宽禁带半导体光电材料及其应用研究  下载: 1515次特邀综述

下载: 1515次特邀综述

1 引言

材料、能源和信息被认为是现代文明社会的三大支柱。半导体材料的不断发展带来了科学技术的一次次革命。20世纪40年代起,以硅(Si)和锗(Ge)等元素半导体为代表的第一代半导体材料将人类社会从电子管时代带入了微电子和集成电路时代。砷化镓(GaAs)和磷化铟(InP)等窄带隙半导体材料作为第二代半导体材料,极大地推动了光纤和微波通信的发展,促进了信息时代的进步。随着高频大功率器件、信息存储和半导体照明的发展,第三代半导体逐渐进入人类的视野。第三代半导体主要以宽禁带半导体为主,如氮化镓(GaN)、碳化硅(SiC)、金刚石和氧化锌(ZnO)等,这些材料的禁带宽度较大(>2.2 eV)、击穿强度高、迁移率高、热导率高,能够在高温和高功率等苛刻条件下工作,成为信息技术新的重要基础材料,在紫外光源技术、透明电子信息技术和全色显示产业发展中优势显著,为社会进步、科技发展发挥重要作用。

20世纪90年代起,GaN由于其禁带宽度大(约3.4 eV)、电子饱和漂移速率高(2.7×107 cm/s)、化学稳定性好等优势,在发光二极管、光电探测、功率器件等领域应用广泛。但GaN材料存在一些不足,如:GaN多生长在蓝宝石或其他异质衬底上,往往存在较大的晶格失配,制备的GaN缺陷密度大,这限制了其在发光二极管(LED)、功率器件等方面的应用;生长设备昂贵,生长温度一般在1000 ℃以上,导致成本很高。此外,GaN的核心生长技术多掌握在欧美国家手中,我国迫切需要掌握核心技术或自主研发新型宽禁带半导体材料。

ZnO因具有与GaN极为相似的性质和优越的光电性能引起了人们的关注。ZnO的禁带宽度(Eg)约为3.37 eV,波长位于近紫外区域[1-2],非常适合制备短波长器件。激子束缚能高,可在室温或更高温度下实现低阈值、高效率的激光发射。此外,ZnO热稳定好、抗辐射性能好、制备工艺简单、无毒无污染、原料丰富,有望替代GaN。

近些年来,宽禁带钙钛矿半导体以其可调的发射光谱、载流子迁移率高和溶液制备方法简单等优势,被广泛应用于LED等光电器件中。

2 氧化锌紫外光源

随着人类社会的进步,紫外光源在环境卫生、生物医学、高端制造、节能照明和信息通信等领域有重要应用。尤其是紫外LED市场巨大。因此,研发高光效、低成本、环境友好型的紫外光源意义重大。

传统型的紫外光源主要为紫外汞灯,设备大、效率低,且存在环境污染隐忧。随着技术的发展,紫外LED成为新型紫外光源。目前,GaN基LED是唯一实现商业化应用的紫外LED,其核心紫外光源半导体材料是氮化铝镓(AlGaN)。欧美国家、日本和我国诸多研究机构和公司在此领域投入巨大,以求在产业竞争中占领有利地位。GaN基LED的制备工艺已发展较为成熟,但紫外GaN-LED仍面临发光效率低(大多10%以下)、输出光功率低,以及芯片结构复杂和成本高等问题。

相比较,宽禁带氧化物半导体ZnO具有高激子束缚能,在400 ℃下激子仍可稳定存在,可实现高效的激子发光;大尺寸ZnO体单晶衬底可实现高质量的同质外延薄膜,进而制备高效ZnO-LED;此外,ZnO原料物丰价廉,制备温度低,有成本优势。因此,研发基于ZnO的新型紫外LED尤为必要。

2.1 ZnO发光原理

ZnO是直接带隙II-VI族化合物半导体,室温下的禁带宽度为3.37 eV,光吸收波长在近紫外区域。激子束缚能高达60 meV,是室温热能(26 meV)的2.3倍,远高于其他宽禁带半导体材料(GaN的禁带宽度为25 meV,ZnSe的禁带宽度为22 meV),因此更容易实现室温或者更高温度下的激子-激子碰撞的受激辐射,相比于电子-空穴对等离子体受激辐射,ZnO所需阈值更低[3]。此外,通过构建多量子阱结构可获得更高的激子束缚能,因此ZnO中的激子可在室温甚至更高的温度下稳定存在。由此可见,在室温甚至更高温度下,ZnO基光电器件有望实现更低阈值、更高效率的自发辐射。

2.2 研究现状

1)p型掺杂

ZnO基发光器件的首要前提是制备性能良好的ZnO同质p-n结。ZnO本征为n型,具有明显的掺杂不对称性,施主掺杂比较容易,但受主掺杂异常艰难。因此,限制ZnO材料走向光电应用的最突出难题是获得高效、稳定、可重复的p型ZnO。借鉴GaN的p型掺杂思路,提高ZnO薄膜的晶体质量、降低薄膜中本征补偿型缺陷的密度、改善p型掺杂是努力方向。研究者们通过探索新的掺杂源、改善掺杂工艺、尝试新的技术路线等方法,解决ZnO的p型掺杂问题及研制p-n结器件。2006年,本课题组[4]首次提出Li-N双受主共掺杂的方法,采用等离子体辅助金属有机化学气相沉积(MOCVD)方法在国内首次实现了N掺杂的p-ZnO薄膜,并成功构建了ZnO同质结LED,如

![MOCVD法制备的p-ZnO薄膜和LED器件[4]。(a)ZnO发光二极管;(b)ZnO LED的I-V特性;(c)LED的室温电致发光光谱随注入电流的变化](/richHtml/gxxb/2022/42/17/1716001/img_02.jpg)

图 1. MOCVD法制备的p-ZnO薄膜和LED器件[4]。(a)ZnO发光二极管;(b)ZnO LED的I-V特性;(c)LED的室温电致发光光谱随注入电流的变化

Fig. 1. p-ZnO thin films and LED devices prepared by MOCVD method[4]. (a) Schematic sketch of ZnO LED; (b) I-V characteristics of ZnO LED; (c) electroluminescence spectra of LED as a function of injected current at room temperature

2)能带工程

ZnO的能带工程,即调节ZnO的禁带宽度,通过能带裁剪制备ZnO的势阱或势垒材料及量子阱结构,用于提高器件的发光效率,这是光电子器件设计中另一个需要重点考虑的问题。ZnO的能带裁剪目前主要通过合金化方法实现,例如:ZnO与CdO、MgO或BeO等氧化物合金化形成禁带宽度更小或者更大的三元或四元合金化合物。为了实现高效发光,势阱、势垒材料的能级匹配、晶格常数匹配、极化系数匹配至关重要。由于ZnMgO和ZnO之间可以形成合适的I型异质结[7],面内晶格常数相比于其他合金体系差异更小[8],而且极化效应导致的内建电场强度较低[9],ZnMgO合金更有利于作为势垒层构筑ZnO基的载流子限域结构,被研究人员更加广泛地研究。围绕ZnO的能带工程,本课题组系统研究Mg组分、生长取向对ZnMgO/ZnO异质结带阶的影响,为设计高效发光量子阱限域结构提供基础[7,10];此外,本课题组利用分子束外延方法调控ZnMgBeO四元合金能带结构,获得更利于p型掺杂的ZnO基合金体系[11]。

![能带结构示意图。(a)ZnMgO/ZnO[7];(b)ZnMgO/ZnMgBeO[11]](/richHtml/gxxb/2022/42/17/1716001/img_03.jpg)

图 2. 能带结构示意图。(a)ZnMgO/ZnO[7];(b)ZnMgO/ZnMgBeO[11]

Fig. 2. Schematic diagrams of band structures. (a) ZnMgO/ZnO[7];(b)ZnMgO/ZnMgBeO[11]

3)多量子阱(MQWs)有源层器件

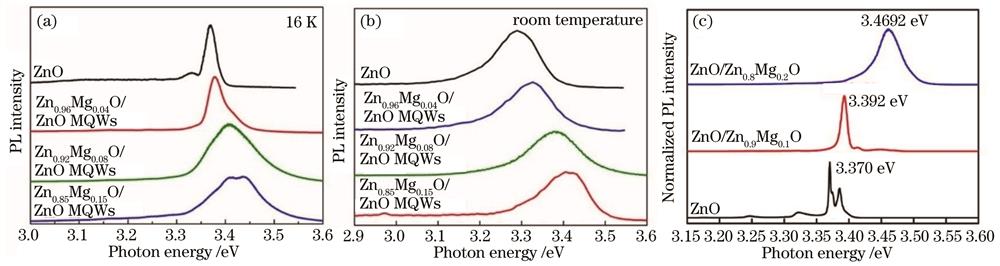

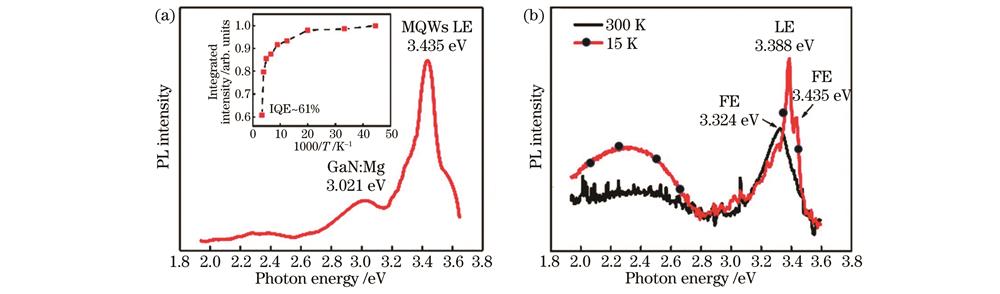

两种不同的半导体材料交替生长,将形成的具有明显量子限制效应的周期性结构称为量子阱。一个周期的结构被称为单量子阱,多个周期的结构则称为多量子阱。在量子阱中,粒子在z方向受到限制,在x-y平面内可以自由运动。所以,在量子阱中,激子将变成二维激子,其复合效率将大大提高。理论计算表明,当势阱宽度远小于三维激子的玻尔半径时,激子的束缚能将增大为三维激子束缚能的4倍,其等效玻尔半径为体材料中的一半。一方面,多量子阱结构可以将注入的电子和空穴限制在阱层内,提高激子的束缚能与振荡能量,改善激子的稳定性,降低激发阈值,提高载流子复合效率,实现高效低阈值发射;另一方面,势垒与势阱层之间因存在折射率差,构成光波导结构,该结构有效地减少光子的内部损耗,提高发射效率和工作稳定性,延长了寿命[12]。在目前商用GaN-LED中采用InGaN多量子阱将载流子限制在势阱层内,可提高有源区载流子浓度,进而提高复合概率及其发光效率。ZnO基LED结构经不断改进,从单一p-n结到采用高质量的绝缘层作为有源区,再到多量子阱有源层器件,LED的性能在逐步提升中[13]。2007年,本课题组[14]制备国际首个硅基ZnO/ZnMgO并实现电致发光。2014年,本课题组[15]通过调控阱宽、垒高,实现最佳量子效应ZnO/ZnMgO多量子阱结构,通过

图 3. 调控ZnO/ZnMgO多量子阱阱宽、垒高的PL强度。(a)温度为16 K时的PL强度;(b)室温下的PL强度;(c)归一化PL强度

Fig. 3. PL intensity obtained by adjusting well width and barrier height of ZnO/ZnMgO multi-quantum wells. (a) PL intensity at 16 K; (b) PL intensity at room temperature; (c) normalized PL intensity

图 4. 高内量子效率ZnO/ZnMgO多量子阱的PL强度。(a)ZnO/Zn0.9Mg0.1O多量子阱生长在GaN/Al2O3衬底上80 K时的PL光谱(插图显示了多量子阱LE发射的综合PL强度作为温度的函数);(b)生长在蓝宝石衬底上的ZnO/Zn0.9Mg0.1O多量子阱在300 K和15 K下的PL光谱

