基于法布里-珀罗腔产生飞秒激光脉冲串在硅表面诱导高质量亚波长周期条纹(特邀)

0 引言

飞秒激光诱导表面周期结构(Laser-induced Periodic Surface Structures,LIPSS)能够广泛应用于不同加工领域[1],涉及半导体[2-4]、电介质[5-7]、金属[8-10]、聚合物[11,12]等各种材料。LIPSS现主要分为两类:周期

通常认为,NSRs是由入射光激发材料表面等离激元(Surface Plasmon Polaritons,SPP),使得激光能量在材料表面周期性分布的结果[22-24]。诱导高质量NSRs目前还存在诸多问题,例如SPP激发弱导致周期性能量沉积不足,条纹浅;剩余热效应较大,条纹易出现分叉,扭曲,甚至被淹没;加工过程中碎屑沉积,条纹粗糙,颗粒感重。为了得到均匀性好、规则性高的高质量NSRs,首要任务是控制和增强SPP。CAO Kaiqiang等[25]利用双光束干涉共振增强SPP激发,在硅上加工出了大面积均匀光栅。JALIL S A等[26]利用两路不同延迟时间的共线飞秒激光脉冲在镍表面制备出了高度均匀的大面积NSRs,认为这种高度均匀性来源于SPP传播长度的减小。

飞秒激光诱导周期性纳米结构的形成是一个复杂的过程。在飞秒激光照射到材料后的几纳秒内,会发生载流子激发、载流子升温、晶格升温、等离子体喷出、纳米颗粒喷出等一系列超快过程。通过脉冲整形能够调控激光能量在时域上的分布,进而调控激光与物质相互作用的超快过程,有效控制激光能量在材料表面的周期性沉积、剩余热效应以及诱导过程中沉积的碎屑,从而获得深度大、均匀性好的LIPSS。随着脉冲整形技术的发展,研究人员已经能够实现对飞秒激光时域上的任意调控,现有脉冲整形方法包括4f结构零色散脉冲整形[2,27,28]、双折射晶体阵列产生脉冲串[29,30]、类迈克尔逊干涉仪方法[31,32]等。ZHANG Yuchan等[2]利用4f脉冲整形系统得到子脉冲间隔为16.2 ps的时域整形脉冲串,在硅表面制备了非常规则、深度大、面积大的NSRs。ZHANG Jin等[31]利用迈克尔逊干涉装置输出两列飞秒激光脉冲,通过改变脉冲延迟时间来控制聚丙乙烯微球内部的电离过程以改进激光加工。但这些时域整形方法都较为繁琐,且稳定性差,有待进一步发展。

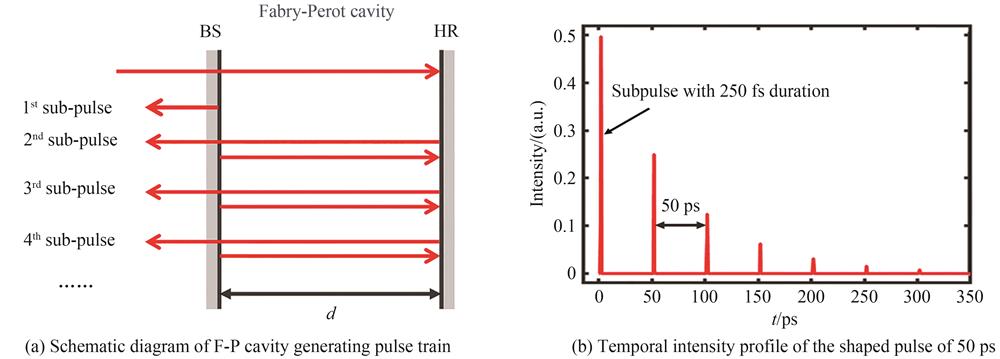

基于法布里-珀罗(Fabry-Perot,F-P)腔的脉冲串产生装置光路易于调节、成本低并且较为稳定可靠。本文利用法布里-珀罗腔对飞秒激光进行时域整形,输出子脉冲间隔在1~300 ps内灵活可调的飞秒激光脉冲串。通过调控脉冲串的子脉冲间隔、加工扫描速度、激光能流密度等诱导NSRs,达到光刻工艺的标准[33]。

