀法和预煅烧Ni(OH)2大规模合成NiOx NP,并配制获得油墨,随后采用激光(还原)烧结在PET基底上制备出Ni电极[

2.2.3 激光烧结Ag纳米油墨

Ag作为一种优良的电热导体,已被广泛应用于电子领域。尽管Ag的成本高昂,但其作为早期激光数字图案化的核心材料,凭借较好的氧化稳定性和优异的基材附着性,使用频率依然很高[63],而且由单元素Ag NP组成的油墨前驱体仍然是光热烧结制备高性能柔性金属透明导电薄膜、柔性应变传感器、贴片天线、射频识别(RFID)标签等的优先选择。

目前已有较多关于激光直写Ag纳米油墨制备电极图案与导电线路的研究报道。例如,Hong等[89]通过对Ag NP油墨进行选择性激光烧结,在柔性PET基材上制备出网格状透明导体,其具有较高透光率(>85%)和较低方阻(30 Ω·sq-1),可应用至触摸屏面板上,在连续机械应力下稳定工作。此外,快速激光烧结可以代替传统热退火工艺,在常温下对印刷Ag NP薄膜进行选择性沉积。Yang等[103]通过内外弯曲、拉伸、循环疲劳和黏附性测试重点探索了激光烧结纳米Ag膜的机械耐久性,以及其在不同高温、高湿条件下的环境稳定性,并与传统热退火Ag膜进行对比。结果表明,激光烧结Ag膜具有足够的机械可靠性,但若面向极端环境应用,仍需进一步优化其性能。Agarwala等[23]使用气溶胶预喷射打印Ag NP油墨,接着采用激光在低温绷带基底上热沉积Ag薄膜,以制造面向家居健康监测的可穿戴应变传感器[

2.2.4 激光烧结Au纳米油墨

Au是贵金属中资源稀缺、价格昂贵的代表性材料,虽然这一特性在一定程度上限制了其在大规模柔性电子领域中的应用,但研究人员仍然在实验和理论上对激光烧结Au纳米油墨工艺进行了广泛研究。

不断开发更小、更细、更紧密的组件是电子制造业的趋势。面对这一需求,Chung等[86]通过激光烧结固化Au NP油墨成功制备出电阻率接近块体金的微细线导体。该工作主要借助NP油墨制备和Au层对激光的吸收来实现油墨中溶剂的蒸发与Au NP的沉积。通过调节激光束光强的空间分布可以有效控制生成Au线的表面形貌和电学特性。Ko等[104]基于选择性激光烧结喷墨打印的Au NP油墨,开发出一种实现高分辨率有机场效晶体管的制造工艺。在激光与Au NP相互作用后的共振耦合效应下,局部激光烧结可以减小热影响区,有助于能量沉积,最终完成热敏聚合物基材上低成本、大面积柔性电子器件的制造。为替代电子元件的传统电镀方法,Yamaguchi等[84]基于预配制的Au NP浆料,采用激光烧结将Au膜沉积在镀镍磷青铜基材上[

2.2.5 激光烧结Zn纳米油墨

Zn具有适中的降解速率和良好生物相容性,被认为是典型的生物可吸收植入材料之一,且不会对环境造成二次污染。然而,近年来关于激光增材烧结Zn纳米材料的研究还处于探索阶段,其中大多数研究聚焦于可降解Zn的成形制造。

为了减小废弃电子垃圾对生态环境造成的危害,开发生物可降解电子器件成为一种有效解决方案。Shou等[85]通过密闭蒸发-冷凝介导的激光烧结制备出Zn NP薄膜,实现了一种低成本生物可吸收导体的制造。该工艺以Zn NP悬浮液为目标主体,利用激光进行高速扫描,以直接在接收基板上沉积出高结晶度Zn迹[

2.2.6 激光烧结LM纳米油墨

Ga基液态金属凭借其优异的机械顺应性在制造柔性应变传感器、柔性压力传感器、柔性加热器、柔性致动器和柔性天线等柔性电子器件方面具有广阔的应用前景[106-107]。然而,LM在环境中容易迅速形成表面氧化膜,屏蔽了其优良导电性,从而限制了它在电子学中的应用[108-109]。激光烧结技术可以有效破坏氧化层,使LM NP核受热凝聚,并通过图案化直写至薄膜基材中,以快速创建柔性数字电路和可拉伸电子器件。

基于上述思路,Liu等[74]利用激光烧结LM纳米油墨,制备出具有定制化电性能的电容器和电阻器、混合柔性电路和可拉伸电路[

3 激光等材制造

3.1 激光等材制造技术特点

通过激光作用引发物理/化学反应,实现对目标材料的改性、修饰即为“激光等材制造”。其中,基于激光加工的等材制造已被广泛用于诱导改性碳基前驱体(如激光诱导石墨烯LIG等),生成物具有良好的力学性能与优异的电化学特性,是柔性功能器件中最具前途的材料之一[111-112]。此外,激光诱导碳化产物可转印至弹性聚合物(PDMS、Ecoflex、SEBS等),进一步拓展了该技术在柔性可拉伸电子器件中的应用。因此,激光诱导改性可以面向实现柔性电极/电路的精细化加工和敏感材料感知层的个性化定制,同时能够最大限度减少原材料的使用、降低对环境的影响。本部分主要就激光诱导碳基前驱体生成石墨烯及其衍生物的过程和机理展开讨论(

![激光等材制造技术特点及典型目标材料。(a)不同波长激光制备无定形碳与LIG的示意图[119];(b)利用各种激光源和碳前驱体制备LIG的示意图;(c)激光碳化PI生成LIG过程中碳前驱体粒子的形态演变[120];(d)基于含碳的布料前驱体生成LIG及其衍生物[114,135];(e)基于含碳的纸张前驱体生成LIG及其衍生物[139-141];(f)基于含碳的食物前驱体生成LIG及其衍生物[114];(g)基于含碳的聚合物前驱体生成LIG及其衍生物[137,142-145];(h)基于含碳的木材前驱体生成LIG及其衍生物[146-148];(i)基于含碳的树叶前驱体生成LIG及其衍生物[11,149]](/richHtml/zgjg/2024/51/4/0402403/img_03.jpg)

图 3. 激光等材制造技术特点及典型目标材料。(a)不同波长激光制备无定形碳与LIG的示意图[119];(b)利用各种激光源和碳前驱体制备LIG的示意图;(c)激光碳化PI生成LIG过程中碳前驱体粒子的形态演变[120];(d)基于含碳的布料前驱体生成LIG及其衍生物[114,135];(e)基于含碳的纸张前驱体生成LIG及其衍生物[139-141];(f)基于含碳的食物前驱体生成LIG及其衍生物[114];(g)基于含碳的聚合物前驱体生成LIG及其衍生物[137,142-145];(h)基于含碳的木材前驱体生成LIG及其衍生物[146-148];(i)基于含碳的树叶前驱体生成LIG及其衍生物[11,149]

Fig. 3. Technical characteristics and typical target materials of laser formative manufacturing. (a) Schematic of fabrication of amorphous carbon (AC) and LIG with different wavelengths of laser[119]; (b) schematic of fabrication of LIG using various laser sources and carbon precursors; (c) morphological evolution of carbon precursor particles during laser carbonization of PI to LIG[120]; (d) generation of LIG and its derivatives from carbon-based cloth precursors[114,135]; (e) generation of LIG and its derivatives from carbon-based paper precursors[139-141]; (f) generation of LIG and its derivatives from carbon-based food precursors[114]; (g) generation of LIG and its derivatives from carbon-based polymer precursors[137,142-145]; (h) generation of LIG and its derivatives from carbon-based wood precursors[146-148]; (i) generation of LIG and its derivatives from carbon-based leaf precursors[11,149]

LIG技术自2014年经Tour团队[113]证实以来,便引起了国内外广泛关注。基于激光处理碳基前驱体材料诱导石墨烯及其衍生物的形成,为原位直写石墨烯基柔性电子器件提供了一种可行方案[114-119]。LIG的形成在很大程度上取决于激光光源和脉冲宽度[111]。根据波长不同,用于制备LIG的激光源可以分为紫外、可见光和红外三类[

接下来以PI为例,针对其向LIG转化过程中的碳前驱体粒子形态演变进行分析。如

综上,激光诱导碳基前驱体生成石墨烯及其衍生物作为一种典型的等材制造方法,将LIG合成和图案化一步融合,既避免了传统制造技术(如机械剥离、化学气相沉积、外延生长、还原氧化石墨烯)制备条件苛刻、化学处理繁琐、反应设备昂贵、生产效率低和能耗较高等缺点,又为进一步材料掺杂和结构功能化创造了可能[121-122],是一种灵活、可定制和可扩展的生产方式,已被成功应用于高性能柔性微纳传感器[123-128]、能源装置[129-131]、可穿戴设备[132-134]、智能服装[135-136]、智能组件[137-138]和绿色电子产品[139-149]等多功能电子领域。

3.2 激光等材制造典型目标材料

在早期研究中,只有PI、PEI和PAI等富含芳香族及酰亚胺重复单元的材料可以被激光诱导转化为LIG[115]。近年来,研究人员通过对LIG工艺进行大量探索发现,大多数含碳材料,如布料[135-136]、纸张[139,150-151]、食物[114-115]、聚合物[152-154]、木材[138]、树叶[149]等,在合适的激光加工参数下均可实现LIG制造。同时,碳源多样化也为回收废物再利用、开发功能电子器件开辟了一条新路径。本部分主要就几类典型碳基前驱物基底在激光等材诱导LIG中的应用展开介绍。

3.2.1 含碳布料前驱体

可拉伸、可穿戴式柔性电子器件备受欢迎,而具有编织结构的碳材料正逐渐成为一种研制新选择[155]。目前,开展激光诱导含碳布料前驱体的研究已成为国内外热点。

将多功能电子器件集成到服装布料中可以定制纺织电子产品,基于这一思路,Wang等[136]通过直接在Kevlar高分子织物上写入LIG,制备出一种正面为多孔石墨烯、背面为纤维结构的一体化自供电智能防护服,其兼具穿着舒适和检测有毒NO2气体的功能。在透气、灵活、高灵敏氮氧化物气体传感器制备方面,研究人员也进行了探索。例如,Yang等[135]基于激光等材工艺,将自组装嵌段共聚物(BCP)/树脂复合体经光热转化为高孔三维LIG泡沫,同时嵌入Ag NP进行修饰,在Kevlar等多种织物基底上获得了高性能柔性气体传感器(检测限低至10-9量级)[

在激光诱导富碳布料前驱体生成LIG方面,Tour团队发现可以利用多重激光处理将其先转化为无定形碳,随后再基于激光束重复照射逐渐实现石墨化。Chyan等[114]通过上述方法在经过预阻燃处理的纱布、平纹棉布、帆布、牛仔布和粗麻布上成功获得了LIG[

3.2.2 含碳纸张前驱体

纸张作为一种环保低成本基材,适用于可丢弃、可回收和环境友好型柔性电子产品(如摩擦发电机、纸基电池、超级电容器、传感器、执行器、微流控系统等[139-140])的制造。然而,传统的纸基电子系统主要通过蜡印、蒸发、光刻等方法沉积贵金属,大大增加了制造成本。为了充分利用纸张的可生物降解特性,探索绿色可持续循环的电子产品制造技术,基于激光诱导碳化纸基前驱体的工艺应运而生[150-151]。

清华大学研发团队[157]利用激光碳化在Nomex纸张表面制造出多孔石墨烯,并基于双面导通LIG在单个器件上同时实现了压力传感和高分辨发声。如

3.2.3 含碳食物前驱体

随着激光工艺的扩展,LIG图案可以在多种碳前驱体基材上生成[116],用于柔性、可生物降解甚至可食用电子产品的开发。目前已经能够在特定食物上制造LIG[

Tour团队发现含有木质素的碳前体在惰性气体或还原性受控气氛中可以通过激光处理转化为较高质量的LIG,这表明交联芳香结构有助于形成石墨烯。椰子壳、马铃薯皮等天然材料的木质素含量较高,即使在大气环境下加工,经脉冲激光多次直写碳化后也能转化为LIG[115]。Chyan等[114]在椰子壳表面制备出LIG微型超级电容器,该电容器具有较高的面电容。此外,基于食物基材的激光诱导碳化还可以扩展至面包[148]、柚子[158]等,所产生的功能性LIG在温度、湿度、紫外线、气体传感方面均可发挥作用[148]。