Fig. 4. PL intensity of ZnO/ZnMgO multi-quantum wells with high internal quantum efficiency. (a) PL spectrum at 80 K of ZnO/Zn0.9Mg0.1O MQWs grown on GaN/Al2O3 substrate (inset shows integrated PL intensity of LE emission for MQWs as a function of temperature); (b) PL spectra at 300 K and 15 K of the ZnO/Zn0.9Mg0.1O MQWs grown on sapphire substrate

3 氧化锌透明导电薄膜

透明导电薄膜(TCF)是兼具光学透明性与导电性能的薄膜化材料,满足可见光波段(400~760 nm)的透光率高于80 %、电阻率低于10-3 Ω·cm的性能指标。透明导电氧化物是透明导电薄膜中的典型材料,以掺杂锡的氧化铟(ITO)薄膜、氧化锡基(SnO2∶X)薄膜、氧化锌基(ZnO∶X)薄膜为主。受限于铟元素的资源稀缺和毒性,ITO的成本和可持续性都存在隐忧。氧化锌基透明导电薄膜具有可与ITO膜相比拟的光学和电学性质,在可见光波段的透过率高达90%,电阻率低至10-4 Ω·cm,同时原料丰富、价格低廉、无毒无污染,是理想的ITO替代材料。

3.1 ZnO透明导电原理

当入射光的能量hν≥Eg时,价带电子会吸收光子的能量并跃迁到导带,入射光则由于损失能量而衰减。对于未掺杂且符合化学配比的ZnO,当可见光入射时,光子能量(1.62~3.11 eV)小于其禁带宽度,不会引起本征激发,同时价电子很难跃迁到导带,导带的自由电子很少,ZnO表现为可见光透明和电学绝缘。但本征ZnO很难形成完美的化学计量比,可能存在间隙(Zni、Oi)、空位(VZn、VO)以及反位(ZnO、OZn)等本征点缺陷,制备过程中也会引入非故意掺杂的H和C杂质。Zn间隙(Zni)和O空位(VO)两种施主型缺陷与非故意掺杂是引起本征ZnO呈现n型导电的重要原因[18-19]。

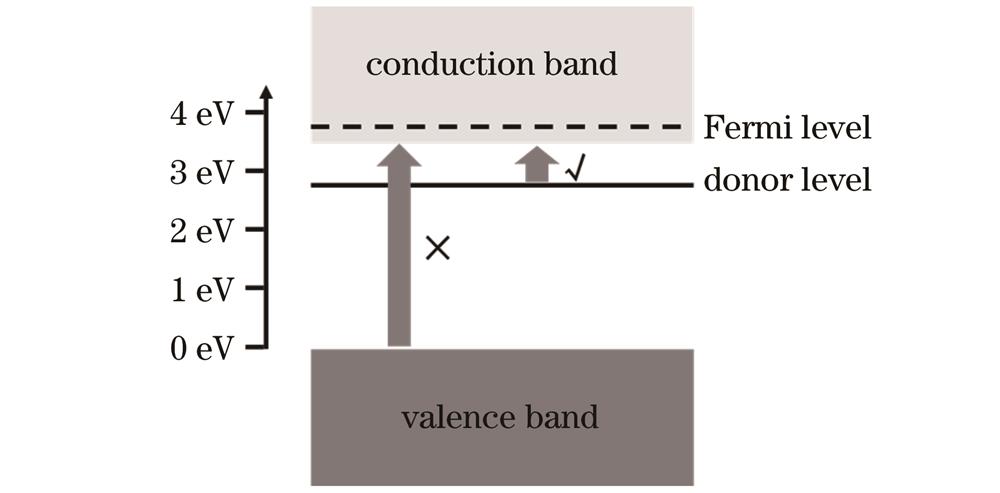

通过人为地掺杂Al、Ga、In等施主元素,掺杂原子取代ZnO晶格中的Zn原子,形成靠近导带底的浅施主能级(

3.2 制备技术

ZnO薄膜的制备方法大致分为物理法和化学法。物理法指采用物理过程将材料输运、沉积在衬底上,主要包括磁控溅射[20-22]、脉冲激光沉积(PLD)[23-24]、原子层沉积(ALD)[25-26]等。化学法则是利用在衬底上发生的化学反应生长固态沉积物,主要包括化学气相沉积(CVD)[27-28]、分子束外延(MBE)[29-30]、溶胶-凝胶法(Sol-Gel)[31-32]等。磁控溅射是较常用的镀膜方法,适用于快速、大面积成膜,能获得致密、高透光率且高度c轴取向的ZnO薄膜,但溅射粒子的轰击使薄膜表面易损伤,不适于生长单晶或低缺陷的ZnO薄膜。分子束外延可生长高质量的ZnO单晶薄膜,但其生长速率低、成本高,难以实现商业化。

不同制备工艺的参数优化均已较为成熟,以磁控溅射为例,适当升温、减小气压和提高功率有利于获得致密薄膜[20]。选择晶格常数、热膨胀系数与ZnO相近的衬底能促进薄膜质量的增大[33],引入缓冲层能改善薄膜与衬底之间的晶格失配,减少晶界和缺陷的产生[34-36],适当的后处理有助于优化电学性能,促进薄膜的晶化以及掺杂原子的扩散和活化等[37-38]。采用还原性气氛或真空退火将增加薄膜内的施主缺陷浓度、提高其载流子浓度[39],或消除光学活性缺陷、提高透过率[40]。

3.3 研究现状

1)单层掺杂ZnO

ZnO的导电性能一般采取施主掺杂的方式实现,最常用的掺杂元素为Al、Ga、In,对应的掺杂ZnO分别写作ZnO∶Al(AZO)、ZnO∶Ga(GZO)、ZnO∶In(IZO),其中AZO和GZO具有明显的性能优势。合适的掺杂浓度对实现ZnO透明导电薄膜的意义重大,目前报道的AZO和GZO透明导电薄膜中,Al3+和Ga3+的原子数分数通常为1%~5%,产生的载流子浓度可以达到1021 cm-3,可见光区透过率均可达到80%[41-42]。

本课题组叶志镇教授[43-44]不仅改进了磁控S枪以适用于直流反应溅射,而且首次采用Zn靶掺In的方法,制备出当时性能最好且方法最简便的IZO薄膜,并采用Drude理论分析了薄膜的光学性能。经过研究人员的不断努力,IZO薄膜的电阻率降低至10-4 Ω·cm[45-46]。AZO薄膜以其原料丰富、价格低廉、易于掺杂、热稳定性好等优点获得了长足的发展。本课题组系统地研究了Al的原子数分数在0~50%范围内的AZO薄膜的结构、光学和电学性能,发现:当Al的原子数分数为4%时,经直流反应磁控溅射制备的n型AZO膜能获得高度c轴取向的晶体质量,电阻率低至10-4 Ω·cm,可见光区透光率约为90%[47],并进一步总结了带隙偏移与载流子浓度间的关系[48]。经本课题组研究发现,AZO的性能还强烈依赖于生长温度[49]、氧压[50]、氩氧比[51]等制备条件,350 ℃制备的AZO膜可获得4.5×10-4 Ω·cm的最低电阻率,并具有良好的红外反射性能,通过H2退火和H等离子体等后处理方式引入氢可减少薄膜内部缺陷或断键,能进一步改善电学性能[52-53]。经过国内外研究人员的不断努力,AZO的电阻率已降低至8.54×10-5 Ω·cm,同时可见光透过率超88%[54]。对于GZO,本课题组也优化了Ga含量[55]、溅射功率[56]、气体压强[57]、氧分压[58]、氩氧比[59]、溅射温度[60]、退火温度[61]等制备条件,得出生长GZO的最佳Ga的原子数分数为3.0%,最低电阻率为3.51×10-4 Ω·cm,并实现了薄膜的柔性化[62]和优异的电气稳定性[63]。现今对于以PLD法在400 ℃沉积的GZO薄膜,400 ℃退火处理可提高晶体质量,电阻率降至1.84×10-4 Ω·cm[64]。

除了掺入阳离子取代Zn2+外,本课题组也通过掺入F-取代O2-提高ZnO的导电性能,研究发现提高衬底温度(300 ℃)有利于F掺杂ZnO(FZO)薄膜获得高透明导电性能[65],而在0.1 Pa的最佳氧压下制备的FZO,其最低电阻率为4.83×10-4 Ω·cm,可见光区的平均透过率高于90%[66]。在F的原子数分数为1%的条件下,F的钝化作用使得FZO薄膜表现出最佳的晶体质量,且Zn间隙和O空位的缺陷浓度最低,实现了45.3 cm2·V-1·s-1的高迁移率[67]。采用不同阳离子或阴阳离子共掺杂,多种异价或杂价阳离子竞争性取代Zn,能提高总掺杂剂的掺入极限[68];阴阳离子的离子半径互补可减小晶格畸变、提高载流子迁移率,化合价互补则有利于提高掺杂元素的固溶度和载流子浓度[69]。Wang等[70]以F、Al、Mg共掺杂,调控了ZnO薄膜的能带结构,使电阻率达到4.07×10-4 Ω·cm,在宽光谱(400~1400 nm)的平均透过率为90.54%。

2)多层复合薄膜

单层的掺杂ZnO薄膜始终受制于半导体的导电机制和透明导电氧化物的本身性能,其电学性能终究存在极限[19]。为了满足不断提高的应用要求,将ZnO薄膜与其他透明导电材料进行复合,形成电阻并联式结构,膜层之间的性能互补为实现更高导电性能的透明导电薄膜带来了新思路。

将ITO膜的高电学性能与ZnO基薄膜的理想光学特性相结合,使其复合为多层氧化物薄膜[70-72],这在整体膜层的光电性能达到实用标准的前提下,有效减少了In元素的用量,降低了薄膜的制备成本。本课题组制备的双层绒面结构ITO/AZO和AZO/AZO,其电阻率保持在10-4 Ω·cm,还具有较强的光捕获能力[73]。此外,本课题组将具有优良导电性的金属引入ZnO薄膜,制备ZnO/金属/ZnO复合薄膜,如GZO/Cu/GZO多层膜[74]、AZO/Cu/AZO多层膜[75],并研究了金属膜厚度[76]、ZnO膜厚度[77]、溅射功率[78]等参数对复合膜的结构、电学和光学性质的影响,极大程度地提高薄膜的整体导电性能,并且增强了膜层的附着性和稳定性。此外,通过调控膜层的结构和厚度,能达到光学增透效果[79-80];在氧化物和金属间覆盖缓冲层,能有效抑制元素扩散或金属氧化[81-82]。但金属薄膜在可见光区的透过率很低,其厚度必须尽量减薄才能保证透明,但金属膜厚度过薄时容易呈现岛状生长而无法连续成膜,导致其迁移率大幅下降,因此,ZnO/金属/ZnO复合薄膜的透过率和导电性都与金属层厚度有关并且相互制约。

金属网格[83-85]则能实现透过率与导电性的独立调节:网格的纵向加厚能提高导电性能,但对光透过的损害较小,而网格的横向设计能调节金属覆盖率、提高透过率。本课题组对金属网格的形状进行了设计和探究,发现GZO/Cu网格双层膜和GZO/Cu网格/GZO多层膜的透过率和方块电阻均高于复合膜,并随着铜网格间距的增大而增大,在最优间距为1 mm时,GZO/Cu网格双层膜的电阻率达到1.10×10-4 Ω·cm,同时透射率保持在83.74%[86]。

石墨烯[87-88]、金属纳米线[89-91]等新型透明导电材料与ZnO薄膜形成复合结构后,相应复合膜的导电性能有显著提升,而覆盖的ZnO薄膜能避免导电层因发生磨损、氧化而失效,整体膜层的缺陷态少且环境稳定性高。将ZnO薄膜与新材料复合,部分复合膜还被赋予了柔性,也不断兴起。本课题组制备的铜纳米线/石墨烯/AZO复合薄膜能同时获得高透光率(550 nm处的透过率为74%)、低方块电阻(9.40 Ω/sq)和良好的空气稳定性(超过30 d),并且方块电阻经过50次循环弯曲后仍能保持9.55 Ω/sq[92]。