1 实验装置

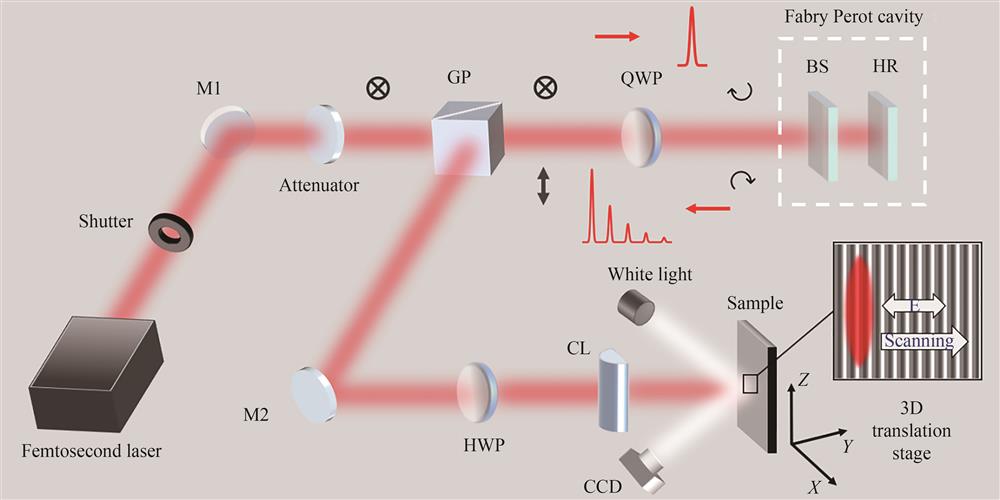

图 1. F-P腔脉冲整形实验装置示意图

Fig. 1. Schematic diagram of experimental device for pulse shaping of F-P cavity

实验样品为商用无掺杂硅晶片(MTI,中国),厚度为0.5 mm,粗糙度小于1 nm,单面抛光。样品加工结束后先使用10%浓度氢氟酸(HF)溶液浸泡90 min以去除表面氧化物和烧蚀碎屑,再经丙酮超声清洗30 min,最后用去离子水超声清洗30 min。样品处理完毕后利用扫描电子显微镜(Scanning Electron Microscope,SEM)(S-4800,日立)对样品表面形貌进行拍摄,利用白光干涉共聚焦显微镜(Smartproof 5 Widefield Confocal Microscope,蔡司)测量样品深度。

2 实验结果

2.1 高斯激光脉冲诱导NSRs

利用中心波长为1 030 nm,重复频率为5 kHz的高斯飞秒激光脉冲,经柱透镜汇聚到硅片表面,诱导出大面积LIPSS。激光偏振方向与扫描方向和柱透镜汇聚的焦斑短轴方向平行。当高斯激光脉冲作用在硅表面时,载流子瞬时吸收光子能量达到激发态,在表面形成SPP层;而后,电子通过电声耦合作用将能量传递给晶格,该过程约数十皮秒;最后,当晶格温度超过材料的烧蚀阈值,硅表层开始发生熔化、汽化等烧蚀过程。

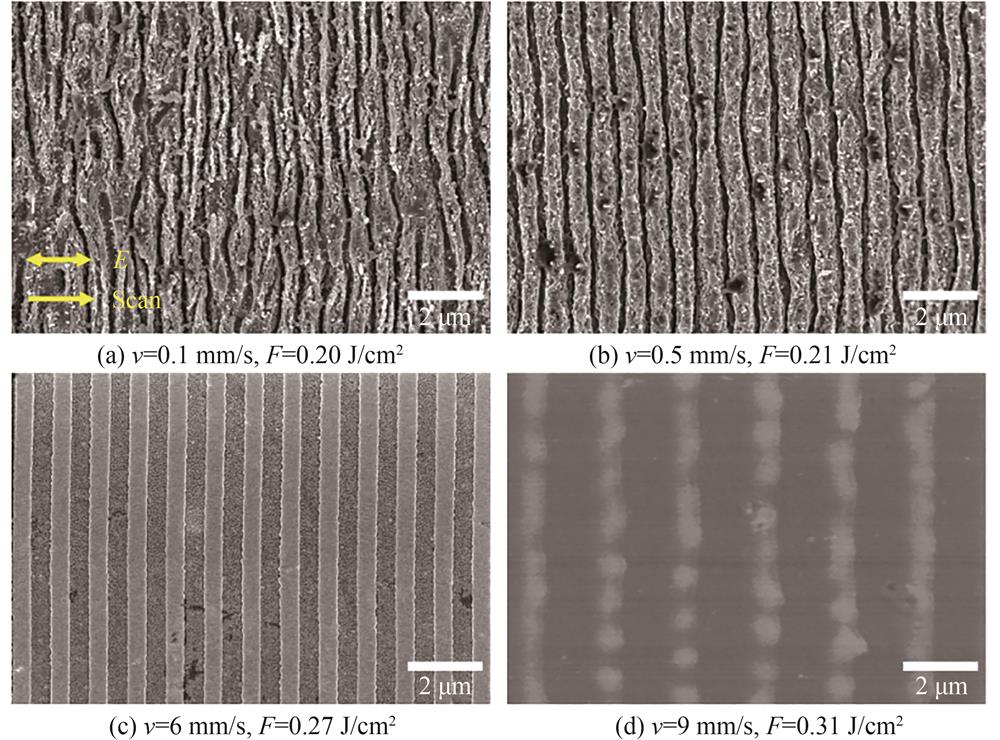

图 3. 不同扫描速度下高斯激光脉冲诱导均匀NSRs的扫描电镜照片

Fig. 3. SEM images of regular NSRs induced by Gaussian laser pulse at different scanning velocity

图 4. 高斯激光脉冲在硅上诱导不同形貌的NSRs的能流密度窗口

Fig. 4. The laser fluence window of spaced,regular and partly damaged NSRs induced by Gaussian laser pulse on silicon

