摘要

Overview: Microstructure sensor is a kind of sensor with a 2D or 3D micron-scale structure prepared by advanced manufacturing technology. It is used as a sensitive part to enhance the transmission characteristics of physical, chemical, and biological signals to the environment, and convert the external signals into electrical signals. The microstructure is generally a regular or disordered structure, usually in the shape of microspheres, microcolumns, microcones, microgrooves and micropores. The microstructures with different shapes can realize the functions of puncture, pressure transmission, vibration transmission, drug transmission, bioelectric transmission, heat transmission, sound transmission, gas adsorption, and so on. In recent years, researchers from all over the world have gradually attached great importance to the research on the manufacturing technology of microstructure sensors. At present, researchers have proposed the MEMS manufacturing processes, such as reactive ion etching and chemical vapor deposition, to achieve mass manufacturing of high-precision microstructures on flexible polymer materials and rigid materials. In addition, some researchers have also proposed the manufacturing processes such as template method, self-assembly, nanoimprinting, and soft lithography to realize microstructure manufacturing. However, the above-mentioned manufacturing processes usually cannot prepare microstructure in one step, which has the problems of complex process, high production cost, limited processing materials, and unable to control the microstructure morphology. In contrast, laser manufacturing technology has the advantages of non-contact processing, no mask, customizable manufacturing, etc. By optimizing the parameters of laser process (such as laser power, scanning speed, filling mode and scanning path), it can achieve efficient and low-cost manufacturing of microstructures with different sizes and shapes. Therefore, using laser manufacturing technology to realize microstructure manufacturing and applying it to bioelectricity, temperature, and pressure sensors has become a research hotspot in microstructure sensor manufacturing technology. Laser manufacturing technology mainly includes laser ablation, laser direct writing, laser induction, laser-template processing, etc. Laser ablation is an auxiliary heating process based on the thermochemical and thermophysical effects of a laser beam, which melts the materials to be processed to realize structural forming. Laser direct writing is a manufacturing process that focuses high-energy photon beams on the materials to be processed to produce a photochemical process, and manufacturing the structures through material removal. Laser-induced modification is a manufacturing process to change the physical and chemical properties of the materials to be processed. Laser-template processing is a manufacturing process that uses a laser to produce microstructure molds on silicon, glass, polymer, and other substrates, and then uses soft lithography technology to reverse die the structures on the molds. Based on the interaction between the laser and materials, the induction, removal, and migration of materials to be processed can be realized. By adjusting the laser processing mode and processing parameters, the controlled manufacturing of the 2D or 3D microstructures or the controlled preparation of functional materials for the sensitive units can be realized, breaking through the limitations of efficiency and cost of traditional manufacturing methods for microstructures. In this paper, the types, functions, and manufacturing technologies of microstructures are summarized and classified. The preparation processes of laser manufacturing technology and other advanced manufacturing technologies of microstructures are summarized. The applications of microstructure sensors prepared by laser ablation, laser direct writing, laser induction, and laser-template processing technology in bioelectric sensing, temperature sensing, and pressure sensing are described in detail. Finally, the development trend of the laser manufacturing technology for microstructure sensors is summarized and prospected.

Abstract

Microstructure sensor is a sensor device with the micro-scale structure as a sensitive unit and can convert external physical, chemical, and biological signals into electrical signals. It has been widely used in intelligent robots, health monitoring, virtual electronics, and other fields. At present, the manufacturing methods of microstructure sensors mainly include laser manufacturing technology, MEMS technology, and 3D printing technology. Laser manufacturing technology is a green processing method that focuses the high-energy laser beam on the object to be processed and makes the laser interact with the material, mainly including laser ablation, laser direct writing, laser induction, and laser-template composite processing. It has the advantages of non-contact processing, no mask, and customizable manufacturing. By optimizing the parameters of the laser manufacturing process, it can realize the efficient and low-cost manufacturing of microstructures with different sizes and shapes. In this paper, the types, function, and manufacturing technology of the microstructures are summarized. At the same time, the microstructure sensors fabricated by laser manufacturing technology are summarized and classified, and the manufacturing technology and application of bioelectric sensors, temperature sensors and pressure sensors are analyzed in detail. Finally, the development trends of the laser manufacturing technology for microstructure sensors are summarized and prospected.

1 引言

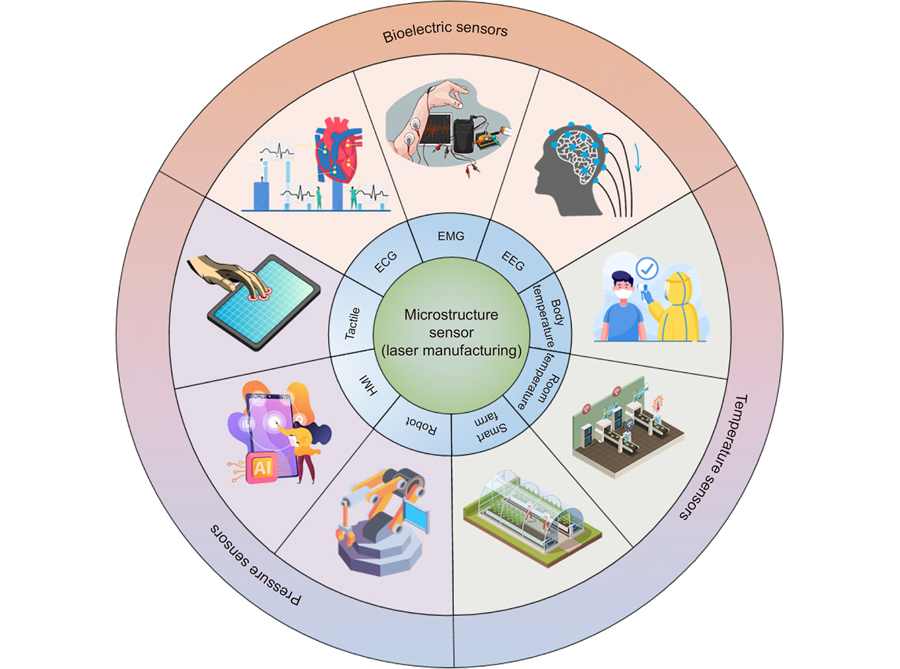

微结构传感器是利用先进制造技术制备的具有二维或三维微米尺度结构,作为敏感单元以增强对外界物理、化学和生物信号传递特性,并将外界信号转化为电信号的传感器。微结构一般是规则或无序排列的结构,通常为微球、微柱、微锥、微沟槽和微孔等形状[1],不同形状的微结构可实现穿刺、压力传递、振动传递、药物传递、生物电传导、热传导、声传导、气体吸附等功能[2-4]。目前微结构传感器在柔性电子、智能机器人、人机交互等领域迅速发展,已在心电检测、脑电波检测、肌电检测、体温感知、压力监测等方面获得应用[5-9]。因此,目前微结构传感器从应用领域来划分包括生物电传感器、温度传感器、压力传感器等,如图1所示。

图 1. 面向生物电、压力、温度检测的微结构传感器应用

Fig. 1. Application of the microstructure sensor for bioelectricity, pressure and temperature detection