3.4 应用

由于ZnO膜既能保证光线大部分透过,又具有电子输运能力,研究者开始逐步将ZnO膜应用于透明电子领域,以其高透光率和独特的陷光结构作为太阳能电池的透明电极[93-99],以其低电阻和高透明度作为触摸屏[100]、显示屏[32,101]或LED[102-103]的透明电极,以其焦耳加热性能及导热性能作为电热膜的发热膜[91]等,以其高可见光透过率及高近红外反射率作为红外反射膜[104],并针对薄膜的耐热性和耐蚀性等展开了研究[105]。

本课题组以织构AZO薄膜为正面接触层制备的单结非晶硅薄膜太阳能电池的转换效率高达10.75%[98],将AZO/ITO双层复合膜作为氮化镓基LED的透明接触层,能实现与300 nm ITO膜几乎相同的器件性能,同时可节省93.3%的ITO[95]。Chen等[95]将溶液法制备的AZO和银纳米线复合为柔性有机太阳能电池的透明电极,其光电转换效率达到了15.21%,并且在机械弯曲下展现出耐久稳定性。为提高ZnO薄膜在高温、高湿、酸性和碱性等恶劣环境下的应用稳定性,生长稳定的覆盖层是提高薄膜热稳定性和化学稳定性的典型策略,通过退火等后处理方式补偿ZnO薄膜内的缺陷是抑制热退化和化学失效的基本方法,实现坚固且导电的ZnO薄膜有希望使其成为未来电子产业所要求的透明电子材料[105]。

4 钙钛矿半导体发光与LED应用

卤素钙钛矿,特别是铅基卤素钙钛矿(简称钙钛矿),近年来由于其多项优异的光学性能,如光谱可调、色纯度高、色域宽、带边缘吸收强、缺陷容忍度高、荧光量子产率高等,受到广泛研究。浙江大学钙钛矿发光材料研究团队在国际上较早开展钙钛矿发光研究,主要包括钙钛矿材料制备[106-109]、钙钛矿发光机制[110-114]、钙钛矿发光二极管(LED)[106-107,115-119]和钙钛矿激射行为研究[120-123]。

半导体发光主要有两种形式,即自由载流子复合发光和激子复合发光。理论上,在LED工作条件下,激子复合更有利于获得高效发光。但三维钙钛矿中激子束缚能较小,在室温下是否存在激子复合一直有争议。本课题组在三维钙钛矿中发现激子局域化现象,且该现象在溶液法制备的钙钛矿薄膜中具有普遍性[110]。多个证据表明,杂化钙钛矿中的弱局域激子主导了三维钙钛矿室温发光,激子局域化对钙钛矿中的电荷输运和复合有重要影响。基于此,本课题组提出了局域激子复合模型,并以此解释了钙钛矿的超长发光寿命。另外,本课题组也探究了准二维钙钛矿薄膜中的多种激子发光机制,发现不同发光峰对应不同的发光机制,包括类零维激子复合机制、二维局域激子复合机制和自限激子复合机制[111]。

![钙钛矿发光研究结果。(a)(d)红光钙钛矿薄膜LED电致发光(EL)谱及最大EQE统计结果[117];(b)(e)绿光钙钛矿薄膜LED的EL谱及最大EQE统计结果[118];(c)(f)天蓝光钙钛矿薄膜LED的EL谱及最大EQE统计结果[107]](/richHtml/gxxb/2022/42/17/1716001/img_07.jpg)

图 6. 钙钛矿发光研究结果。(a)(d)红光钙钛矿薄膜LED电致发光(EL)谱及最大EQE统计结果[117];(b)(e)绿光钙钛矿薄膜LED的EL谱及最大EQE统计结果[118];(c)(f)天蓝光钙钛矿薄膜LED的EL谱及最大EQE统计结果[107]

Fig. 6. Results of perovskite luminescence. (a)(d) Statistical results of electroluminescence (EL) spectrum and external quantum efficiency (EQE) of red perovskite film LED[117]; (b)(e) statistical results of EL spectrum and maximum EQE of green perovskite film LED[118]; (c)(f) statistical results of EL spectrum and maximum EQE of sky blue perovskite film LED[107]

本课题组[106]在2015年报道了钙钛矿薄膜发光器件,通过界面改性获得了最高外量子效率(EQE)为3.5%的高亮度红外光LED和最大亮度高达20000 cd/m2的绿光LED。之后,本课题组[115-116]通过钙钛矿高效发光薄膜的原位自组装可控制备和器件结构设计,不断深化研究绿光LED。2017年,Si等[119]利用原位形成的钙钛矿纳米片自组装薄膜,结合NiO空穴传输层,将绿光LED的EQE提升到10.4%。2021年,Cui等[118]通过原位合成取向一致的钙钛矿纳米片,通过调控其激子跃迁偶极,显著提高器件的出光效率,获得了最高EQE达23.6%的绿光钙钛矿LED。2019年,本课题组通过反溶剂法制备了纯溴基的准二维钙钛矿,获得了荧光量子产率(PL QY)大于60%的蓝光和天蓝光薄膜,并将天蓝光LED的最高EQE提高到9.5%。同年,本课题组[117]通过优化准二维钙钛矿薄膜制备过程中的有机间隔分子,将红光钙钛矿薄膜的PL QY从不到10%提高到50%左右,并获得了最高EQE为13.3%的红光LED。

本课题组[120]从2015年开始在钙钛矿激射方面也已取得了系列研究成果,在绿光钙钛矿激射方面,通过引入聚甲基丙烯酸甲酯(PMMA)钝化有机杂化钙钛矿薄膜表面缺陷并形成对称波导结构,将放大自发辐射(ASE)阈值降低了一半。通过同时钝化钙钛矿薄膜底部缺陷和表层缺陷,获得了在纳秒激光器激发下ASE阈值仅为34.2 μJ/cm2、最高光增益达694 cm-1的全无机钙钛矿薄膜激射[121]。进一步地,通过在薄膜制备过程中引入辛基溴化铵优化钙钛矿薄膜的结晶形貌,获得了表面光滑致密的薄膜,在纳秒激光器激发下将ASE阈值降低至14.9 μJ/cm2,并实现波长从绿光到红光的可调[122]。在此基础上发展了一种气相离子交换方法,制备了氯溴混合铅卤化物薄膜,将钙钛矿ASE拓展到蓝光波段,并显著提高了钙钛矿在高功率密度光辐照下的光谱稳定性[123]。

![钙钛矿薄膜ASE结果。(a)(e)PMMA表层钝化绿光钙钛矿薄膜ASE结果[120];(b)(f)底层钝化和表层钝化绿光钙钛矿薄膜ASE结果[121];(c)结晶形貌优化后的绿光钙钛矿薄膜ASE结果[122];(d)蓝光钙钛矿薄膜ASE结果;(g)红绿光钙钛矿薄膜ASE激射;(h)蓝绿光钙钛矿薄膜ASE激射[123]](/richHtml/gxxb/2022/42/17/1716001/img_08.jpg)

图 7. 钙钛矿薄膜ASE结果。(a)(e)PMMA表层钝化绿光钙钛矿薄膜ASE结果[120];(b)(f)底层钝化和表层钝化绿光钙钛矿薄膜ASE结果[121];(c)结晶形貌优化后的绿光钙钛矿薄膜ASE结果[122];(d)蓝光钙钛矿薄膜ASE结果;(g)红绿光钙钛矿薄膜ASE激射;(h)蓝绿光钙钛矿薄膜ASE激射[123]

Fig. 7. ASE results of perovskite thin films. (a)(e) ASE results of green perovskite thin films with PMMA surface passivation[120]; (b)(f) ASE results of green perovskite thin films passivated in bottom and surface layers[121]; (c) ASE results of green light perovskite thin films after optimization of crystal morphology[122]; (d) ASE results of blue perovskite films; (g) ASE excitation results of red-green perovskite thin films; (h) ASE results of blue-green perovskite thin films[123]

尽管钙钛矿在红光和绿光波段获得了飞速的发展,红光和绿光LED的EQE均已超过20%,但在蓝光等宽禁带发光方面,钙钛矿存在更多缺陷、材料和光谱稳定性较差,以及器件界面能带匹配问题,使得蓝光发光效率远远落后,面临巨大挑战。

本文将聚焦禁带宽度大于2.585 eV或发光波长小于480 nm的宽禁带钙钛矿的光电性能和光电器件应用。针对波长调节和效率提升问题,主要从组分调控、维度调控、组分和维度共同调控三个方面综述宽禁带卤素钙钛矿制备及LED应用的近期进展。

4.1 组分调控

铅基卤素钙钛矿的化学式为ABX3[124],其中:A位为一价阳离子,如Cs+、甲胺阳离子(CH3NH3+,MA)、甲脒阳离子(CH4N2+,FA);B位为Pb2+;X位为Cl-、Br-和/或I-。钙钛矿的晶体结构包括顶点相连的铅卤八面体和位于铅卤八面体构成的十二面体的体心上的一价阳离子,其中:一价阳离子对能带结构几乎没有贡献,主要起稳定晶体结构的作用;铅卤八面体决定了钙钛矿的能带结构,卤素的np轨道对价带顶位置起决定性作用,Pb的6p轨道对导带底位置起决定性作用。因此,价带顶位置对卤素的组成极为敏感[125-127]。通过调控卤素的组分,可以调控钙钛矿的禁带宽度[128],从而调控钙钛矿的光电性能,如当卤素由半径较大的I-向半径较小的Cl-变化时,钙钛矿的禁带宽度逐渐增大,发光可以由近红外光变到紫外光,遍历整个可见光区域[129]。

![钙钛矿CsPbX3的能带结构、禁带宽度、光吸收谱和荧光光谱。(a)钙钛矿CsPbX3的能带结构示意图[124];(b)MAPbX3.的禁带宽度示意图[126];(c)CsPbX3纳米晶卤素组分依赖的光吸收谱和荧光光谱[129]](/richHtml/gxxb/2022/42/17/1716001/img_09.jpg)

图 8. 钙钛矿CsPbX3的能带结构、禁带宽度、光吸收谱和荧光光谱。(a)钙钛矿CsPbX3的能带结构示意图[124];(b)MAPbX3.的禁带宽度示意图[126];(c)CsPbX3纳米晶卤素组分依赖的光吸收谱和荧光光谱[129]

Fig. 8. Band structure, gap width, and absorption and fluorescence spectra of perovskite CsPbX3. (a) Schematic diagram of CsPbX3 band structure of perovskite[124]; (b) schematic diagram of gap width of MAPbX3[126]; (c) composition dependent light absorption and fluorescence spectra of CsPbX3 nanocrystalline halogen[129]

对于宽禁带钙钛矿,通过调控Cl-和Br-的比例可以获得不同蓝光。Kim等[130]于2017年采用三元混合一价阳离子和混合卤素制备三维蓝光钙钛矿薄膜Cs10(MA0.17FA0.83)(100-x)PbCl1.5Br1.5,其LED的EL峰位于475 nm,半峰全宽(FWHM)为28 nm,LED的EQE为1.7%,最高发光亮度达3567 cd/m2。结合元素掺杂进行A位或B位取代可以改善钙钛矿的发光性能和光谱稳定性[131-132]。Wang等[131]使用RuCl部分替代CsCl作为氯源,通过改变RuCl和CsCl的比例,调控三维钙钛矿薄膜RbxCs1-xPbBryCl3-y的禁带宽度,获得了发光峰位于473 nm和468 nm的钙钛矿蓝光LED,且EL光谱较稳定。

4.2 维度调控

1)铅基宽禁带钙钛矿纳米粒子

利用低维纳米材料的量子限域效应也可以调控钙钛矿的能带。Protesescu等[129]于2015年通过控制热注入合成钙钛矿量子点过程中的反应温度,获得了不同粒径的CsPbBr3量子点,实现了纯溴基钙钛矿从绿光到蓝光的调控。计算结果表明,CsPbBr3量子点的Wannier-Mott激子玻尔半径为7 nm,即粒径小于7 nm的CsPbBr3量子点的禁带宽度会随粒径的减小显著增大。