3.2.4 含碳聚合物前驱体

大多数含碳的高性能聚合物材料,包括热塑性、热固性和天然聚合物,在合适的激光条件及工艺参数下均有望转化为LIG[159]。PI作为热塑性聚合物的典型代表,在材料稳定性、耐高温和柔韧性等方面表现优异,也是早期LIG研究中最常用的碳源[115]。具体而言,商业PI膜经CO2激光处理后颜色由橙色变为黑色,对应拉曼光谱显示出以2700 cm-1为中心的突出二维峰,这表明生成了石墨烯结构[113]。

近年来,随着LIG制备技术的快速发展,其他常见聚合物,如PEEK[152]、PPS[153]、PSU[142]、PES[160]、PPSU[161]、PDMS[154]、PR[162]、PTFE[129]和光刻胶[163]等,均已被证明可以制备LIG,部分如

3.2.5 含碳木材前驱体

木材作为一种丰富的可再生、可回收自然资源,开发与之相关的生物降解、环保型木制电子产品将有助于减少日益增长的电子垃圾问题[165]。从木材中获得高导电性LIG可以激发未来多功能绿色电子器件的可持续发展[

研究表明,木质素含量高的木材所固有的交联纤维素结构比木质素含量低的木材更有利于生成高质量石墨烯。莱斯大学的Ye等[146]利用CO2激光在特定环境(室温常压、氩气或氢气保护气氛)下辐照松木,将其表面转化为良好的石墨烯导体(方阻≈10 Ω·sq-1)。他们发现此过程中隔绝氧气至关重要,这使得木材在被诱导改性的同时不发生燃烧,仅生成石墨烯泡沫皱状薄片,与木材表面紧密黏结。此外,通过改变激光强度还可以改变LIG的化学组成和热稳定性。

随着激光光源多样化和LIG技术精细化,Kim团队[11]在空气环境中采用超快高光子能量激光脉冲在天然木材上实现了高导电性石墨烯图案的一步式直写,并用于制备高能量密度超级电容器。该方法首先通过高重复频率的紫外飞秒激光脉冲将木材转变为中间焦炭,再通过直接光转化过程将其连续转化为LIG。由于热预算较低且烧蚀程度小,LIG在未经任何预处理的情况下能够直接在木材表面形成高分辨图案。

在集成应用方面,基于木材的LIG同样可以在智能家居中发挥作用。Nam等[138]展示了利用飞秒激光直写技术制造木源LIG电子单元。通过形成LIG基温度传感器、加热器等,可构建基于物联网的绿色木制家居智能组件。此外,该技术还可以用于机械组装木块上的互连线路/电极,其可作为低成本和可生物降解的绿色电线替代品。

3.2.6 含碳树叶前驱体

尽管木材基LIG在生产成本和生态友好性方面具有明显优势,但其制备条件普遍较为严苛,而且无法实现共形贴附。因此,寻找一种用于LIG合成的通用绿色前驱体成为了探索趋势。其中,树叶作为天然肥料的重要来源,具有资源丰富、绿色可再生、生物可降解等特点,它们大部分由生物矿物质组成,可作为生产三维纳米石墨烯的前驱体模板[

Le等[149]利用聚焦紫外飞秒激光束直接在空气环境中基于自然落叶制造出任意石墨烯图案。研究发现,叶片对紫外光具有高吸收率,因此紫外光是一种可将叶片中的天然生物矿物质转化为无机晶体的理想光源。该无机晶体可以作为介孔少层石墨烯生长的成核位点。在石墨化诱导过程中,利用重复激光脉冲的热量累积可以精确控制叶片基底温度,实现叶片有效碳化;利用超强激光脉冲的极高瞬时温度可以将非晶碳进一步转化为石墨碳。此外,超短激光脉冲还可以在加工辐照位点诱导超快加热速率,以促进石墨烯形成。利用以上技术制得的LIG-无机混合微电极具有优异导电性(方阻低至23.3 Ω·sq-1),可作为高性能柔性微型超级电容器(在5 mV·s-1下的面电容为34.68 mF·cm-2,在50000次充放电循环后的电容保持率约为99%),为LED或电子台钟供电。

4 激光减材制造

基于激光精确可控的热效应以及直接能量去除机制对材料进行图案化刻写/切割、烧蚀/热解和精细微纳结构制备即为“激光减材制造”。其中:激光刻写/切割可用于获得特定轮廓形状的图案和器件,尤其是小尺寸、微型化器件;激光烧蚀/热解可实现对材料的高效、高质量去除,实现精密微加工;激光微纳织构可跨尺度形成多级复合结构,并动态调控材料的界面性能(例如,激光诱导周期表面结构(LIPSS)技术相较于烧蚀工艺可以生成更为复杂的表面纳米结构)。本部分主要就激光对几种典型材料的热解、烧蚀、切割与LIPSS的减材过程及机理展开讨论(

![激光减材制造。热解:(a)基于激光背面扫描的高纵横比三维PDMS阵列结构[168];(b)由PDMS气动手指组成的软机器人手在无重力阻力状态下抓取物体的示意图[168]。烧蚀:(c)飞秒激光加工复合超疏水/亲水多微孔SERS基底并用于超痕量分子拉曼检测[170];(d)紫外激光刻写PDMS纹理化表面[32]。LIPSS:(e)飞秒激光诱导绝缘硅表面生成高度均匀可控的光子结构[191];(f)绝缘硅器件上高均匀亚波长光栅的三维形貌图(插图:扫描电镜图)[191]。切割:(g)紫外激光数字切割的可拉伸透明Kirigami电极[199];(h)激光辅助制造的Kirigami结构可拉伸应变传感器[200]](/richHtml/zgjg/2024/51/4/0402403/img_04.jpg)

图 4. 激光减材制造。热解:(a)基于激光背面扫描的高纵横比三维PDMS阵列结构[168];(b)由PDMS气动手指组成的软机器人手在无重力阻力状态下抓取物体的示意图[168]。烧蚀:(c)飞秒激光加工复合超疏水/亲水多微孔SERS基底并用于超痕量分子拉曼检测[170];(d)紫外激光刻写PDMS纹理化表面[32]。LIPSS:(e)飞秒激光诱导绝缘硅表面生成高度均匀可控的光子结构[191];(f)绝缘硅器件上高均匀亚波长光栅的三维形貌图(插图:扫描电镜图)[191]。切割:(g)紫外激光数字切割的可拉伸透明Kirigami电极[199];(h)激光辅助制造的Kirigami结构可拉伸应变传感器[200]

Fig. 4. Laser subtractive manufacturing. Pyrolysis: (a) high-aspect-ratio 3D PDMS array structures fabricated by laser back surface scanning[168]; (b) schematic diagram of a soft-robotic hand consisting of PDMS pneumatic fingers grabbing an object without gravitational resistance[168]. Ablation: (c) femtosecond laser-processed hybrid superhydrophobic/-philic microporous SERS substrate for ultratrace molecular Raman detection[170]; (d) UV laser engraving of PDMS textured surface[32]. LIPSS: (e) femtosecond laser-induced formation of highly uniform and controllable photonic structures on an SOI surface[191]; (f) 3D topography image of highly uniform subwavelength grating on an SOI device (inset: SEM image)[191]. Cutting: (g) stretchable transparent Kirigami electrode by UV laser digital cutting[199]; (h) Kirigami-structured stretchable strain sensor by laser-assisted fabrication[200]

物质在聚焦激光高温作用下受热分解的反应即为“激光热解”,该工艺常用于生成生物传感器敏感材料[166]和微通道制造[167]。这里以韩国首尔国立大学Ko团队实现PDMS高效三维成形的工作[168]为例,对激光热解过程进行介绍。当激光以黑色油墨作为引发剂辐照在PDMS上时,其表面热解起始点区域的组分被转化为非透明SiC层;随着黑体SiC的吸光度增加,激光热能进一步增加,这使得激光聚焦几微米范围内的PDMS基材持续热解,并引发热解诱导的连锁反应,最终通过激光正表面扫描技术沿辐射路径完成PDMS结构的加工[

目标材料在高功率激光诱导的瞬时高温下被选择性去除即为“激光烧蚀”,其常用于制备多功能传感器[169-170]、功能性超亲水[171]/疏水[172-173]表面、表面增强拉曼散射(SERS)基底[174-176]和导电电极[177-178]。

采用线偏振激光脉冲多次照射固体材料表面形成自组织微纳米结构即为“LIPSS”。与传统光刻和激光直写等方法相比,LIPSS可以在大范围内实现具有亚波长特征结构的并行加工[180],而且结构周期和方向等取决于激光波长、激光脉宽、脉冲能量、脉冲数、偏振方向和物质类型[181],几乎适用于所有材料[182-183](如金属、玻璃、聚合物和半导体等),是一种可有效实现表面纳米图案化的激光加工技术,目前已在仿生结构着色[184]、润湿性调控[185]、SERS[186]、太阳能热转换[187]、防冰[188]和数据存储[189-190]等方面得到了广泛应用。如

利用高能密度激光束直接在目标材料表面产生高强度应力场,使其价键结构迅速瓦解,并随光束移动在材料上形成连续切缝从而实现材料分割,即为“激光切割”。近年来,激光切割技术已被广泛用于制备各类柔性微纳传感器[192-195]和储能电子器件[196-197],该工艺具有制样简单、成本低廉、可加工各种原材料和开发不同功能等优点[198]。Ko团队[199]利用紫外脉冲激光在AgNWs/cPI上刻写出Kirigami图案[

5 激光融合制造在柔性微纳传感器上的应用

5.1 柔性物理传感器

在电子皮肤、医疗保健和物联网等高端应用中,实时监测各种物理参量(如压力、应变、温度、湿度、振动等)是必不可少的。激光融合制造凭借其在微纳敏感材料和功能结构单元制备方面的一体化优势,已成为开发柔性物理传感器的先进制造技术。

柔性应变传感器作为柔性物理传感器的典型代表,近年来引起了广泛关注,尤其是基于皮肤的可穿戴电子设备[201-204]。然而,对于目标系统的复杂状态监测(如预测精确的手指运动)往往需要多个应变传感器,在不创建传感器网络的情况下实现对目标对象的全状态测量便成为软电子学的重要研究方向。基于此,Ko团队[205]介绍了一种集成深度神经网络的皮肤传感器。他们利用激光烧蚀加工出周期性蛇形结构,使传感器富有更大弹性变形,保持与皮肤的共形接触;同时,利用激光退火诱导裂纹层,将其作为传感元件,检测微小机械刺激[

![柔性物理传感器。(a)利用激光图案化和激光诱导裂纹制造高灵敏皮肤传感器的示意图[205];(b)测量手指震中运动的示意图,其中左上图展示了手指运动引起手腕形态变化的测量,右下图展示了传感器裂纹区域的扫描电镜图,比例尺为40 μm[205];(c)应变传感器的制造过程示意图,包括丝网印刷Ag、激光直写制备石墨烯薄膜和Kirigami结构,以及Ecoflex钝化[200];(d)具有印刷电极的集成装置示意图[200];(e)弯曲状态下的装置照片[200];(f)上图是一名志愿者在办公室工作期间的呼吸监测结果(插图:装置固定在腹部区域的照片以及对应呼吸的阻值变化放大图),下图是从上图中提取的实时平均呼吸周期(插图:2 h内的呼吸周期直方图)[200];(g)蛇形互连压阻式传感器材料阵列的激光制备工艺[206];(h)活性层的俯视图,包括感知像素和绝缘蛇形路径[206];(i)材料阵列图片[206];(j)蛇形互连模型底视角下的活性层变形分布[206]](/richHtml/zgjg/2024/51/4/0402403/img_05.jpg)

图 5. 柔性物理传感器。(a)利用激光图案化和激光诱导裂纹制造高灵敏皮肤传感器的示意图[205];(b)测量手指震中运动的示意图,其中左上图展示了手指运动引起手腕形态变化的测量,右下图展示了传感器裂纹区域的扫描电镜图,比例尺为40 μm[205];(c)应变传感器的制造过程示意图,包括丝网印刷Ag、激光直写制备石墨烯薄膜和Kirigami结构,以及Ecoflex钝化[200];(d)具有印刷电极的集成装置示意图[200];(e)弯曲状态下的装置照片[200];(f)上图是一名志愿者在办公室工作期间的呼吸监测结果(插图:装置固定在腹部区域的照片以及对应呼吸的阻值变化放大图),下图是从上图中提取的实时平均呼吸周期(插图:2 h内的呼吸周期直方图)[200];(g)蛇形互连压阻式传感器材料阵列的激光制备工艺[206];(h)活性层的俯视图,包括感知像素和绝缘蛇形路径[206];(i)材料阵列图片[206];(j)蛇形互连模型底视角下的活性层变形分布[206]