下载图片 查看所有图片

近年来,微结构传感器制造技术研究逐渐获得了世界各国研究者的高度重视。目前,研究者已经提出采用MEMS制造工艺,如反应性离子蚀刻[10]、化学气相沉积[11]等,以实现在柔性聚合物材料和刚性材料上批量制造高精度微结构。除此之外,部分研究者们也提出模板法[12]、自组装[13]、纳米压印[14]和软光刻[15]等制造工艺,实现了微结构制造。但是,上述制造工艺通常无法一步制备微结构,具有工艺复杂、生产成本高,还存在加工材料受限、微结构形貌无法调控等问题。相比而言,激光制造技术由于具有非接触式加工、无需掩膜版、可定制化制造等优势[16-18],通过优化激光工艺参数(如激光的功率、扫描速度、填充模式和扫描路径),可实现不同尺寸和形状微结构的高效低成本制造。因此,利用激光制造技术实现微结构制造并应用于生物电、温度和压力传感器中,已成为当前微结构传感器制造技术的研究热点。激光制造技术主要包括激光烧蚀、激光直写、激光诱导、激光-倒模复合加工等。激光烧蚀是基于激光束的热化学、热物理等作用的辅助加热工艺,将待加工材料熔融后实现结构成形;激光直写是将高能光子束聚焦于待加工材料产生光化学过程,通过材料去除制造结构的制造工艺;激光诱导是对待加工材料进行诱导改性,改变材料的物理化学性质的制造工艺;激光-倒模复合加工是利用激光在硅基、玻璃、聚合物等基底上制造出微结构模具,再使用软光刻技术将模具上的结构倒模成形的制造工艺。基于激光与物质相互作用关系,可实现待加工材料的诱导、去除和迁移,通过调控激光加工模式和加工参数,可实现二维或三维微结构的控形制造或敏感单元功能材料的控性制备,突破了微结构传统制造方法的效率和成本的局限。

本文围绕微结构的类型、功能和制造技术进行了归纳分类,总结了微结构的激光制造技术与其他先进制造技术的制备工艺,详细阐述了激光烧蚀、激光直写、激光诱导、激光-倒模复合加工制造技术制备的微结构传感器在生物电传感、温度传感和压力传感方面的应用,最后对微结构传感器激光制造技术的发展趋势进行了总结与展望。

2 微结构的分类与功能

微结构通常可分为微球、微柱、微锥、微沟槽和微孔五类,如图2所示。根据几何结构划分,微球结构分为椭球形和圆球形;微柱结构分为微圆柱和微棱柱;微锥结构分为微圆锥和微棱锥。上述三类微结构根据特定尺寸及排布设计,可实现于穿刺、压力传递、振动传递、药物传递、生物电传导、超疏水表面、自清洁表面、射流减阻、非润湿液体转移和微流道等不同的功能。微沟槽结构根据其几何结构可分为矩形、三角形和波纹状微沟槽;微孔结构可分为蜂巢式微孔、泡沫微孔。微槽孔结构主要用于压力传递、热传导、声传导、气体吸附等,根据孔、槽的尺寸及疏密设计,可实现液体形状控制和运输特性,用于自清洁、油水分离、减阻、液滴运动控制及微流控芯片[19]。

图 2. 微结构的分类

Fig. 2. Classification of microstructures

下载图片 查看所有图片

微结构由于其形状和特性丰富,因此具有不同的功能,被广泛应用于生物医药、柔性电子和光学等领域。在生物医药领域,微锥结构用于药物精准递送[20],如胰岛素、降压药物等;除此之外,还常用于生物电信号传感[21],实现脑电、心电、肌电信号采集。微沟槽广泛应用于微流控芯片[22],可实现生物、化学、医学分析过程的样品制备、反应、分离、检测等操作。微球结构用于药物制备,可作为药物的缓控释载体并提高载药量[23]。在柔性电子领域,五类微结构均被广泛运用,如用于提升压力检测的灵敏度和量程检测范围的压力传感器[24];葡萄糖、乳酸和PH原位检测的生物电化学传感器[25-26];即时诊断新策略的SERS传感器[27];感知温度与压力的智能传感复合电子织物[28]以及柔性热电器件[29]等。在光学领域,微锥和微沟槽结构被制造于光学元件表面,可实现光学增透效果、降低光学各向异性,避免传统增透镀膜制备导致热失配、稳定性差等问题[30];柔性光学超构微柱表面用于表面等离激元传感设备[31];微球结构被广泛用于微透镜设备,提高微纳加工速度和精度,同时也被用于提升光学显微镜分辨率[32]。微柱、微沟槽结构可用于光学谐振腔[33]和菲涅尔透镜等,提升光学性能。

3 微结构的激光制造技术

微球、微柱、微锥、微沟槽和微孔五类微结构适用于不同领域,为实现特定功能,通常需要开展微结构设计,并研究不同尺寸和形状的微结构的制备方法及工艺[34]。随着激光制造技术的发展及微结构应用潜力的开发,现已发展出多种微结构制造方法及工艺,如激光烧蚀、激光直写、激光诱导、激光-倒模复合加工制造技术等,可直接或间接制造出不同类型的微结构,如图3所示。

图 3. 微结构的激光制造方法

Fig. 3. Laser manufacturing method of microstructure

下载图片 查看所有图片

3.3 激光烧蚀技术

激光烧蚀是利用高功率密度激光束照射待加工材料,对材料表面进行烧蚀熔融,转变为液体或气体,通过材料的迁移形成特定的功能结构。吉林大学Jiang等人[35]通过调控飞秒激光器,利用激光烧蚀工艺在铜表面构建了周期性波浪微结构,波浪形微槽结构实现了超疏水性能,也赋予了它们类似蝴蝶翅膀的光学结构色。厦门大学周伟等人[36]利用激光烧蚀工艺,在铜板上制造出微锥阵列,用于生物电传导。西安交通大学Yong等人[37]利用飞秒激光器在硅片上通过烧蚀和喷射粒子的再结晶构建了网格排布的微锥结构,通过氟硅烷的修饰,成功实现了超疏水低粘滞性。麦克马斯特大学Crawford等人[38]通过改变激光能量密度、扫描速度、扫描次数参数,在硅片上切割出不同深度的V型凹槽。中国科学技术大学吴东等人[39]提出了一种通过钛蓝宝石飞秒激光烧蚀的规则微孔阵列铝箔,用于高效水油分离。Yan等人[40]使用飞秒激光烧蚀和选择性激光去除氟化区域制造了具有锥形微孔的Janus铝膜。中国科学技术大学Chen等人[41]使用飞秒激光烧蚀制造疏水性微柱阵列氧化锌薄膜(ZOF),以实现超低电压下各种液体运动状态的原位调控。Lu等人[42]报道了一种简单有效的方法,通过使用能量调谐激光扫描策略在 PDMS薄膜上制造分级微槽仿生结构。首先,通过大功率激光(

)烧蚀获得具有各向异性特征的大槽,然后使用低功率激光(

)制造超疏水微/纳米结构。所制备的表面具有各向异性滑动能力,沿垂直和平行方向的滑动角差异约为6°。激光烧蚀还可以实现金属或非金属纳米线焊接,Han等人[43]使用激光在铜纳米线表面进行加工处理,铜纳米线表面产生等离子体共振,在铜纳米线交界处产生热点,相邻铜纳米线在局部加热下焊接成网络,焊接后的铜纳米线网络的总电阻显著降低。