Dong等[133]同样采用热注入法在80 ℃合成了粒径为4 nm左右的CsPbBr3蓝光量子点,通过在量子点表面形成带负电的阳离子内壳层和带正电的阴离子及溶剂分子外壳层,量子点的PL QY可以高达91%,以该量子点作为发光层制备的蓝光LED器件的EL峰位于479 nm,最高EQE达12.3%。Bi等[134]通过HBr刻蚀粒径为4 nm左右的CsPbBr3蓝光量子点以减少量子点表面缺陷,之后通过引入二正十二烷基胺和苯乙胺取代量子点表面的原长链有机配体,进一步钝化量子点表面缺陷,获得了发光峰位在470 nm、PL QY高达97%的纯蓝光钙钛矿量子点。基于该量子点的蓝光LED的最高EQE为4.7%,最高亮度为3850 cd/m2。

![纯溴基钙钛矿纳米粒子及其器件发光性能。(a)静电双壳层超小CsPbBr3蓝光量子点低倍TEM图和溶液示意图[133];(b)(c)刻蚀及配体交换处理后的超小CsPbBr3蓝光量子点TEM图和EL光谱图[134];(d)CsPbBr3纳米片TEM图[135];(e)(f)以CsPbBr3纳米片为发光层的LED器件性能图](/richHtml/gxxb/2022/42/17/1716001/img_10.jpg)

图 9. 纯溴基钙钛矿纳米粒子及其器件发光性能。(a)静电双壳层超小CsPbBr3蓝光量子点低倍TEM图和溶液示意图[133];(b)(c)刻蚀及配体交换处理后的超小CsPbBr3蓝光量子点TEM图和EL光谱图[134];(d)CsPbBr3纳米片TEM图[135];(e)(f)以CsPbBr3纳米片为发光层的LED器件性能图

Fig. 9. Luminescence properties of pure brominated perovskite nanoparticles and corresponding devices. (a) Low-power TEM and solution diagram of ultra-small CsPbBr3 blue quantum dots of electrostatic double shell [133]; (b)(c) TEM and EL spectra of ultra-small CsPbBr3 blue quantum dots after etching and ligand exchange treatment[134]; (d) TEM image of CsPbBr3 nanosheets[135]; (e)(f) performance diagram of LED device with CsPbBr3 nanosheet as luminescent layer

在一个维度上实现量子限域也可以增大CsPbBr3的禁带宽度[135-138],Akkerman等[136]于2016年报道了热注入法合成发光峰位于460 nm的蓝光CsPbBr3纳米片。Yang等[137]通过调控合成中的反应温度和反应时间,获得了厚度和长度可调控的CsPbBr3纳米片,并使用厚度为3.1 nm的CsPbBr3纳米片制备了发光峰位于480 nm的蓝光钙钛矿LED。Wu等[135]通过在合成过程中引入HBr和溴化油胺原位钝化铅溴八面体,获得了发光峰位于460 nm、PL QY高达96%的蓝光CsPbBr3纳米片。

2)铅基宽禁带准二维钙钛矿

准二维钙钛矿的化学式为B2(APbX3)n-1PbX4,其中,B为诸如脂肪酸阳离子、芳香胺阳离子等的有机间隔阳离子,A为诸如Cs+、MA、FA等的一价阳离子;X为Cl-和/或Br-,n是铅卤八面体[PbX6]4-层的数量。铅卤八面体层夹在相邻两层有机间隔阳离子层之间,构成多量子阱结构,其中铅卤八面体层充当势阱,有机阳离子间隔层充当势垒,在外场激发下生成的激子由于量子限域效应和介电限域效应被限制在铅卤八面体层。在准二维钙钛矿中,n值决定了材料的禁带宽度,n值越小,禁带宽度越大。由于能量瀑布效应,激发态能量会从较宽的禁带转移到较小的禁带中,并最终在较小的禁带或高n值的钙钛矿中发生激子复合。因此,要想获得准二维钙钛矿宽禁带发光或蓝光发射,合理调控n值至关重要[139]。

![纯溴基准二维钙钛矿及其器件发光性能。(a)准二维钙钛矿结构示意图和能量转移示意图[139];(b)准二维钙钛矿中不同间隔分子的排列方式示意图[140];(c)(d)两种间隔分子共存对准二维钙钛矿n值分布的影响及其器件EL光谱[141];(e)~(g)准二维钙钛矿钝化前后的光谱对比图和LED性能图[142]](/richHtml/gxxb/2022/42/17/1716001/img_11.jpg)

图 10. 纯溴基准二维钙钛矿及其器件发光性能。(a)准二维钙钛矿结构示意图和能量转移示意图[139];(b)准二维钙钛矿中不同间隔分子的排列方式示意图[140];(c)(d)两种间隔分子共存对准二维钙钛矿n值分布的影响及其器件EL光谱[141];(e)~(g)准二维钙钛矿钝化前后的光谱对比图和LED性能图[142]

Fig. 10. Luminescence properties of pure brominated quasi-two-dimensional perovskite nanoparticles and corresponding devices. (a) Schematic diagram of quasi-two-dimensional perovskite structure and energy transfer[139]; (b) schematic diagram of arrangement of different spacer molecules in quasi-two-dimensional perovskite[140]; (c)(d) effect of coexistence of two spacer molecules on n value distribution and EL spectra of quasi-two-dimensional perovskite[141]; (e)-(g) spectral contrast and LED performance before and after passivation of quasi-two-dimensional perovskite [142]

间隔阳离子类型和结构的微小变化都会影响准二维钙钛矿中有机阳离子的排列方式,从而影响n值[143]。Chen等[144]通过在形成纯溴基钙钛矿薄膜的过程中引入2-苯氧基乙胺作为间隔阳离子,实现了从三维到准二维材料、从窄禁带到宽禁带、从绿光到深蓝光的变化。Tam等[140]发现引入苯丙基溴化胺可以获得在466 nm具有单一发光峰的PPA2MAPb2Br7,对应n=2的铅卤八面体层。Wang等[145]通过引入γ-氨基丁酸调控准二维CsPbBr3薄膜的生长,获得了n为2和3、发光峰位于464 nm和475 nm的准二维CsPbBr3薄膜,相应的蓝光LED器件的EL峰位位于478 nm,最大EQE为6.3%。

一价阳离子也会影响n值,Ren等[139]探究了Cs+、MA和FA等对准二维钙钛矿形成的影响,发现溶解度较低的Cs+有利于抑制n=1的铅卤八面体层的形成,并促进n为2~4的铅卤八面体层的形成。

除了n值的调控,合理选择间隔阳离子也可以钝化准二维钙钛矿中的缺陷,从而提高准二维钙钛矿的光电性能和稳定性。适度过量的溴被广泛证明可以钝化卤素空位,减少钙钛矿中的缺陷[141-142,146]。Jiang等[142]通过在前驱体中加入过量的RbBr,将准二维PEA2(Rb0.6Cs0.4)2Pb3Br10的PL QY从11%提高到82%。

4.3 组分维度协同调控

1)铅基宽禁带氯溴混合钙钛矿纳米粒子

三维铅基氯溴混合钙钛矿的空间限域效应较弱,电子空穴不易复合,PL QY较低。粒径极小的纯溴基[147-149]或纯氯基[150]钙钛矿量子点的禁带宽度可以扩展到3.4 eV,获得较高PL QY的深蓝光甚至深紫光溶液,但是这类量子点难以进行清洗纯化或操作步骤极其复杂[133-134],且难以形成光学性能稳定的薄膜,这限制了其在光电器件中的广泛应用。结合纳米粒子的量子限域效应和卤素组分调控,可以获得发光纯度高、PL QY高、光谱连续可调、可重复性高的混合卤素宽禁带钙钛矿。

![混合卤素基钙钛矿纳米粒子及其器件发光性能。(a)配体钝化后的氯溴混合钙钛矿量子点溶液的荧光光谱图和紫外-可见光吸收光谱图[151];(b)氯溴混合钙钛矿量子点表面缺陷钝化示意图[152];(c)不同含量Ni+掺杂的氯溴混合钙钛矿量子点的发光示意图[153];(d)(e)Ni+掺杂前后氯溴混合钙钛矿量子点LED性能对比图[153]](/richHtml/gxxb/2022/42/17/1716001/img_12.jpg)

图 11. 混合卤素基钙钛矿纳米粒子及其器件发光性能。(a)配体钝化后的氯溴混合钙钛矿量子点溶液的荧光光谱图和紫外-可见光吸收光谱图[151];(b)氯溴混合钙钛矿量子点表面缺陷钝化示意图[152];(c)不同含量Ni+掺杂的氯溴混合钙钛矿量子点的发光示意图[153];(d)(e)Ni+掺杂前后氯溴混合钙钛矿量子点LED性能对比图[153]

Fig. 11. Luminescence properties of mixed halogen-based perovskite nanoparticles and corresponding devices. (a) Fluorescence and UV-visible absorption spectra of chlorobromine mixed perovskite quantum dot solution after ligand passivation[151]; (b) schematic diagram of surface defect passivation of chloro-bromine mixed perovskite quantum dots[152]; (c) luminescence diagram of different content Ni+ doped chloro-bromine mixed perovskite quantum dots[153]; (d)(e) comparison of LED performance of chloro-bromine mixed perovskite quantum dots before and after Ni+ doping[153]

Song等[154]通过调控氯溴比例,采用热注入法合成了蓝光钙钛矿量子点,并制备了EL峰位于455 nm的蓝光钙钛矿量子点LED,其最高EQE为0.07%。Xun等[155]通过反溶剂共沉淀法改变前驱体中的氯溴比例,合成了在空气中具有高稳定性、发光峰在408~488 nm之间的钙钛矿量子点溶液。

氯溴混合蓝光钙钛矿量子点的PL QY相对较低,主要是因为这种量子点缺陷较多。Pan等[153]通过在热注入法合成中引入四辛基溴化铵,合成了富溴的量子点表面,将CsPbBr1.3Cl1.7量子点的PL QY从10%提高到了92%。优化量子点的配体也可以钝化缺陷[151,156-159],改善氯溴混合蓝光钙钛矿量子点的光电性能。Shynkarenko等[151]将双十二烷基二甲基溴化铵(DDAB)、双十二烷基二甲基氯化铵(DDAC)和双(2,4,4-三甲基戊基)膦酸引入热注入合成氯溴混合钙钛矿量子点的过程,通过调控氯溴比例获得了发光峰分别位于462 nm和476 nm、PL QY分别为25%和32%的蓝光钙钛矿量子点,相应的LED的最高EQE分别为1.03%和2.25%,最高亮度分别为193 cd/m2和678 cd/m2。Shao等[158]在热注入合成氯溴混合钙钛矿量子点的过程中引入了苯乙基氯化铵(PEACl)来钝化氯空位和取代长链有机配体,获得了发光峰为470 nm、PL QY为80%的蓝光钙钛矿量子点。配体优化也可以在量子点清洗纯化过程中进行[152,159-162]。Zheng等[152]在氯溴混合蓝光钙钛矿量子点溶液中加入十二烷基硫氰化铵,将PL QY从83%提高到近100%,基于钝化处理后的量子点可用于制备EL峰位为470 nm的LED,获得的最高EQE为6.3%,最高亮度接近500 cd/m2。

金属离子掺杂包括二价金属离子掺杂部分替换铅离子和一价金属离子掺杂部分替换Cs离子等,可用于调控钙钛矿量子点的禁带宽度和光学性能[153,163-167]。Hou等[163]在热注入合成CsPbBr3-xClx量子点的过程中使用不同含量的氯化锰取代氯化铅来改善量子点的光学性能,原子数分数为0.19%的锰掺杂将氯溴混合蓝光钙钛矿量子点的峰位从469 nm蓝移到466 nm,PL QY从9%提高到28%,LED器件的最高EQE从0.5%提高到2.12%,最高亮度从111 cd/m2提高到245 cd/m2。Pan等[167]在热注入前驱体中加入碳酸铷,将氯溴混合钙钛矿量子点的发光峰从475 nm移动到469 nm。进一步通过在合成中引入氯化镍和溴化镍,获得了Cs0.8Rb0.2Pb0.95Ni0.05Br1.8Cl1.2 蓝光钙钛矿量子点,将PL QY从20.4%提高到了86.7%。