2.2 飞秒激光脉冲串诱导NSRs

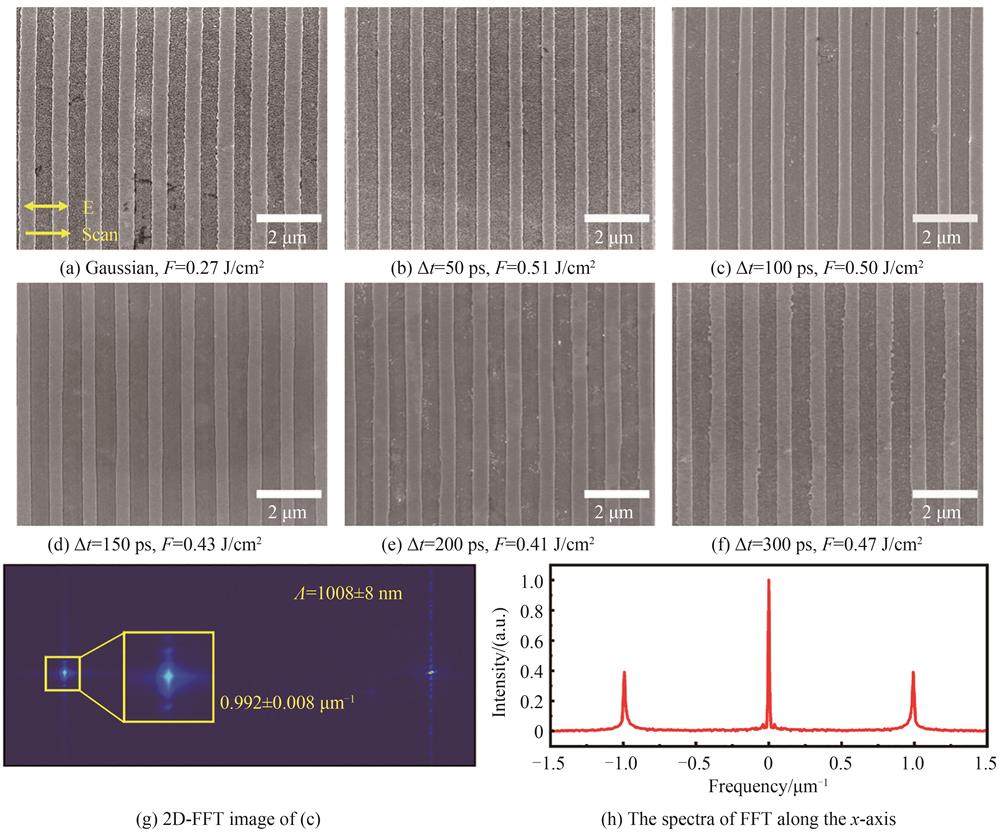

图 5. 飞秒激光脉冲串诱导均匀NSRs的扫描电镜照片,扫描速度为6 mm/s

Fig. 5. SEM images of regular NSRs induced by femtosecond laser pulse train with scanning velocity of 6 mm/s

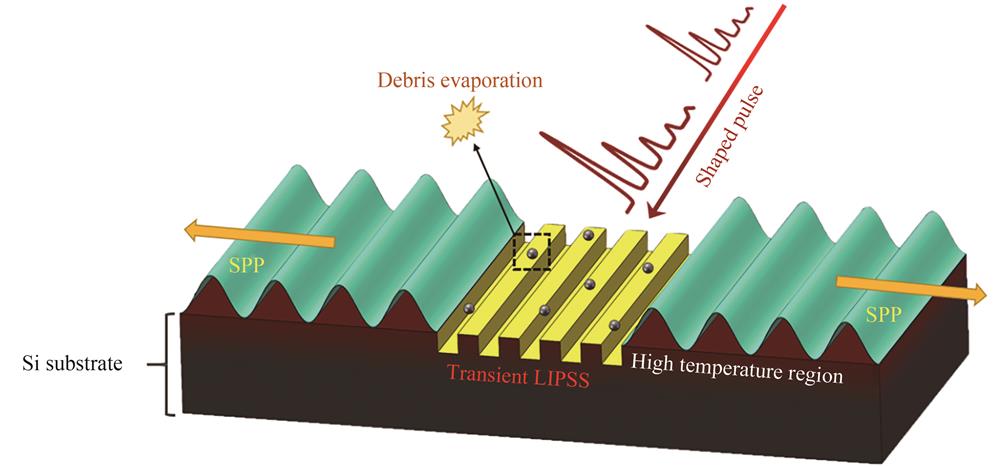

激光诱导表面周期结构是入射光激发SPP使得激光能量周期性沉积的结果[22-24]。SPP的波矢与入射光波矢不匹配[22],需要材料表面有部分介电常数突变区使得SPP和入射光矢量匹配,增强激光周期性沉积[10,25]。对于高斯飞秒激光来说,通常需要前面多个脉冲烧蚀材料,使得材料表面出现烧蚀喷出物,满足诱导周期条纹的条件。而烧蚀喷出物严重影响了周期条纹的取向,使得条纹弯曲、分叉等。同时,飞秒激光烧蚀材料时发生的库伦爆炸[35]和热流体力学[36]等使得条纹边沿呈锯齿状,粗糙度高。