3.4 激光直写技术

激光直写工艺应用较为广泛,是将高能光子束聚焦于待加工材料,通过材料去除制造结构的制造工艺。电子科技大学何宇豪等人[44]通过激光直写工艺制备了圆柱状阵列结构,应用于柔性压力传感器增强压力传递功能。湖北工业大学Li[45]等人利用飞秒激光的高斯分布特性,在亚克力板上激光直写制备了分层多孔微圆形结构,并采用激光-模板复合制造工艺制造了压阻式压力传感器。北京科技大学Wu等人[46]采用KrF准分子激光器在二氧化硅、ITO玻璃和碳化硅上分别制造了微孔阵列。西安交通大学Fang等人[47]利用激光选择性烧蚀技术制造了聚二甲基硅氧烷(PDMS)表面微槽阵列结构,再通过对微槽的宽度和深度进行调节,引入阶梯结构,使得所制备的PDMS表面具有双向各向异性。西安交通大学陈烽等人[48]采用飞秒激光聚四氟乙烯(PTFE)直写制造尺寸宽度小于100 μm的微通道结构,获得了空气环境超疏水表面,并能在水下环境具备气体自发定向运输功能,实现“气流控”。西安交通大学陈烽等人[49]报道了一种通过湿法蚀刻和飞秒激光直写制造超疏水PDMS微透镜阵列的简单策略。制造的样品表现出出色的成像特征和自清洁功能。最近,该团队利用飞秒激光在形状记忆聚合物上制备了分级微柱阵列(直径约20 μm,高度约45 μm,间距约40 μm),赋予表面超疏水性,微柱阵列在加热条件下可实现倾斜和直立状态之间的可逆调谐。

3.5 激光诱导技术

激光诱导是利用激光束极快地加热材料表面,利用光化学还原、光物理还原制造微结构表面,常用于材料改性。清华大学Tian等人[50]使用激光还原氧化石墨烯的方法制备了具有海绵多孔状结构的石墨烯压力传感器。厦门大学周伟等人[51]改变纳秒激光器扫描间距及氧化石墨烯浓度,通过激光照射光热还原制备了不同电阻的多孔结构石墨烯,使温度传感器实现更稳定的热传导功能。中国科学技术大学Zhu等人[52]通过调节二极管激光器参数,在PDMS薄膜上激光诱导多孔石墨烯结构,可以直接作为柔性导电层使用。北京航空航天大学He等人[53]通过精确调制不同组合的激光功率和脉冲分辨率,在聚酰亚胺原位热解碳化制造了多孔石墨烯结构,制造了用于液体传感、气流和呼吸监测、超声波频率捕获的多模态传感器。Kim等人[54]通过激光辅助光还原可以选择性地诱导

上的Ag纳米粒子,并通过改变辐照时间来控制p型掺杂效应。Szustakiewicz等人[55]使用飞秒激光对聚(L-丙交酯) (PLLA)和羟基磷灰石复合材料进行表面改性,诱导了部分表面非晶化现象,并且使得PLLA分子量降低,可用于人体骨骼修饰。奥本大学Parvin等人[56]通过激光功率、扫描速度和脉冲宽度控制,在钛表面诱导出具有锐钛矿和金红石相的微/纳米结构

。激光诱导水热反应已被用来制备特定性质/功能的金属氧化物,Ko等人[57]使用532 nm连续激光器在具有Au/Ti (厚度220 nm/30 nm)吸收层的玻璃基板上生长的ZnO NW阵列,通过调节衬底的物理性质(尺寸和热导率),实现了对激光诱导温度场的控制,从而在不改变任何复杂光学元件的情况下成功地合成了更小的纳米线阵列。

3.6 激光-倒模复合加工

激光-倒模复合加工是利用激光在硅基、玻璃、聚合物等基底上制造出微结构模具,再使用软光刻技术将模具上的结构倒模成形的制造工艺。亚克力(PMMA)材料可塑性强,造型变化大,加工成型容易,常被用于制造模具。Palaniappan等人[58]使用激光加工亚克力板模具,制造了一组具有锥形微结构的PDMS薄膜。Rana等人[59]用

激光器在亚克力板上制造出微柱结构,制造了双级微结构阵列的Ecoflex薄膜。Igreja等人[60]同样采用激光直写工艺在亚克力板上加工出微锥结构,并制造了PDMS微锥微结构薄膜。Igreja团队[61]还将PDMS固化剂与PDMS预置剂以1:5比例混合配置出较硬的PDMS材料,并采用

激光器进行激光加工,加工出微圆球模具,再制造出具有微球结构的PDMS薄膜。中国科学院Li等人[62]通过近红外激光器在丙烯腈丁二烯苯乙烯(ABS板)上制备了具有多级半球微结构模板并转印出PDMS薄膜。吉林大学徐淮良等人[63]采用飞秒激光在硅片上制造出球状微结构模具,采用软光刻制备了PDMS球状微结构。上述微球结构均用于柔性压力传感器压力敏感层,提升压力传感器灵敏度。Kam等人[64]采用近红外纳秒激光直写硅片,制造了深度范围为20 μm~200 μm的微沟槽,通过激光参数调控微沟槽粗糙度,倒模的PDMS沟槽薄膜可用于人工血管网络。

综上所述,激光制造技术可以实现快速、灵活、高效地制造不同类型的微结构,微结构在传感器的应用领域也随着激光制造技术的发展而不断拓展。

4 微结构传感器的应用

4.1 压力检测

压力传感器是感受压力信号并按照一定的规律将压力信号转换成电信号的传感器,是智能机器人、可穿戴设备的核心功能器件,广泛应用于人机交互、电子皮肤、机器人触觉等领域。根据压力传感机理,压力传感器通常可分为三种类型:压阻式、压电容式和压电式[65]。压力传感器的基本工作原理是在压力作用下,传感器产生的形变或者结构的变化转化为传感器电学(电阻、电容、电流等)或者光学性能参数的变化,由此来反馈外界压力的大小和分布状况。

压力传感器一般采用激光-倒模复合加工技术、激光直写技术制造微结构压力敏感单元,以增强压力传感器的性能。厦门大学周伟等人[66]通过调控紫外激光器的功率、扫描次数等参数,在透明玻璃上制造了有序化排列的三种不同尺寸的半球结构,通过软光刻技术实现半球微结构制造。相较于单一尺寸微结构传感器,有序化排列的多尺寸半球结构将传感器灵敏度提升了1.5倍(8.3 kPa−1),如图4(a)所示。吉林大学徐淮良等人[63]通过半波片和偏正器调节飞秒激光脉冲能量,在硅片上制造了球状微结构模具,采用软光刻制备了PDMS锥状微结构,通过堆叠具有球状结构的PDMS/SWCNTs薄膜制备压阻式压力传感器,实现了高灵敏度(5.4 kPa−1)并成功应用于手部运动压力检测和手腕脉搏的检测。中国科学院杨小牛等人[62]设计了间距400 μm的圆形点阵,通过调控近红外激光器的电流和扫描速度,在ABS板上制造了光滑半球(一级微结构)和粗糙半球(两级微结构)两种不同形貌的阵列结构,两级微结构相较于一级微结构的压力传感器灵敏度提升了3倍(15.4 kPa−1),拥有更好的线性度和更宽量程(200 kPa)。

图 4. 激光制造的压力传感器。(a) 传感器照片及微结构超景深图、响应时间测试、语音识别应用[66];(b) 三种微结构SEM图及传感器性能测试[67];(c) 二级微结构传感器示意图及SEM图像及灵敏度、脉搏性能测试[71];(d) 传感器微结构示意图及SEM图像[72]