除了对溶液状态的量子点进行钝化改性,宽禁带钙钛矿量子点在用于光电器件中时,也可以从成膜角度对氯溴混合钙钛矿量子点的光电性能进行优化,如通过优化量子点的溶剂[168-170]或使用交联物质固定量子点[171]来改善量子点薄膜质量,通过优化量子点与空穴传输层之间的界面减少引起非辐射复合的表界面缺陷等[172-173]。

2)铅基宽禁带准二维氯溴混合钙钛矿

类似于准二维纯溴基钙钛矿,氯溴混合准二维钙钛矿结合维度调控和卤素组分调控[174-179],进一步对价带位置进行调控,从而更好地实现禁带宽度或发光波长的可调性。Ma等[174]于2020年报道了以丁基胺(C4H9NH3,BA)为间隔阳离子层的准二维钙钛矿薄膜的制备和光电性能研究,通过调控卤素比例获得了分子式为BA2MA2Pb3Br7Cl3、EL峰位为468 nm、最高EQE为0.01%的纯蓝光宽禁带LED器件。

兼具铅卤八面体间隔作用和钝化效果的有机分子也被用于制备氯溴混合准二维铅基宽禁带钙钛矿[178-181]。Wang等[175]通过同时引入物质的量之比为1∶1的PEABr和3,3-二苯基丙基溴化胺(DPPABr)作为间隔层分子,缩小了n值范围,获得了发光峰位在470 nm、PL QY高达60%的准二维CsPbClBr2 薄膜,相应的LED器件的EL峰位为473 nm,最高EQE为8.8%,最高亮度为482 cd/m2。Yantara等[179]引入二苯基次膦酰氯(DPPOCl)调节准二维PEA2Cs1.6MA0.4Pb3Br10薄膜的发光峰位,同时钝化钙钛矿中的缺陷,进一步结合空穴传输层优化,获得了EL峰位为479 nm、最高EQE为5.2%、最高亮度为468 cd/m2的准二维蓝光钙钛矿LED。

![混合卤素基准二维钙钛矿及其器件发光性能。(a)准二维钙钛矿配体钝化示意图[174];(b)不同间隔分子对准二维钙钛矿n值的影响[175];(c)不同间隔分子制备的准二维钙钛矿LED器件示意图[176];(d)不同氯溴比例的准二维钙钛矿禁带宽度示意图[180]](/richHtml/gxxb/2022/42/17/1716001/img_13.jpg)

图 12. 混合卤素基准二维钙钛矿及其器件发光性能。(a)准二维钙钛矿配体钝化示意图[174];(b)不同间隔分子对准二维钙钛矿n值的影响[175];(c)不同间隔分子制备的准二维钙钛矿LED器件示意图[176];(d)不同氯溴比例的准二维钙钛矿禁带宽度示意图[180]

Fig. 12. Luminescence properties of mixed halogen-based perovskite and corresponding devices. (a) Schematic diagram of passivation of quasi-two-dimensional perovskite ligand[174]; (b) effect of different spacer molecules on n value of two-dimensional perovskite[175]; (c) schematic diagram of quasi-two-dimensional perovskite LED devices prepared by different spacer molecules[176]; (d) schematic diagram of quasi-two-dimensional perovskite bandgap width with different chloro-bromine ratios[180]

5 结论与展望

ZnO作为一种极具应用潜力的第三代半导体,其优异的本征特性使其在紫外发光领域具有广阔的应用前景。经过国内外众多研究者的不懈努力,p型掺杂、薄膜外延、能带工程、多量子阱结构和发光器件等方面的研究都取得了显著进展。尽管如此,提高ZnO发光器件的光效、真正实现其在发光器件领域的应用仍然任重而道远。未来可通过高效稳定p型掺杂、外延高质量单晶薄膜及多量子阱、优化器件结构等方法,提高ZnO材料的光电性能及器件的发光效率,有望实现ZnO的高效发光及其在发光器件领域的应用。

经过多年探索和研究,ZnO薄膜的光学性能和电学性能均已达到了较高水平,单层掺杂ZnO薄膜的电阻率已经达到10-5 Ω·cm量级,多层复合结构显著提高了透明导电性能,ZnO基薄膜正作为ITO的替代品不断应用于透明电子领域。在高透光率低方阻透明导电膜的研究领域里,仍然是机遇与挑战并存,需要研究人员进行更深入的研究。为实现单层ZnO薄膜的性能突破,需进一步探究ZnO薄膜的导电机制。多元材料的组合往往能带来更优秀甚至奇特的新性能,基于ZnO的复合透明导电膜将持续拥有巨大的发展前景,但透过率超过90%的导电薄膜依然缺乏。在应用方面,随着柔性电子器件的兴起,如何在柔性衬底上低温沉积高质量高性能的ZnO薄膜并使其在实际应用环境下保持性能稳定,正是如今火热的研究议题。为使ZnO薄膜的产业化进程持续发展,需要进一步了解缺陷形成和补偿机制,开发一种低成本且快速高效的大面积成膜工艺,提高薄膜性能的均匀性、稳定性及可重复性,因而未来有必要对磁控溅射技术等制备工艺进行进一步研究,并对使用场景下的湿、热、力等稳定性进行研究。

钙钛矿的光学性能优异,可以获得色纯度较高、色域较大的发光,有望用于显示领域。使用合适的缺陷钝化处理方法可以获得高亮度的发光器件。单一卤素或混合卤素的钙钛矿量子点或纳米粒子都可以通过粒径调控或卤素组分调控获得可调范围较大的禁带宽度,特别是低维氯溴混合钙钛矿,较容易实现发光连续可调的宽禁带钙钛矿;而且,低维氯溴混合钙钛矿合成的重复性较高,应用场景较广泛。但是,低维氯溴混合钙钛矿的电致光谱稳定性相较于纯溴基纳米钙钛矿还有待继续提高。准二维钙钛矿的发光波长多大于470 nm,较难实现深蓝光或紫光;另外,原位成膜的均匀性和可重复性也需要进一步提高。相较于较窄禁带宽度钙钛矿的光电应用,宽禁带钙钛矿的荧光量子产率、器件效率和亮度、稳定性等光电性能正在快速提升,但是还有很大改善空间。除了LED应用,钙钛矿在激光方面也有巨大的应用潜力,随着宽禁带钙钛矿材料的稳定性和光学性能的不断进步,有望实现钙钛矿短波长激光器。总之,宽禁带卤素钙钛矿天然就具有较优异的光电性能,且可塑性较好,具有良好的光电器件开发潜力。

[1] Klingshirn C. ZnO∶from basics towards applications[J]. Physica Status Solidi (b), 2007, 244(9): 3027-3073.

[2] Kołodziejczak-Radzimska A, Jesionowski T. Zinc oxide-from synthesis to application: a review[J]. Materials, 2014, 7(4): 2833-2881.

[3] Bagnall D M, Chen Y F, Shen M Y, et al. Room temperature excitonic stimulated emission from zinc oxide epilayers grown by plasma-assisted MBE[J]. Journal of Crystal Growth, 1998, 184/185: 605-609.

[4] Xu W Z, Ye Z Z, Zeng Y J, et al. ZnO light-emitting diode grown by plasma-assisted metal organic chemical vapor deposition[J]. Applied Physics Letters, 2006, 88(17): 173506.

[5] Jiao S J, Zhang Z Z, Lu Y M, et al. ZnO p-n junction light-emitting diodes fabricated on sapphire substrates[J]. Applied Physics Letters, 2006, 88(3): 031911.

[6] Liu W, Gu S L, Ye J D, et al. Blue-yellow ZnO homostructural light-emitting diode realized by metalorganic chemical vapor deposition technique[J]. Applied Physics Letters, 2006, 88(9): 092101.

[7] Zhang H H, Pan X H, Lu B, et al. Mg composition dependent band offsets of Zn1-xMgxO/ZnO heterojunctions[J]. Physical Chemistry Chemical Physics, 2013, 15(27): 11231-11235.

[8] Wassner T A, Laumer B, Maier S, et al. Optical properties and structural characteristics of ZnMgO grown by plasma assisted molecular beam epitaxy[J]. Journal of Applied Physics, 2009, 105(2): 023505.

[9] Park S H, Ahn D. Spontaneous and piezoelectric polarization effects in wurtzite ZnO/MgZnO quantum well lasers[J]. Applied Physics Letters, 2005, 87(25): 253509.

[10] Zhang H H, Pan X H, Li Y, et al. The role of band alignment in p-type conductivity of Na-doped ZnMgO: polar versus non-polar[J]. Applied Physics Letters, 2014, 104(11): 112106.

[11] Chen S S, Pan X H, Chen W, et al. The role of beryllium in the band structure of MgZnO∶lifting the valence band maximum[J]. Applied Physics Letters, 2014, 105(12): 122112.

[12] 潘新花. Sb掺杂制备p-ZnO及Si衬底Zn1-xMgxO外延薄膜和ZnMgO/ZnO量子阱的研究[D]. 杭州: 浙江大学, 2010: 121-131.

PanX H. Investigation on Sb doping p-ZnO and Zn1-xMgxO epitaxial films, ZnMgO/ZnO MQWs grown on Si substrates[D]. Hangzhou: Zhejiang University, 2010: 121-131.

[13] Choi Y S, Kang J W, Hwang D K, et al. Recent advances in ZnO-based light-emitting diodes[J]. IEEE Transactions on Electron Devices, 2010, 57(1): 26-41.

[14] Gu X Q, Zhu L P, Ye Z Z, et al. Room-temperature photoluminescence from ZnO/ZnMgO multiple quantum wells grown on Si(111) substrates[J]. Applied Physics Letters, 2007, 91(2): 022103.

[15] Zhang H H, Pan X H, He H P, et al. Temperature dependence of exciton localization in ZnO/Zn1-xMgxO multiple quantum wells with different barrier compositions[J]. Optics Communications, 2014, 318: 37-40.

[16] Chen S S, Xu C X, Pan X H, et al. High internal quantum efficiency ZnO/ZnMgO multiple quantum wells prepared on GaN/sapphire templates for ultraviolet light emitting diodes[J]. Journal of Materials Chemistry C, 2019, 7(22): 6534-6538.

[17] Lotin A A, Novodvorsky O A, Zuev D A. Room-temperature stimulated emission in two-dimensional MgxZn1-xO/ZnO heterostructures under optical pumping[J]. Laser Physics Letters, 2013, 10(5): 055902.

[18] Janotti A, van de Walle C G. Fundamentals of zinc oxide as a semiconductor[J]. Reports on Progress in Physics, 2009, 72(12): 126501.

[19] Klingshirn C. ZnO∶material, physics and applications[J]. Chemphyschem, 2007, 8(6): 782-803.

[20] Guillén C, Herrero J. Optical, electrical and structural characteristics of Al∶ZnO thin films with various thicknesses deposited by DC sputtering at room temperature and annealed in air or vacuum[J]. Vacuum, 2010, 84(7): 924-929.

[21] Wen L, Sahu B B, Kim H R, et al. Study on the electrical, optical, structural, and morphological properties of highly transparent and conductive AZO thin films prepared near room temperature[J]. Applied Surface Science, 2019, 473: 649-656.

[22] Zhu B L, Wang C C, Xie T, et al. Highly transparent conductive ZnO films prepared by reactive RF sputtering with Zn/ZnO composite target[J]. Applied Physics A, 2021, 127(9): 668.

[23] Hassan A, Jin Y H, Chao F, et al. Dopant-driven enhancements in the optoelectronic properties of laser ablated ZnO∶Ga thin films[J]. Journal of Applied Physics, 2018, 123(16): 161401.

[24] Bruncko J, Šutta P, Netrvalová M, et al. Comparative study of ZnO thin film prepared by pulsed laser deposition-comparison of influence of different ablative lasers[J]. Vacuum, 2017, 138: 184-190.

[25] Zhao K, Xie J Y, Zhao Y D, et al. Investigation on transparent, conductive ZnO∶Al films deposited by atomic layer deposition process[J]. Nanomaterials, 2022, 12(1): 172.