图 6. 飞秒激光脉冲串诱导规则NSRs原理

Fig. 6. Schematic diagram of femtosecond laser pulse train induced regular NSRs

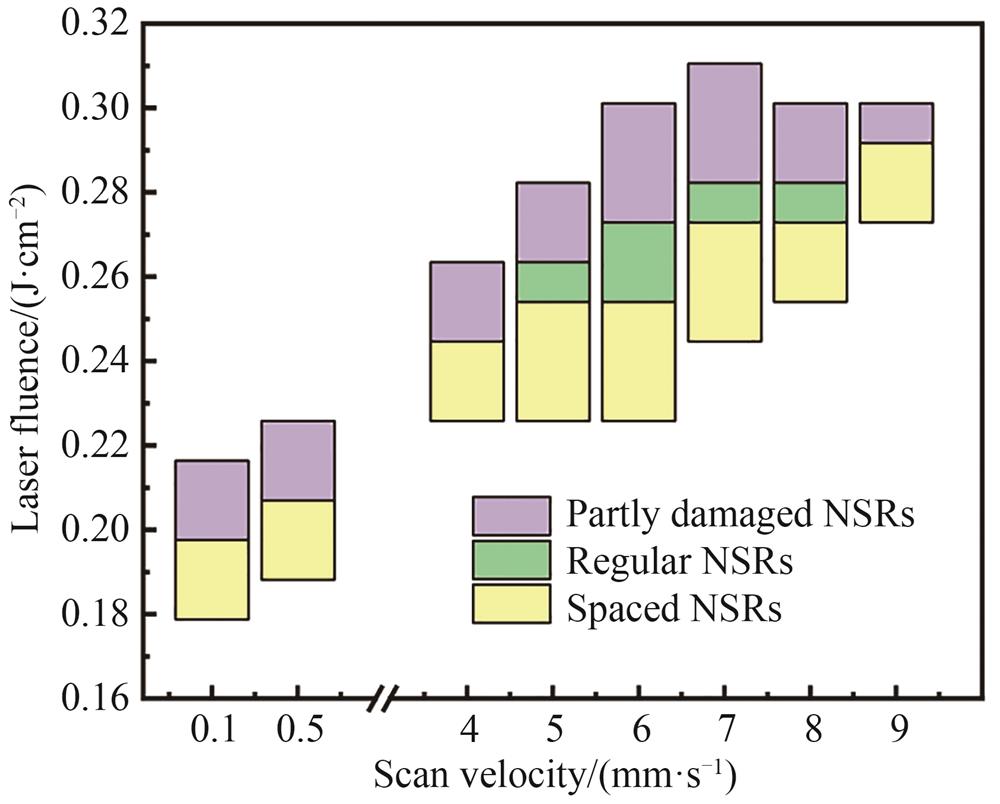

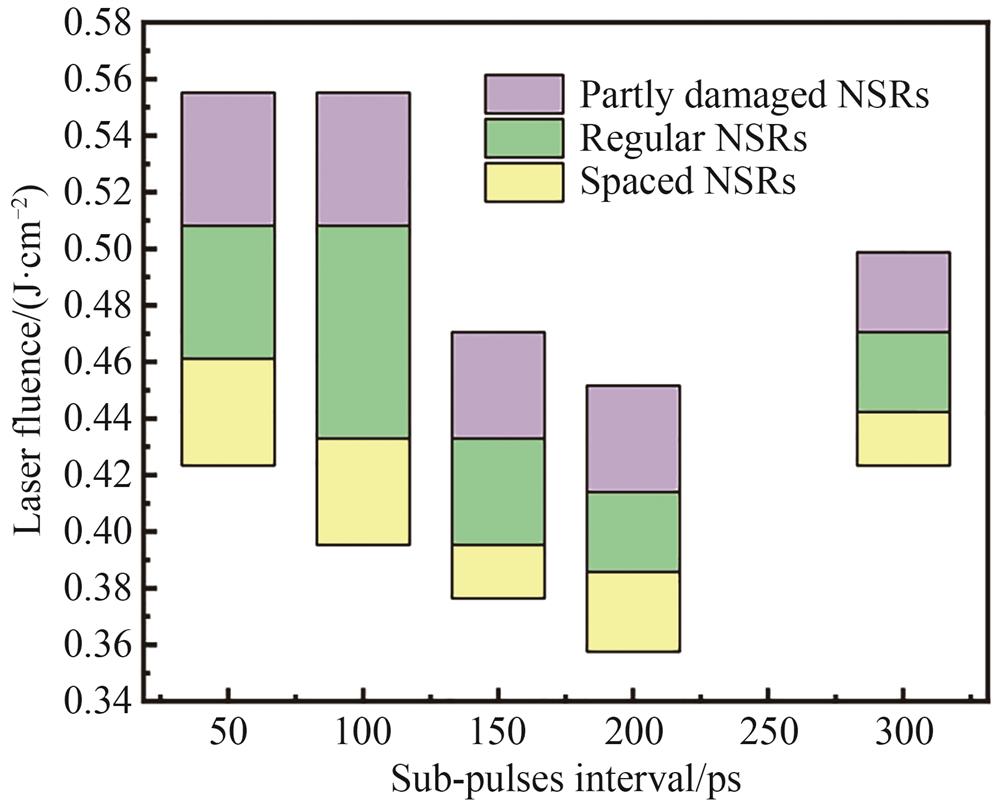

图 7. 飞秒激光脉冲串在硅上诱导不同形貌NSRs的能流密度窗口,扫描速度为6 mm/s

Fig. 7. Laser fluence window of NSRs induced by femtosecond laser pulse train on silicon with scanning velocity of 6 mm/s