Fig. 4. Laser manufacturing pressure sensor. (a) Image of the sensor and microstructure super-depth maps, response time testing, speech recognition applications[66]; (b) SEM images of three microstructures and performance test of sensors[67]; (c) Schematic diagram of microstructure sensor, SEM image, sensitivity and pulse performance test[71]; (d) Schematic diagram of sensor microstructure and SEM image[72]

下载图片 查看所有图片

上述研究工作均采用激光-倒模复合加工技术,该技术制造成本低,可大批量生产,但是工艺较为繁琐且制造效率较低。为进一步提升微结构的高效制备,Xuan等人[67]通过激光器制备了长条形、短条形和微球三种不同尺寸和形状的微结构阵列,实现了电阻式压力传感器的控性制备,微球结构灵敏度性能(1.82 kPa−1)是长条形结构(0.107 kPa−1)的17倍,如图4(b)所示。为了进一步提升柔性压力传感器的灵敏度和量程范围,根据Archard理论[68]和赫兹理论[69]分析,微结构设计由单级微结构向两级或多级微结构拓展[24, 70]。厦门大学周伟等人[71]通过调节激光扫描速度、激光功率及扫描路径,在MWCNTs/PDMS复合柔性聚合物基底上直写制造了一级(直径约200 μm、高约200 μm)和二级(直径约50 μm、高约50 μm)微结构阵列。相较于单级结构性能(0.45 kPa−1),二级压阻式压力传感器灵敏度(11.06 kPa−1)在10 kPa量程范围内提升超过20倍,如图4(c)所示。清华大学冯雪等人[72]通过调节激光扫描间距和功率,在PDMS薄膜上快速制造两级微柱结构,根据激光功率和光斑重叠率构建了微结构加工理论模型,并准确预估了激光制造微结构的高度,为PDMS微结构的控形制造提供了理论依据。制造的压力传感器具有极快的响应速度(7 ms),如图4(d)所示。中国科学技术大学朱芸松等人[73]通过改变二极管激光器的参数,在PDMS基底上原位诱导出石墨烯结构,通过堆叠具有微裂纹结构的PDMS薄膜制备压阻式压力传感器,实现了超高灵敏度(~480 kPa−1)和较好的稳定性。上述激光制造压力传感器性能对比如表1所示。

表 1. 激光制造压力传感器性能对比

Table 1. Performance comparison of laser-manufactured pressure sensors

| 文献 | 最大灵敏度/kPa−1 | 量程/kPa | 响应时间/ms | 循环加载/次 | 微结构类型 | 制造工艺 | | [65] | 8.3 | 200 | 60/70 | 10000 | 微球 | 激光-倒模复合加工 | | [62] | 5.4 | 25 | 80 | — | 微锥 | 激光-倒模复合加工 | | [61] | 15.4 | 200 | 15/20 | 7500 | 微球 | 激光-倒模复合加工 | | [66] | 1.82 | 80 | 36/52 | 6000 | 微球 | 激光直写 | | [70] | 11.06 | 35 | — | 1000 | 两级微球 | 激光直写 | | [71] | 4.48 | 65 | 7/7 | 1000 | 微柱 | 激光直写 | | [72] | 480 | 1 | 2000/3000 | 4000 | 微孔 | 激光诱导 |

|

查看所有表

4.2 温度检测

温度是反映被测物体和周围环境状态的最基本物理参数,温度测量对于医疗保健、可穿戴设备、环境监测和工业生产至关重要。近年来,随着微纳制造技术和新材料(纳米材料、导电聚合物)的发展,微结构柔性温度传感器的应用也越来越广泛[74]。根据温度测量原理,可将温度传感器分为热电偶和热敏电阻两类。热电偶是由两种不同的导热元件(导体或半导体)构成,它们可以根据热电现象产生电位差或电压,由此精确感知温度。热敏电阻是利用电阻随温度发生变化的热敏材料制成,根据热敏电阻随温度变化趋势不同,可将热敏电阻分为正温度系数电阻和负温度系数电阻。微孔结构具有较大的比表面积,可显著增强热传递作用,是提高温度传感器传热性能的关键结构。

碳基柔性温度传感器一般采用激光诱导技术制造微孔结构以增强热传递效应。目前,多孔结构氧化石墨烯的激光还原(laser reduction of graphene oxide, LrGO)已成为在室温和大气环境下快速、低成本制备多孔微结构石墨烯的最佳选择[75]。厦门大学周伟等人[51]通过调控紫外纳秒激光器的扫描线间距和氧化石墨烯(GO)浓度两个关键工艺参数,实现了还原氧化石墨烯(rGO)高效低成本的控性制备,揭示了LrGO中的缺陷程度与温度传感器的灵敏度呈正相关,实现了超快响应速度(193 ms)、重复性好(R2 = 0.999)、迟滞小和湿度稳定性好等优点,可用于呼吸监测、曲面温度检测等应用,如图5(a)所示。Francisco等人[76]通过调节激光功率,在GO薄膜上还原出多孔石墨烯结构,通过对rGO电阻的可控调节,制备了良好线性度(R2 = 0.99)的温度传感器,如图5(b)所示。Kazemzadeh等人[77]通过改变CO2激光扫描间距,制备了高导电性(电阻率小于3×10−3 S/m)的多孔石墨烯薄膜,可用于人体皮肤健康检测,如图5(c)所示。韩国西营大学Lee等人[78]通过激光照射技术将GO还原成半透明多孔石墨烯,实现了高灵敏度(0.52% ℃−1)温度传感性能,如图5(d)所示。

图 5. 基于激光还原氧化石墨烯的温度传感器。(a) 传感器实物图和还原氧化石墨烯SEM图以及传感器灵敏度、弯曲测试、迟滞测试、吹气和呼吸性能测试及曲面测试[51];(b) 激光还原氧化石墨烯传感器实物图[76];(c) 激光划线加工还原氧化石墨烯[77];(d) 温度传感器制造流程[78].

Fig. 5. Temperature sensor based on the laser reduction of graphene oxide. (a) Image of the sensor, SEM image of the reduced graphene oxide, sensitivity, bending test hysteresis test, blowing and breathing performance test and curved surface test of the sensor[51]; (b) Laser reduced graphene oxide sensor diagram[76]; (c) Reduction of graphene oxide by laser[77]; (d) Sensor manfacturing process[78]

下载图片 查看所有图片

近几年,研究者们利用CO2红外激光器在大气环境条件下对聚酰亚胺(PI)、木材和棉花等富含碳的前体进行原位制造多孔微结构的石墨烯[79-80],该方法基于激光诱导技术直接利用衬底材料作为碳源,极大地简化了制备过程,降低了成本。韩国光云大学Park等人[81]通过改变CO2脉冲激光器的激光功率、扫描轨迹和扫描速度,在PI上原位制备了不同电阻的多孔石墨烯结构,实现了表现出了0.174% ℃−1的良好灵敏度,如图6(a)所示。大阪府立大学Takei等人[82]通过调节激光器功率和扫描速度,在PI上诱导出多孔石墨电极,并将30 µL的