[26] Gao Z N, Banerjee P. Review article: atomic layer deposition of doped ZnO films[J]. Journal of Vacuum Science & Technology A, 2019, 37(5): 050802.

[27] Ponja S D, Sathasivam S, Parkin I P, et al. Highly conductive and transparent gallium doped zinc oxide thin films via chemical vapor deposition[J]. Scientific Reports, 2020, 10: 638.

[28] Tsai C Y, Lai J D, Feng S W, et al. Characterizations and growth of textured well-faceted ZnO films by low-pressure chemical vapor deposition on ITO glass substrates[J]. Superlattices and Microstructures, 2017, 111: 1073-1081.

[29] Kennedy O W, Coke M L, White E R, et al. MBE growth and morphology control of ZnO nanobelts with polar axis perpendicular to growth direction[J]. Materials Letters, 2018, 212: 51-53.

[30] Dai K, Ying M J, Lian J, et al. Optical properties of polar thin films: ZnO (0001) and ZnO (000-1) on sapphire substrate[J]. Optical Materials, 2019, 94: 272-276.

[31] Shahid M U, Deen K M, Ahmad A, et al. Formation of Al-doped ZnO thin films on glass by sol-gel process and characterization[J]. Applied Nanoscience, 2016, 6(2): 235-241.

[32] Morita Y, Ohtani N. Fabrication of aluminum and gallium codoped ZnO multilayer transparent conductive films by spin coating method and discussion about improving their performance[J]. Japanese Journal of Applied Physics, 2018, 57(2S2): 02CB03.

[33] Dimitrov D Z, Chen Z F, Marinova V, et al. ALD deposited ZnO∶Al films on mica for flexible PDLC devices[J]. Nanomaterials, 2021, 11(4): 1011.

[34] Ajimsha R S, Das A K, Misra P, et al. Observation of low resistivity and high mobility in Ga doped ZnO thin films grown by buffer assisted pulsed laser deposition[J]. Journal of Alloys and Compounds, 2015, 638: 55-58.

[35] Giri P, Chakrabarti P. Effect of Mg doping in ZnO buffer layer on ZnO thin film devices for electronic applications[J]. Superlattices and Microstructures, 2016, 93: 248-260.

[36] Gong L, Lu J G, Ye Z Z. Room-temperature growth and optoelectronic properties of GZO/ZnO bilayer films on polycarbonate substrates by magnetron sputtering[J]. Solar Energy Materials and Solar Cells, 2010, 94(7): 1282-1285.

[37] Nian Q, Zhang M Y, Schwartz B D, et al. Ultraviolet laser crystallized ZnO∶Al films on sapphire with high Hall mobility for simultaneous enhancement of conductivity and transparency[J]. Applied Physics Letters, 2014, 104(20): 201907.

[38] Lyubchyk A, Vicente A, Alves P U, et al. Influence of post-deposition annealing on electrical and optical properties of ZnO-based TCOs deposited at room temperature[J]. Physica Status Solidi (a), 2016, 213(9): 2317-2328.

[39] Mahmood K, Samaa B M. Influence of annealing treatment on structural, optical, electric, and thermoelectric properties of MBE-grown ZnO[J]. Journal of Experimental and Theoretical Physics, 2018, 126(6): 766-771.

[40] Yamada Y, Inoue S, Kikuchi H, et al. Resistivity reduction in Ga-doped ZnO films with a barrier layer that prevents Zn desorption[J]. Thin Solid Films, 2018, 657: 50-54.

[41] Ma J G, Lin D, Li P, et al. ZnO transparent conducting thin films codoped with anions and cations[J]. Chinese Science Bulletin, 2020, 65(25): 2678-2690.

[42] Zhang W, Gan J, Li L Q, et al. Tailoring of optical and electrical properties of transparent and conductive Al-doped ZnO films by adjustment of Al concentration[J]. Materials Science in Semiconductor Processing, 2018, 74: 147-153.

[43] 叶志镇, 唐晋发. 直流反应磁控溅射制备掺铟ZnO透明导电薄膜的研究[J]. 光学学报, 1988, 8(5): 448-453.

[44] Ye Z Z, Tang J F. Transparent conducting indium doped ZnO films by DC reactive S-gun magnetron sputtering[J]. Applied Optics, 1989, 28(14): 2817-2819.

[45] Lei P, Chen X T, Yan Y, et al. Transparent and conductive IZO films: oxygen and discharge voltage controlled sputtering growth and properties[J]. Vacuum, 2022, 195: 110645.

[46] Tsai D C, Chang Z C, Kuo B H, et al. Thickness dependence of the structural, electrical, and optical properties of amorphous indium zinc oxide thin films[J]. Journal of Alloys and Compounds, 2018, 743: 603-609.

[47] Lu J G, Ye Z Z, Zeng Y J, et al. Structural, optical, and electrical properties of (Zn, Al)O films over a wide range of compositions[J]. Journal of Applied Physics, 2006, 100(7): 073714.

[48] Lu J G, Fujita S, Kawaharamura T, et al. Carrier concentration dependence of band gap shift in n-type ZnO∶Al films[J]. Journal of Applied Physics, 2007, 101(8): 083705.

[49] Gong L, Ye Z Z, Lu J G, et al. Highly transparent conductive and near-infrared reflective ZnO∶Al thin films[J]. Vacuum, 2010, 84(7): 947-952.

[50] Gu X Q, Zhu L P, Cao L, et al. Optical and electrical properties of ZnO∶Al thin films synthesized by low-pressure pulsed laser deposition[J]. Materials Science in Semiconductor Processing, 2011, 14(1): 48-51.

[51] Wang Y P, Lu J G, Bie X, et al. Transparent conductive Al-doped ZnO thin films grown at room temperature[J]. Journal of Vacuum Science & Technology A, 2011, 29(3): 031505.

[52] Jiang Q J, Lu J G, Yuan Y L, et al. Tailoring the morphology, optical and electrical properties of DC-sputtered ZnO∶Al films by post thermal and plasma treatments[J]. Materials Letters, 2013, 106: 125-128.

[53] Jiang Q J, Lu J G, Ye Z Z. Plasma-induced surface textures of ZnO∶Al transparent conductive films[J]. Vacuum, 2015, 111: 42-47.

[54] Agura H, Suzuki A, Matsushita T, et al. Low resistivity transparent conducting Al-doped ZnO films prepared by pulsed laser deposition[J]. Thin Solid Films, 2003, 445(2): 263-267.

[55] Ma Q B, Ye Z Z, He H P, et al. Structural, electrical, and optical properties of transparent conductive ZnO∶Ga films prepared by DC reactive magnetron sputtering[J]. Journal of Crystal Growth, 2007, 304(1): 64-68.

[56] Ma Q B, Ye Z Z, He H P, et al. Preparation and characterization of transparent conductive ZnO∶Ga films by DC reactive magnetron sputtering[J]. Materials Characterization, 2008, 59(2): 124-128.

[57] Ma Q B, Ye Z Z, He H P, et al. Effects of deposition pressure on the properties of transparent conductive ZnO∶Ga films prepared by DC reactive magnetron sputtering[J]. Materials Science in Semiconductor Processing, 2007, 10(4/5): 167-172.

[58] Gong L, Lu J G, Ye Z Z. Transparent and conductive Ga-doped ZnO films grown by RF magnetron sputtering on polycarbonate substrates[J]. Solar Energy Materials and Solar Cells, 2010, 94(6): 937-941.

[59] Ma Q B, Ye Z Z, He H P, et al. Influence of Ar/O2 ratio on the properties of transparent conductive ZnO∶Ga films prepared by DC reactive magnetron sputtering[J]. Materials Letters, 2007, 61(11/12): 2460-2463.

[60] Bie X, Lu J G, Gong L, et al. Transparent conductive ZnO∶Ga films prepared by DC reactive magnetron sputtering at low temperature[J]. Applied Surface Science, 2009, 256(1): 289-293.

[61] Ma Q B, Ye Z Z, He H P, et al. Influence of annealing temperature on the properties of transparent conductive and near-infrared reflective ZnO∶Ga films[J]. Scripta Materialia, 2008, 58(1): 21-24.

[62] Ma Q B, Ye Z Z, He H P, et al. Substrate temperature dependence of the properties of Ga-doped ZnO films deposited by DC reactive magnetron sputtering[J]. Vacuum, 2007, 82(1): 9-14.

[63] Gong L, Lu J G, Ye Z Z. Study on the structural, electrical, optical, adhesive properties and stability of Ga-doped ZnO transparent conductive films deposited on polymer substrates at room temperature[J]. Journal of Materials Science: Materials in Electronics, 2013, 24(1): 148-152.

[64] Mo G K, Liu J H, Lin G T, et al. Characterization of low resistivity Ga-doped ZnO thin films on Si substrates prepared by pulsed laser deposition[J]. Materials Research Express, 2019, 6(10): 106421.

[65] Cao L, Zhu L P, Chen W F, et al. Preparation and thermal stability of F-doped ZnO transparent conducting thin films[J]. Optical Materials, 2013, 35(6): 1293-1296.

[66] Cao L, Zhu L P, Jiang J, et al. Highly transparent and conducting fluorine-doped ZnO thin films prepared by pulsed laser deposition[J]. Solar Energy Materials and Solar Cells, 2011, 95(3): 894-898.

[67] Pham A T T, Ngo N M, Le O K T, et al. High-mobility sputtered F-doped ZnO films as good-performance transparent-electrode layers[J]. Journal of Science: Advanced Materials and Devices, 2021, 6(3): 446-452.

[68] Khuili M, El Hallani G, Fazouan N, et al. First-principles calculation of (Al, Ga) co-doped ZnO[J]. Computational Condensed Matter, 2019, 21: e00426.

[69] Mallick A, Basak D. Revisiting the electrical and optical transmission properties of co-doped ZnO thin films as n-type TCOs[J]. Progress in Materials Science, 2018, 96: 86-110.

[70] Wang Y F, Song J M, Zhang H R, et al. High optoelectronic performance of ZnO films co-doped with ternary functional elements of F, Al and Mg[J]. Journal of Alloys and Compounds, 2020, 822: 153688.

[71] Wang K L, Xin Y Q, Zhao J F, et al. High transmittance in IR region of conductive ITO/AZO multilayers deposited by RF magnetron sputtering[J]. Ceramics International, 2018, 44(6): 6769-6774.

[72] Kang D W, Kuk S H, Ji K S, et al. Effects of ITO precursor thickness on transparent conductive Al doped ZnO film for solar cell applications[J]. Solar Energy Materials and Solar Cells, 2011, 95(1): 138-141.

[73] Jiang Q J, Lu J G, Yuan Y L, et al. Enhancement of the light trapping by double-layered surface texture of ITO/AZO and AZO/AZO transparent conductive films[J]. Materials Letters, 2014, 123: 14-18.

[74] Gong L, Lu J G, Ye Z Z. Conductive Ga doped ZnO/Cu/Ga doped ZnO thin films prepared by magnetron sputtering at room temperature for flexible electronics[J]. Thin Solid Films, 2011, 519(11): 3870-3874.

[75] Wang Y P, Lu J G, Bie X, et al. Transparent conductive and near-infrared reflective Cu-based Al-doped ZnO multilayer films grown by magnetron sputtering at room temperature[J]. Applied Surface Science, 2011, 257(14): 5966-5971.

[76] Lu J G, Bie X, Wang Y P, et al. Transparent conductive and near-infrared reflective Ga-doped ZnO/Cu bilayer films grown at room temperature[J]. Journal of Vacuum Science & Technology A, 2011, 29(3): 03A115.

[77] Gong L, Lu J G, Ye Z Z. Transparent conductive Ga-doped ZnO/Cu multilayers prepared on polymer substrates at room temperature[J]. Solar Energy Materials and Solar Cells, 2011, 95(7): 1826-1830.

[78] Huang J J, Wang Y P, Lu J G, et al. Transparent conductive Al-doped ZnO/Cu bilayer films grown on polymer substrates at room temperature[J]. Chinese Physics Letters, 2011, 28(12): 255-258.