Fig. 5. Flexible physical sensors. (a) Schematic diagram of fabrication of highly sensitive skin sensor by laser-patterning and laser-induced crack generation[205]; (b) illustration of measuring the epicentral motions of fingers, where the upper left image depicts the measurement of the topographical change of the wrist caused by the finger motions, and the lower right image shows the SEM image of the cracked region of the sensor, with a scale bar of 40 μm[205]; (c) schematic of the strain sensors fabrication processes, including screen printing of Ag, laser direct writing to form graphene films and Kirigami structures, and Ecoflex passivation[200]; (d) schematic of an integrated device with printed electrodes[200]; (e) a device photo under bending[200]; (f) upper image shows respiration monitoring during office work of a volunteer (insets: a photo of the device attached to the abdominal area and zoom-in of the resistance change results corresponding to breathing), and lower image shows the real-time averaged breathing period extracted from the upper image (inset: histogram of the breathing period for 2 h)[200]; (g) laser fabrication process of the piezoresistive sensor material array with the serpentine interconnect[206]; (h) top view of the active layer, including sensing pixels and insulating serpentine paths[206]; (i) picture of the material array[206]; (j) deformation distribution on active layers from the bottom view of the serpentine-interconnect model[206]

当前,大多数应变传感器的研究主要集中在提高灵敏度和可拉伸性上,为了保证实际设备的可应用性,在不牺牲灵敏度的前提下实现稳定重复的可拉伸和可扩展也是开发应变传感器的关键。基于上述思想,一种激光处理的可拉伸石墨烯基应变传感器被成功制备[200],其具有高稳定性的核心是减小器件在拉伸条件下的应变。该传感器以Kirigami结构为骨干,在二维至三维面外变形过程中,Kirigami结构内的应变分布增大,赋予了器件优异可逆性。如

在实际应用中,压力传感器能够检测到各种身体运动信号和生物信号,如轻微触摸、手腕脉搏、心跳、呼吸频率等,具有重要意义。过去10年内,研究人员已经开发出大量柔性可穿戴压力传感器[206-208]。为了同时实现高空间分辨率和低串扰干扰,Li等[206]展示了一种利用两步激光工艺制造的高分辨率柔性压力传感器阵列,其中单个传感像素及其互连分别通过激光低功率诱导碳化和高功率烧蚀形成[

此外,在追求综合性能优越的柔性触觉电子皮肤传感器方面,人们基于电容传感原理,结合双面微金字塔介质层和LM电极,制造出一种高灵敏(2.78 kPa-1)全柔性触觉传感器[

![柔性物理传感器。(a)电容式压力传感器的组装示意图[209];(b)LM在激光结构化介质层上的示意图[209];(c)信号强度的增强原理[209];(d)将水倒在传感器上时,附着在手腕上的传感器电容曲线[209];(e)可穿戴高灵敏全柔性触觉传感器,用于实时监测来自人体手腕脉搏、手掌运动、肘部弯曲、膝盖弯曲、手指弯曲以及行走和奔跑运动的机械信号[209];(f)全软体自供电振动传感器的示意图,展示了其结构细节和激光辅助制造[32];(g)软自供电振动传感器的截面示意图[32];(h)组装后的软自供电振动传感器照片,比例尺为1 cm[32];(i)佩戴在人手臂上的无线数据采集系统和软自供电振动传感器照片[32];(j)软自供电振动传感器在日常活动和紧急情况下的测量信号,所有波形均以相同放大倍数显示,展示出不同高宽比[32];(k)卷对卷制造示意图[48];(l)一种无电池电感电容传感器的设计概念,用于测量密封包装内的湿度水平[48];(m)制造出的3 cm×3 cm湿度传感器[48];(n)不同传感器谐振频率随相对湿度的变化[48];(o)传感器的谐振频率可以通过连接到射频(RF)读卡器的外部线圈进行远程测量[48]](/richHtml/zgjg/2024/51/4/0402403/img_06.jpg)

图 6. 柔性物理传感器。(a)电容式压力传感器的组装示意图[209];(b)LM在激光结构化介质层上的示意图[209];(c)信号强度的增强原理[209];(d)将水倒在传感器上时,附着在手腕上的传感器电容曲线[209];(e)可穿戴高灵敏全柔性触觉传感器,用于实时监测来自人体手腕脉搏、手掌运动、肘部弯曲、膝盖弯曲、手指弯曲以及行走和奔跑运动的机械信号[209];(f)全软体自供电振动传感器的示意图,展示了其结构细节和激光辅助制造[32];(g)软自供电振动传感器的截面示意图[32];(h)组装后的软自供电振动传感器照片,比例尺为1 cm[32];(i)佩戴在人手臂上的无线数据采集系统和软自供电振动传感器照片[32];(j)软自供电振动传感器在日常活动和紧急情况下的测量信号,所有波形均以相同放大倍数显示,展示出不同高宽比[32];(k)卷对卷制造示意图[48];(l)一种无电池电感电容传感器的设计概念,用于测量密封包装内的湿度水平[48];(m)制造出的3 cm×3 cm湿度传感器[48];(n)不同传感器谐振频率随相对湿度的变化[48];(o)传感器的谐振频率可以通过连接到射频(RF)读卡器的外部线圈进行远程测量[48]

Fig. 6. Flexible physical sensors. (a) Schematic of assembly of the capacitive pressure sensor[209]; (b) schematic of the LM on the laser-structured dielectric layer[209]; (c) enhancement principle of signal intensity[209]; (d) capacitance curve of the sensor attached on the wrist when pouring the water on the sensor[209]; (e) wearable highly sensitive all-flexible tactile sensor for real-time monitoring of mechanical signals from human wrist pulse, palm movement, elbow bending, knee bending, finger bending, and walking and running movement[209]; (f) schematic of the fully soft self-powered vibration sensor (SSVS) showing its structural details and laser-assisted fabrication[32]; (g) cross-sectional schematic of SSVS[32]; (h) photo of the assembled SSVS, with a scale bar of 1 cm[32]; (i) photo of a wireless data acquisition system and SSVS worn on a human arm[32]; (j) measured signals of SSVS during daily activities and emergencies, all waveforms are displayed at the same magnification showing various height-width ratios[32]; (k) schematic illustration of roll-to-roll fabrication[48]; (l) design concept of a battery-less inductive-capacitive (LC) sensor that measures the humidity level inside a sealed package[48]; (m) fabricated 3 cm×3 cm humidity sensor[48]; (n) change in sensors resonant frequency of different sensors as a function of relative humidity (RH)[48]; (o) the resonant frequency of the sensor can be remotely measured using an external coil connected to an RF reader[48]

基于全激光直写方法,Xu等[32]提出了一种全软体自供电振动传感器[

除了上述提及的典型接触式物理传感参量,柔性湿度传感器凭借其对湿度变化快速响应的独特特性,在非接触测量中发挥着至关重要的作用[216-218]。基于激光融合制造技术,一种用于食品智能包装的柔性无线湿度传感器应运而生[

5.2 柔性化学传感器

化学传感器能够通过快速检测生物标志物、代谢物、气体等化学信息揭示多种生化指标[219]。与大多数以获取目标对象物理状态或生命体征信息为目的的柔性微纳传感器不同,柔性化学传感器为分子水平的无创监测提供了直接方式[220],在人体生理信号感知、体液成分检测、环境质量监控和自供电传感系统集成等方面具有一定可行性。目前,基于激光融合制造技术,一系列先进的柔性微纳化学传感器已经被开发出来[49,221-222]。

在环境离子传感方面,Chen等[221]通过激光诱导调整石墨烯的结构、电导率和润湿性,构造出多路复用的开放式微流体传感器。研究发现,激光加工作为一种可扩展技术,不仅可以将PI转化为亲水性LIG,用于实现开放式微流体路径和电化学传感通道,还可以在低通量原位二次处理下将石墨烯表面由润湿态转变为近超疏水态,用于创建通道侧壁,以完成全LIG开放微流体模式[

![柔性化学传感器。(a)一体化开放微流控多路生物传感平台的激光制备示意图[221];(b)该生物传感平台用于离子和农药检测的功能化示意图[221];(c)(d)(e)钾离子选择电极(K+ ISE)、硝酸盐离子选择电极(NO3- ISE)和铵离子选择电极(NH4+ ISE)在10-6~10-2 mol/L浓度范围内分别对KCl、KNO3和NH4Cl溶液的开路电位响应[221];(f)酶促农药传感器对不同浓度对硫磷的电流和时间响应[221];(g)柔性ZnO气体传感器的制作过程示意图[222];(h)柔性ZnO气体传感器的照片[222];(i)(j)用于痛风管理和评估体内水分状况的多通道电化学传感器结构及其制造过程示意图[37];(k)与微流控网络集成的电化学传感器弯曲前后的光学图像[37];(l)高强度锻炼前,低嘌呤和高嘌呤饮食下人体汗液中尿酸水平的比较[37]](/richHtml/zgjg/2024/51/4/0402403/img_07.jpg)

图 7. 柔性化学传感器。(a)一体化开放微流控多路生物传感平台的激光制备示意图[221];(b)该生物传感平台用于离子和农药检测的功能化示意图[221];(c)(d)(e)钾离子选择电极(K+ ISE)、硝酸盐离子选择电极(NO

Fig. 7. Flexible chemical sensors. (a) Laser fabrication schematic of the all in one open-microfluidics multiplex biosensing platform[221]; (b) functionalization schematic of the biosensing platform for ion and pesticide sensing[221]; (c)(d)(e) open circuit potential response of the potassium ion-selective electrode (K+ ISE), nitrate ion-selective electrode (NO

在气体传感方面,利用激光微纳加工可以制造多种气敏材料。其中的金属氧化物半导体作为关键气敏材料之一,对极性气体或还原/氧化性气体尤其敏感[223-225]。Qian等[222]利用激光微加工法合成了一种用于室温下NO2检测的柔性ZnO气体传感器[

基于多激光辅助集成工艺,Lei等[49]成功制备出纳米晶SnO2气体传感器。与热蒸发和湿化学合成等其他纳米材料制备方法相比,此工作采用的多激光工艺具有独特优势,其将电极制造、纳米材料组装和后处理集成在同一道工序中,显著提升了加工效率。该柔性气体传感器已被证明可用于H2检测,在320 ℃最佳工作温度下的传感响应值约为2.105×10-4~2.500×10-3。

在生物标志物传感方面,可穿戴电化学传感器可以从生物液体中检测出分子水平信息,常用于生理健康评估[226-229]。然而,要在复杂的生物液体中对多种标志物进行多重检测,通常需要高密度阵列[230],这对低成本制造方法提出了挑战。面对这一问题,研究人员将激光直写三维多孔石墨烯泡沫作为多路柔性电化学传感器来同时检测人体汗液中的特定生物标志物和电解质[

5.3 柔性电生理传感器

人体内的器官、组织和神经活动等均与电势有关,通过监测生物特征电生理信号有助于发现异常生命体征。特别地,心脏(心电,ECG)、肌肉组织(肌电,EMG)和大脑(脑电,EEG)等相关疾病可以通过电生理传感器进行预判[231]。近年来,与电生理信号监测相关的可穿戴传感器已被广泛用于获取身体和认知功能,并作为健康监测、诊断的重要基础[232-234]。就传感器制造而言,激光融合加工具有高效、高质量制备功能纳米/微米级材料的技术优势,赋予了柔性电生理传感器独特、无创的感知能力,可助力定制化健康诊疗服务和面向假肢、机器人技术的可穿戴设备开发。

在柔性电生理传感中,通过皮肤贴片式可拉伸装置进行生理监测已受到广泛关注[235-236],然而,阻碍其发展的关键问题在于如何在外部变形下保持设备性能。对此,Gandla团队[237]基于自然启发的可变形结构和机械隔离思路,设计了一款包括Kirigami图案(具有高三维面外变形能力)、蜘蛛网图案(具有结构稳定和高面积覆盖特点)和丝状蛇形图案(具有二维可拉伸性)的几何传感器[