纳米片溶液滴在多孔电极表面形成多孔薄膜,展现出了良好的实时温度监测性能,如图6(b)所示。日本国家先进工业科学技术研究所Nakajima等人[83]利用紫外脉冲激光器在PI薄膜上原位诱导出5 µm的超薄热敏电阻多孔薄膜,通过浸渍纳米银颗粒制备温度传感器,在1000次循升降温测试,温度仅发生±0.4 ℃(高温)和±0.5 ℃(低温)范围内波动,展示了良好的稳定性,如图6(c)所示。Le等人[84]使用紫外飞秒激光器在树叶上实现石墨烯图案快速制备,叶子仍然保持柔韧性。将叶子弯曲套于手腕,可实现温度传感,且具有0.08% ℃−1的灵敏度,如图6(d)所示。

图 6. 基于激光诱导石墨烯的温度传感器。(a) NMP钝化BP纳米片典型层状形态的TEM图像和传感器颈静脉测量的照片[81];(b) 多孔石墨烯电极上ZIS纳米片横截面图的照片和SEM图像[82];(c) 3×3传感器照片和温度监测响应曲线[83];(d) 树叶表面诱导石墨烯图案化用于温度传感器[84]

Fig. 6. Temperature sensor based on the laser-induced graphene. (a) TEM image of the typical layered morphology of NMP-passivated BP nanosheet and Photograph illustrating location of sensor for jugular vein pulse measurement[81]; (b) Device photograph and SEM images of cross-sectional view of the ZIS nanosheets on porous graphene electrodes[82]; (c) Photograph of the 3 × 3 sensor and response curves for temperature monitoring[83]; (d) Leaf surface induced graphene patterning for temperature sensors[84]

下载图片 查看所有图片

上述采用激光诱导工艺制造的多孔微结构温度传感器均展现了良好的灵敏度性能和较大的温度测量范围,如表2所示。

表 2. 激光制造温度传感器性能对比

Table 2. Performance comparison of laser-manufactured temperature sensors

| 文献 | 灵敏度 | 范围/℃ | 响应时间 | 微结构类型 | 制造工艺 | | [50] | 0.37% ℃−1 | 30~100 | 0.196 s/9.7 s | 微孔 | 激光诱导(rGO) | | [75] | 0.08% ℃−1 | 25~75 | — | 微孔 | 激光诱导(rGO) | | [77] | 0.52% ℃−1 | 15~170 | — | 微孔 | 激光诱导(rGO) | | [79] | 0.174% ℃−1 | 25~50 | — | 微孔 | 激光诱导(LIG) | | [80] | 9.84 Ω/℃ | 18~54 | — | 微孔 | 激光诱导(LIG) | | [81] | — | 20~80 | 106 ms/281 ms | 微孔 | 激光诱导(LIG) | | [82] | 0.08% ℃−1 | 25~50 | 7.0 s/6.2 s | 微孔 | 激光诱导(LIG) |

|

查看所有表

4.3 生物电检测

生物电是生物的器官、组织和细胞在生命活动过程中发生的电位和极性变化,通常指生物细胞的静电压及在组织中的电流(如神经和肌肉中的电流),是正常生理活动的表现,也是生物组织的一个基本特征。各种生物电位的测量都需要使用生物电传感器,在生物电信号采集与利用过程中,生物电传感器作为一种能够有效地将生物体电化学活动产生的离子电位转换成测量系统电子电位的传感器,广泛应用于现代临床检测和生物医学测量。由于生物电传感器使用过程中与人体皮肤组织直接接触,因此需要电极具有良好的导电性、皮肤贴合稳定性和舒适性以及电信号采集可靠性和稳定性。为了让电极具备上述功能,研究者们将微结构阵列制造于电极表面,使得电极可直接穿透皮肤角质层,不需要涂覆导电凝胶,避免了皮肤过敏、测量过程中的接触不稳定[85-86]。因此,微结构电极一般是采用硅、金属、聚合物或玻璃等材料制备而成,以增强刺入性能和导电性。

生物电传感器一般采用激光-倒模复合加工技术、激光直写技术、激光烧蚀制造传感器微针阵列敏感单元,实现皮肤穿刺和生物电信号传导功能。韩国仁川大学Kang等人[87]通过调节CO2激光器扫描速度、在聚四氟乙烯上制造出微针模具,通过聚乳酸热压成型制造微针阵列,实现了微针长度(390 μm~1600 μm)的精准调控,如图7(a)所示。日本东海大学Tsuchiya等人[88]通过激光-倒模复合加工制造工艺,在不锈钢上制造微针模具,通过软光刻技术制造PDMS微针生物电传感器,如图7(b)所示。由于软光刻工艺的材料特点,使得微针阵列的刚度较低,多次使用后易变形。为了解决电极刚度较低、制造工艺复杂等问题,厦门大学周伟等人[36, 89]通过纳秒激光器的扫描间距、扫描功率、扫描速度和扫描次数等激光工艺参数优化,精准调控金属溶体飞溅和重铸方向,实现材料的定点去除和堆积,在金属铜表面形成疏密可调的微针结构阵列,如图7(c)所示。除此之外,通过改变激光的入射角度,在金属铜表面上制备倾斜微针阵列结构,与传统垂直微结构相比,倾斜微结构的电极在生物电测量中具有更小的阻抗(<18 Ω)[90]。乔治亚理工学院Birchall等人[91]采用激光烧蚀工艺在钢板上切割出平面微针图案,然后将微针弯曲90°,以实现微针阵列制造,如图7(d)所示。中山大学Liu等人[92]通过调控脉冲光纤激光器的工艺参数,在钛金属表面切割出平面微针阵列,制造复合微针阵列电极,刺入皮肤100次后,微针不产生断裂,表现出了良好的机械性能,如图7(e)所示。

图 7. 微针阵列生物电传感器。(a) 传感器上的微针阵列的SEM图像和顶部光学图像[87];(b) Au沉积前PDMS微针的扫描电子显微镜图像[88];(c) 干电极制造流程及微针阵列SEM图像[36, 89];(d) 电极光学图像[91];(e) 电极照片和微针阵列SEM图像[92]

Fig. 7. Microneedle Array Bioelectric Sensors. (a) SEM image of an array of microneedles on the sensor and top views of the microneedle sensor equipped with an adhesive film[87]; (b) Scanning electron microscope image of the PDMS microneedle before Au deposition[88]; (c) Dry electrode manufacturing process and SEM image of microneedle array[36, 89]; (d) Electrode optical image[91]; (e) Photograph of the sensor and SEM image of the microneedle[92]

下载图片 查看所有图片

5 结论与展望

随着激光制造技术、微电子技术的飞速发展,微结构传感器的研究与开发获得长足的进步。微结构作为传感器的关键敏感单元,显著提升了传感器的生物电信号传导稳定性、传热效率、力传递、传感范围等特性,已经广泛应用于生物电传感器、温度传感器及压力传感器,更多的潜在传感器应用也随着微结构创新设计而不断拓展与完善。根据现有的文献报道分析,利用激光技术实现了微球、微柱、微锥、微沟槽和微孔等结构的高效低成本制造,均已在传感器设计开发中发挥了重要作用,显著提升了传感器灵敏度、量程、线性度等性能。随着微结构传感器应用于智能机器人、可穿戴设备、生物医疗、人机交互等领域的需求不断扩大,对于三维有序化微结构制造、复杂曲面原位/保形制造的要求也日益增加。但是,激光制造微结构传感器仍面临着巨大挑战:微结构加工过程中,微结构表面形貌的关键影响因素如何确定?如何调控工艺参数实现三维有序化多级微结构制造成形?如何建立三维有序化多级微结构的激光加工材料去除机理等。因此,迫切需要提出激光制造新方法和新理论,将有利于进一步完善智能传感器设计、制造理论及应用集成方法体系,在智能传感器领域形成具有核心自主知识产权的技术,为有效解决智能传感器共性问题提供相关技术和理论支撑。