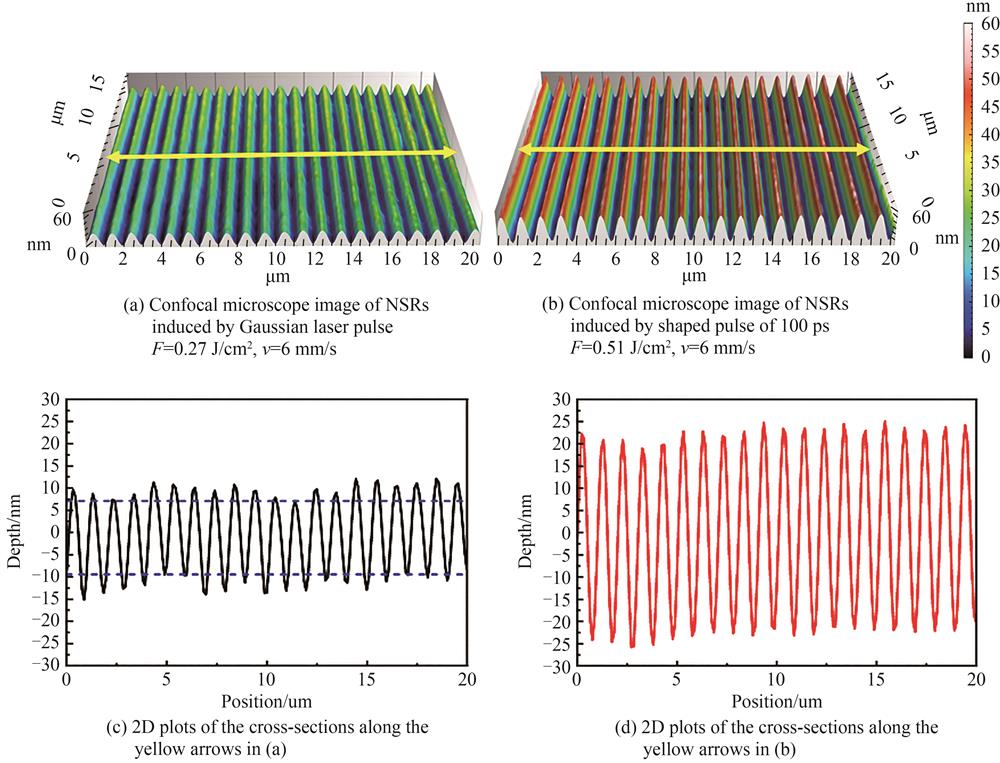

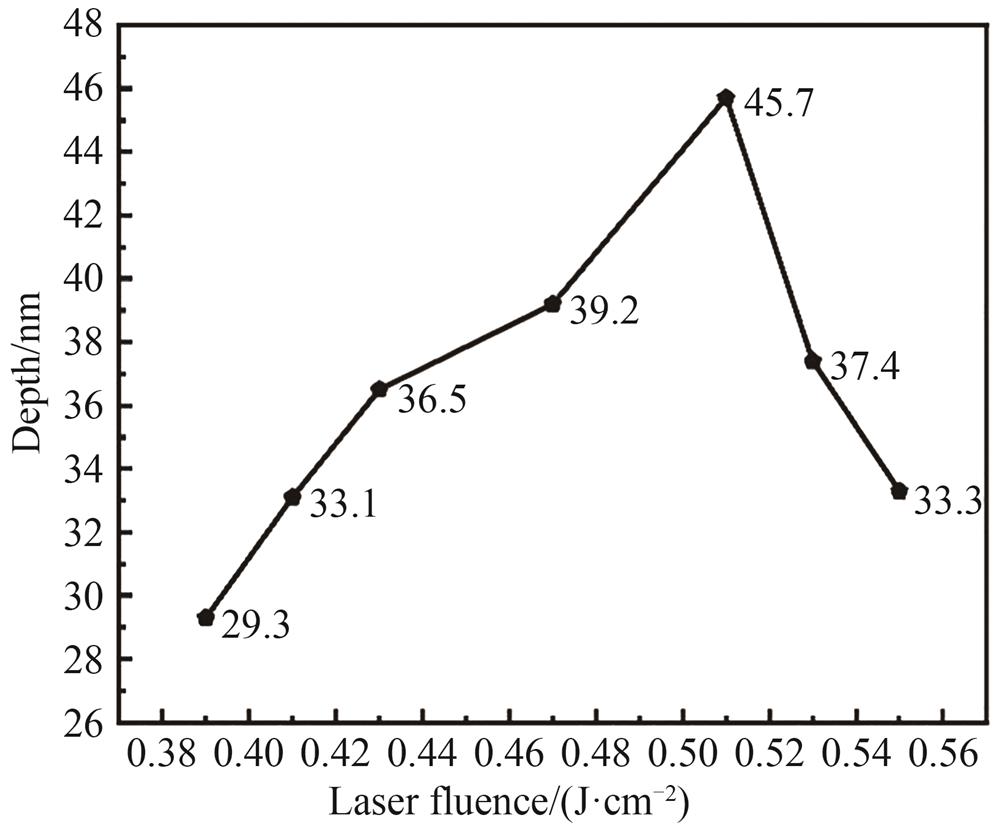

2.3 NSRs深度

NSRs深度是影响表面结构色、衍射效率、偏振特性[39,40]的重要因素。

图 8. 高斯激光脉冲和子脉冲间隔100 ps飞秒激光脉冲串诱导出的NSRs的深度对比

Fig. 8. Depth comparison of NSRs induced by Gaussian laser pulse and femtosecond laser pulse train of 100 ps

图 9. 子脉冲间隔100 ps飞秒激光脉冲串诱导出的NSRs深度与能流密度变化关系

Fig. 9. The relationship between laser fluence and depth of NSRs induced by femtosecond laser pulse train of 100 ps