![柔性电生理传感器。(a)用于电生理传感的受自然启发的Kiri-Spider蛇形结构设计和激光制造示意图[237];(b)放置在球面上的具有高度可变形性的电极图案[237];(c)传感器的逐层设计布局[237];(d)传感器附在具有黏性、透气和可拉伸性的贴片上[237];(e)用于测量EMG、ECG和EOG的制造电极和传统电极示意图与图形表示[237];(f)紫外激光烧蚀对Al膜进行图案化,随后切割堆叠层[50];(g)CO2激光在贴片上钻孔[50];(h)贴片传感器阵列的光学图像,展示出对人体皮肤的柔性、可拉伸、黏性和共形贴附特点[50];(i)最大应变为30%时的循环测量[50];(j)2.5维激光切割工作原理侧视图[245];(k)基于开发的传感器袖套和以卷积神经网络(CNN)为基础的意图识别算法进行手势识别[245]](/richHtml/zgjg/2024/51/4/0402403/img_08.jpg)

图 8. 柔性电生理传感器。(a)用于电生理传感的受自然启发的Kiri-Spider蛇形结构设计和激光制造示意图[237];(b)放置在球面上的具有高度可变形性的电极图案[237];(c)传感器的逐层设计布局[237];(d)传感器附在具有黏性、透气和可拉伸性的贴片上[237];(e)用于测量EMG、ECG和EOG的制造电极和传统电极示意图与图形表示[237];(f)紫外激光烧蚀对Al膜进行图案化,随后切割堆叠层[50];(g)CO2激光在贴片上钻孔[50];(h)贴片传感器阵列的光学图像,展示出对人体皮肤的柔性、可拉伸、黏性和共形贴附特点[50];(i)最大应变为30%时的循环测量[50];(j)2.5维激光切割工作原理侧视图[245];(k)基于开发的传感器袖套和以卷积神经网络(CNN)为基础的意图识别算法进行手势识别[245]

Fig. 8. Flexible electrophysiological sensors. (a) Schematic illustration of the nature-inspired Kiri-Spider serpentine structural design and laser fabrication for electrophysiological sensing[237]; (b) electrode patterns exhibiting high levels of deformability placed over a spherical surface[237]; (c) layout of layer-by-layer design of the sensor[237]; (d) sensor attached to the sticky, breathable and stretchable patch[237]; (e) schematic and graphical representation of both proposed and conventional electrodes for measuring EMG, ECG and EOG[237]; (f) UV laser ablation to pattern Al films followed by cutting the stack layer[50]; (g) CO2 laser to drill the holes in the patch[50]; (h) optical image of the patch-based sensor array exhibiting flexible, stretchable, sticky, and conformal adhesion to human skin[50]; (i) cyclic measurements under a maximum strain of 30%[50]; (j) side view of working principle of 2.5D laser cutting[245]; (k) gesture recognition using developed sensor sleeve and employed convolutional neural network (CNN)-based intention recognition algorithm[245]

由于可拉伸电子皮肤传感器在连续监测电生理活动方面的极大促进作用[238-240],该团队继续充分挖掘激光融合制造的可扩展优势,巧妙利用不同波长激光器的加工特点,提出了一种贴片式可拉伸大面积多通道肌电传感器阵列[50]。如

此外,可穿戴式柔性电生理传感器在人机界面应用中也大有前景。作为最直接反映肌肉运动信息的生物电位信号之一,EMG常用于医学及相关研究领域的运动状态评估,同时也在向健康监测、假肢/矫形器控制、人机界面等领域扩展[241]。近年来,基于织物的表面EMG传感器已成为长期可穿戴系统的研究热点[242-244],然而,如何保持皮肤-电极接触以获得可靠的表面EMG信号仍是一个关键问题。摒弃染色、电镀、刺绣、针织/编织、喷墨印刷等传统工艺手段,Jeong等[245]介绍了一种基于2.5维激光切割的密织导电织物加工技术。如

5.4 柔性多模态传感器

尽管人们已经致力于通过激光融合制造技术来提高各种柔性传感器在物理[32,48,200,205-206,209]、化学[37,49,221-222]、电生理[50,237,245]参量监测等方面的性能,但这些设备往往只能对某种特定的物理或化学量实现单一感知、检测或监测,不足以解读多层次和全局性信息。因此,开发柔性多模态传感器成为了一种必然趋势。多模态传感器集成了多类感知元件,可以对多目标、多参量进行同时测量和综合分析,以获取更多相关性指标[246],在可穿戴传感平台[47,247]、人-机-环境交互[46,248]中具有广阔应用前景。这里将主要展示一些激光融合制造及其在柔性多模态传感器中的典型例子。

在多功能传感系统中,丰富的信号和多参数解耦对于同时进行多模态测量至关重要,当界面上多种参数同时变化时,功能间的相互干扰会使系统无法准确响应。对此,Zhang团队[46]提出了一种基于全激光单步直写的双面可穿戴系统解决方案[

![柔性多模态传感器。(a)具有双面装置模块的可穿戴多功能系统放大示意图[46];(b)健身房中的多功能系统照片,比例尺为5 cm[46];(c)人体运动过程中的系统功能示意图[46];(d)~(f)基于LIG的自供电、无线、可穿戴传感平台的示意图和光学图像,该平台通过TENG从人体运动中收集能量为微型超级电容器阵列充电,从而为皮肤传感器、信号处理单元和无线数据传输组件持续供电[47];(g)TENG中采用岛桥布局的可拉伸LIG基顶部电极的光学图像[47];(h)贴附在人手腕上的可拉伸LIG基微型超级电容器阵列的光学图像[47];(i)多功能无线平台的概念图,展示了组成该平台不同分层的爆炸视图,其中包含惯性、温度、湿度和呼吸传感器[247];(j)所制造的多功能平台光学照片(插图:LM被置于弯曲状PDMS通道内)[247];(k)身体活动实时监测,显示传感器贴附在人体胸部时,执行如站立、行走、慢跑、躺下和起身等任务的电阻变化原始输出[247];(l)机体活动实时监测,显示传感器贴附在四足机器人后背时,执行如原地行走、小幅移动、向前行走和扭转等动作的电阻变化原始输出[247];(m)全激光刻写的传感器组件:微流体模块和基于LEG的化学和物理传感器[35];(n)矢量模式激光切割制造微流体模块的示意图[35];(o)光栅模式激光制造LEG基化学传感器的示意图[35];(p)柔性实验室皮肤贴片的照片,比例尺为1 cm[35];(q)传感器的各层结构,从与表皮接触的底层到顶层[35];(r)健康受试者在身体不同部位佩戴传感器贴片的照片[35]](/richHtml/zgjg/2024/51/4/0402403/img_09.jpg)

图 9. 柔性多模态传感器。(a)具有双面装置模块的可穿戴多功能系统放大示意图[46];(b)健身房中的多功能系统照片,比例尺为5 cm[46];(c)人体运动过程中的系统功能示意图[46];(d)~(f)基于LIG的自供电、无线、可穿戴传感平台的示意图和光学图像,该平台通过TENG从人体运动中收集能量为微型超级电容器阵列充电,从而为皮肤传感器、信号处理单元和无线数据传输组件持续供电[47];(g)TENG中采用岛桥布局的可拉伸LIG基顶部电极的光学图像[47];(h)贴附在人手腕上的可拉伸LIG基微型超级电容器阵列的光学图像[47];(i)多功能无线平台的概念图,展示了组成该平台不同分层的爆炸视图,其中包含惯性、温度、湿度和呼吸传感器[247];(j)所制造的多功能平台光学照片(插图:LM被置于弯曲状PDMS通道内)[247];(k)身体活动实时监测,显示传感器贴附在人体胸部时,执行如站立、行走、慢跑、躺下和起身等任务的电阻变化原始输出[247];(l)机体活动实时监测,显示传感器贴附在四足机器人后背时,执行如原地行走、小幅移动、向前行走和扭转等动作的电阻变化原始输出[247];(m)全激光刻写的传感器组件:微流体模块和基于LEG的化学和物理传感器[35];(n)矢量模式激光切割制造微流体模块的示意图[35];(o)光栅模式激光制造LEG基化学传感器的示意图[35];(p)柔性实验室皮肤贴片的照片,比例尺为1 cm[35];(q)传感器的各层结构,从与表皮接触的底层到顶层[35];(r)健康受试者在身体不同部位佩戴传感器贴片的照片[35]

Fig. 9. Flexible multimodal sensors. (a) Enlarged schematic illustration of the wearable multifunctional system with double-sided device modules[46]; (b) photograph of the multifunctional system in the gym, with a scale bar of 5 cm[46]; (c) schematic illustration of the functions of the system during human sports[46]; (d)‒(f) schematic illustration and optical images of the LIG-based self-powered, wireless, wearable sensing platform, with the energy harvested by TENGs from kinetic human motion to charge micro-supercapacitor arrays (MSCAs) as the sustained power supply for powering on-skin sensors, signal processing units, and wireless data transmission components[47]; (g) optical image of the stretchable LIG-based top electrode with island-bridge layout in the TENG[47]; (h) optical image of the stretchable LIG-based MSCAs attached on a human wrist[47]; (i) conceptual illustration of the multifunctional wireless platform showing an exploded view of the different layers composing the platform containing the inertial, temperature, humidity, and breathing sensors[247]; (j) optical photograph of the fabricated multifunctional platform (inset: the LM placed inside the curved patterned PDMS channel)[247]; (k) real-time physical activity monitoring showing the raw output of resistance variation of the sensor when attached to the chest of a human subject performing tasks such as standing still, walking, jogging, laying down, and getting up[247]; (l) real-time physical activity monitoring showing the raw output of resistance variation of the sensor when attached to the back of a legged robot performing movements such as walking in place, small movement, walking forward, and twisting[247]; (m) the sensor with entirely laser-engraved components: the microfluidic module and the LEG-based chemical and physical sensors[35]; (n) schematic of vector-mode laser cutting for microfluidic fabrication[35]; (o) schematic of raster-mode laser for LEG-based chemical sensors fabrication[35]; (p) photograph of a flexible lab-on-skin patch, with a scale bar of 1 cm[35]; (q) layers of the sensor, from the bottom layer in contact with epidermis to the top layer[35]; (r) photographs of a healthy subject wearing the sensor patch at different body parts[35]

虽然表皮电子设备可以无线、灵敏地检测人体健康状况,实现个性化、远程医疗保健,但其实际应用还取决于持续电源的发展。当前,一种前景性的解决方案是将高性能表皮电子传感器和信号处理电路与可伸缩能量采集器、能量存储设备、电源管理电路以及用于全自供电可穿戴电子器件的无线数据传输组件集成在一起[249-250],然而这往往涉及到复杂的制造工艺(如光刻、沉积或蚀刻),而且器件加工过程中的高温也会破坏活性功能材料,导致柔性/弹性体聚合物基底变形。此外,大多数具有不同材料和工作原理的自供电可穿戴系统在机械变形和人体皮肤运动时存在输出功率低和信号不稳定的问题。为克服上述不足,一种基于激光诱导石墨烯泡沫的自供电可穿戴传感平台被制造出来[47]。在加工工艺方面,该工作利用CO2激光光热转换生成三维多孔LIG,通过无机盐涂覆和激光二次还原实现对LIG的原位功能化修饰,形成具有层状结构或嵌入纳米晶体的复合材料,为进一步调控、优化传感性能提供可能;在自供电方面,该传感平台联合纳米发电机(TENG)、整流器以及平面微型超级电容器实现高效收集人体机械能并将其转化为连续、稳定的电能[

由前述案例可以看出,柔性可穿戴监测系统对于诊断身体状况至关重要,与此同时,它对预测病理情况也十分关键。运动传感器是柔性可穿戴监测系统的重要组成部分,然而,迄今为止,在软电子学领域,基于无疲劳软质量块的惯性运动传感器尚未得到广泛探索。为了解决这一需求并简化设备制造,研究人员提出了一种全软的LIG-LM一体化多功能可穿戴运动监测平台[247],该平台同时集成了惯性、温度、湿度和呼吸传感器[

未来,对于表皮多功能平台的开发还将继续扩展至生化传感,以便更准确和更全面地反映健康状况,为个性化诊疗和疾病预防提供深层次信息。在这一方面,Gao团队[35]率先利用激光融合制造技术实现了一种集微流体汗液采样(激光减材刻蚀)、化学分子传感和多重生命体征监测(激光光热诱导碳化)为一体的柔性可穿戴传感器[