参考文献

[1] Ruth S R A, Feig V R, Tran H, et alMicroengineering pressure sensor active layers for improved performanceAdv Funct Mater20203039200349110.1002/adfm.202003491

[2] Satti A T, Park J, Park J, et alFabrication of parylene-coated microneedle array electrode for wearable ECG deviceSensors20202018518310.3390/s20185183

[3] Jiang H, Zhang X, Gu W, et alSynthesis of ZnO particles with multi-layer and biomorphic porous microstructures and ZnO/rGO composites and their applications for photocatalysisChem Phys Lett201871110010610.1016/j.cplett.2018.08.013

[4] Chao M Y, Wang Y G, Ma D, et alWearable MXene nanocomposites-based strain sensor with tile-like stacked hierarchical microstructure for broad-range ultrasensitive sensingNano Energy20207810518710.1016/j.nanoen.2020.105187

[5] Schwartz G, Tee B C K, Mei J G, et alFlexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoringNat Commun20134185910.1038/ncomms2832

[6] Billard A, Kragic DTrends and challenges in robot manipulationScience20193646446eaat841410.1126/science.aat8414

[7] Yang J C, Mun J, Kwon S Y, et alElectronic skin: recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prostheticsAdv Mater20193148190476510.1002/adma.201904765

[8] Tran A V, Zhang X M, Zhu B LThe development of a new piezoresistive pressure sensor for low pressuresIEEE Trans Ind Electron20186586487649610.1109/TIE.2017.2784341

[9] Li J, Bao R R, Tao J, et alRecent progress in flexible pressure sensor arrays: from design to applicationsJ Mater Chem C2018644118781189210.1039/C8TC02946F

[10] Tachi S, Tsujimoto K, Okudaira SLow-temperature reactive ion etching and microwave plasma etching of siliconAppl Phys Lett198852861661810.1063/1.99382

[11] Kong J, Cassell A M, Dai H JChemical vapor deposition of methane for single-walled carbon nanotubesChem Phys Lett19982924–656757410.1016/S0009-2614(98)00745-3

[12] Martin C R, Van Dyke L S, Cai Z H, et alTemplate synthesis of organic microtubulesJ Am Chem Soc1990112248976897710.1021/ja00180a050

[13] Whitesides G M, Grzybowski BSelf-assembly at all scalesScience200229555642418242110.1126/science.1070821

[14] Chou S Y, Krauss P R, Renstrom P JNanoimprint lithographyJ Vac Sci Technol B Microelectron Nanometer Struct Process Meas Phenom19961464129413310.1116/1.588605

[15] Xia Y N, Whitesides G MSoft lithographyAnnu Rev Mater Sci199828115318410.1146/annurev.matsci.28.1.153

[16] Yong J L, Yang Q, Guo C L, et alA review of femtosecond laser-structured superhydrophobic or underwater superoleophobic porous surfaces/materials for efficient oil/water separationRSC Adv2019922124701249510.1039/C8RA10673H

[17] Zhang C Y, Zhou W, Geng D, et alLaser direct writing and characterizations of flexible piezoresistive sensors with microstructuresOpto-Electron Adv2021440420006110.29026/oea.2021.200061

[18] 张嘉琪, 高阳, 李淳, 等基于激光直写的柔性天线传感器研究光电工程202249121031610.12086/oee.2022.210316

Zhang J Q, Gao Y, Li C, et alLaser direct writing of flexible antenna sensor for strain and humidity sensingOpto-Electron Eng202249121031610.12086/oee.2022.210316

[19] 汪延成, 刘佳薇, 盘何旻, 等聚合物基表面微结构的逐面式制造技术研究进展机械工程学报2021572122023310.3901/JME.2021.21.220

Wang Y C, Liu J W, Pan H M, et alRecent progress on manufacturing technologies in layer-by-layer mode for the fabrication of polymer-based surface microstructuresJ Mech Eng2021572122023310.3901/JME.2021.21.220

[20] Tran K T M, Gavitt T D, Farrell N J, et alTransdermal microneedles for the programmable burst release of multiple vaccine payloadsNat Biomed Eng202159998100710.1038/s41551-020-00650-4

[21] 周伟, 刘伟, 邱清富, 等生物医用电极制造技术及应用研究进展科学通报201560151352136010.1360/N972014-01093

Zhou W, Liu W, Qiu Q F, et alDevelopment, fabrication, and applications of biomedical electrodesChin Sci Bull201560151352136010.1360/N972014-01093

[22] Shi Y, Xu B, Wu D, et alResearch progress on fabrication of functional microfluidic chips using femtosecond laser direct writing technologyChin J Lasers20194610100000110.3788/CJL201946.1000001

史杨, 许兵, 吴东, 等飞秒激光直写技术制备功能化微流控芯片研究进展中国激光20194610100000110.3788/CJL201946.1000001

[23] Cao Y, Yuan X W, Wang X, et alSynthesis and controlled release kinetics of pH-sensitive hollow polyaniline microspheres encapsuled with the corrosion inhibitorJ Mol Liq202134211749710.1016/j.molliq.2021.117497

[24] Tang X, Wu C Y, Gan L, et alMultilevel microstructured flexible pressure sensors with ultrahigh sensitivity and ultrawide pressure range for versatile electronic skinsSmall20191510180455910.1002/smll.201804559

[25] 肖靖吁. 新型可穿戴式生物传感器的构建及其对汗液分析的研究[D]. 北京: 北京科技大学, 2022.

Xiao J Y. Construction of novel wearable biosensors and their researches on sweat analysis[D]. Beijing: University of Science and Technology Beijing, 2022.

[26] Xu G, Cheng C, Liu Z Y, et alBattery-free and wireless epidermal electrochemical system with all-printed stretchable electrode array for multiplexed In situ sweat analysisAdv Mater Technol201947180065810.1002/admt.201800658

[27] Xu K C, Zhou R, Takei K, et alToward flexible surface-enhanced Raman scattering (SERS) sensors for point-of-care diagnosticsAdv Sci2019616190092510.1002/advs.201900925

[28] Wu R H, Ma L Y, Hou C, et alSilk composite electronic textile sensor for high space precision 2D combo temperature–pressure sensingSmall20191531190155810.1002/smll.201901558

[29] Wang Y, Yang L, Shi X L, et alFlexible thermoelectric materials and generators: challenges and innovationsAdv Mater20193129180791610.1002/adma.201807916

[30] Park K C, Choi H J, Chang C H, et alNanotextured silica surfaces with robust superhydrophobicity and omnidirectional broadband supertransmissivityACS Nano2012653789379910.1021/nn301112t

[31] Cai J X, Zhang C P, Liang C W, et alSolution-processed large-area gold nanocheckerboard metasurfaces on flexible plastics for plasmonic biomolecular sensingAdv Opt Mater2019719190051610.1002/adom.201900516

[32] Chen L W, Zhou Y, Wu M X, et alRemote-mode microsphere nano-imaging: new boundaries for optical microscopesOpto-Electron Adv20181117000110.29026/oea.2018.170001

[33] Esmann M, Lamberti F R, Harouri A, et alBrillouin scattering in hybrid optophononic Bragg micropillar resonators at 300 GHzOptica20196785485910.1364/OPTICA.6.000854