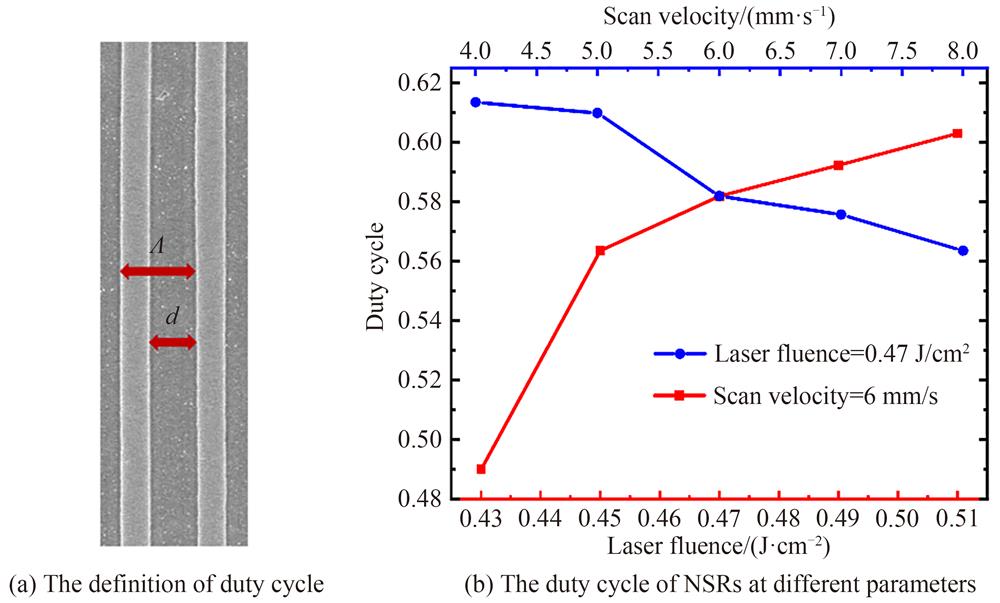

2.4 NSRs占空比

如

图 10. 子脉冲间隔100 ps飞秒激光脉冲串诱导出的NSRs的占空比分析

Fig. 10. Duty cycle analysis of NSRs induced by femtosecond laser pulse train of 100 ps

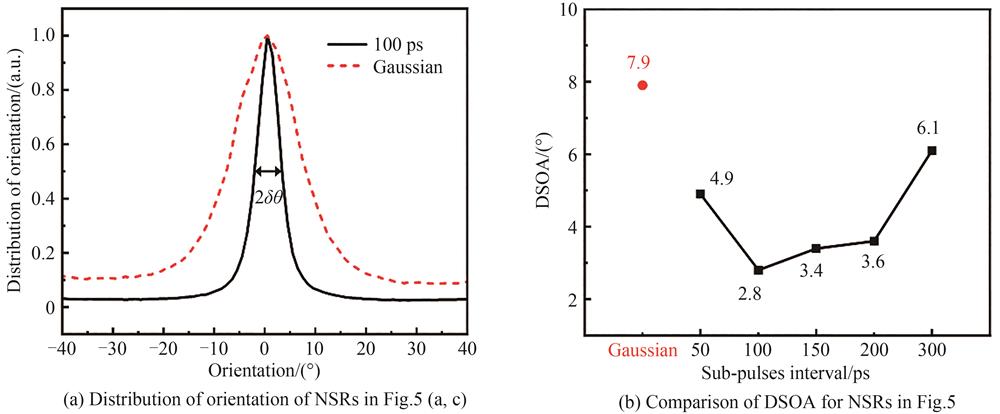

2.5 NSRs取向性

结构取向角差异(Divergence of Structure Orientation Angle,DSOA)是指待测结构其角度分布最大值一半处的半宽值

图 11. 高斯激光脉冲和飞秒激光脉冲串诱导规则NSRs的取向角分析

Fig. 11. DSOA analysis of regular NSRs induced by Gaussian laser pulse and femtosecond laser pulse train

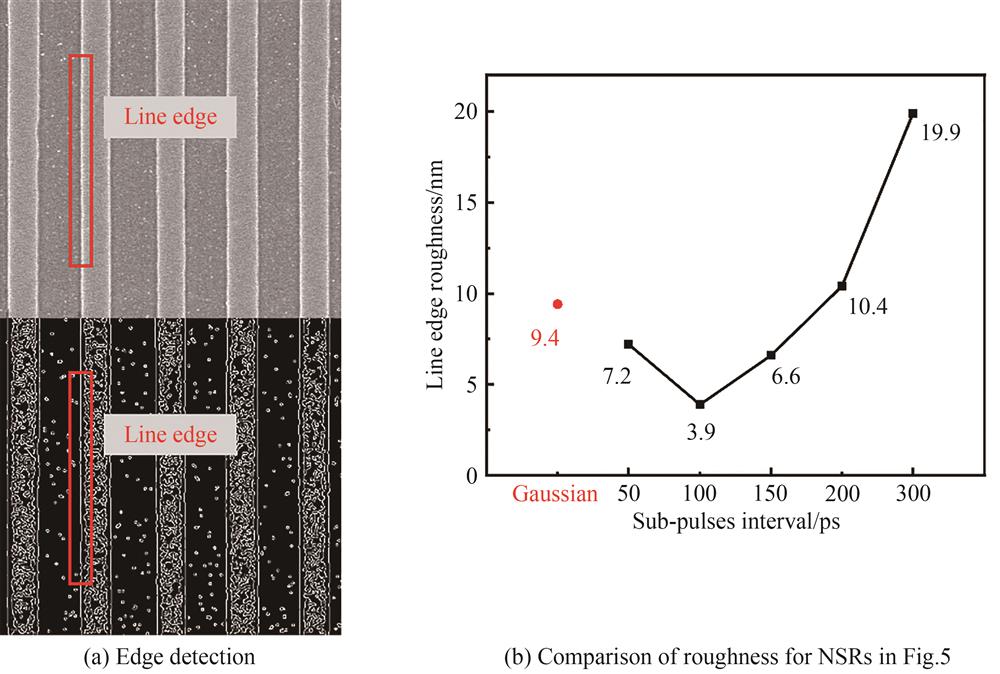

2.6 NSRs边缘粗糙度

边缘粗糙度(Line Edge Roughness,LER)常用于表征光刻图形边缘的粗糙程度[33],也是飞秒激光诱导规则NSRs的重要评价指标之一。利用Matlab对