同样专注于皮肤电子开发,Ko团队发现以往的研究大多侧重于提高设备本征性能而缺乏对佩戴传感器个体特性差异化的考虑,这种趋势将会限制设备在实际使用中执行多样化任务和适应不同环境的能力。尤其是皮肤传感器,其受到目标身体部位和用户的影响很大,因此需要进行各种设计调整,以获得最佳器件性能[251-253]。面对修改时的整体流程初始化挑战,他们提出了一种设计-制造同步化的可定制超薄电子平台[51],用于原位适应性操作(SOA)。如

![柔性多模态传感器。(a)第一层(堆叠和形成垂直互连通道)和第二层的绘制示意图[51];(b)擦除顶层电极的示意图,附带光学图像的比例尺为200 μm[51];(c)四层器件可控过孔的扫描电镜图和相应图示,以及三层电路系统选择性过孔控制的演示[51];(d)该装置通过阻抗和传感器SOA主动适应各种用户需求和相应附着位置,SOA基于激光重写金属纳米颗粒[51];(e)开发的皮肤电子装置图,包括具有皮肤能量传输能力的各种传感元件,比例尺分别为15、15、20 mm[51];(f)测量与皮肤状况相关的各种因素(实时温度、紫外线和湿度)[51];(g)测量ECG和EMG信号[51];(h)实时测量与虚拟手控制相关的陀螺仪和肌电信号[51];(i)激光烧蚀策略示意图,使用低功率激光图案化金属迹线,使用更高功率激光切割PET薄膜[248];(j)传感器和导线的显微图,显示出烧蚀的Al传感器(红色)和切断的互连导线(青色)[248];(k)软手指接近并轻轻触摸玩具娃娃额头时的相应传感器触点示意图[248];(l)相应的接近度和温度信号图(标定数据位于右纵轴)[248]](/richHtml/zgjg/2024/51/4/0402403/img_10.jpg)

图 10. 柔性多模态传感器。(a)第一层(堆叠和形成垂直互连通道)和第二层的绘制示意图[51];(b)擦除顶层电极的示意图,附带光学图像的比例尺为200 μm[51];(c)四层器件可控过孔的扫描电镜图和相应图示,以及三层电路系统选择性过孔控制的演示[51];(d)该装置通过阻抗和传感器SOA主动适应各种用户需求和相应附着位置,SOA基于激光重写金属纳米颗粒[51];(e)开发的皮肤电子装置图,包括具有皮肤能量传输能力的各种传感元件,比例尺分别为15、15、20 mm[51];(f)测量与皮肤状况相关的各种因素(实时温度、紫外线和湿度)[51];(g)测量ECG和EMG信号[51];(h)实时测量与虚拟手控制相关的陀螺仪和肌电信号[51];(i)激光烧蚀策略示意图,使用低功率激光图案化金属迹线,使用更高功率激光切割PET薄膜[248];(j)传感器和导线的显微图,显示出烧蚀的Al传感器(红色)和切断的互连导线(青色)[248];(k)软手指接近并轻轻触摸玩具娃娃额头时的相应传感器触点示意图[248];(l)相应的接近度和温度信号图(标定数据位于右纵轴)[248]

Fig. 10. Flexible multimodal sensors. (a) Schematic illustration of drawing of the first layer (stacking and vertical interconnect access (VIA) formation) and the second layer[51]; (b) illustration of erasing the top layer electrode with accompanying optical images with a scale bar of 200 µm[51]; (c) SEM images and corresponding illustration of the controlled VIA of four-layer device and the demonstration of the selective VIA control of the three-layer circuit system[51]; (d) the device is actively adapted to the various user demands and corresponding attachment locations through impedance and sensor SOA, SOA is based on the laser rewriting of metal nanoparticles[51]; (e) images of the developed skin electronic device including various sensing elements with on-skin power transferring ability, with scale bars of 15, 15, and 20 mm, respectively[51]; (f) measuring of various factors that relates to skin conditions (real-time temperature, UV and humidity)[51]; (g) measuring of ECG and EMG signals; (h) measuring of gyroscopic and EMG signals that relates to virtual hand control in real-time[51]; (i) illustration of laser ablation strategy, using low power laser to pattern the metal traces and higher power laser to cut the PET film[248]; (j) microscopic images of sensors and wires showing ablated Al sensors (red) and cut interconnect wires (cyan)[248]; (k) schematic of corresponding sensor contacts of a soft finger approaching and gently touching a doll's forehead[248]; (l) plots of corresponding proximity and temperature signals (calibrated data on the right vertical axis)[248]

柔性多模态传感系统除了用于以“人”为核心的智能监测与医疗诊断,还可以用于软体机器人交互控制。尽管软体机器人已经在复杂物体抓取上克服了传统刚性机器人所面临的长期挑战[254],但它们在手部灵巧活动方面仍有待提高[255-256]。因此,为软体机器人手开发传感器便成为关键一步。用于软体机器人手的传感器网络需要具备柔性和可拉伸性,以贴合柔软表面并随其移动,同时避免传感器信号受到应变影响,这就对制造成本、复杂性、定制化需求以及传感集成等提出了较大挑战。除此之外,为了避免污染,食品处理和人机交互等应用还要求传感器易于更换。为解决上述问题,Bao团队[248]提出一种基于紫外激光加工的柔性可拉伸多模态传感器网络,它可以与软体机器人手集成。该传感器网络的制造和集成复杂度较低,成本接近于一次性用品。研究人员通过激光烧蚀策略在低功率下进行金属导线和传感单元的图案化,在高功率下进行导线分离和基底薄膜切割[

过去10多年中,各类柔性多模态传感器已被用于人体运动追踪[257-258]、生命体征监测[259-261]、人机交互服务[248]等。然而,鲜少有传感系统被报道用于弱势群体的健康观测和反馈警报。Xu等[33]展示了一种基于LIG的可穿戴多模态无线传感器系统,将柔性多模态传感片与放置在一次性尿布上的无线反馈信号处理系统进行集成,可实现对婴儿睡眠状态的持续跟踪[

![柔性多模态传感器。(a)贴附在一次性尿布上的可穿戴传感器系统示意图[33];(b)集成倾斜、呼吸和湿度传感器的可穿戴体征传感器系统示意图,多通道信号通过蓝牙无线传输到智能手机界面,智能手机可以在特定条件下发出警报[33];(c)对LM液滴非黏附的LIG基软基底制备工艺示意图[33];(d)制造的多模态柔性传感片照片[33];(e)贴附在尿布上的多模态柔性传感器照片[33];(f)从智能手机中提取的穿戴无线集成倾斜传感器的人工婴儿模型在不同体位时的照片和结果,包括仰卧(1)、右侧卧(2)、左侧卧(3)、俯卧(4)和站立姿势(5)[33];(g)智能手机上的无线监测结果[33];(h)躺在床垫上的成年人的无线实时监测结果[33];(i)配备储存计算处理的柔性雨水传感器系统示意图[262];(j)柔性雨水传感器和贴附在雨伞上的传感器照片[262];(k)有、无水滴时柔性雨水传感器的传感机制[262];(l)在自然风速为1.5~3.5、0~10 m·s-1的环境中,传感器的电阻变化、估算风速以及估算体积[262]](/richHtml/zgjg/2024/51/4/0402403/img_11.jpg)

图 11. 柔性多模态传感器。(a)贴附在一次性尿布上的可穿戴传感器系统示意图[33];(b)集成倾斜、呼吸和湿度传感器的可穿戴体征传感器系统示意图,多通道信号通过蓝牙无线传输到智能手机界面,智能手机可以在特定条件下发出警报[33];(c)对LM液滴非黏附的LIG基软基底制备工艺示意图[33];(d)制造的多模态柔性传感片照片[33];(e)贴附在尿布上的多模态柔性传感器照片[33];(f)从智能手机中提取的穿戴无线集成倾斜传感器的人工婴儿模型在不同体位时的照片和结果,包括仰卧(1)、右侧卧(2)、左侧卧(3)、俯卧(4)和站立姿势(5)[33];(g)智能手机上的无线监测结果[33];(h)躺在床垫上的成年人的无线实时监测结果[33];(i)配备储存计算处理的柔性雨水传感器系统示意图[262];(j)柔性雨水传感器和贴附在雨伞上的传感器照片[262];(k)有、无水滴时柔性雨水传感器的传感机制[262];(l)在自然风速为1.5~3.5、0~10 m·s-1的环境中,传感器的电阻变化、估算风速以及估算体积[262]

Fig. 11. Flexible multimodal sensors. (a) Schematic of the wearable sensor system attached onto a disposable diaper[33]; (b) schematic of a wearable body condition sensor system integrated with tilt, breath, and moisture sensors, multiple channel signals are wirelessly transmitted to a smartphone interface via Bluetooth, the smartphone can generate an alarm under certain conditions[33]; (c) schematic of the fabrication process for the non-adhesive LIG-based soft substrate to an LM droplet[33]; (d) photo of the fabricated multimodal flexible sensor sheet[33]; (e) photo of multimodal flexible sensors attached onto a diaper[33]; (f) photos and results extracted from the smartphone of an artificial baby model wearing a wireless integrated tilt sensor for various body positions, including sleeping on the back (1), right side (2), left side (3), stomach (4), and standing posture (5)[33]; (g) wireless monitoring results on a smartphone[33]; (h) wireless real-time monitoring results measured from an adult lying on a mattress[33]; (i) schematic of the flexible rain sensor system with reservoir computing (RC) processing[262]; (j) photo of the flexible rain sensor and the sensor attached to an umbrella[262]; (k) sensing mechanism of flexible rain sensor with and without water droplets[262]; (l) resistance change of the sensor, estimated wind velocity, and estimated volume in an ambient environment with natural wind flow in the range of 1.5‒3.5, and 0‒1.0 m·s-1[262]

在面向大自然的柔性多模态传感器中,一个典型的例子是Takei团队[262]为监测实时降雨量和风速而开发的轻量雨水传感器[

6 总结与展望

激光融合制造涵盖了光学工程、材料科学、机械制造等多学科内容,以多脉冲、多波长激光为工具,充分集成增材、等材、减材多形式加工特点,将敏感单元的高效沉积、材料介质的诱导改性与微纳结构的精密制备融为一体,为实现高性能柔性微纳传感器提供了有效解决方案。相比于传统微纳复合加工方法,激光融合制造在以下方面具有显著优势:1)多机制协同作用——充分结合激光加工过程中主要涉及的“热效应”与“冷加工”效应,诱导材料发生汽化、烧蚀、热膨胀、熔融凝固、反应改性、去除剥离、等离子化等现象,同时伴随着光热、光电、光化学与光机械效应;2)多尺度制造集成——通过激光增材烧结、等材改性与减材蚀刻实现毫米、微米和纳米级跨尺度精密结构的“控形”与“控性”;3)多材料体系兼容——利用物质对不同波长激光的吸收特性差异,实现对金属、碳基、陶瓷、聚合物等材料的选择性微纳加工。此外,激光融合制造还具有灵活可控、环境友好、加工高效、成本较低等特点,有效克服了传统工艺中存在的自由度低、流程复杂、低产低效与设备昂贵等难题。

虽然激光融合制造正在不断丰富和拓宽柔性微纳传感器的加工渠道,然而,在面向实际应用场景时,其发展仍然存在诸多挑战。首先,尽管激光融合制造在微纳加工精度方面已经取得较大突破,但精度的进一步提高受到光学衍射极限的限制,从而在一定程度上限制了该技术在高密度、高集成度器件制造方面的应用。其次,传统激光加工主要通过点扫描模式工作,对于复杂结构的制备通常需要几小时甚至更长时间,极大地降低了产率,无法满足大面积或批量化加工需求。对此,可以考虑采用微透镜、多光束干涉法、多焦点并行加工等技术优化激光扫描工艺。此外,目标材料的多样性也是激光融合制造在多模态处理方面的难题。由于不同材料需要适配不同的激光波长与加工形式,因此,在实现材料切换和工艺过渡上还需要开展更为广泛的材料特性研究,为不同材料的激光融合微纳制造提供依据,并通过参数优化,实现多材料体系的高质量加工,从而推动新型柔性微纳器件的开发。最后,在器件应用方面,由于激光融合制造具有一体化加工多功能集成传感器的潜力,因此,克服不同传感单元之间的信号串扰也是器件在设计与制造过程中面临的挑战。

总之,激光融合制造的未来发展势必会加速柔性微纳传感器的创新与迭代,开辟柔性微纳制造新路径,拓展激光加工应用新场景。

[1] Um S H, Hwang S W, Grigoropoulos C P, et al. Recent advances in selective laser-material interaction for biomedical device applications[J]. Applied Physics Reviews, 2022, 9(4): 041302.

