高能激光单晶硅反射镜纳米精度控形控性制造技术  下载: 1372次特邀综述

下载: 1372次特邀综述

石峰, 田野, 乔硕, 周光奇, 宋辞, 薛帅, 铁贵鹏, 周林, 舒勇, 周港. 高能激光单晶硅反射镜纳米精度控形控性制造技术[J]. 中国激光, 2021, 48(4): 0401007.

Feng Shi, Ye Tian, Shuo Qiao, Guangqi Zhou, Ci Song, Shuai Xue, Guipeng Tie, Lin Zhou, Yong Shu, Gang Zhou. Nanoprecision Control of Shape and Performance Manufacturing Technology for High-Energy Laser Silicon Components[J]. Chinese Journal of Lasers, 2021, 48(4): 0401007.

[2] 余德明, 段微波, 李大琪, 等. 偏振和相位调控反射镜的设计与制备[J]. 光学学报, 2020, 40(15): 1531001.

[3] 邵山川, 陶小平, 王孝坤. 基于条纹反射的超精密车削反射镜的在位面形检测[J]. 激光与光电子学进展, 2018, 55(7): 071203.

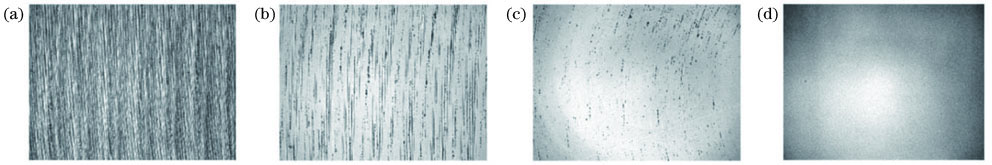

[5] Tian Y, Shi F, Dai Y F, et al. Laser absorption precursor research: microstructures in the subsurface of mono-crystalline silicon substrate[J]. Applied Optics, 2017, 56(30): 8507-8512.

[6] 田野, 戴一帆, 石峰, 等. 单晶硅反射镜激光能量吸收系数与衬底表面质量的关联[J]. 国防科技大学学报, 2015, 37(6): 26-29.

[8] 张欣, 黄婷, 肖荣诗. 不同晶面单晶硅在飞秒激光作用下的行为特性[J]. 中国激光, 2017, 44(1): 0102012.

[12] 康仁科, 田业冰, 郭东明, 等. 一种硬脆晶体基片超精密磨削砂轮: CN1951635[P].2007-04-25.

Kang RK, Tian YB, Guo D M. An ultra-precision grinding wheel for hard and brittle crystal substrates:CN1951635[P]. 2007-04-25.

[13] 金钊, 李锦胜, 康仁科, 等. 应用软磨料磨削的单晶硅超精密制造技术[J]. 光电工程, 2011, 38(12): 75-80.

[14] 陈冰. 红外材料非球面透镜的超精密磨削加工关键技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.

ChenB. Key technology on ultra-precision grinding of infrared aspheric lens[D]. Harbin:Harbin Institute of Technology, 2015.

[15] Niu YJ, Dai YF, Guan CL, et al. Study on the technology of ultra-precision grinding for aspheric mirror of monocrystalline silicon[C]//The 6th International Conference of Asian Society for Precision Engineering and Nanotechnology. Harbin: [s.n.], 2015.

[16] 尹韶辉, 陈逢军, 张导成, 等. 结合ELID磨削与磁流变光整加工的单晶硅反射镜超精密制造技术[J]. 纳米技术与精密工程, 2007, 5(3): 220-223.

[17] 田野. 单晶硅反射镜高精度低缺陷制造关键技术研究[D]. 长沙: 国防科技大学, 2018.

TianY. The key technology research of high-precision and low-defect fabrication for silicon reflectors[D]. Changsha: National University of Defense Technology, 2018.

[18] Shen Z X, Ma B, Wang Z S, et al. Fabrication of flat and supersmooth surfaces with bowl-feed polishing process[J]. Proceedings of SPIE, 2007, 6722: 67220U.

[21] Cheng W M, Chen M Y. Transformation and connection of subapertures in the multiaperture overlap-scanning technique for large optics tests[J]. Optical Engineering, 1993, 32: 1947-1950.

[22] 周林. 光学镜面离子束修形理论与工艺研究[D]. 长沙: 国防科学技术大学, 2008.

ZhouL. Study on theory and technology in ion beam figuring for optical surfaces[D]. Changsha: National University of Defense Technology, 2008.

[23] 宋辞, 田野, 石峰, 等. 单晶硅柱面反射镜离子束倾斜入射加工工艺优化[J]. 光学学报, 2020, 40(12): 1222001.

石峰, 田野, 乔硕, 周光奇, 宋辞, 薛帅, 铁贵鹏, 周林, 舒勇, 周港. 高能激光单晶硅反射镜纳米精度控形控性制造技术[J]. 中国激光, 2021, 48(4): 0401007. Feng Shi, Ye Tian, Shuo Qiao, Guangqi Zhou, Ci Song, Shuai Xue, Guipeng Tie, Lin Zhou, Yong Shu, Gang Zhou. Nanoprecision Control of Shape and Performance Manufacturing Technology for High-Energy Laser Silicon Components[J]. Chinese Journal of Lasers, 2021, 48(4): 0401007.