式中,

图 12. 高斯激光脉冲和飞秒激光脉冲串诱导规则NSRs的边缘粗糙度分析

Fig. 12. Edge roughness analysis of regular NSRs induced by Gaussian laser pulse and femtosecond laser pulse train

3 结论

本文提出一种高效输出飞秒激光脉冲串的装置——基于F-P腔的脉冲串产生系统,利用子脉冲强度递减的飞秒激光脉冲串在硅表面诱导NSRs。实验结果表明,子脉冲间隔为100 ps的脉冲串能够诱导出周期为1 008 nm,结构取向角为2.8°,边缘粗糙度为3.9 nm的高质量亚波长周期条纹,相较高斯飞秒激光加工,条纹平直度好、深度大、边缘粗糙度小。更多的激光能量周期性沉积和更小的热效应,以及更少的表面沉积颗粒,是飞秒激光脉冲串诱导高质量亚波长条纹的原因。利用F-P腔产生的飞秒激光脉冲串能够显著提升NSRs的加工质量,达到光刻工艺的水平,有望提高传统飞秒激光加工的精度。

[1] LIN Z, HONG M. Femtosecond laser precision engineering: from micron, submicron, to nanoscale[J]. Ultrafast Science, 2021, 2021: 9783514.

[3] YANG Q X, LIU H L, HE S, et al. Circular cladding waveguides in Pr:YAG fabricated by femtosecond laser inscription: Raman, luminescence properties and guiding performance[J]. Opto-Electronic Advances, 2021, 4(2): 200005.

[4] JIA T Q, CHEN H X, HUANG M, et al. Formation of nanogratings on the surface of a ZnSe crystal irradiated by femtosecond laser pulses[J]. Physical Review B, 2005, 72(12): 125429.

[5] SHIMOTSUMA Y, KAZANSKY P G, QIU J, et al. Self-organized nanogratings in glass irradiated by ultrashort light pulses[J]. Physical Review Letters, 2003, 91(24): 247405.

[6] BHARDWAJ V R, SIMOVA E, RAJEEV P P, et al. Optically produced arrays of planar nanostructures inside fused silica[J]. Physical Review Letters, 2006, 96(5): 057404.

[7] HOHM S, ROSENFELD A, KRUGER J, et al. Femtosecond laser-induced periodic surface structures on silica[J]. Journal of Applied Physics, 2012, 112(1): 014901.

[8] WANG H T, HAO C L, LIN H, et al. Generation of super-resolved optical needle and multifocal array using graphene oxide metalenses[J]. Opto-Electronic Advances, 2021, 4(2): 200031.

[9] WANG J C, GUO C L. Ultrafast dynamics of femtosecond laser-induced periodic surface pattern formation on metals[J]. Applied Physics Letters, 2005, 87(25): 251914.

[10] CHENG K, LIU J K, CAO K Q, et al. Ultrafast dynamics of single-pulse femtosecond laser-induced periodic ripples on the surface of a gold film[J]. Physical Review B, 2018, 98(18): 184106.

[11] TSUTSUMI N, FUJIHARA A. Pulsed laser induced spontaneous gratings on a surface of azobenzene polymer[J]. Applied Physics Letters, 2004, 85(20): 4582-4584.

[12] REBOLLAR E, DE ALDANA J R V, PEREZ-HERNANDEZ J A, et al. Ultraviolet and infrared femtosecond laser induced periodic surface structures on thin polymer films[J]. Applied Physics Letters, 2012, 100(4): 041106.

[13] DUSSER B, SAGAN Z, SODER H, et al. Controlled nanostructrures formation by ultra fast laser pulses for color marking[J]. Optics Express, 2010, 18(3): 2913-2924.

[14] MARTINEZ-CALDERON M, RODRIGUEZ A, DIAS-PONTE A, et al. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS[J]. Applied Surface Science, 2016, 374: 81-89.

[15] 李艳丽, 贾鑫, 曹凯强, 等. 飞秒激光双光束干涉高效率地制备硅表面超亲水结构[J]. 光子学报, 2021, 50(6): 0650111.

LI Yanli, JIA Xin, CAO Kaiqiang, et al. Highly efficient fabrication of superhydrophilic structures on silicon surface by the interference of two femtosecond laser beams[J]. Acta Photonica Sinica, 2021, 50(6): 0650111.

[16] BAI S, SERIEN D, MA Y, et al. Attomolar sensing based on liquid interface-assisted surface-enhanced Raman scattering in microfluidic chip by femtosecond laser processing[J]. Acs Applied Materials & Interfaces, 2020, 12(37): 42328-42338.

[17] ERKIZAN S N, IDIKUT F, DEMIRTAS O, et al. LIPSS for SERS: metal coated direct laser written periodic nanostructures for surface enhanced raman spectroscopy[J]. Advanced Optical Materials, 2022, 10(22): 2200233.

[18] HUANG J, JIANG L, LI X W, et al. Fabrication of highly homogeneous and controllable nanogratings on silicon via chemical etching-assisted femtosecond laser modification[J]. Nanophotonics, 2019, 8(5): 869-878.

[19] BRICCHI E, KAZANSKY P G. Extraordinary stability of anisotropic femtosecond direct-written structures embedded in silica glass[J]. Applied Physics Letters, 2006, 88(11): 111119.