[2] Li X X, Guan Y C. Theoretical fundamentals of short pulse laser-metal interaction: a review[J]. Nanotechnology and Precision Engineering, 2020, 3(3): 105-125.

[3] Joe D J, Kim S, Park J H, et al. Laser-material interactions for flexible applications[J]. Advanced Materials, 2017, 29(26): 1606586.

[4] Zhang C Y, Zhou W, Geng D, et al. Laser direct writing and characterizations of flexible piezoresistive sensors with microstructures[J]. Opto-Electronic Advances, 2021, 4(4): 200061.

[5] 邵长香, 赵扬, 陈南, 等. 激光微纳制造在传感领域中的应用[J]. 中国激光, 2021, 48(2): 0202014.

[6] Bian J, Zhou L B Y, Wan X D, et al. Laser transfer, printing, and assembly techniques for flexible electronics[J]. Advanced Electronic Materials, 2019, 5(7): 1800900.

[7] Zhang Y B, Wang X Y, Yan K, et al. Laser micro/nano-structuring pushes forward smart sensing: opportunities and challenges[J]. Advanced Functional Materials, 2023, 33(8): 2211272.

[8] Zhao L L, Liu Z, Chen D, et al. Laser synthesis and microfabrication of micro/nanostructured materials toward energy conversion and storage[J]. Nano-Micro Letters, 2021, 13(1): 49.

[9] Carvalho A F, Fernandes A J S, Leitão C, et al. Laser-induced graphene strain sensors produced by ultraviolet irradiation of polyimide[J]. Advanced Functional Materials, 2018, 28(52): 1805271.

[10] Kulyk B, Silva B F R, Carvalho A F, et al. Laser-induced graphene from paper for mechanical sensing[J]. ACS Applied Materials & Interfaces, 2021, 13(8): 10210-10221.

[11] Le T S D, Park S, An J N, et al. Ultrafast laser pulses enable one-step graphene patterning on woods and leaves for green electronics[J]. Advanced Functional Materials, 2019, 29(33): 1902771.

[12] Fang L N, Li J C, Zhang J R, et al. Femtosecond laser structuring for flexible surface-enhanced Raman spectroscopy substrates[J]. IEEE Photonics Journal, 2021, 13(2): 6800908.

[13] Nag A, Mukhopadhyay S C, Kosel J. Sensing system for salinity testing using laser-induced graphene sensors[J]. Sensors and Actuators A: Physical, 2017, 264: 107-116.

[14] Sharma S, Ganeshan S K, Pattnaik P K, et al. Laser induced flexible graphene electrodes for electrochemical sensing of hydrazine[J]. Materials Letters, 2020, 262: 127150.

[15] Zhang L Q, Wang L, Li J Y, et al. Surface engineering of laser-induced graphene enables long-term monitoring of on-body uric acid and pH simultaneously[J]. Nano Letters, 2022, 22(13): 5451-5458.

[16] Puetz P, Behrent A, Baeumner A J, et al. Laser-scribed graphene (LSG) as new electrode material for impedance-based cellular assays[J]. Sensors and Actuators B: Chemical, 2020, 321: 128443.

[17] Soares R R A, Hjort R G, Pola C C, et al. Laser-induced graphene electrochemical immunosensors for rapid and label-free monitoring of Salmonella enterica in chicken broth[J]. ACS Sensors, 2020, 5(7): 1900-1911.

[18] Fenzl C, Nayak P, Hirsch T, et al. Laser-scribed graphene electrodes for aptamer-based biosensing[J]. ACS Sensors, 2017, 2(5): 616-620.

[19] Du Q F, Liu L L, Tang R T, et al. High-performance flexible pressure sensor based on controllable hierarchical microstructures by laser scribing for wearable electronics[J]. Advanced Materials Technologies, 2021, 6(9): 2100122.

[20] Yang R X, Dutta A, Li B W, et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids[J]. Nature Communications, 2023, 14: 2907.

[21] Cheng L, Fang G Q, Wei L, et al. Laser-induced graphene strain sensor for conformable lip-reading recognition and human-machine interaction[J]. ACS Applied Nano Materials, 2023, 6(9): 7290-7298.

[22] Chen X, Hou Z R, Li G X, et al. A laser-scribed wearable strain sensing system powered by an integrated rechargeable thin-film zinc-air battery for a long-time continuous healthcare monitoring[J]. Nano Energy, 2022, 101: 107606.

[23] Agarwala S, Goh G L, Le T S D, et al. Wearable bandage-based strain sensor for home healthcare: combining 3D aerosol jet printing and laser sintering[J]. ACS Sensors, 2019, 4(1): 218-226.

[24] Shin J, Jeong B, Kim J, et al. Sensitive wearable temperature sensor with seamless monolithic integration[J]. Advanced Materials, 2020, 32(2): e1905527.

[25] Chen R, Luo T, Geng D, et al. Facile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interface[J]. Carbon, 2022, 187: 35-46.

[27] Lan L Y, Le X H, Dong H Y, et al. One-step and large-scale fabrication of flexible and wearable humidity sensor based on laser-induced graphene for real-time tracking of plant transpiration at bio-interface[J]. Biosensors and Bioelectronics, 2020, 165: 112360.

[28] Xu K C, Li Q A, Lu Y Y, et al. Laser direct writing of flexible thermal flow sensors[J]. Nano Letters, 2023, 23(22): 10317-10325.

[29] Wang H, Zhao Z F, Liu P P, et al. A soft and stretchable electronics using laser-induced graphene on polyimide/PDMS composite substrate[J]. NPJ Flexible Electronics, 2022, 6: 26.

[30] Yao Y B, Jiang Z F, Yao J W, et al. Self-sealing carbon patterns by one-step direct laser writing and their use in multifunctional wearable sensors[J]. ACS Applied Materials & Interfaces, 2020, 12(45): 50600-50609.

[31] Liu K, Yang C, Zhang S Y, et al. Laser direct writing of a multifunctional superhydrophobic composite strain sensor with excellent corrosion resistance and anti-icing/deicing performance[J]. Materials & Design, 2022, 218: 110689.

[32] Luo H Y, Lu Y Y, Xu Y H, et al. A fully soft, self-powered vibration sensor by laser direct writing[J]. Nano Energy, 2022, 103: 107803.

[33] Xu K C, Fujita Y, Lu Y Y, et al. A wearable body condition sensor system with wireless feedback alarm functions[J]. Advanced Materials, 2021, 33(18): e2008701.

[34] Saisahas K, Soleh A, Somsiri S, et al. Electrochemical sensor for methamphetamine detection using laser-induced porous graphene electrode[J]. Nanomaterials, 2021, 12(1): 73.

[35] Yang Y R, Song Y, Bo X J, et al. A laser-engraved wearable sensor for sensitive detection of uric acid and tyrosine in sweat[J]. Nature Biotechnology, 2020, 38: 217-224.

[36] Tu J B, Min J H, Song Y, et al. A wireless patch for the monitoring of C-reactive protein in sweat[J]. Nature Biomedical Engineering, 2023, 7: 1293-1306.

[37] Yang L, Wang H, Abdullah A M, et al. Direct laser writing of the porous graphene foam for multiplexed electrochemical sweat sensors[J]. ACS Applied Materials & Interfaces, 2023, 15(29): 34332-34342.

[38] Yang L, Zheng G H, Cao Y Q, et al. Moisture-resistant, stretchable NOx gas sensors based on laser-induced graphene for environmental monitoring and breath analysis[J]. Microsystems & Nanoengineering, 2022, 8: 78.

[39] Li D S, Shao Y Z, Zhang Q, et al. A flexible virtual sensor array based on laser-induced graphene and MXene for detecting volatile organic compounds in human breath[J]. Analyst, 2021, 146(18): 5704-5713.

[40] Yang J, Zhang K, Yu J J, et al. Facile fabrication of robust and reusable PDMS supported graphene dry electrodes for wearable electrocardiogram monitoring[J]. Advanced Materials Technologies, 2021, 6(9): 2100262.

[41] Wei Y H, Li X S, Wang Y F, et al. Graphene-based multifunctional textile for sensing and actuating[J]. ACS Nano, 2021, 15(11): 17738-17747.

[42] Zhang Q, Qu M L, Liu X Y, et al. Three-in-one portable electronic sensory system based on low-impedance laser-induced graphene on-skin electrode sensors for electrophysiological signal monitoring[J]. Advanced Materials Interfaces, 2023, 10(3): 2201735.

[43] Sun B H, McCay R N, Goswami S, et al. Gas-permeable, multifunctional on-skin electronics based on laser-induced porous graphene and sugar-templated elastomer sponges[J]. Advanced Materials, 2018, 30(50): e1804327.

[44] Tian H, Li X S, Wei Y H, et al. Bioinspired dual-channel speech recognition using graphene-based electromyographic and mechanical sensors[J]. Cell Reports Physical Science, 2022, 3(10): 101075.

[45] Ling Y, Pang W B, Li X P, et al. Laser-induced graphene for electrothermally controlled, mechanically guided, 3D assembly and human-soft actuators interaction[J]. Advanced Materials, 2020, 32(17): e1908475.

[46] Wang H B, Xiang Z H, Zhao P C, et al. Double-sided wearable multifunctional sensing system with anti-interference design for human-ambience interface[J]. ACS Nano, 2022, 16(9): 14679-14692.

[47] Zhang C, Chen H M, Ding X H, et al. Human motion-driven self-powered stretchable sensing platform based on laser-induced graphene foams[J]. Applied Physics Reviews, 2022, 9(1): 011413.

[48] Gopalakrishnan S, Sedaghat S, Krishnakumar A, et al. Wireless humidity sensor for smart packaging via one-step laser-induced patterning and nanoparticle formation on metallized paper[J]. Advanced Electronic Materials, 2022, 8(7): 2101149.

[49] Lei J C, Zhang Q, Zhao Z Y, et al. One-step fabrication of nanocrystalline nanonetwork SnO2 gas sensors by integrated multilaser processing[J]. Advanced Materials Technologies, 2020, 5(8): 2000281.

[50] Gandla S, Chae H, Kwon H J, et al. Ultrafast prototyping of large-area stretchable electronic systems by laser ablation technique for controllable robotic arm operations[J]. IEEE Transactions on Industrial Electronics, 2022, 69(4): 4245-4253.

[51] Kim K K, Choi J, Kim J H, et al. Evolvable skin electronics by in situ and in operando adaptation[J]. Advanced Functional Materials, 2022, 32(4): 2106329.

[52] Liu S L Z, Yuen M C, White E L, et al. Laser sintering of liquid metal nanoparticles for scalable manufacturing of soft and flexible electronics[J]. ACS Applied Materials & Interfaces, 2018, 10(33): 28232-28241.

[53] Nam V B, Thi Giang T, Lee D. Laser digital patterning of finely-structured flexible copper electrodes using copper oxide nanoparticle ink produced by a scalable synthesis method[J]. Applied Surface Science, 2021, 570: 151179.

[54] Kang B C, Han S Y, Kim J S, et al. One-step fabrication of copper electrode by laser-induced direct local reduction and agglomeration of copper oxide nanoparticle[J]. The Journal of Physical Chemistry C, 2011, 115(48): 23664-23670.

[55] Nam V B, Shin J, Yoon Y, et al. Highly stable Ni-based flexible transparent conducting panels fabricated by laser digital patterning[J]. Advanced Functional Materials, 2019, 29(8): 1806895.

[56] Huang F, Shen L, Zhou S K, et al. Flexible broadband photodetector based on laser-induced graphene/CH3NH3PbI3 composite[J]. Optical Materials, 2022, 128: 112364.

[57] Qu M L, Tian Y X, Cheng Y B, et al. Whole-device mass-producible perovskite photodetector based on laser-induced graphene electrodes[J]. Advanced Optical Materials, 2022, 10(24): 2201741.

[58] Wu C, Wu F M, Hu H Z, et al. Work function tunable laser induced graphene electrodes for Schottky type solar-blind photodetectors[J]. Applied Physics Letters, 2022, 120(10): 101102.

[59] Xia S Y, Long Y F, Huang Z Y, et al. Laser-induced graphene (LIG)-based pressure sensor and triboelectric nanogenerator towards high-performance self-powered measurement-control combined system[J]. Nano Energy, 2022, 96: 107099.