[34] Liao J N, Zhang D S, Li Z GAdvance in femtosecond laser fabrication of flexible electronicsOpto-Electron Eng202249221038810.12086/oee.2022.210388

廖嘉宁, 张东石, 李铸国飞秒激光制备柔性电子器件进展光电工程202249221038810.12086/oee.2022.210388

[35] Jiang H B, Zhang Y L, Liu Y, et alBioinspired few-layer graphene prepared by chemical vapor deposition on femtosecond laser-structured Cu foilLaser Photonics Rev201610344145010.1002/lpor.201500256

[36] Zhou W, Liu W, Liu S Y, et alExperimental investigation on surface wettability of copper-based dry bioelectrodesSensors Actuat A Phys201624423724210.1016/j.sna.2016.04.044

[37] Yong J L, Yang Q, Chen F, et alStable superhydrophobic surface with hierarchical mesh-porous structure fabricated by a femtosecond laserAppl Phys A2013111124324910.1007/s00339-013-7572-z

[38] Crawford T H R, Borowiec A, Haugen H KFemtosecond laser micromachining of grooves in silicon with 800 nm pulsesAppl Phys A20058081717172410.1007/s00339-004-2941-2

[39] Li G Q, Fan H, Ren F F, et alMultifunctional ultrathin aluminum foil: oil/water separation and particle filtrationJ Mater Chem A2016448188321884010.1039/C6TA08231A

[40] Yan S G, Ren F F, Li C Z, et alUnidirectional self-transport of air bubble via a Janus membrane in aqueous environmentAppl Phys Lett20181132626160210.1063/1.5052566

[41] Chen C, Huang Z C, Jiao Y L, et alIn situ reversible control between sliding and pinning for diverse liquids under ultra-low voltageACS Nano20191355742575210.1021/acsnano.9b01180

[42] Lu Y, Yu L D, Zhang Z, et alBiomimetic surfaces with anisotropic sliding wetting by energy-modulation femtosecond laser irradiation for enhanced water collectionRSC Adv2017718111701117910.1039/C6RA28174E

[43] Han S, Hong S, Ham J, et alFast plasmonic laser nanowelding for a Cu-nanowire percolation network for flexible transparent conductors and stretchable electronicsAdv Mater201426335808581410.1002/adma.201400474

[44] 何宇豪. 基于SU8胶制备立体结构柔性压阻传感器及其性能研究[D]. 成都: 电子科技大学, 2019.

He Y H. The fabrication and capability researches about flexible piezoresistive sensor based on SU8 photoresist[D]. Chengdu: University of Electronic Science and Technology of China, 2019.

[45] Li J, Wu T Y, Jiang H, et alUltrasensitive hierarchical piezoresistive pressure sensor for wide-range pressure detectionAdv Intell Syst2021311210007010.1002/aisy.202100070

[46] Wu Y, Ji L F, Lin Z Y, et alSubstrate effect of laser surface sub-micro patterning by means of self-assembly SiO2 microsphere arrayAppl Surf Sci201535783283710.1016/j.apsusc.2015.09.066

[47] Fang Y, Yong J L, Chen F, et alBioinspired fabrication of bi/tridirectionally anisotropic sliding superhydrophobic PDMS surfaces by femtosecond laserAdv Mater Interfaces201856170124510.1002/admi.201701245

[48] Yong J L, Yang Q, Huo J L, et alUnderwater gas self-transportation along femtosecond laser-written open superhydrophobic surface microchannels (< 100µm) for bubble/gas manipulationInt J Extreme Manuf20224101500210.1088/2631-7990/ac466f

[49] Li M J, Yang Q, Chen F, et alIntegration of great water repellence and imaging performance on a superhydrophobic PDMS microlens array by femtosecond laser microfabricationAdv Eng Mater2019213180099410.1002/adem.201800994

[50] Tian H, Shu Y, Wang X F, et alA graphene-based resistive pressure sensor with record-high sensitivity in a wide pressure rangeSci Rep20155860310.1038/srep08603

[51] Chen R, Luo T, Geng D, et alFacile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interfaceCarbon2022187354610.1016/j.carbon.2021.10.064

[52] Zhu Y S, Cai H B, Ding H Y, et alFabrication of low-cost and highly sensitive graphene-based pressure sensors by direct laser scribing polydimethylsiloxaneACS Appl Mater Interfaces20191166195620010.1021/acsami.8b17085

[53] He M H, Wang Y N, Wang S R, et alLaser-induced graphene enabled 1D fiber electronicsCarbon202016830831810.1016/j.carbon.2020.06.084

[54] Kim E, Lee Y, Ko C, et alTuning the optical and electrical properties of MoS2 by selective Ag photo-reductionAppl Phys Lett2018113101310510.1063/1.5022705

[55] Szustakiewicz K, Stępak B, Antończak A, et alFemtosecond laser-induced modification of PLLA/hydroxyapatite compositePolym Degrad Stab201814915216110.1016/j.polymdegradstab.2018.01.015

[56] Fathi-Hafshejani P, Johnson H, Ahmadi Z, et alPhase-selective and localized TiO2 coating on additive and wrought titanium by a direct laser surface modification approachACS Omega2020527167441675110.1021/acsomega.0c01671

[57] Yeo J, Hong S, Kim G, et alLaser-induced hydrothermal growth of heterogeneous metal-oxide nanowire on flexible substrate by laser absorption layer designACS Nano2015966059606810.1021/acsnano.5b01125

[58] Palaniappan V, Masihi S, Panahi M, et al. Laser-assisted fabrication of flexible micro-structured pressure sensor for low pressure applications[C]//2019 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), 2019: 1–3.

[59] Rana A, Roberge J P, Duchaine VAn improved soft dielectric for a highly sensitive capacitive tactile sensorIEEE Sens J201616227853786310.1109/JSEN.2016.2605134

[60] Dos Santos A, Pinela N, Alves P, et alPiezoresistive E-skin sensors produced with laser engraved moldsAdv Electron Mater201849180018210.1002/aelm.201800182

[61] Dos Santos A, Pinela N, Alves P, et alE-skin bimodal sensors for robotics and prosthesis using PDMS molds engraved by laserSensors201919489910.3390/s19040899

[62] Li Z Y, Zhang B, Li K, et alA wide linearity range and high sensitivity flexible pressure sensor with hierarchical microstructures via laser markingJ Mater Chem C2020893088309610.1039/C9TC06352H

[63] Su Y, Zhang W, Chen S M, et alPiezoresistive electronic-skin sensors produced with self-channeling laser microstructured silicon moldsIEEE Trans Electron Devices202168278679210.1109/TED.2020.3045962

[64] Kam D H, Kim J, Mazumder JNear-IR nanosecond laser direct writing of multi-depth microchannel branching networks on siliconJ Manuf Process2018359910610.1016/j.jmapro.2018.07.023

[65] Xu F L, Li X Y, Shi Y, et alRecent developments for flexible pressure sensors: a reviewMicromachines201891158010.3390/mi9110580

[66] Geng D, Chen S Y, Chen R, et alTunable wide range and high sensitivity flexible pressure sensors with ordered multilevel microstructuresAdv Mater Technol202276210103110.1002/admt.202101031

[67] Gao Y, Lu C, Yu G H, et alLaser micro-structured pressure sensor with modulated sensitivity for electronic skinsNanotechnology2019303232550210.1088/1361-6528/ab1a86