[20] DREVINSKAS R, GECEVICIUS M, BERESNA M, et al. Tailored surface birefringence by femtosecond laser assisted wet etching[J]. Optics Express, 2015, 23(2): 1428-1437.

[21] CERKAUSKAITE A, DREVINSKAS R, SOLODAR A, et al. Form-birefringence in ITO thin films engineered by ultrafast laser nanostructuring[J]. Acs Photonics, 2017, 4(11): 2944-2951.

[22] HUANG M, ZHAO F L, CHENG Y, et al. Origin of laser-induced near-subwavelength ripples: interference between surface plasmons and incident laser[J]. Acs Nano, 2009, 3(12): 4062-4070.

[23] BONSE J, ROSENFELD A, KRUGER J. On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structures upon irradiation of silicon by femtosecond-laser pulses[J]. Journal of Applied Physics, 2009, 106(10): 104910.

[24] DERRIEN T J Y, ITINA T E, TORRES R, et al. Possible surface plasmon polariton excitation under femtosecond laser irradiation of silicon[J]. Journal of Applied Physics, 2013, 114(8): 083104.

[25] CAO K Q, CHEN L, WU H C, et al. Large-area commercial-grating-quality subwavelength periodic ripples on silicon efficiently fabricated by gentle ablation with femtosecond laser interference via two cylindrical lenses[J]. Optics and Laser Technology, 2020, 131: 106441.

[26] JALIL S A, YANG J J, ELKABBASH M, et al. Maskless formation of uniform subwavelength periodic surface structures by double temporally-delayed femtosecond laser beams[J]. Applied Surface Science, 2019, 471: 516-520.

[27] WEINER A M, HERITAGE J P, KIRSCHNER E M. High-resolution femtosecond pulse shaping[J]. Journal of the Optical Society of America B (Optical Physics), 1988, 5(8): 1563-1572.

[28] JIANG L, WANG A D, LI B, et al. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication: modeling, method, measurement and application[J]. Light-Science & Applications, 2018, 7: 17134.

[29] GIANNUZZI G, GAUDIUSO C, DI FRANCO C, et al. Large area laser-induced periodic surface structures on steel by bursts of femtosecond pulses with picosecond delays[J]. Optics and Lasers in Engineering, 2019, 114: 15-21.

[30] DROMEY B, ZEPF M, LANDREMAN M, et al. Generation of a train of ultrashort pulses from a compact birefringent crystal array[J]. Applied Optics, 2007, 46(22): 5142-5146.

[31] ZHANG J, WANG S M, JIANG L, et al. Morphology control of nanostructure using microsphere-assisted femtosecond laser double-pulse ablation and chemical etching[J]. Applied Surface Science, 2020, 502: 144272.

[32] WANG Z, JIANG L, LI X W, et al. High-throughput microchannel fabrication in fused silica by temporally shaped femtosecond laser Bessel-beam-assisted chemical etching[J]. Optics Letters, 2018, 43(1): 98-101.

[33] 韦亚一. 超大规模集成电路先进光刻理论与应用[M]. 北京: 科学出版社, 2016.

[34] 陈天琦, 杨坚, 贾天卿. 飞秒激光脉冲序列烧蚀硅的孔型质量研究[J]. 光子学报, 2021, 50(6): 0650112.

CHEN Tianqi, YANG Jian, JIA Tianqing. A study on ablation quality of silicon by femtosecond laser pulse trains[J]. Acta Photonica Sinica, 2021, 50(6): 0650112.

[35] DONG Y Y, MOLIAN P. Coulomb explosion-induced formation of highly oriented nanoparticles on thin films of 3C-SiC by the femtosecond pulsed laser[J]. Applied Physics Letters, 2004, 84(1): 10-12.

[36] RUDENKO A, MAUCLAIR C, GARRELIE F, et al. Amplification and regulation of periodic nanostructures in multipulse ultrashort laser-induced surface evolution by electromagnetic-hydrodynamic simulations[J]. Physical Review B, 2019, 99(23): 235412.

[37] LIU J K, JIA X, WU W S, et al. Ultrafast imaging on the formation of periodic ripples on a Si surface with a prefabricated nanogroove induced by a single femtosecond laser pulse[J]. Optics Express, 2018, 26(5): 6302-6315.

[38] HASHIDA M, SEMEROK A F, GOBERT O, et al. Ablation threshold dependence on pulse duration for copper[J]. Applied Surface Science, 2002, 197: 862-867.

[39] HUANG J, JIANG L, LI X W, et al. Cylindrically focused nonablative femtosecond laser processing of long-range uniform periodic surface structures with tunable diffraction efficiency[J]. Advanced Optical Materials, 2019, 7(20): 1900706.

[40] WU H, JIAO Y L, ZHANG C C, et al. Large area metal micro-/nano-groove arrays with both structural color and anisotropic wetting fabricated by one-step focused laser interference lithography[J]. Nanoscale, 2019, 11(11): 4803-4810.

Article Outline

许宇锋, 张羽婵, 蒋其麟, 沈辉辉, 贾天卿. 基于法布里-珀罗腔产生飞秒激光脉冲串在硅表面诱导高质量亚波长周期条纹(特邀)[J]. 光子学报, 2023, 52(7): 0752301. Yufeng XU, Yuchan ZHANG, Qilin JIANG, Huihui SHEN, Tianqing JIA. High Quality Near-subwavelength Ripples on Si Induced by Femtosecond Pulse Train Output from Fabry-Perot Cavity(Invited)[J]. ACTA PHOTONICA SINICA, 2023, 52(7): 0752301.