[60] Shi X Y, Zhou F, Peng J X, et al. One-step scalable fabrication of graphene-integrated micro-supercapacitors with remarkable flexibility and exceptional performance uniformity[J]. Advanced Functional Materials, 2019, 29(50): 1902860.

[61] Yi J S, Chen J H, Yang Z, et al. Facile patterning of laser-induced graphene with tailored Li nucleation kinetics for stable lithium-metal batteries[J]. Advanced Energy Materials, 2019, 9(38): 1901796.

[62] 陈锐, 王锦成, 章文卓, 等. 微结构传感器的激光制造技术研究进展[J]. 光电工程, 2023, 50(3): 220041.

[63] Hwang E, Hong J, Yoon J, et al. Direct writing of functional layer by selective laser sintering of nanoparticles for emerging applications: a review[J]. Materials, 2022, 15(17): 6006.

[64] Rho Y, Kang K T, Lee D. Highly crystalline Ni/NiO hybrid electrodes processed by inkjet printing and laser-induced reductive sintering under ambient conditions[J]. Nanoscale, 2016, 8(16): 8976-8985.

[65] Kefer S, Bischoff K, Roth G L, et al. Tunable bulk polymer planar Bragg gratings electrified via femtosecond laser reductive sintering of CuO nanoparticles[J]. Advanced Optical Materials, 2021, 9(13): 2002203.

[66] Theodorakos I, Zacharatos F, Geremia R, et al. Selective laser sintering of Ag nanoparticles ink for applications in flexible electronics[J]. Applied Surface Science, 2015, 336: 157-162.

[67] Li X B, Huang J T, Lu J S, et al. Fabrication and characterization of SiO2@SiC shell-core nanowire prepared by laser sintering[J]. Journal of Materials Science, 2017, 52(6): 3344-3352.

[68] Li W W, Yang S, Shamim A. Screen printing of silver nanowires: balancing conductivity with transparency while maintaining flexibility and stretchability[J]. NPJ Flexible Electronics, 2019, 3: 13.

[69] Spechler J A, Nagamatsu K A, Sturm J C, et al. Improved efficiency of hybrid organic photovoltaics by pulsed laser sintering of silver nanowire network transparent electrode[J]. ACS Applied Materials & Interfaces, 2015, 7(19): 10556-10562.

[70] Zhou M X, Zhu W, Yu S Z, et al. Selective laser sintering of carbon nanotube-coated thermoplastic polyurethane: mechanical, electrical, and piezoresistive properties[J]. Composites Part C: Open Access, 2022, 7: 100212.

[71] Zhuang Y, Guo Y L, Li J, et al. Preparation and laser sintering of a thermoplastic polyurethane carbon nanotube composite-based pressure sensor[J]. RSC Advances, 2020, 10(40): 23644-23652.

[72] Mizoshiri M, Kondo Y. Direct writing of Cu-based fine micropatterns using femtosecond laser pulse-induced sintering of Cu2O nanospheres[J]. Japanese Journal of Applied Physics, 2019, 58: SDDF05.

[73] Nam V B, Giang T T, Koo S, et al. Laser digital patterning of conductive electrodes using metal oxide nanomaterials[J]. Nano Convergence, 2020, 7(1): 23.

[74] Liu S L Z, Yuen M C, Kramer-Bottiglio R. Reconfigurable electronic devices enabled by laser-sintered liquid metal nanoparticles[J]. Flexible and Printed Electronics, 2019, 4(1): 015004.

[75] Suh Y D, Kwon J, Lee J, et al. Maskless fabrication of highly robust, flexible transparent Cu conductor by random crack network assisted Cu nanoparticle patterning and laser sintering[J]. Advanced Electronic Materials, 2016, 2(12): 1600277.

[76] Huang Y J, Xie X Z, Li M N, et al. Copper circuits fabricated on flexible polymer substrates by a high repetition rate femtosecond laser-induced selective local reduction of copper oxide nanoparticles[J]. Optics Express, 2021, 29(3): 4453-4463.

[77] Mizoshiri M, Ito Y, Arakane S, et al. Direct fabrication of Cu/Cu2O composite micro-temperature sensor using femtosecond laser reduction patterning[J]. Japanese Journal of Applied Physics, 2016, 55(6S1): 06GP05.

[78] Nam V B, Lee D. Evaluation of Ni-based flexible resistance temperature detectors fabricated by laser digital pattering[J]. Nanomaterials, 2021, 11(3): 576.

[79] Ho L D A, Nam V B, Lee D. Flexible Ni/NiOx-based sensor for human breath detection[J]. Materials, 2021, 15(1): 47.

[80] Nam V B, Shin J, Choi A, et al. High-temperature, thin, flexible and transparent Ni-based heaters patterned by laser-induced reductive sintering on colorless polyimide[J]. Journal of Materials Chemistry C, 2021, 9(17): 5652-5661.

[81] Kwon J, Cho H, Suh Y D, et al. Flexible and transparent Cu electronics by low-temperature acid-assisted laser processing of Cu nanoparticles[J]. Advanced Materials Technologies, 2017, 2(2): 1600222.

[82] Lee D, Paeng D, Park H K, et al. Vacuum-free, maskless patterning of Ni electrodes by laser reductive sintering of NiO nanoparticle ink and its application to transparent conductors[J]. ACS Nano, 2014, 8(10): 9807-9814.

[83] 申超, 翁沛希, 王子杰, 等. 激光直写柔性电路的研究进展[J]. 中国科学: 物理学 力学 天文学, 2021, 51(8): 084201.

Shen C, Weng P X, Wang Z J, et al. Research progress in laser direct writing of flexible circuit[J]. Scientia Sinica (Physica, Mechanica & Astronomica), 2021, 51(8): 084201.

[84] Yamaguchi M, Araga S, Mita M, et al. On-demand infrared laser sintering of gold nanoparticle paste for electrical contacts[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2015, 5(8): 1160-1168.

[85] Chung J, Ko S H, Bieri N R, et al. Conductor microstructures by laser curing of printed gold nanoparticle ink[J]. Applied Physics Letters, 2004, 84(5): 801-803.

[86] Shou W, Mahajan B K, Ludwig B, et al. Low-cost manufacturing of bioresorbable conductors by evaporation-condensation-mediated laser printing and sintering of Zn nanoparticles[J]. Advanced Materials, 2017, 29(26): 1700172.

[87] Tan H W, An J, Chua C K, et al. Metallic nanoparticle inks for 3D printing of electronics[J]. Advanced Electronic Materials, 2019, 5(5): 1800831.

[88] Mu B Y, Wang X P, Zhang X S, et al. Laser direct sintering approach for additive manufacturing in flexible electronic[J]. Results in Engineering, 2022, 13: 100359.

[89] Hong S, Yeo J, Kim G, et al. Nonvacuum, maskless fabrication of a flexible metal grid transparent conductor by low-temperature selective laser sintering of nanoparticle ink[J]. ACS Nano, 2013, 7(6): 5024-5031.

[90] Zenou M, Ermak O, Saar A, et al. Laser sintering of copper nanoparticles[J]. Journal of Physics D: Applied Physics, 2014, 47(2): 025501.

[91] Cheng C W, Chen J K. Femtosecond laser sintering of copper nanoparticles[J]. Applied Physics A, 2016, 122(4): 289.

[92] Kwon J, Cho H, Eom H, et al. Low-temperature oxidation-free selective laser sintering of Cu nanoparticle paste on a polymer substrate for the flexible touch panel applications[J]. ACS Applied Materials & Interfaces, 2016, 8(18): 11575-11582.

[93] Rahman M K, Lu Z, Kwon K S. Green laser sintering of copper oxide (CuO) nano particle (NP) film to form Cu conductive lines[J]. AIP Advances, 2018, 8(9): 095008.

[94] Zhou X W, Guo W, Fu J, et al. Laser writing of Cu/CuxO integrated structure on flexible substrate for humidity sensing[J]. Applied Surface Science, 2019, 494: 684-690.

[95] Paeng D, Lee D, Yeo J, et al. Laser-induced reductive sintering of nickel oxide nanoparticles under ambient conditions[J]. The Journal of Physical Chemistry C, 2015, 119(11): 6363-6372.

[96] Lee H S, Yang M Y. The effect of negative pressure aging on the aggregation of Cu2O nanoparticles and its application to laser induced copper electrode fabrication[J]. Physical Chemistry Chemical Physics: PCCP, 2015, 17(6): 4360-4366.

[97] Lee D, Pan H, Ko S H, et al. Non-vacuum, single-step conductive transparent ZnO patterning by ultra-short pulsed laser annealing of solution-deposited nanoparticles[J]. Applied Physics A, 2012, 107(1): 161-171.

[98] Pan H, Misra N, Ko S H, et al. Melt-mediated coalescence of solution-deposited ZnO nanoparticles by excimer laser annealing for thin-film transistor fabrication[J]. Applied Physics A, 2009, 94(1): 111-115.

[99] Li W L, Sun Q Q, Li L Y, et al. The rise of conductive copper inks: challenges and perspectives[J]. Applied Materials Today, 2020, 18: 100451.

[100] Nguyen T B, Nguyen T D, Tran T D, et al. Laser-induced synthesis of Au-Ag alloy nanoparticles in polyvinylpyrrolidone (C6H9NO)n solution[J]. Journal of Cluster Science, 2015, 26(5): 1787-1799.

[101] Han S, Hong S, Yeo J, et al. Nanorecycling: monolithic integration of copper and copper oxide nanowire network electrode through selective reversible photothermochemical reduction[J]. Advanced Materials, 2015, 27(41): 6397-6403.

[102] Lee H, Yang M Y. Effect of solvent and PVP on electrode conductivity in laser-induced reduction process[J]. Applied Physics A, 2015, 119(1): 317-323.

[103] Yang M, Chon M W, Kim J H, et al. Mechanical and environmental durability of roll-to-roll printed silver nanoparticle film using a rapid laser annealing process for flexible electronics[J]. Microelectronics Reliability, 2014, 54(12): 2871-2880.

[104] Ko S H, Chung J, Pan H, et al. Fabrication of multilayer passive and active electric components on polymer using inkjet printing and low temperature laser processing[J]. Sensors and Actuators A: Physical, 2007, 134(1): 161-168.

[105] Feng S X, Tian Z S, Wang J, et al. Laser sintering of Zn microparticles and its application in printable biodegradable electronics[J]. Advanced Electronic Materials, 2019, 5(3): 1800693.

[106] Lu G X, Ni E L, Jiang Y Y, et al. Room-temperature liquid metals for flexible electronic devices[J]. Small, 2023: e2304147.

[107] Hu G H, Zhu H Y, Guo H R, et al. Maskless fabrication of highly conductive and ultrastretchable liquid metal features through selective laser activation[J]. ACS Applied Materials & Interfaces, 2023, 15(23): 28675-28683.

[108] Hu L, Wang L, Ding Y J, et al. Manipulation of liquid metals on a graphite surface[J]. Advanced Materials, 2016, 28(41): 9210-9217.

[109] Handschuh-Wang S, Gan T S, Wang T, et al. Surface tension of the oxide skin of gallium-based liquid metals[J]. Langmuir, 2021, 37(30): 9017-9025.

[110] Cho C, Shin W, Kim M, et al. Monolithically programmed stretchable conductor by laser-induced entanglement of liquid metal and metallic nanowire backbone[J]. Small, 2022, 18(37): e2202841.

[111] You R, Liu Y Q, Hao Y L, et al. Laser fabrication of graphene-based flexible electronics[J]. Advanced Materials, 2020, 32(15): 1901981.

[112] Wang H, Zhao Z F, Liu P P, et al. Laser-induced graphene based flexible electronic devices[J]. Biosensors, 2022, 12(2): 55.

[113] Lin J, Peng Z W, Liu Y Y, et al. Laser-induced porous graphene films from commercial polymers[J]. Nature Communications, 2014, 5: 5714.

[114] Chyan Y, Ye R Q, Li Y L, et al. Laser-induced graphene by multiple lasing: toward electronics on cloth, paper, and food[J]. ACS Nano, 2018, 12(3): 2176-2183.

[115] Ye R Q, James D K, Tour J M. Laser-induced graphene: from discovery to translation[J]. Advanced Materials, 2019, 31(1): 1803621.

[116] Le T S D, Phan H P, Kwon S, et al. Recent advances in laser-induced graphene: mechanism, fabrication, properties, and applications in flexible electronics[J]. Advanced Functional Materials, 2022, 32(48): 2205158.

