1 合肥工业大学仪器科学与光电工程学院,安徽 合肥 230009

2 中国科学技术大学工程科学学院,安徽 合肥 230026

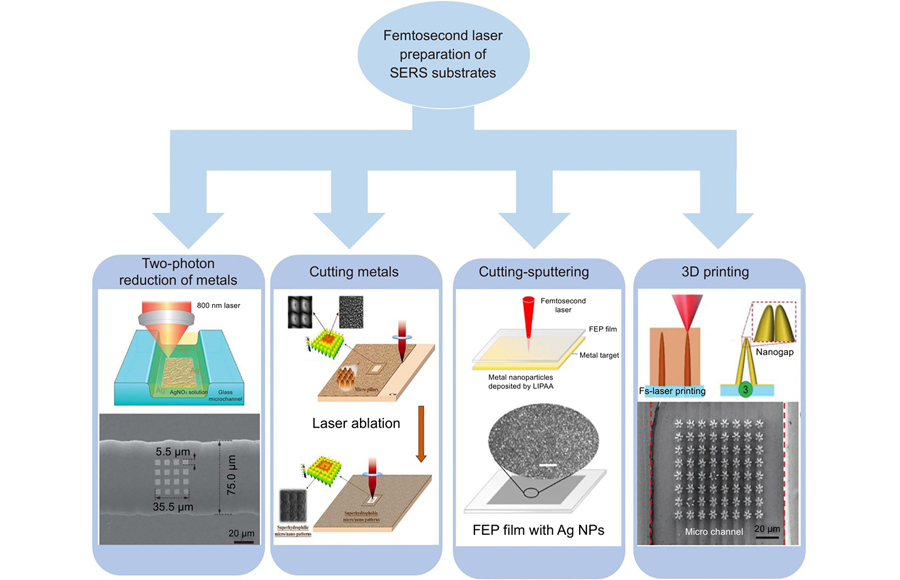

Overview: Surface-Enhanced Raman spectroscopy (SERS) is a highly sensitive and high-resolution molecular recognition technique with important applications in many fields. As an emerging low-cost, high-resolution, and highflexibility micro-nano processing method, femtosecond laser direct writing has been widely used in the field of preparing SERS substrates. Compared with traditional processing methods for preparing SERS substrates, femtosecond laser direct writing processing has certain advantages in terms of flexibility, three-dimensional molding, processing material range, processing accuracy, and other aspects. In this review, we classify the processing methods of femtosecond laser preparation of SERS substrates into four categories, including femtosecond laser two-photon metal reduction, femtosecond laser cutting metal, femtosecond laser cutting-sputtering, and femtosecond laser 3D printing. Femtosecond laser two-photon metal reduction uses the two-photon reduction effect to reduce metal cations in metal solutions to metals, such as silver ions in silver nitrate solutions to silver nanoparticles. This method is suitable for the one-step preparation of SERS substrates in closed microchannels. Femtosecond laser cutting metal directly prepares the SERS substrate structure on a metal substrate. This method takes advantage of the high peak power of the femtosecond laser to ablate the surface of the metal sample to obtain a patterned surface structure. At the same time, femtosecond laser ablation produces particle fragments, which are usually redeposited on the patterned surface, resulting in SERS "hot spots". Femtosecond laser direct cutting of metal can prepare SERS substrates in one step, which has the advantages of high processing efficiency and simple processing and is more conducive to the application of large-scale production of practical SERS detection. Femtosecond laser cutting-sputtering is to process any structure on non-metallic substrates such as polymers and then sputtering/evaporating metal nanoparticles on the surface of the structure. This method can prepare transparent and flexible SERS substrates, which are rich in application scenarios. Femtosecond laser 3D printing is to use the three-dimensional processing ability of femtosecond lasers to obtain rich "hot spots" by designing the structure of SERS substrates, and then using template-guided self-assembly technology with different driving forces to deposit/evaporate metal nanoparticles at designated locations. In this paper, we first introduce the current methods for preparing SERS and then conduct a comprehensive review of the processing methods of four femtosecond lasers to prepare SERS substrates. Finally, the advantages and disadvantages of the four femtosecond laser preparation methods for SERS substrate are briefly summarized, and the development prospects of this technology are prospected, aiming to provide it for future related research.

表面增强拉曼光谱 飞秒激光直写 微纳加工 SERS基底 SERS femtosecond laser direct writing micro/nano processing SERS substrate

Author Affiliations

Abstract

1 Anhui Province Key Laboratory of Aerospace Structural Parts Forming Technology and Equipment, Institute of Industry and Equipment Technology, Hefei University of Technology, Hefei 230009, China

2 Caltech Optical Imaging Laboratory, Andrew and Peggy Cherng Department of Medical Engineering, California Institute of Technology, Pasadena, CA 91125, USA

3 Hefei National Laboratory for Physical Sciences at the Microscale and CAS Key Laboratory of Mechanical Behavior and Design of Materials, Department of Precision Machinery and Precision Instrumentation, University of Science and Technology of China, Hefei 230026, China

A ring-shaped focus, such as a focused vortex beam, has played an important role in microfabrication and optical tweezers. The shape and diameter of the ring-shaped focus can be easily adjusted by the topological charge of the vortex. However, the flow energy is also related to the topological charge, making the individual control of diameter and flow energy of the vortex beam impossible. Meanwhile, the shape of the focus of the vortex beam remains in the hollow ring. Expanding the shape of focus of structural light broadens the applications of the vortex beam in the field of microfabrication. Here, we proposed a ring-shaped focus with controllable gaps by multiplexing the vortex beam and annular beam. The multiplexed beam has several advantages, such as the diameter and flow energy of the focal point can be individually controlled and are not affected by the zero-order beam, and the gap size and position are controllable.

microfabrication femtosecond laser structural beams microring Chinese Optics Letters

2022, 20(2): 023801

1 南通职业大学机械工程学院, 江苏 南通 226007

2 合肥工业大学仪器科学与光电工程学院, 安徽 合肥 230009

3 安徽建筑大学机械与电气工程学院, 安徽 合肥 230601

4 合肥师范学院化学与化学工程学院, 安徽 合肥 230601

双面神亲/疏膜可用于实现水下气泡的单向运输,在学术研究和工业应用中具有重要的意义。利用纳秒脉冲激光打孔,并结合加热改性工艺,在锌箔上下表面制备出锥形微孔阵列。通过控制激光加工参数,研制出双面神锌箔,其上下表面具有不同的粗糙度和微观结构,并开展了水下气泡单向运动特性研究。通过能谱仪(EDS)对双面神锌箔表面的化学成分进行了分析,结果表明,锌箔上表面的润湿性变化主要归因于激光打孔和加热处理中亲水性羟基的吸附和解吸作用。利用高清工业相机观测水下气泡的动态行为,发现气泡可以在0.6 s内从疏气面渗透到亲气面,但在相反方向则会被堵塞。研究结果显示,在一定范围内,脉冲激光能量的增加不仅可以增大锌箔表面的微孔尺寸并改善锌箔表面疏水性,还可以显著提高气泡的运输速率,气泡在双面神锌箔中的运输特性主要归因于表面微纳结构和化学成分的共同作用。研究结论可为超高速气泡捕捉、输送、收集和气液分离等领域的先进材料设计提供参考。

材料 纳秒激光 超疏水 微纳结构 气泡运输 中国激光

2020, 47(10): 1003003