[68] Archard J FElastic deformation and the laws of frictionProc Roy Soc A Math Phys Sci1957243123319020510.1098/rspa.1957.0214

[69] Schallamach AThe load dependence of rubber frictionProc Phys Soc B195265965766110.1088/0370-1301/65/9/301

[70] Shi J D, Wang L, Dai Z H, et alMultiscale hierarchical design of a flexible piezoresistive pressure sensor with high sensitivity and wide linearity rangeSmall20181427180081910.1002/smll.201800819

[71] Zhang C Y, Chen R, Xiao C Q, et alLaser direct writing of highly ordered two-level hierarchical microstructures for flexible piezoresistive sensor with enhanced sensitivityAdv Mater Interfaces202291210159610.1002/admi.202101596

[72] Du Q F, Liu L L, Tang R T, et alHigh-performance flexible pressure sensor based on controllable hierarchical microstructures by laser scribing for wearable electronicsAdv Mater Technol202169210012210.1002/admt.202100122

[73] 朱芸松. 基于石墨烯的表皮压力传感器的设计、制备与建模[D]. 合肥: 中国科学技术大学, 2018.

Zhu Y S. Design, fabrication and modeling of Graphene epidermal pressure sensor[D]. Hefei: University of Science and Technology of China, 2018.

[74] Chen Z T, Zhao D N, Ma R, et alFlexible temperature sensors based on carbon nanomaterialsJ Mater Chem B2021981941196410.1039/D0TB02451A

[75] Gao W, Singh N, Song L, et alDirect laser writing of micro-supercapacitors on hydrated graphite oxide filmsNat Nanotechnol20116849650010.1038/nnano.2011.110

[76] Romero FJ, Ortiz-Gomez I, Salinas A, et al. Temperature sensing by laser reduced graphene oxide at different laser power levels[C]//2020 IEEE Sensors, 2020: 1–5.

[77] Kazemzadeh R, Kim W S. Flexible temperature sensor with laser scribed Graphene oxide[C]//14th IEEE International Conference on Nanotechnology, 2014: 420–423.

[78] Jung H, Lee HSemi-transparent reduced graphene oxide temperature sensor on organic light-emitting diodes for fingerprint liveness detection of smartphone authenticationSensors Actuat A Phys202133111287610.1016/j.sna.2021.112876

[79] Lin J, Peng Z W, Liu Y Y, et alLaser-induced porous graphene films from commercial polymersNat Commun201451571410.1038/ncomms6714

[80] Wan Z F, Chen X, Gu MLaser scribed graphene for supercapacitorsOpto-Electron Adv20214720007910.29026/oea.2021.200079

[81] Chhetry A, Sharma S, Barman S C, et alBlack phosphorus@laser-engraved graphene heterostructure-based temperature-strain hybridized sensor for electronic-skin applicationsAdv Funct Mater20213110200766110.1002/adfm.202007661

[82] Lu Y Y, Fujita Y, Honda S, et alWireless and flexible skin moisture and temperature sensor sheets toward the study of thermoregulator centerAdv Healthcare Mater20211017210010310.1002/adhm.202100103

[83] Nakajima T, Tsuchiya TUltrathin highly flexible featherweight ceramic temperature sensor arraysACS Appl Mater Interfaces20201232366003660810.1021/acsami.0c08718

[84] Le T S D, Park S, An J N, et alUltrafast laser pulses enable one-step graphene patterning on woods and leaves for green electronicsAdv Funct Mater20192933190277110.1002/adfm.201902771

[85] Niu X, Gao X H, Liu Y F, et alSurface bioelectric dry electrodes: a reviewMeasurement202118310977410.1016/j.measurement.2021.109774

[86] Fu Y L, Zhao J J, Dong Y, et alDry electrodes for human bioelectrical signal monitoringSensors20202013365110.3390/s20133651

[87] Baek J Y, Kang K M, Kim H J, et alManufacturing process of polymeric microneedle sensors for mass productionMicromachines20211211136410.3390/mi12111364

[88] Mania G K, Ponnusamy D, Tsuchiya K. Ultrafast fabrication of microneedle array for transdermal Ion detection[C]//2018 International Symposium on Micro-NanoMechatronics and Human Science (MHS), 2018: 1–3.

[89] Zhou W, Ling W S, Liu W, et alLaser direct micromilling of copper-based bioelectrode with surface microstructure arrayOpt Lasers Eng20157371510.1016/j.optlaseng.2015.03.011

[90] Zhou W, Liu S Y, Liu W, et alNovel dry metal electrode with tilted microstructure fabricated with laser micromilling processSensors Actuat A Phys2017264768310.1016/j.sna.2017.07.028

[91] Pearton M, Saller V, Coulman S A, et alMicroneedle delivery of plasmid DNA to living human skin: formulation coating, skin insertion and gene expressionJ Control Release2012160356156910.1016/j.jconrel.2012.04.005

[92] Sun Y W, Ren L, Jiang L L, et alFabrication of composite microneedle array electrode for temperature and bio-signal monitoringSensors2018184119310.3390/s18041193

陈锐, 王锦成, 章文卓, 计东生, 朱鑫宁, 罗涛, 王菁, 周伟. 微结构传感器的激光制造技术研究进展[J]. 光电工程, 2023, 50(3): 220041. Rui Chen, Jincheng Wang, Wenzhuo Zhang, Dongsheng Ji, Xinning Zhu, Tao Luo, Jing Wang, Wei Zhou. Research progress of laser manufacturing technology for microstructure sensor[J]. Opto-Electronic Engineering, 2023, 50(3): 220041.

![激光制造的压力传感器。(a) 传感器照片及微结构超景深图、响应时间测试、语音识别应用[66];(b) 三种微结构SEM图及传感器性能测试[67];(c) 二级微结构传感器示意图及SEM图像及灵敏度、脉搏性能测试[71];(d) 传感器微结构示意图及SEM图像[72]](/richHtml/gdgc/2023/50/3/220041/5_220041-4.jpg)

![基于激光还原氧化石墨烯的温度传感器。(a) 传感器实物图和还原氧化石墨烯SEM图以及传感器灵敏度、弯曲测试、迟滞测试、吹气和呼吸性能测试及曲面测试[51];(b) 激光还原氧化石墨烯传感器实物图[76];(c) 激光划线加工还原氧化石墨烯[77];(d) 温度传感器制造流程[78].](/richHtml/gdgc/2023/50/3/220041/5_220041-5.jpg)

![基于激光诱导石墨烯的温度传感器。(a) NMP钝化BP纳米片典型层状形态的TEM图像和传感器颈静脉测量的照片[81];(b) 多孔石墨烯电极上ZIS纳米片横截面图的照片和SEM图像[82];(c) 3×3传感器照片和温度监测响应曲线[83];(d) 树叶表面诱导石墨烯图案化用于温度传感器[84]](/richHtml/gdgc/2023/50/3/220041/5_220041-6.jpg)

![微针阵列生物电传感器。(a) 传感器上的微针阵列的SEM图像和顶部光学图像[87];(b) Au沉积前PDMS微针的扫描电子显微镜图像[88];(c) 干电极制造流程及微针阵列SEM图像[36, 89];(d) 电极光学图像[91];(e) 电极照片和微针阵列SEM图像[92]](/richHtml/gdgc/2023/50/3/220041/5_220041-7.jpg)