[117] Wang M Q, Yang Y R, Gao W. Laser-engraved graphene for flexible and wearable electronics[J]. Trends in Chemistry, 2021, 3(11): 969-981.

[118] Wan Z F, Nguyen N T, Gao Y S, et al. Laser induced graphene for biosensors[J]. Sustainable Materials and Technologies, 2020, 25: e00205.

[119] Yu H Y, Gai M X, Liu L, et al. Laser-induced direct graphene patterning: from formation mechanism to flexible applications[J]. Soft Science, 2023, 3(1): 4.

[120] Parmeggiani M, Zaccagnini P, Stassi S, et al. PDMS/polyimide composite as an elastomeric substrate for multifunctional laser-induced graphene electrodes[J]. ACS Applied Materials & Interfaces, 2019, 11(36): 33221-33230.

[121] Zhang Z, Zhu H, Zhang W J, et al. A review of laser-induced graphene: from experimental and theoretical fabrication processes to emerging applications[J]. Carbon, 2023, 214: 118356.

[123] Huang L B, Su J J, Song Y, et al. Laser-induced graphene: en route to smart sensing[J]. Nano-Micro Letters, 2020, 12(1): 157.

[124] Stanford M G, Yang K C, Chyan Y, et al. Laser-induced graphene for flexible and embeddable gas sensors[J]. ACS Nano, 2019, 13(3): 3474-3482.

[125] Zhu J B, Huang X, Song W X. Physical and chemical sensors on the basis of laser-induced graphene: mechanisms, applications, and perspectives[J]. ACS Nano, 2021, 15(12): 18708-18741.

[126] Lu Y Y, Xu K C, Zhang L S, et al. Multimodal plant healthcare flexible sensor system[J]. ACS Nano, 2020, 14(9): 10966-10975.

[127] Lu Y Y, Kong D P, Yang G, et al. Machine learning-enabled tactile sensor design for dynamic touch decoding[J]. Advanced Science, 2023, 10(32): e2303949.

[128] Chen S W, Cao Z K, Zhou K, et al. Screen printing and laser-induced flexible sensors for the simultaneous sensitive detection of uric acid, tyrosine, and ascorbic acid in sweat[J]. The Analyst, 2023, 148(13): 2965-2974.

[129] Peng Y Y, Zhao W W, Ni F, et al. Forest-like laser-induced graphene film with ultrahigh solar energy utilization efficiency[J]. ACS Nano, 2021, 15(12): 19490-19502.

[130] Ma W, Zhu J, Wang Z, et al. Recent advances in preparation and application of laser-induced graphene in energy storage devices[J]. Materials Today Energy, 2020, 18: 100569.

[131] Wan Z F, Chen X, Gu M. Laser scribed graphene for supercapacitors[J]. Opto-Electronic Advances, 2021, 4(7): 200079.

[132] Gandla S, Naqi M, Lee M, et al. Highly linear and stable flexible temperature sensors based on laser-induced carbonization of polyimide substrates for personal mobile monitoring[J]. Advanced Materials Technologies, 2020, 5(7): 2000014.

[133] Mudhulu S, Channegowda M, Balaji S, et al. Trends in graphene-based E-skin and artificial intelligence for biomedical applications: a review[J]. IEEE Sensors Journal, 2023, 23(17): 18963-18976.

[134] Lu Y Y, Yang G, Wang S Q, et al. Stretchable graphene-hydrogel interfaces for wearable and implantable bioelectronics[J]. Nature Electronics, 2024, 7: 51-65.

[135] Yang L, Ji H D, Meng C Z, et al. Intrinsically breathable and flexible NO2 gas sensors produced by laser direct writing of self-assembled block copolymers[J]. ACS Applied Materials & Interfaces, 2022, 14(15): 17818-17825.

[136] Wang H M, Wang H M, Wang Y L, et al. Laser writing of Janus graphene/Kevlar textile for intelligent protective clothing[J]. ACS Nano, 2020, 14(3): 3219-3226.

[137] Yang W W, Zhao W, Li Q S, et al. Fabrication of smart components by 3D printing and laser-scribing technologies[J]. ACS Applied Materials & Interfaces, 2020, 12(3): 3928-3935.

[138] Nam H K, Le T S D, Yang D, et al. Smart wooden home enabled by direct-written laser-induced graphene[J]. Advanced Materials Technologies, 2023, 8(9): 2201952.

[139] Jung Y, Min J, Choi J, et al. Smart paper electronics by laser-induced graphene for biodegradable real-time food spoilage monitoring[J]. Applied Materials Today, 2022, 29: 101589.

[140] Zang X N, Shen C W, Chu Y, et al. Laser-induced molybdenum carbide-graphene composites for 3D foldable paper electronics[J]. Advanced Materials, 2018, 30(26): e1800062.

[141] Cantarella G, Madagalam M, Merino I, et al. Laser-induced, green and biocompatible paper-based devices for circular electronics[J]. Advanced Functional Materials, 2023, 33(17): 2210422.

[142] Singh S P, Li Y L, Zhang J B, et al. Sulfur-doped laser-induced porous graphene derived from polysulfone-class polymers and membranes[J]. ACS Nano, 2018, 12(1): 289-297.

[143] Wang W, Liu Y Q, Liu Y, et al. Direct laser writing of superhydrophobic PDMS elastomers for controllable manipulation via marangoni effect[J]. Advanced Functional Materials, 2017, 27(44): 1702946.

[144] Zhang Z C, Song M M, Hao J X, et al. Visible light laser-induced graphene from phenolic resin: a new approach for directly writing graphene-based electrochemical devices on various substrates[J]. Carbon, 2018, 127: 287-296.

[145] Zhang C, Peng Z X, Huang C L, et al. High-energy all-in-one stretchable micro-supercapacitor arrays based on 3D laser-induced graphene foams decorated with mesoporous ZnP nanosheets for self-powered stretchable systems[J]. Nano Energy, 2021, 81: 105609.

[146] Ye R Q, Chyan Y, Zhang J B, et al. Laser-induced graphene formation on wood[J]. Advanced Materials, 2017, 29(37): 1702211.

[147] Kim Y J, Le T S D, Nam H K, et al. Wood-based flexible graphene thermistor with an ultra-high sensitivity enabled by ultraviolet femtosecond laser pulses[J]. CIRP Annals, 2021, 70(1): 443-446.

[148] Zheng B J D, Zhao G G, Yan Z, et al. Direct freeform laser fabrication of 3D conformable electronics[J]. Advanced Functional Materials, 2023, 33(1): 2210084.

[149] Le T S D, Lee Y A, Nam H K, et al. Green flexible graphene-inorganic-hybrid micro-supercapacitors made of fallen leaves enabled by ultrafast laser pulses[J]. Advanced Functional Materials, 2022, 32(20): 2107768.

[150] Kulyk B, Matos M, Silva B F R, et al. Conversion of paper and xylan into laser-induced graphene for environmentally friendly sensors[J]. Diamond and Related Materials, 2022, 123: 108855.

[151] Kulyk B, Silva B F R, Carvalho A F, et al. Laser-induced graphene from paper by ultraviolet irradiation: humidity and temperature sensors[J]. Advanced Materials Technologies, 2022, 7(7): 2101311.

[152] Zhu C G, Zhao D M, Wang K D, et al. Direct laser writing of graphene films from a polyether ether ketone precursor[J]. Journal of Materials Science, 2019, 54(5): 4192-4201.

[153] Song Y P, Zhang J X, Li N, et al. Design of a high performance electrode composed of porous nickel-cobalt layered double hydroxide nanosheets supported on vertical graphene fibers for flexible supercapacitors[J]. New Journal of Chemistry, 2020, 44(16): 6623-6634.

[154] Zaccagnini P, Ballin C, Fontana M, et al. Laser-induced graphenization of PDMS as flexible electrode for microsupercapacitors[J]. Advanced Materials Interfaces, 2021, 8(23): 2101046.

[155] Yang D, Nam H K, Le T S D, et al. Multimodal E-textile enabled by one-step maskless patterning of femtosecond-laser-induced graphene on nonwoven, knit, and woven textiles[J]. ACS Nano, 2023, 17(19): 18893-18904.

[156] Li Z H, Lu L S, Xie Y X, et al. Preparation of laser-induced graphene fabric from silk and its application examples for flexible sensor[J]. Advanced Engineering Materials, 2021, 23(9): 2100195.

[157] Wang G Y, Tao L Q, Peng Z R, et al. Nomex paper-based double-sided laser-induced graphene for multifunctional human-machine interfaces[J]. Carbon, 2022, 193: 68-76.

[158] Yang Q Z, Cao L, Li S, et al. Upgrading pomelo peels into laser-induced graphene for multifunctional sensors[J]. Journal of Analytical and Applied Pyrolysis, 2023, 173: 106074.

[159] Yue Y, Li X Y, Zhao Z F, et al. Stretchable flexible sensors for smart tires based on laser-induced graphene technology[J]. Soft Science, 2023, 3(2): 13.

[160] Sun X Z, Liu X J, Li F. Sulfur-doped laser-induced graphene derived from polyethersulfone and lignin hybrid for all-solid-state supercapacitor[J]. Applied Surface Science, 2021, 551: 149438.

[161] Thakur A K, Mahbub H, Nowrin F H, et al. Highly robust laser-induced graphene (LIG) ultrafiltration membrane with a stable microporous structure[J]. ACS Applied Materials & Interfaces, 2022, 14(41): 46884-46895.

[162] Liu J B, Zhang L J, Yang C, et al. Preparation of multifunctional porous carbon electrodes through direct laser writing on a phenolic resin film[J]. Journal of Materials Chemistry A, 2019, 7(37): 21168-21175.

[163] Beckham J L, Li J T, Stanford M G, et al. High-resolution laser-induced graphene from photoresist[J]. ACS Nano, 2021, 15(5): 8976-8983.

[164] Hu X J, Huang J C, Wei Y Z, et al. Laser direct-write sensors on carbon-fiber-reinforced poly-ether-ether-ketone for smart orthopedic implants[J]. Advanced Science, 2022, 9(11): e2105499.

[165] Dreimol C H, Guo H Z, Ritter M, et al. Sustainable wood electronics by iron-catalyzed laser-induced graphitization for large-scale applications[J]. Nature Communications, 2022, 13: 3680.

[166] Jiang S L, Chen Q, Lin J B, et al. Thermal stress-induced fabrication of carbon micro/nanostructures and the application in high-performance enzyme-free glucose sensors[J]. Sensors and Actuators B: Chemical, 2021, 345: 130364.

[167] Min K, Lim J, Lim J H, et al. Fabrication of perforated PDMS microchannel by successive laser pyrolysis[J]. Materials, 2021, 14(23): 7275.

[168] Shin J, Ko J, Jeong S, et al. Monolithic digital patterning of polydimethylsiloxane with successive laser pyrolysis[J]. Nature Materials, 2021, 20: 100-107.

[169] Jiang Y T, Wang Y, Wu H T, et al. Laser-etched stretchable graphene-polymer composite array for sensitive strain and viscosity sensors[J]. Nano-Micro Letters, 2019, 11(1): 99.

[170] Yu J, Wu J G, Yang H, et al. Extremely sensitive SERS sensors based on a femtosecond laser-fabricated superhydrophobic /-philic microporous platform[J]. ACS Applied Materials & Interfaces, 2022, 14(38): 43877-43885.

[171] Khew S Y, Tan C F, Yan H P, et al. Nanosecond laser ablation for enhanced adhesion of CuO nanowires on copper substrate and its application for oil-water separation[J]. Applied Surface Science, 2019, 465: 995-1002.

[172] Yang H, Xu K C, Xu C W, et al. Femtosecond laser fabricated elastomeric superhydrophobic surface with stretching-enhanced water repellency[J]. Nanoscale Research Letters, 2019, 14(1): 333.

[173] Pan R, Zhang H J, Zhong M L. Triple-scale superhydrophobic surface with excellent anti-icing and icephobic performance via ultrafast laser hybrid fabrication[J]. ACS Applied Materials & Interfaces, 2021, 13(1): 1743-1753.

[174] 余建, 杨焕, 吴建根, 等. 超快激光制造表面增强拉曼散射传感器[J]. 光电工程, 2023, 50(3): 220333.

[175] Xu K C, Yan H P, Tan C F, et al. Hedgehog inspired CuO nanowires/Cu2O composites for broadband visible-light-driven recyclable surface enhanced Raman scattering[J]. Advanced Optical Materials, 2018, 6(7): 1701167.