[79] Chen W H, Chou C Y, Li B J, et al. Conductive and transparent properties of ZnO/Cu/ZnO sandwich structure[J]. Journal of Electronic Materials, 2021, 50(3): 779-785.

[80] Manzen I, Yoshimura Y, Matsubara K, et al. Improvement of characteristics of flexible Al-doped ZnO/Ag/Al-doped ZnO transparent conductive film using silver[J]. Journal of Vacuum Science & Technology B, 2020, 38(2): 022205.

[81] Lin Q J, Zhang F Z, Zhao N, et al. Influence of annealing temperature on optical properties of sandwiched ZnO/metal/ZnO transparent conductive thin films[J]. Micromachines, 2022, 13(2): 296.

[82] Liu X N, Gao J, Gong J H, et al. Optoelectronic properties of an AZO/Ag multilayer employed as a flexible electrode[J]. Ceramics International, 2021, 47(4): 5671-5676.

[83] Jang C, Jiang Q J, Lu J G, et al. Structural, optical and electrical properties of Ga doped ZnO/Cu grid/Ga doped ZnO transparent electrodes[J]. Journal of Materials Science & Technology, 2015, 31(11): 1108-1110.

[85] Wang C T, Ting C C, Kao P C, et al. Enhanced optical, electrical, and mechanical characteristics of ZnO/Ag grids/ZnO flexible transparent electrodes[J]. Journal of Applied Physics, 2017, 122(8): 085501.

[86] Jang C, Ye Z Z, Lü J G. Highly transparent low resistance Ga doped ZnO/Cu grid double layers prepared at room temperature[J]. Journal of Semiconductors, 2015, 36(12): 42-45.

[87] Li F S, Lin Z X, Zhang B B, et al. Fabrication of flexible conductive graphene/Ag/Al-doped zinc oxide multilayer films for application in flexible organic light-emitting diodes[J]. Organic Electronics, 2013, 14(9): 2139-2143.

[88] Yu S H, Zhao L, Liu R C, et al. Performance enhancement of Cu-based AZO multilayer thin films via graphene fence engineering for organic solar cells[J]. Solar Energy Materials and Solar Cells, 2018, 183: 66-72.

[89] Wang P, Chen Y, Hu Y, et al. Preparation and stability of AZO/AgNWs/AZO composite film[J]. China Ceramics, 2021, 57(6): 38.

[90] Duan Y H, Duan Y, Chen P, et al. High-performance flexible Ag nanowire electrode with low-temperature atomic-layer-deposition fabrication of conductive-bridging ZnO film[J]. Nanoscale Research Letters, 2015, 10: 90.

[91] Han X P, Huang Y, Wang J M, et al. Flexible hierarchical ZnO/AgNWs/carbon cloth-based film for efficient microwave absorption, high thermal conductivity and strong electro-thermal effect[J]. Composites Part B: Engineering, 2022, 229: 109458.

[92] Zhang L Q, Yang R, Chen K, et al. The fabrication of Cu nanowire/graphene/Al doped ZnO transparent conductive film on PET substrate with high flexibility and air stability[J]. Materials Letters, 2017, 207: 62-65.

[93] Das R, Das H S, Nandi P K, et al. Comparative studies on the properties of magnetron sputtered transparent conductive oxide thin films for the application in solar cell[J]. Applied Physics A, 2018, 124(9): 631.

[94] Jeong J A, Park Y S, Kim H K. Comparison of electrical, optical, structural, and interface properties of IZO-Ag-IZO and IZO-Au-IZO multilayer electrodes for organic photovoltaics[J]. Journal of Applied Physics, 2010, 107(2): 023111.

[95] Chen X B, Xu G Y, Zeng G, et al. Realizing ultrahigh mechanical flexibility and >15% efficiency of flexible organic solar cells via a welding flexible transparent electrode[J]. Advanced Materials, 2020, 32(14): e1908478.

[96] Zhou Z X, Zhang Y L, Chen X L, et al. Innovative wide-spectrum Mg and Ga-codoped ZnO transparent conductive films grown via reactive plasma deposition for Si heterojunction solar cells[J]. ACS Applied Energy Materials, 2020, 3(2): 1574-1584.

[97] Zhao X, Li M, Jiang L P, et al. Preparation of device-level ZnO-covered silver nanowires films and their applications as sub-electrode for polymer solar cells[J]. Frontiers in Chemistry, 2021, 9: 683728.

[98] Jiang Q J, Lu J G, Zhang J, et al. Texture surfaces and etching mechanism of ZnO∶Al films by a neutral agent for solar cells[J]. Solar Energy Materials and Solar Cells, 2014, 130: 264-271.

[99] Gong L, Liu Y Z, Gu X Q, et al. Study on the thermal stability of Ga-doped ZnO thin film: a transparent conductive layer for dye-sensitized TiO2 nanoparticles based solar cells[J]. Materials Science in Semiconductor Processing, 2014, 26: 276-281.

[100] Shin Y H, Cho C K, Kim H K. Resistance and transparency tunable Ag-inserted transparent InZnO films for capacitive touch screen panels[J]. Thin Solid Films, 2013, 548: 641-645.

[101] Dimitrov D, Tsai C L, Petrov S, et al. Atomic layer-deposited Al-doped ZnO thin films for display applications[J]. Coatings, 2020, 10(6): 539.

[102] Chen D, Lu J G, Lu R K, et al. High-performance GaN-based LEDs with AZO/ITO thin films as transparent contact layers[J]. IEEE Transactions on Electron Devices, 2017, 64(6): 2549-2555.

[103] 陈丹, 吕建国, 黄靖云, 等. AZO薄膜用于GaN基LED透明电极的性能研究[J]. 无机材料学报, 2013, 28(6): 649-652.

Chen D, Lü J G, Huang J Y, et al. Performances of GaN-based LEDs with AZO films as transparent electrodes[J]. Journal of Inorganic Materials, 2013, 28(6): 649-652.

[104] Zhang P, Zhang W, Wang J Y, et al. The electro-optic mechanism and infrared switching dynamic of the hybrid multilayer VO2/Al∶ZnO heterojunctions[J]. Scientific Reports, 2017, 7: 4425.

[105] Yan R L, Takahashi T, Zeng H, et al. Robust and electrically conductive ZnO thin films and nanostructures: their applications in thermally and chemically harsh environments[J]. ACS Applied Electronic Materials, 2021, 3(7): 2925-2940.

[106] Wang J P, Wang N N, Jin Y Z, et al. Interfacial control toward efficient and low-voltage perovskite light-emitting diodes[J]. Advanced Materials, 2015, 27(14): 2311-2316.

[107] Liu Y, Cui J Y, Du K, et al. Efficient blue light-emitting diodes based on quantum-confined bromide perovskite nanostructures[J]. Nature Photonics, 2019, 13(11): 760-764.

[108] Huang H W, Liu M, Li J, et al. Atomically thin cesium lead bromide perovskite quantum wires with high luminescence[J]. Nanoscale, 2017, 9(1): 104-108.

[109] Xu X L, He H P, Li J, et al. Embedded two-dimensional perovskite nanoplatelets with air-stable luminescence[J]. ACS Applied Materials & Interfaces, 2019, 11(8): 8436-8442.

[110] He H P, Yu Q Q, Li H, et al. Exciton localization in solution-processed organolead trihalide perovskites[J]. Nature Communications, 2016, 7: 10896.

[111] Gan L, He H P, Li S X, et al. Distinctive excitonic recombination in solution-processed layered organic-inorganic hybrid two-dimensional perovskites[J]. Journal of Materials Chemistry C, 2016, 4(43): 10198-10204.

[112] Fang Z S, He H P, Gan L, et al. Understanding the role of lithium doping in reducing nonradiative loss in lead halide perovskites[J]. Advanced Science, 2018, 5(12): 1800736.

[113] Li J, Gan L, Fang Z S, et al. Bright tail states in blue-emitting ultrasmall perovskite quantum dots[J]. The Journal of Physical Chemistry Letters, 2017, 8(24): 6002-6008.

[114] Li J, Yu Q Q, Lu B, et al. Ambience dependent photoluminescence reveals the localization and trap filling effects in CH3NH3PbI3-xClx perovskite films[J]. Journal of Materials Chemistry C, 2017, 5(1): 54-58.

[115] Li J, Yu Q Q, Gan L, et al. Perovskite light-emitting devices with a metal-insulator-semiconductor structure and carrier tunnelling[J]. Journal of Materials Chemistry C, 2017, 5(31): 7715-7719.

[116] Si J J, Liu Y, Wang N N, et al. Green light-emitting diodes based on hybrid perovskite films with mixed cesium and methylammonium cations[J]. Nano Research, 2017, 10(4): 1329-1335.

[117] He Z F, Liu Y, Yang Z L, et al. High-efficiency red light-emitting diodes based on multiple quantum wells of phenylbutylammonium-cesium lead iodide perovskites[J]. ACS Photonics, 2019, 6(3): 587-594.

[118] Cui J Y, Liu Y, Deng Y Z, et al. Efficient light-emitting diodes based on oriented perovskite nanoplatelets[J]. Science Advances, 2021, 7(41): eabg8458.

[119] Si J J, Liu Y, He Z F, et al. Efficient and high-color-purity light-emitting diodes based on in situ grown films of CsPbX3 (X=Br, I) nanoplates with controlled thicknesses[J]. ACS Nano, 2017, 11(11): 11100-11107.

[120] Li J, Si J J, Gan L, et al. Simple approach to improving the amplified spontaneous emission properties of perovskite films[J]. ACS Applied Materials & Interfaces, 2016, 8(48): 32978-32983.

[121] Jiang L, Fang Z S, Lou H R, et al. Achieving long carrier lifetime and high optical gain in all-inorganic CsPbBr3 perovskite films via top and bottom surface modification[J]. Physical Chemistry Chemical Physics, 2019, 21(39): 21996-22001.

[122] Li J, Zhou W, Jiang L, et al. Highly compact and smooth all-inorganic perovskite films for low threshold amplified spontaneous emission from additive-assisted solution processing[J]. Journal of Materials Chemistry C, 2019, 7(48): 15350-15356.

[123] Lu G C, Chen Z H, Fang Z S, et al. Mixed halide perovskite films by vapor anion exchange for spectrally stable blue stimulated emission[J]. Small, 2021, 17(39): e2103169.

[124] Akkerman Q A, Rainò G, Kovalenko M V, et al. Genesis, challenges and opportunities for colloidal lead halide perovskite nanocrystals[J]. Nature Materials, 2018, 17(5): 394-405.

[125] Rudd P N, Huang J S. Metal ions in halide perovskite materials and devices[J]. Trends in Chemistry, 2019, 1(4): 394-409.

[126] Ou Q D, Li C, Wang Q K, et al. Recent advances in energetics of metal halide perovskite interfaces[J]. Advanced Materials Interfaces, 2017, 4(2): 1600694.

[127] Wang Y, Sun H D. All-inorganic metal halide perovskite nanostructures: from photophysics to light-emitting applications[J]. Small Methods, 2018, 2(1): 1700252.

[128] Li C, Wei J, Sato M, et al. Halide-substituted electronic properties of organometal halide perovskite films: direct and inverse photoemission studies[J]. ACS Applied Materials & Interfaces, 2016, 8(18): 11526-11531.

[129] Protesescu L, Yakunin S, Bodnarchuk M I, et al. Nanocrystals of cesium lead halide perovskites (CsPbX3, X=Cl, Br, and I): novel optoelectronic materials showing bright emission with wide color gamut[J]. Nano Letters, 2015, 15(6): 3692-3696.

[130] Kim H P, Kim J, Kim B S, et al. High-efficiency, blue, green, and near-infrared light-emitting diodes based on triple cation perovskite[J]. Advanced Optical Materials, 2017, 5(7): 1600920.

[131] Wang H L, Zhao X F, Zhang B H, et al. Blue perovskite light-emitting diodes based on RbX-doped polycrystalline CsPbBr3 perovskite films[J]. Journal of Materials Chemistry C, 2019, 7(19): 5596-5603.

[132] Karlsson M, Yi Z Y, Reichert S, et al. Mixed halide perovskites for spectrally stable and high-efficiency blue light-emitting diodes[J]. Nature Communications, 2021, 12: 361.

[133] Dong Y T, Wang Y K, Yuan F L, et al. Bipolar-shell resurfacing for blue LEDs based on strongly confined perovskite quantum dots[J]. Nature Nanotechnology, 2020, 15(8): 668-674.

[134] Bi C H, Yao Z W, Sun X J, et al. Perovskite quantum dots with ultralow trap density by acid etching-driven ligand exchange for high luminance and stable pure-blue light-emitting diodes[J]. Advanced Materials, 2021, 33(15): e2006722.

[135] Wu Y, Wei C T, Li X M, et al. In situ passivation of PbBr64- octahedra toward blue luminescent CsPbBr3 nanoplatelets with near 100% absolute quantum yield[J]. ACS Energy Letters, 2018, 3(9): 2030-2037.

[136] Akkerman Q A, Motti S G, Kandada A R S, et al. Solution synthesis approach to colloidal cesium lead halide perovskite nanoplatelets with monolayer-level thickness control[J]. Journal of the American Chemical Society, 2016, 138(3): 1010-1016.

[137] Yang D, Zou Y T, Li P L, et al. Large-scale synthesis of ultrathin cesium lead bromide perovskite nanoplates with precisely tunable dimensions and their application in blue light-emitting diodes[J]. Nano Energy, 2018, 47: 235-242.

[138] Hoye R L Z, Lai M L, Anaya M, et al. Identifying and reducing interfacial losses to enhance color-pure electroluminescence in blue-emitting perovskite nanoplatelet light-emitting diodes[J]. ACS Energy Letters, 2019, 4(5): 1181-1188.

[139] Ren Z W, Wang K, Sun X W, et al. Strategies toward efficient blue perovskite light-emitting diodes[J]. Advanced Functional Materials, 2021, 31(30): 2100516.

[140] Tam H W, Leung T L, Sun W T, et al. Phase control for quasi-2D blue emitters by spacer cation engineering[J]. Journal of Materials Chemistry C, 2020, 8(32): 11052-11060.

[141] Yuan S, Wang Z K, Xiao L X, et al. Optimization of low-dimensional components of quasi-2D perovskite films for deep-blue light-emitting diodes[J]. Advanced Materials, 2019, 31(44): e1904319.

[142] Jiang Y Z, Qin C C, Cui M H, et al. Spectra stable blue perovskite light-emitting diodes[J]. Nature Communications, 2019, 10: 1868.

[143] Hu J, Oswald I W H, Stuard S J, et al. Synthetic control over orientational degeneracy of spacer cations enhances solar cell efficiency in two-dimensional perovskites[J]. Nature Communications, 2019, 10(1): 1276.

[144] Chen Z M, Zhang C Y, Jiang X F, et al. High-performance color-tunable perovskite light emitting devices through structural modulation from bulk to layered film[J]. Advanced Materials, 2017, 29(8): 1603157.

[145] Wang Y K, Ma D X, Yuan F L, et al. Chelating-agent-assisted control of CsPbBr3 quantum well growth enables stable blue perovskite emitters[J]. Nature Communications, 2020, 11: 3674.

[146] Worku M, He Q Q, Xu L J, et al. Phase control and in situ passivation of quasi-2D metal halide perovskites for spectrally stable blue light-emitting diodes[J]. ACS Applied Materials & Interfaces, 2020, 12(40): 45056-45063.

[147] Peng L C, Geng J, Ai L S, et al. Room temperature synthesis of ultra-small, near-unity single-sized lead halide perovskite quantum dots with wide color emission tunability, high color purity and high brightness[J]. Nanotechnology, 2016, 27(33): 335604.

[148] Zhang F, Xiao C T, Li Y F, et al. Gram-scale synthesis of blue-emitting CH3NH3PbBr3 quantum dots through phase transfer strategy[J]. Frontiers in Chemistry, 2018, 6: 444.

[149] Deng J D, Xun J, Qin Y C, et al. Blue-emitting NH4+-doped MAPbBr3 perovskite quantum dots with near unity quantum yield and super stability[J]. Chemical Communications, 2020, 56(79): 11863-11866.

[150] Kong X B, Wu Y Q, Xu F, et al. Ultrasmall CsPbBr3 quantum dots with bright and wide blue emissions[J]. Physica Status Solidi: Rapid Research Letters, 2021, 15(7): 2100134.

[151] Shynkarenko Y, Bodnarchuk M I, Bernasconi C, et al. Direct synthesis of quaternary alkylammonium-capped perovskite nanocrystals for efficient blue and green light-emitting diodes[J]. ACS Energy Letters, 2019, 4(11): 2703-2711.

[152] Zheng X P, Yuan S, Liu J K, et al. Chlorine vacancy passivation in mixed halide perovskite quantum dots by organic pseudohalides enables efficient rec. 2020 blue light-emitting diodes[J]. ACS Energy Letters, 2020, 5(3): 793-798.

[153] Pan G C, Bai X, Xu W, et al. Bright blue light emission of Ni2+ ion-doped CsPbClxBr3-x perovskite quantum dots enabling efficient light-emitting devices[J]. ACS Applied Materials & Interfaces, 2020, 12(12): 14195-14202.

[154] Song J Z, Li J H, Li X M, et al. Quantum dot light-emitting diodes based on inorganic perovskite cesium lead halides (CsPbX3)[J]. Advanced Materials, 2015, 27(44): 7162-7167.

[155] Xun J, Deng J D, Shen W, et al. Rapid synthesis of highly stable all-inorganic perovskite nanocrystals exhibiting strong blue luminescence[J]. Journal of Alloys and Compounds, 2021, 872: 159612.

[156] Park Y R, Kim H H, Eom S, et al. Luminance efficiency roll-off mechanism in CsPbBr3-xClx mixed-halide perovskite quantum dot blue light-emitting diodes[J]. Journal of Materials Chemistry C, 2021, 9(10): 3608-3619.

[157] Ochsenbein S T, Krieg F, Shynkarenko Y, et al. Engineering color-stable blue light-emitting diodes with lead halide perovskite nanocrystals[J]. ACS Applied Materials & Interfaces, 2019, 11(24): 21655-21660.

[158] Shao H, Zhai Y, Wu X F, et al. High brightness blue light-emitting diodes based on CsPb(Cl/Br)3 perovskite QDs with phenethylammonium chloride passivation[J]. Nanoscale, 2020, 12(21): 11728-11734.

[159] Zhang F, Zhang X, Wang C H, et al. Chlorine distribution management for spectrally stable and efficient perovskite blue light-emitting diodes[J]. Nano Energy, 2021, 79: 105486.

[160] Zhang B B, Yuan S, Ma J P, et al. General mild reaction creates highly luminescent organic-ligand-lacking halide perovskite nanocrystals for efficient light-emitting diodes[J]. Journal of the American Chemical Society, 2019, 141(38): 15423-15432.

[161] Ye F H, Zhang H J, Wang P, et al. Spectral tuning of efficient CsPbBrxCl3-x blue light-emitting diodes via halogen exchange triggered by benzenesulfonates[J]. Chemistry of Materials, 2020, 32(7): 3211-3218.

[162] Shin Y S, Yoon Y J, Lee K T, et al. Vivid and fully saturated blue light-emitting diodes based on ligand-modified halide perovskite nanocrystals[J]. ACS Applied Materials & Interfaces, 2019, 11(26): 23401-23409.

[163] Hou S C, Gangishetty M K, Quan Q M, et al. Efficient blue and white perovskite light-emitting diodes via Manganese doping[J]. Joule, 2018, 2(11): 2421-2433.

[164] Yang F, Chen H T, Zhang R, et al. Efficient and spectrally stable blue perovskite light-emitting diodes based on potassium passivated nanocrystals[J]. Advanced Functional Materials, 2020, 30(10): 1908760.

[165] Todorović P, Ma D X, Chen B, et al. Spectrally tunable and stable electroluminescence enabled by rubidium doping of CsPbBr3 nanocrystals[J]. Advanced Optical Materials, 2019, 7(24): 1901440.

[166] Meng F Y, Liu X Y, Cai X Y, et al. Incorporation of rubidium cations into blue perovskite quantum dot light-emitting diodes via FABr-modified multi-cation hot-injection method[J]. Nanoscale, 2019, 11(3): 1295-1303.

[167] Pan J Y, Zhao Z H, Fang F, et al. Multiple cations enhanced defect passivation of blue perovskite quantum dots enabling efficient light-emitting diodes[J]. Advanced Optical Materials, 2020, 8(24): 2001494.

[168] Yao E P, Yang Z L, Meng L, et al. High-brightness blue and white LEDs based on inorganic perovskite nanocrystals and their composites[J]. Advanced Materials, 2017, 29(23): 1606859.

[169] Chen F, Xu L M, Li Y, et al. Highly efficient sky-blue light-emitting diodes based on Cu-treated halide perovskite nanocrystals[J]. Journal of Materials Chemistry C, 2020, 8(38): 13445-13452.

[170] Chen F, Liu Y L, Salerno M. Dispersing solvent effect on halide perovskite nanocrystals-based films and devices[J]. Journal of Materials Science, 2022, 57(3): 1902-1913.

[171] Li G R, Rivarola F W R, Davis N J L K, et al. Highly efficient perovskite nanocrystal light-emitting diodes enabled by a universal crosslinking method[J]. Advanced Materials, 2016, 28(18): 3528-3534.

[172] Gangishetty M K, Hou S C, Quan Q M, et al. Reducing architecture limitations for efficient blue perovskite light-emitting diodes[J]. Advanced Materials, 2018, 30(20): e1706226.

[173] Shin Y S, Yoon Y J, Heo J, et al. Functionalized PFN-X (X=Cl, Br, or I) for balanced charge carriers of highly efficient blue light-emitting diodes[J]. ACS Applied Materials & Interfaces, 2020, 12(31): 35740-35747.

[174] Ma D X, Todorović P, Meshkat S, et al. Chloride insertion-immobilization enables bright, narrowband, and stable blue-emitting perovskite diodes[J]. Journal of the American Chemical Society, 2020, 142(11): 5126-5134.

[175] Wang C H, Han D B, Wang J H, et al. Dimension control of in situ fabricated CsPbClBr2 nanocrystal films toward efficient blue light-emitting diodes[J]. Nature Communications, 2020, 11: 6428.

[176] Kim Y C, An H J, Kim D H, et al. High‐performance perovskite-based blue light-emitting diodes with operational stability by using organic ammonium cations as passivating agents[J]. Advanced Functional Materials, 2021, 31(5): 2005553.

[177] Vashishtha P, Ng M, Shivarudraiah S B, et al. High efficiency blue and green light-emitting diodes using ruddlesden-popper inorganic mixed halide perovskites with butylammonium interlayers[J]. Chemistry of Materials, 2019, 31(1): 83-89.

[178] Shen Y, Shen K C, Li Y Q, et al. Interfacial potassium-guided grain growth for efficient deep-blue perovskite light-emitting diodes[J]. Advanced Functional Materials, 2021, 31(6): 2006736.

[179] Yantara N, Jamaludin N F, Febriansyah B, et al. Designing the perovskite structural landscape for efficient blue emission[J]. ACS Energy Letters, 2020, 5(5): 1593-1600.

[180] Li Z C, Chen Z M, Yang Y C, et al. Modulation of recombination zone position for quasi-two-dimensional blue perovskite light-emitting diodes with efficiency exceeding 5%[J]. Nature Communications, 2019, 10: 1027.

[181] Hu H W, Salim T, Chen B B, et al. Molecularly engineered organic-inorganic hybrid perovskite with multiple quantum well structure for multicolored light-emitting diodes[J]. Scientific Reports, 2016, 6: 33546.

Article Outline

叶志镇, 王凤志, 陈芳, 陆杨丹. 宽禁带半导体光电材料及其应用研究[J]. 光学学报, 2022, 42(17): 1716001. Zhizhen Ye, Fengzhi Wang, Fang Chen, Yangdan Lu. Wide Band Gap Semiconductor Optoelectronic Materials and Their Applications[J]. Acta Optica Sinica, 2022, 42(17): 1716001.